When working with screws, bolts, or fasteners, one of the most important things to get right is the hole size before threading. If the hole is too small, the tap might break. If it’s too large, the threads won’t hold the fastener securely. That’s where a metric drill and tap chart becomes incredibly useful.

This guide will walk you through everything you need to know about metric drill and tap sizes, why they matter, and provide a handy chart to help you get precise results every time.

What is a Drill and Tap Chart?

A drill and tap chart is a reference table that shows you which drill bit size to use for a particular tap size.

Drill bit → makes the hole.

Tap → cuts the threads inside the hole so that a screw or bolt can fit properly.

The chart helps machinists, engineers, mechanics, and DIYers ensure they’re matching the right hole size with the right thread size.

Why Use a Metric Drill and Tap Chart?

Using the right drill and tap size has several benefits:

Accuracy – Ensures threads are cut cleanly and fit perfectly.

Prevents Damage – Reduces the risk of breaking taps or stripping threads.

Saves Time – You don’t waste material by drilling the wrong hole size.

Stronger Fastening – Proper hole and thread fit mean stronger, more reliable assemblies.

Understanding Metric Threads

Before using a metric drill and tap chart, it’s important to understand how metric threads are measured.

M Size → The “M” stands for metric. Example: M6 means the screw is 6 mm in diameter.

Pitch → This is the distance between threads, measured in millimeters. Example: M6 × 1.0 means the screw has a 6 mm diameter and 1 mm thread pitch.

Coarse vs. Fine Threads

Coarse threads have larger pitch (e.g., M6 × 1.0).

Fine threads have smaller pitch (e.g., M6 × 0.75).

Formula for Tap Drill Size

A simple formula often used is:

Tap Drill Size = Major Diameter – Pitch

Example: For an M6 × 1.0 screw:

Major diameter = 6 mm

Pitch = 1.0 mm

Tap Drill Size = 6 – 1 = 5 mm drill bit

This matches what you’ll find in most metric drill and tap charts.

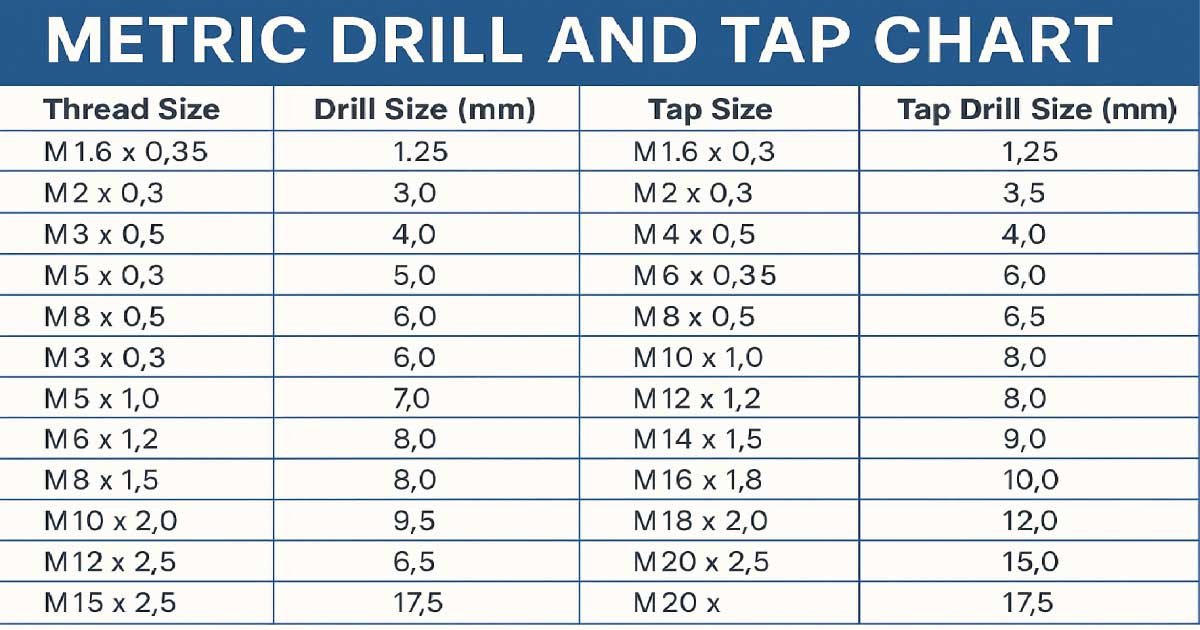

Metric Drill and Tap Chart

Here’s a reference table for common metric sizes:

| Thread Size | Pitch (mm) | Tap Drill Size (mm) |

|---|---|---|

| M2 × 0.4 | 0.40 | 1.6 mm |

| M2.5 × 0.45 | 0.45 | 2.05 mm |

| M3 × 0.5 | 0.50 | 2.5 mm |

| M4 × 0.7 | 0.70 | 3.3 mm |

| M5 × 0.8 | 0.80 | 4.2 mm |

| M6 × 1.0 | 1.00 | 5.0 mm |

| M8 × 1.25 | 1.25 | 6.8 mm |

| M10 × 1.5 | 1.50 | 8.5 mm |

| M12 × 1.75 | 1.75 | 10.2 mm |

| M14 × 2.0 | 2.00 | 12.0 mm |

| M16 × 2.0 | 2.00 | 14.0 mm |

| M20 × 2.5 | 2.50 | 17.5 mm |

👉 Note: Always check manufacturer recommendations for critical applications.

Coarse vs Fine Pitch Drill Sizes

Some metric bolts come in fine thread options. Here’s a quick comparison:

| Thread Size | Coarse Pitch | Drill Size | Fine Pitch | Drill Size |

|---|---|---|---|---|

| M6 | 1.0 mm | 5.0 mm | 0.75 mm | 5.25 mm |

| M8 | 1.25 mm | 6.8 mm | 1.0 mm | 7.0 mm |

| M10 | 1.5 mm | 8.5 mm | 1.25 mm | 8.8 mm |

| M12 | 1.75 mm | 10.2 mm | 1.5 mm | 10.5 mm |

This helps when working with precision fasteners, such as in automotive or aerospace applications.

How to Read a Metric Drill and Tap Chart

A metric drill and tap chart is a valuable reference for precision work with screws, bolts, and threaded fasteners. Knowing how to read it ensures accurate hole sizes and strong, reliable threads. Here’s how to use the chart effectively:

Identify Thread Size: Find the metric designation (e.g., M6, M8) of your bolt or screw.

Check Thread Pitch: Look for the pitch value in millimeters. Coarse threads have a larger pitch; fine threads have a smaller pitch.

Determine Tap Drill Size: The chart lists the recommended drill bit size for each thread and pitch combination. Using the correct size ensures proper thread engagement and strength.

Confirm Coarse vs. Fine Options: Some bolts have the both coarse and fine thread options. Always match the drill size to the specific pitch you are using.

Benefits of Using a Metric Drill and Tap Chart

Using a metric drill and tap chart offers multiple advantages:

Accuracy and Consistency: Ensures threads are cut cleanly and fit perfectly every time.

Prevents Damage: Reduces the risk of broken taps or stripped threads, saving time and materials.

Stronger Assemblies: Properly sized holes and threads provide maximum holding strength.

Time Efficiency: Eliminates guesswork and minimizes errors during drilling and tapping.

Versatility: Useful for engineers, mechanics, machinists, and DIY enthusiasts across a wide range of projects.

By referring to a metric drill and tap chart, you can confidently select the correct drill bit for any threaded fastener, ensuring strong, professional-quality results. Whether you are working in automotive repair, mechanical engineering, metal fabrication, or DIY projects, the chart is an indispensable tool for accurate and efficient threading.

Tips for Using a Drill and Tap Chart

Use Sharp Drill Bits – Dull drills make oversized holes.

Lubricate the Tap – Reduces friction and prevents breakage.

Drill Straight – Keep the hole perpendicular for accurate threading.

Back Out the Tap – Every quarter turn, reverse slightly to break chips.

Check Threads with a Gauge – Ensures proper fit.

Common Mistakes to Avoid

Drilling too small – The tap may break inside the hole.

Drilling too large – Threads will be weak and won’t hold properly.

Ignoring pitch – Always match both diameter and pitch for accuracy.

Using wrong chart (imperial vs metric) – Mixing up systems can cause major errors.

Applications of Metric Drill and Tap Charts

Mechanical Engineering – Designing machine parts.

Automotive Repair – Re-threading damaged bolt holes.

Metal Fabrication – Creating threaded joints in sheet metal.

DIY Projects – Furniture, bikes, or equipment assembly.

Final Thoughts

A metric drill and tap chart is an essential tool for anyone working with threaded fasteners. It saves time, prevents mistakes, and ensures your work is strong and professional.

Whether you are an engineer, machinist, mechanic, or hobbyist, keeping a printed copy of this chart in your workshop can make your job a lot easier.

Explore our recent post: