Stud bolts are fundamental components in the industrial world, yet they are often overlooked outside of engineering and construction circles. These fasteners are integral to securing flanges, heavy machinery, and high-pressure piping systems in industries ranging from oil and gas to power plants and chemical facilities. Selecting the correct stud bolt size is essential for maintaining structural integrity, preventing leaks, and ensuring safety under extreme conditions.

In this guide, we will explore stud bolt sizes, thread types, lengths, materials, and industrial applications. You will learn how to choose the right bolt, avoid common mistakes, and implement best practices to maximize safety and efficiency. By the end of this article, you will have a thorough understanding of stud bolts and their importance in industrial settings.

What Are Stud Bolts?

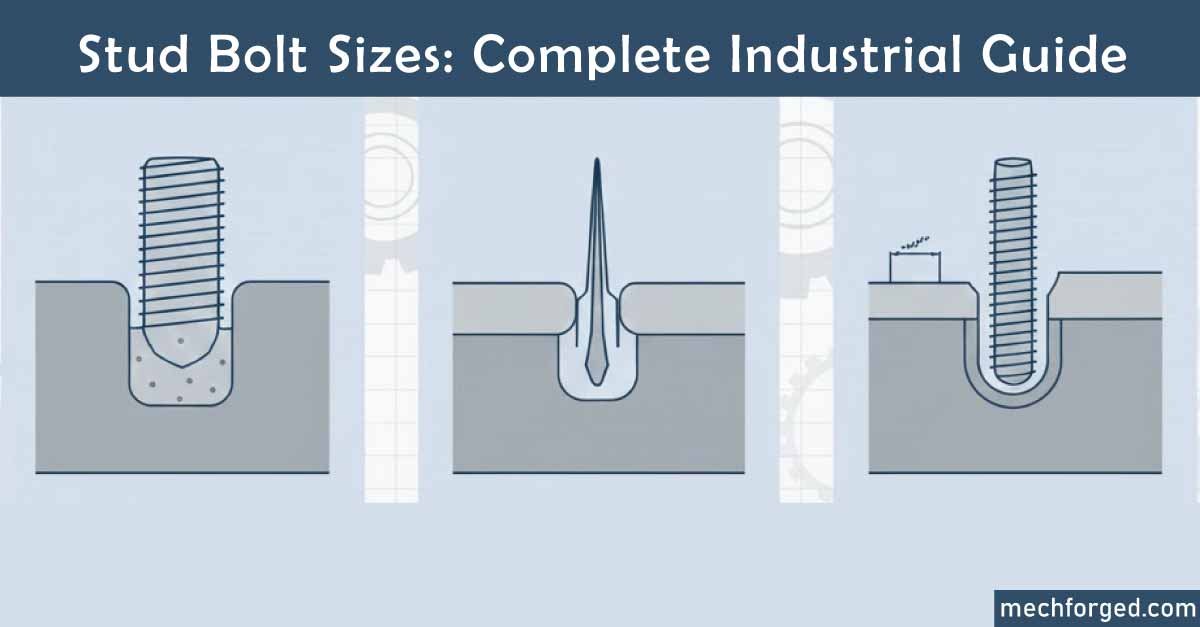

Stud bolts are threaded rods with no head, designed to be used with nuts on both ends. They are typically installed through flanges, equipment connections, or structural plates to provide strong clamping forces. Unlike conventional bolts, which have a head and a shank, stud bolts rely entirely on their threads and nut engagement for strength.

These bolts are particularly valuable in high-pressure applications because they allow even distribution of force and can be tightened in controlled sequences to ensure uniform clamping. Stud bolts are often made from high-strength materials such as carbon steel, alloy steel, or stainless steel to withstand harsh industrial conditions.

| Feature | Description |

|---|---|

| Headless Design | No bolt head, nuts secure both ends |

| Threaded Ends | Standard or fine threads for high-strength clamping |

| Length | Variable; determined by flange or joint thickness |

| Material Options | Carbon steel, alloy steel, stainless steel |

Why Stud Bolt Size Matters

Choosing the correct stud bolt size is critical because it affects the strength, safety, and performance of the assembly. An undersized stud may fail under tension or shear loads, while an oversized stud can cause misalignment, difficulty in tightening, or unnecessary material costs.

Industrial applications require careful calculation of load, flange type, and material properties. Engineers often refer to standards such as ASTM, ANSI, or ISO to determine appropriate sizes and specifications. Using the correct stud bolt ensures optimal clamping force, reduces maintenance requirements, and prevents catastrophic failures.

| Parameter | Importance |

|---|---|

| Diameter | Determines tensile and shear strength |

| Length | Ensures proper nut engagement and clamping |

| Thread Pitch | Affects tightening accuracy and load distribution |

| Material Grade | Ensures durability and resistance to corrosion |

👉 Explore the complete M screw sizing guide to choose the right diameter, length, and thread for any project. This chart helps you match screws perfectly to materials, ensuring strength and precision. For hassle-free assembly and accurate hardware selection, check out the full detailed post now!

Stud Bolt Thread Types

Stud bolts come in various thread types, each designed for specific applications. The most common thread types are coarse threads (UNC) and fine threads (UNF). Coarse threads are easier to install, less prone to cross-threading, and suitable for soft materials. Fine threads offer higher tensile strength and better vibration resistance, making them ideal for high-pressure or precision assemblies.

Thread standards also vary regionally. For instance, metric threads are widely used in Europe and Asia, while unified threads dominate North America. Engineers must ensure that the thread type matches the mating nuts and conforms to the required industrial standard.

| Thread Type | Characteristics | Common Uses |

|---|---|---|

| UNC (Coarse) | Easier installation, better in soft materials | Piping, general assembly |

| UNF (Fine) | Higher tensile strength, vibration resistant | High-pressure flanges, precision machinery |

| Metric | International standard sizes | Global industrial applications |

Standard Stud Bolt Sizes

Stud bolts are available in a wide range of diameters and lengths to accommodate different flanges and equipment. Diameters typically range from 1/4 inch (M6) to over 2 inches (M52), while lengths can vary from a few inches to several feet for specialized applications.

Selecting the proper size requires consideration of flange thickness, gasket type, and clamping force. For example, a standard 150 lb ANSI flange may require smaller diameter studs than a 600 lb high-pressure flange, even if both flanges are the same nominal size.

| Diameter (inches) | Metric Equivalent | Common Lengths (inches) | Typical Application |

|---|---|---|---|

| 1/4 | M6 | 1–6 | Small equipment, low-pressure flanges |

| 3/8 | M10 | 2–12 | Medium flanges, machinery |

| 1/2 | M12 | 3–18 | Industrial piping, moderate pressure |

| 5/8 | M16 | 4–24 | Heavy machinery, structural |

| 3/4 | M20 | 6–30 | High-pressure flanges, power plants |

| 1–2 | M24–M52 | 12–60+ | Large industrial applications |

Material Selection for Industrial Uses

Stud bolts must withstand extreme pressures, temperatures, and environmental conditions. Carbon steel bolts are suitable for general-purpose applications, while stainless steel offers corrosion resistance for chemical or marine environments. Alloy steel studs are often used in high-pressure or high-temperature applications because of their superior mechanical properties.

Coatings such as galvanization, black oxide, or epoxy are also applied to enhance durability, prevent rust, and extend service life. Selecting the appropriate material is as critical as choosing the right size, as it affects both strength and longevity.

| Material | Strength | Corrosion Resistance | Best Application |

|---|---|---|---|

| Carbon Steel | High | Low | General industrial, indoor use |

| Stainless Steel | Medium | High | Chemical, marine, outdoor |

| Alloy Steel | Very High | Medium | High-pressure, high-temperature systems |

| Galvanized Steel | High | High | Outdoor or humid environments |

Length Considerations

The length of a stud bolt is determined by the thickness of the flange or plate, plus allowance for nut engagement. Too short a stud compromises clamping force, while excessively long studs may complicate installation or reduce thread engagement.

A common rule of thumb is that the nut should engage at least 1.5 times the diameter of the stud. For example, a 1-inch diameter stud should have nuts that engage at least 1.5 inches of thread for secure fastening.

| Diameter | Recommended Nut Engagement | Typical Length Adjustment |

|---|---|---|

| 1/4 | 3/8 in | Add flange thickness + 3/8 in |

| 3/8 | 1/2 in | Add flange thickness + 1/2 in |

| 1/2 | 3/4 in | Add flange thickness + 3/4 in |

| 3/4 | 1 in | Add flange thickness + 1 in |

| 1 | 1.5 in | Add flange thickness + 1.5 in |

Stud Bolt Standards

Stud bolts are manufactured to meet various standards, ensuring compatibility, performance, and safety. Key standards include ASTM A193, ASTM A320, and ANSI/ASME B16.5. Each standard specifies bolt dimensions, material grades, mechanical properties, and allowable stress.

For example, ASTM A193 B7 studs are commonly used in high-pressure steam applications due to their tensile strength and heat resistance, while ASTM A320 L7 studs are suitable for low-temperature applications.

| Standard | Material Grade | Application |

|---|---|---|

| ASTM A193 B7 | Alloy steel | High-pressure steam, petrochemical |

| ASTM A320 L7 | Alloy steel | Low-temperature services |

| ANSI B16.5 | Carbon/Alloy | Flanges, piping systems |

| ISO 898-1 | Metric grades | International mechanical applications |

Installation Practices

Proper installation of stud bolts is crucial for achieving the desired clamping force and ensuring safety. Studs should be installed with matching nuts on both ends, tightened in a crisscross pattern to distribute stress evenly. Using a calibrated torque wrench ensures consistent torque and prevents over-tightening, which can damage threads or compromise flange integrity.

Lubrication of threads with anti-seize compounds is often recommended in high-temperature or corrosive environments. Additionally, ensuring that stud lengths and nut engagement are correct avoids uneven clamping and potential leaks in piping systems.

Common Mistakes to Avoid

Even experienced engineers and technicians make mistakes with stud bolts. Common errors include using incorrect thread types, underestimating nut engagement, over-torquing, and choosing materials unsuitable for the environment.

Improper stud length or diameter selection can lead to reduced clamping force, leaks, or even structural failures in industrial equipment. Always consult design specifications, flange thickness charts, and torque tables before installation.

| Mistake | Effect |

|---|---|

| Wrong thread type | Incompatibility, cross-threading |

| Insufficient nut engagement | Reduced clamping force, potential pullout |

| Over-tightening | Thread damage, flange distortion |

| Inappropriate material | Corrosion, premature failure |

| Wrong length | Misalignment, inadequate clamping |

Industrial Applications

Stud bolts are used extensively across industries. In oil and gas pipelines, they secure flanges that contain high-pressure fluids. In power plants, they hold together high-temperature steam lines and turbines. Structural applications in bridges or large machinery also rely on stud bolts to provide high-strength connections.

| Industry | Typical Stud Bolt Size | Material | Application |

|---|---|---|---|

| Oil & Gas | 1/2–1 in | Alloy Steel | High-pressure flanges |

| Power Generation | 3/4–1 in | Alloy/Stainless | Steam and gas turbines |

| Construction | 1/2–1-1/4 in | Carbon/Alloy | Heavy structural beams |

| Chemical Plants | 1/2–1 in | Stainless Steel | Corrosive piping systems |

👉 Learn everything about square U-bolt sizes, including diameter, length, and thread details for strong, secure fittings. This guide helps you select the perfect square U-bolt for pipes, beams, or machinery. For precise measurements and reliable installations, read the full, detailed post now!

Torque and Tension Calculations

Achieving correct torque is essential for stud bolts, particularly in high-pressure applications. Torque specifications vary depending on stud diameter, material grade, and friction. Engineers often use torque-tension charts or formulas to determine the exact torque required to achieve the desired clamping force without over-stressing the bolt or flange.

| Diameter | Material | Torque (ft-lbs) | Notes |

|---|---|---|---|

| 1/2 | Carbon | 75–90 | Standard low-pressure flanges |

| 3/4 | Alloy | 200–220 | High-pressure industrial |

| 1 | Stainless | 250–300 | Corrosion-resistant applications |

| 1-1/4 | Alloy | 400–450 | Large industrial equipment |

Pre-Installation Checks

Before installing stud bolts, verify dimensions, thread compatibility, material grade, and surface conditions. Ensure that nuts and washers match the stud specifications, and inspect threads for damage or debris. Proper cleaning, lubrication, and alignment reduce the risk of installation errors and improve joint longevity.

A mini-checklist includes: verify diameter and length, confirm thread type, inspect threads, choose appropriate lubrication, and ensure correct flange alignment.

👉 Explore flange sizes with this complete guide covering diameter, thickness, and bolt patterns for secure connections. Understand how to select the right flange for pipes, machinery, or structural projects. For accurate fitting and safer installations, check out the full detailed post now!

Comparative Strength Analysis

Comparing different stud bolt sizes and materials helps in selecting the best option for industrial projects. Larger diameters and higher-grade materials offer increased tensile and shear strength, while fine-thread studs provide better resistance to vibration and cyclic loads.

| Stud Size & Material | Tensile Strength (lbs) | Shear Strength (lbs) | Recommended Application |

|---|---|---|---|

| 1/2 in Carbon Steel | 12,000 | 10,000 | Low-pressure piping |

| 3/4 in Alloy Steel | 25,000 | 20,000 | High-pressure flanges |

| 1 in Stainless Steel | 30,000 | 24,000 | Corrosive piping |

| 1-1/4 in Alloy Steel | 45,000 | 38,000 | Heavy industrial equipment |

Conclusion: Selecting the Right Stud Bolt

Selecting the correct stud bolt size requires careful consideration of diameter, length, thread type, material, and industrial application. Proper installation, torque control, and pre-installation checks are equally important to ensure safety, performance, and longevity.

Remember, the best stud bolt is not just the strongest but the one that fits the flange thickness, withstands environmental conditions, and provides adequate nut engagement. By following these guidelines, engineers and technicians can confidently choose stud bolts that maintain structural integrity and support industrial operations safely and effectively.

| Quick Reference: Stud Bolt Guide | Diameter | Length | Material | Thread Type | Industrial Use |

|---|---|---|---|---|---|

| Small flanges | 1/4–3/8 in | 1–6 in | Carbon Steel | UNC | Low-pressure |

| Medium machinery | 3/8–1/2 in | 2–12 in | Alloy/Carbon | UNC/UNF | Moderate pressure |

| High-pressure flanges | 3/4–1 in | 6–30 in | Alloy/Stainless | UNF | Oil & gas, power plants |

| Heavy industrial equipment | 1–1-1/4 in | 12–60 in | Alloy Steel | UNF | Structural, turbines |

FAQs:

What is the use of a stud bolt?

Stud bolts are primarily used to secure flanges, machinery parts, and heavy equipment where high-strength fastening is required. Unlike regular bolts, they are threaded on both ends, allowing nuts to be fastened on each side. This makes them ideal for high-pressure piping, engines, and structural applications.

How to determine what thread size for a bolt?

To determine a bolt’s thread size, measure the major diameter of the threaded portion and count the threads per inch (TPI) or pitch in millimeters. A thread gauge can provide precise readings. Always verify with standard size charts to ensure proper compatibility with nuts or tapped holes.

What is the standard thread length of a bolt?

The standard thread length of a bolt depends on its diameter and total length. For smaller bolts, threads often cover half the bolt, while longer bolts may have threads covering one-third. Standards like ISO or ANSI provide guidelines, but always check manufacturer specifications for precise applications.

What is the difference between a bolt and a stud?

A bolt is partially threaded and has a head for wrenching, fastening objects directly with a nut. A stud is fully or partially threaded on both ends, without a head, and requires nuts on both sides. Studs are used for high-strength or permanent installations where alignment is critical.

What are the different types of stud bolts?

Common types of stud bolts include full-thread studs, tap-end studs, double-ended studs, and heavy hex studs. Each serves specific purposes, such as connecting flanges, machinery, or high-pressure equipment. Selection depends on load requirements, material, and application conditions for secure fastening.

How to read stud bolt size?

Reading a stud bolt size involves noting its diameter, thread pitch, and overall length. Metric studs are labeled like “M12 x 50,” meaning 12 mm diameter and 50 mm length. Imperial studs may show threads per inch. Correct reading ensures compatibility with nuts and threaded holes.

What are the three types of bolts?

Three main types of bolts are hex bolts, carriage bolts, and machine bolts. Hex bolts have a hexagonal head, carriage bolts have a rounded head with a square neck, and machine bolts are used with tapped holes or nuts. Each type suits different fastening requirements and surfaces.

How to determine stud type?

To determine a stud type, examine thread length, end type, material grade, and application. Check if it’s a tap-end, full-thread, or double-ended stud, and match it to the required strength, load, and environmental conditions. Manufacturer markings or specifications often provide additional identification details.