Wire ropes are one of the most versatile and reliable components used in industries worldwide. From lifting loads at construction sites to anchoring ships in ports, wire ropes play a vital role in ensuring strength, durability, and safety. Among all the factors that define wire rope performance, size is perhaps the most critical.

Choosing the right wire rope size ensures that equipment works smoothly, loads are handled safely, and the rope lasts longer. In this guide, we’ll dive deep into everything you need to know about wire rope sizes, including how to measure them, size charts, applications, and safety considerations.

What Does Wire Rope Size Mean?

When people talk about wire rope size, they are usually referring to its diameter. The diameter is the distance across the rope’s widest point. This simple measurement determines how much weight the rope can handle, how it fits into pulleys and drums, and how durable it will be over time.

The size is expressed in inches in the U.S. system and in millimeters in the metric system. For example:

A ½-inch wire rope is 0.5 inches across.

A 12 mm wire rope measures 12 millimeters in diameter.

Wire rope size doesn’t just reflect the rope’s thickness—it also indirectly indicates its strength and load capacity. Larger ropes have more steel wires, which means they can withstand higher tension and stress.

How to Measure Wire Rope Size Correctly

Measuring wire rope might sound easy, but doing it incorrectly can lead to serious safety issues. Many people mistakenly measure between two strands, which results in an incorrect diameter reading.

The correct method involves:

Use the right tools – A pair of calipers or a wire rope gauge should always be used. These tools provide precise readings.

Measure across the widest point – Place the caliper across the rope, ensuring it touches the outer edges, not the gaps between strands.

Check multiple points – Ropes can flatten or become slightly deformed after use. Measuring at more than one location ensures accuracy.

Safety Tip: If you are replacing an old rope, always measure the original size before wear and tear reduced its diameter. A rope that looks like ½-inch might have originally been 9/16-inch.

Accurate measurement ensures proper fitting with sockets, thimbles, and pulleys, reducing wear and extending service life.

Why Wire Rope Size Matters

Wire rope size is more than just a technical detail—it affects strength, safety, and cost efficiency.

Strength: Larger diameters increase the breaking strength, allowing the rope to handle heavier loads without snapping.

Durability: Thicker ropes resist abrasion, crushing, and fatigue better than smaller ones.

Compatibility: If the rope size doesn’t match the groove of a pulley or drum, it will wear out quickly and could fail.

Safety: Undersized ropes are dangerous. A rope that is too small may appear to work fine but can suddenly fail under stress, leading to accidents.

Cost Efficiency: Oversized ropes may provide unnecessary strength but at a higher price. The correct size balances safety and cost.

Standard Wire Rope Sizes

Wire ropes come in a wide variety of sizes. Depending on the industry, you might encounter very small ropes for light work or extremely large ropes for heavy-duty tasks.

Small/light-duty wire ropes (1/8″ – 1/4″ / 3–6 mm)

Common in residential projects like garage doors, cable railings, or light hoisting.Medium-duty wire ropes (3/8″ – 5/8″ / 10–16 mm)

Used in construction cranes, forestry work, and marine applications.Heavy-duty wire ropes (3/4″ – 1-1/2″ / 19–38 mm)

Found in large cranes, elevators, and heavy lifting operations.Extra heavy-duty wire ropes (2″ and above / 50+ mm)

Applied in ship mooring, oil rigs, and towing massive loads.

This wide range ensures that there is a wire rope size suitable for every type of job.

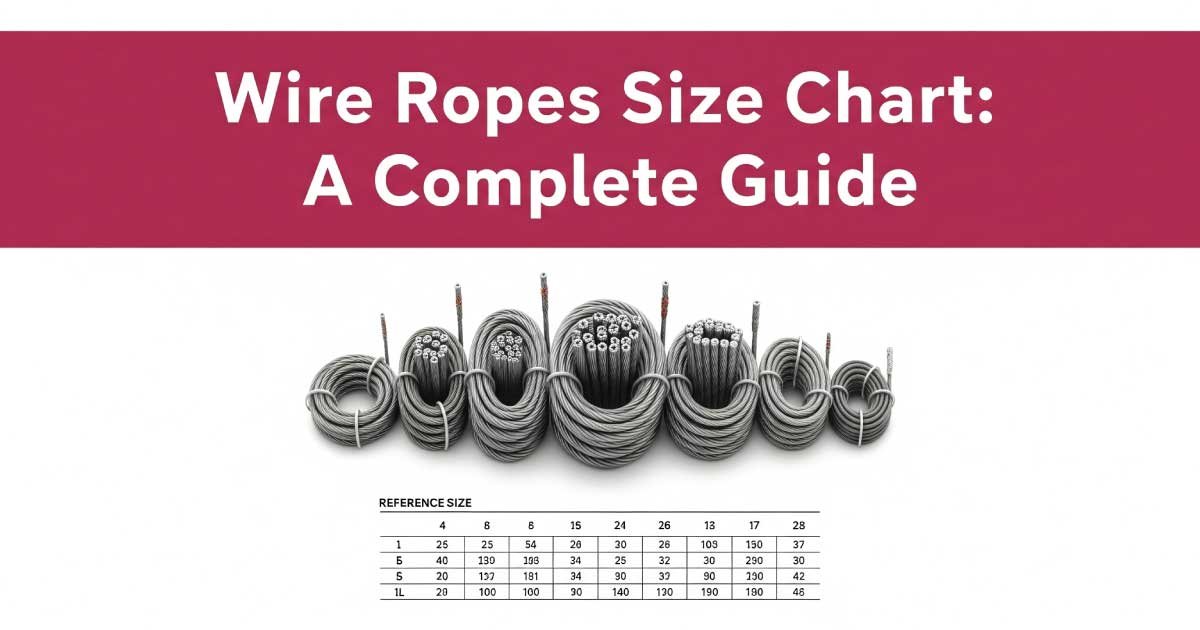

Wire Rope Size Chart (Inches and Millimeters)

Here’s a detailed chart showing common wire rope diameters, their approximate breaking strengths, and typical uses.

| Wire Rope Diameter | Diameter (mm) | Approx. Breaking Strength (lbs) | Approx. Breaking Strength (kg) | Common Uses |

|---|---|---|---|---|

| 1/8″ | 3.2 mm | 2,000 lbs | 900 kg | Light rigging, garage doors |

| 3/16″ | 4.8 mm | 4,200 lbs | 1,900 kg | Safety cables, DIY lifting |

| 1/4″ | 6.4 mm | 7,000 lbs | 3,175 kg | Winches, small cranes |

| 3/8″ | 9.5 mm | 14,400 lbs | 6,530 kg | Construction, forestry |

| 1/2″ | 12.7 mm | 24,000 lbs | 10,886 kg | Mining, elevators |

| 5/8″ | 16 mm | 38,000 lbs | 17,236 kg | Logging, offshore |

| 3/4″ | 19 mm | 54,000 lbs | 24,494 kg | Heavy cranes, bridges |

| 1″ | 25.4 mm | 96,000 lbs | 43,545 kg | Ship mooring, marine towing |

| 1-1/2″ | 38 mm | 216,000 lbs | 97,977 kg | Oil rigs, structural lifting |

| 2″ | 50.8 mm | 384,000 lbs | 174,181 kg | Heavy industry, marine towing |

Note: Breaking strength depends on rope construction (6×19, 6×36, 7×7, etc.). Always check the manufacturer’s exact specifications.

Wire Rope Size Chart PDF

Download our Wire Rope Size Chart PDF in landscape format for clear and easy viewing. The chart includes wire rope diameters in inches and millimeters, along with approximate breaking strengths and common applications. Perfect for quick reference in construction, marine, mining, and industrial projects, this guide ensures you choose the correct size for safety and efficiency.

Factors That Influence Wire Rope Size Selection

Selecting the right size isn’t only about weight—it’s about application. Here are the key factors:

Load Requirements – Calculate the maximum expected load, not just the average. Always choose a rope with a working load limit (WLL) higher than the load.

Type of Load – Dynamic loads (with shocks and jerks) require stronger ropes than static loads.

Equipment Compatibility – The rope must fit sheave grooves, drums, and sockets properly.

Safety Factor – OSHA and ISO recommend a minimum safety factor of 5:1 (meaning the rope’s breaking strength should be at least five times the expected load).

Environment – Corrosive, wet, or abrasive environments may require stainless steel or galvanized ropes of the right size.

Wire Rope Construction and Its Impact on Size

Wire rope isn’t just a bundle of wires—it’s an engineered product. Different constructions change how the rope behaves.

6×19 construction – Offers a good balance of strength and flexibility. Common in cranes and hoists.

7×7 construction – Slightly stiffer, often used in rigging and aircraft control cables.

6×36 construction – Very flexible, ideal for applications requiring frequent bending, like winches.

The same diameter rope in different constructions may have different strengths and bending capacities. That’s why you must consider both size and construction.

Common Applications of Different Wire Rope Sizes

Let’s break it down by size category:

1. Small Sizes (1/8″ – 1/4″)

Used in cable railings for buildings.

Employed in garage door lifting systems.

Ideal for winches and small pulleys.

Popular in DIY projects and safety barriers.

2. Medium Sizes (3/8″ – 5/8″)

Extensively used in construction cranes and lifting slings.

Common in forestry equipment for pulling logs.

Marine rigging and fishing applications.

Industrial hoists for warehouses.

3. Large Sizes (3/4″ – 2″)

Ship mooring lines and offshore drilling rigs.

Heavy construction equipment like tower cranes.

Bridges and structural engineering projects.

Mining operations requiring massive hauling strength.

Wire Rope Size and Safety

Safety is the most important reason to pay attention to size. Using the wrong rope size can result in catastrophic accidents.

Inspection: Ropes should be inspected regularly for broken strands, corrosion, or kinks.

Load Limit: Never exceed the working load limit. A rope rated for 10,000 lbs should not lift 12,000 lbs.

End Fittings: Always use thimbles, clamps, and sockets designed for the rope’s size. Mismatched fittings cause slippage.

Discard Criteria: If a rope shows wear beyond safe limits, replace it immediately—even if it still looks “usable.”

Wire Rope Size Conversion (Inches to Millimeters)

Since wire rope is sold globally, knowing conversions helps when ordering or replacing.

1/8″ ≈ 3.2 mm

3/16″ ≈ 4.8 mm

1/4″ ≈ 6.4 mm

3/8″ ≈ 9.5 mm

1/2″ ≈ 12.7 mm

5/8″ ≈ 16 mm

3/4″ ≈ 19 mm

1″ ≈ 25.4 mm

1-1/2″ ≈ 38 mm

2″ ≈ 50.8 mm

This quick guide helps avoid errors when switching between systems.

📌 Don’t miss 👉 Metric Drill and Tap Chart: A Complete Guide

Tips for Choosing the Right Wire Rope Size

Never guess – Always measure and check manufacturer charts.

Think about safety – Add a safety factor, especially for lifting.

Check environment – For saltwater, stainless steel may be necessary.

Match with equipment – Wrong size reduces efficiency and damages equipment.

Consult experts – For critical projects, get advice from rope suppliers or engineers.

Conclusion

Wire rope size plays a central role in ensuring safety and efficiency across industries. From the smallest 1/8-inch ropes for everyday tasks to massive 2-inch ropes anchoring ships, every size is carefully engineered for a purpose.

By measuring correctly, understanding load requirements, and matching the rope with the right equipment, you can ensure maximum performance and safety. Choosing the right wire rope size isn’t just about numbers—it’s about protecting lives, equipment, and investments.

📌 Don’t miss 👉 Drill Chart: Complete Guide

FAQs Related To Wire Rope Size:

How do I measure wire rope size correctly?

To measure wire rope size, use calipers or a rope gauge and measure across the widest point of the rope, not between strands. Take measurements at several points since ropes may flatten under use. Accurate measurement ensures proper fitting with pulleys, sheaves, and fittings, which is critical for both performance and safety in applications.

What is the smallest wire rope size available?

The smallest common wire rope size is 1/16 inch (about 1.6 mm), used for very light-duty applications like small cables, display hanging, and hobby projects. Sizes more commonly used for everyday purposes start at 1/8 inch (3.2 mm). Selecting the right size always depends on the weight of the load and safety requirements.

Can I use a larger wire rope than required?

Yes, you can use a larger wire rope than required, but it may not always be practical. Larger ropes are heavier, cost more, and may not fit correctly in sheaves or pulleys. The goal is to match the rope size to the equipment and load. Oversizing unnecessarily can reduce efficiency and increase operational costs.

What happens if I choose the wrong wire rope size?

Using the wrong size wire rope can cause serious issues. If undersized, the rope may snap under load, creating a major safety hazard. If oversized, it may not fit equipment properly, leading to excessive wear and damage. In both cases, efficiency is compromised, and the risk of accidents or costly equipment failures increases significantly.

Are wire rope sizes standardized worldwide?

Wire rope sizes are commonly standardized, but measurement systems vary. In the U.S., sizes are given in inches, while most other countries use millimeters. Conversion between the two is straightforward, but always check manufacturer charts for load capacity since strength depends not only on size but also on construction type (such as 6×19 or 7×7).

How does wire rope construction affect size selection?

Wire rope construction refers to the number of strands and wires per strand. For example, a 6×19 rope is stronger but less flexible, while a 6×36 rope is very flexible but may wear faster. When selecting size, construction matters because two ropes with the same diameter may have different flexibility, fatigue resistance, and load capacities.