A constant mesh gearbox maintains all gears engaged at all times, allowing for smoother shifting without the need for a clutch. It uses synchronizers to match gear speeds during shifts, reducing wear and improving performance. This design is ideal for racing and high-performance vehicles, as it ensures efficient power transfer and quicker gear changes.

How Does a Constant Mesh Gearbox Work?

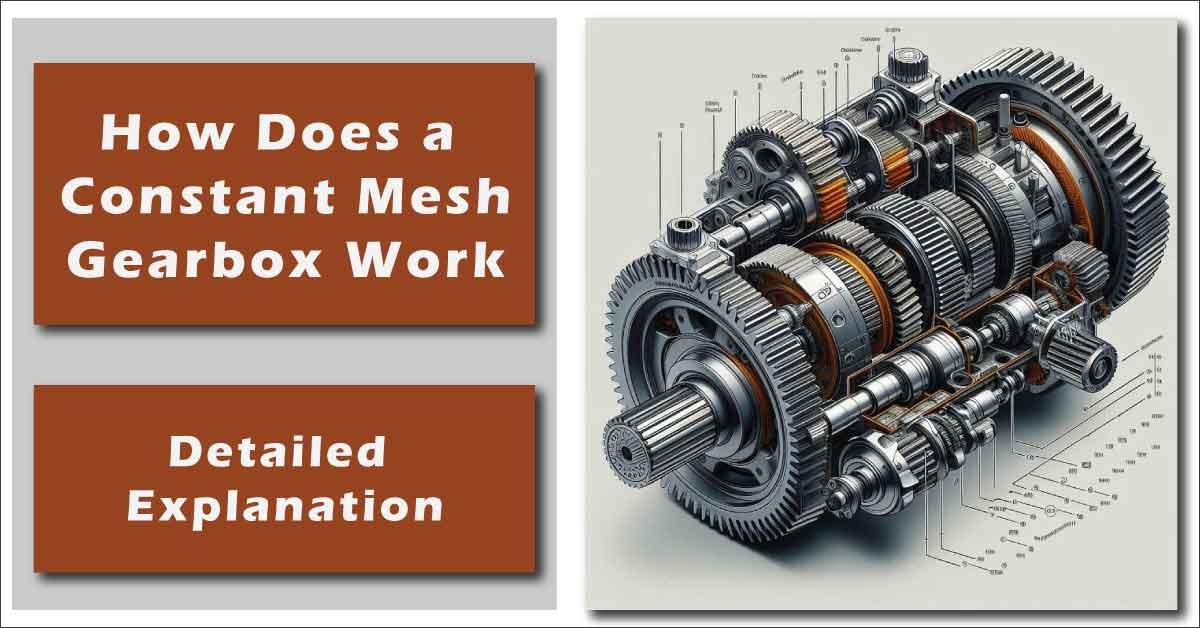

A constant mesh gearbox is a critical component in many automotive applications, particularly in manual transmission vehicles. It is designed to provide efficient power transfer from the engine to the wheels while allowing for smooth gear changes. The unique mechanism of constant engagement of gears sets it apart from other types of gearboxes. This article delves into the working principles, components, advantages, disadvantages, and applications of constant mesh gearboxes.

1. Understanding the Basics of Mesh Gear Box

In a constant mesh gearbox, all gears are always engaged with each other. This means that, unlike sliding mesh gearboxes, where gears must disengage to shift, constant mesh gearboxes maintain continuous contact among gears. This design facilitates smoother transitions between gears, enhancing the overall driving experience.

Key Components Of Mesh Gear Box

The primary components of a constant mesh gearbox include:

| Component | Description |

|---|---|

| Input Shaft | Transfers power from the engine to the gearbox. |

| Output Shaft | Sends power to the wheels, effectively driving the vehicle. |

| Gears | Multiple gears that are always in mesh with one another. |

| Sliding Dog Clutch | Engages and disengages specific gears while keeping others in constant mesh. |

| Bearings | Support the rotating shafts and reduce friction. |

| Housing | Encloses all components to protect them from debris and maintain alignment. |

Working Mechanism Of Mesh Gear Box

The working principle of a constant mesh gearbox revolves around its ability to maintain gear engagement while allowing for quick gear changes. The following steps outline how it operates:

1. Power Transfer

The engine generates power, which is transmitted to the input shaft of the gearbox. This rotation drives the gears connected to the input shaft, causing them to turn.

2. Gear Engagement

All gears are constantly meshed with the input shaft, ensuring continuous engagement. When the driver wishes to change gears, the sliding dog clutch moves to select the desired gear.

3. Clutch Engagement

1. The driver depresses the clutch pedal, temporarily disconnecting the engine from the gearbox. This step is crucial as it allows the driver to change gears without damaging the system.

2. Synchronizers may be present in modern constant mesh gearboxes, which help match the speeds of the gears, ensuring smooth engagement.

4. Gear Selection

1. Once the clutch is disengaged, the driver selects the desired gear. The sliding dog clutch moves into position, locking the chosen gear to the output shaft while keeping all other gears in mesh.

2. This design allows for immediate power transfer without the need for complete disengagement of the engine from the gearbox.

5. Restoring Power

1. The driver releases the clutch pedal, re-establishing the connection between the engine and the gearbox. The selected gear now transmits power to the output shaft, driving the wheels.

2. This seamless process allows for quick and efficient gear changes, making constant mesh gearboxes ideal for various automotive applications.

Also Read: Mechanical Components: Detailed Explanation for Everyone

Advantages of Constant Mesh Gearboxes

Constant mesh gearboxes offer numerous benefits compared to traditional sliding mesh designs:

| Advantage | Description |

|---|---|

| Smoother Gear Changes | Continuous gear engagement reduces shock during shifting, providing a seamless experience. |

| Enhanced Durability | Minimal wear and tear due to the absence of sliding contact between gears. |

| Quick Power Transfer | Immediate power flow during gear changes, improving vehicle responsiveness. |

| Reduced Noise Levels | Quieter operation, especially with helical gears, minimizes noise and vibration. |

| Versatility | Suitable for a wide range of vehicles, including motorcycles, trucks, and sports cars. |

Disadvantages of Constant Mesh Gearboxes

Despite their advantages, constant mesh gearboxes also have some drawbacks:

| Disadvantage | Description |

|---|---|

| Complexity | More complex design can lead to higher manufacturing costs and maintenance challenges. |

| Weight | Additional components may increase the overall weight of the vehicle. |

| Cost of Repairs | Repairs can be expensive due to the intricate nature of the gearbox. |

Applications of Constant Mesh Gearboxes

Constant mesh gearboxes are widely used in various applications due to their reliability and efficiency:

1. Motorcycles

In motorcycles, constant mesh gearboxes provide a lightweight solution for power transfer, enabling quick shifts and improved handling. Their design allows for a more engaging riding experience, particularly in sport bikes.

2. Heavy-Duty Vehicles

Trucks and buses utilize constant mesh gearboxes for their durability and strength. These vehicles often encounter heavy loads, making the smooth power transfer essential for navigating challenging terrains.

3. Performance Cars

High-performance vehicles often employ constant mesh gearboxes to enhance driving dynamics. The ability to shift gears quickly and smoothly is vital for racing and performance driving, making this gearbox type a popular choice among enthusiasts.

Also Read: Mechanical Maintenance Explained: Basics, Types, Benefits

Comparison with Other Gearbox Types

To appreciate the uniqueness of constant mesh gearboxes, it’s helpful to compare them with other gearbox designs:

| Feature | Constant Mesh Gearbox | Sliding Mesh Gearbox | Synchromesh Gearbox |

|---|---|---|---|

| Gear Engagement | Gears always engaged, uses sliding dog clutches | Gears engage by sliding along shafts | Gears engage smoothly using synchronizers |

| Shifting Ease | Smoother shifts with less effort | Requires more effort and skill | Easiest to shift, especially for novice drivers |

| Durability | High durability, low wear | Higher wear due to sliding contact | Moderate durability, requires maintenance |

| Application | Motorcycles, heavy-duty vehicles, sports cars | Older cars, basic vehicles | Most modern vehicles, including manuals and automatics |

Maintenance of Constant Mesh Gearboxes

Proper maintenance is crucial to ensure the longevity and performance of a constant mesh gearbox:

1. Regular Fluid Changes

Changing the gearbox oil regularly is vital for optimal lubrication and to prevent overheating. Using the correct type of oil ensures that the gearbox operates smoothly.

2. Inspection of Components

Regularly inspect the gears, dog clutches, and bearings for signs of wear. Replacing worn components can prevent failures and extend the gearbox’s life.

3. Monitoring Performance

Keep an eye on gear engagement and shifting smoothness. If any issues arise, consult a professional mechanic for diagnostics and repairs.

Conclusion

In summary, a constant mesh gearbox is a sophisticated and efficient transmission system that plays a crucial role in various automotive applications. Its design, characterized by the continuous engagement of gears, allows for smooth and quick gear changes, enhancing the driving experience. While there are some drawbacks, such as increased complexity and potential repair costs, the advantages often outweigh these concerns.

Understanding how a constant mesh gearbox works, its components, advantages, disadvantages, and maintenance requirements is essential for automotive engineers, mechanics, and enthusiasts alike. As technology continues to evolve, constant mesh gearboxes will likely remain a vital part of the automotive landscape, delivering reliable and efficient power transfer for years to come.