Machine screws may seem like small, everyday components, but they are essential for everything from assembling machinery to building furniture. Unlike wood screws, which are designed to grip soft materials, machine screws are designed to work with pre-tapped holes or nuts, providing precision fastening and consistent strength. Choosing the correct machine screw size is crucial because the wrong diameter, length, or thread pitch can result in stripped threads, loose assemblies, or even costly damage to parts.

Whether you are a professional builder, a DIY enthusiast, or a hobbyist working on electronics or metal fabrication, understanding machine screw sizes is key to building durable, safe, and reliable projects. This guide provides a complete reference for selecting, measuring, and using machine screws effectively.

Understanding Machine Screw Anatomy

Before selecting a machine screw, it’s important to understand its anatomy. A typical machine screw consists of a head, shank, threads, and tip. The head type determines the tool needed for installation and can affect the surface finish of the material. Common head types include flat, pan, round, and hex. The shank is the smooth portion, sometimes partially threaded, while the threads provide gripping power in nuts or tapped holes. The tip, whether blunt or pointed, assists in alignment or penetration during installation.

Knowing the anatomy helps beginners understand why diameter, thread pitch, and length are all important measurements. Each element affects how the screw behaves under stress, torque, and vibration.

Machine Screw Anatomy Overview Table

| Part | Description | Importance |

|---|---|---|

| Head | Top of the screw | Determines tool and surface contact |

| Shank | Smooth or partially threaded section | Guides screw and provides alignment |

| Threads | Spiral ridges along the shank | Secure engagement with nut or tapped hole |

| Tip | End of the screw | Helps alignment and starting the screw |

Metric vs. Standard Machine Screws

Machine screws are manufactured in both metric and standard (imperial) sizes. Metric screws are measured in millimeters, while standard screws are measured in inches. This distinction is important because using the wrong system can lead to mismatched threads, stripped holes, or poor fit.

For example, an M6 screw is 6mm in diameter and may look similar to a 1/4″ standard screw, but the threads per inch (TPI) and pitch differ, making them incompatible. Builders and DIYers need to know which system their equipment or project uses before selecting screws.

Metric vs. Standard Screw Comparison Table

| System | Example | Diameter | Thread Pitch / TPI | Typical Use |

|---|---|---|---|---|

| Metric | M3 | 3mm | 0.5mm | Electronics, small machinery |

| Metric | M6 | 6mm | 1.0mm | Furniture, bicycles |

| Standard | 1/4″-20 | 0.25″ | 20 TPI | Construction, furniture |

| Standard | 3/8″-16 | 0.375″ | 16 TPI | Automotive, medium-duty projects |

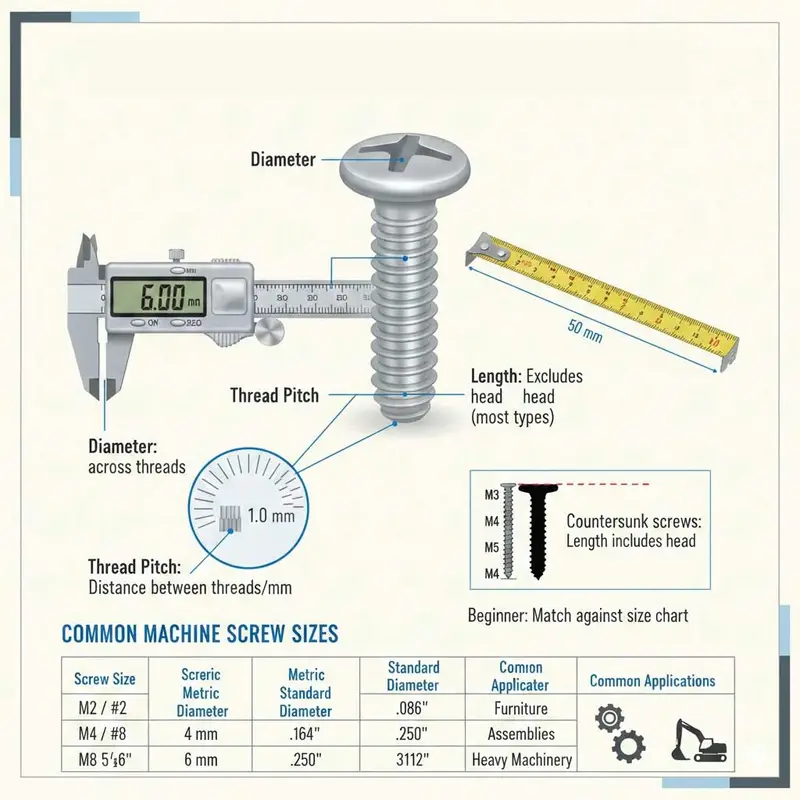

Measuring Machine Screw Size

Accurate measurement is essential for selecting the right screw. Start by measuring the diameter across the threaded portion using calipers. This ensures the screw fits precisely in a tapped hole or nut. Next, measure the length from the bottom of the head to the tip. Countersunk screws may require measuring from the top of the head if flush mounting is needed. Thread pitch is another critical measurement, as it determines how tightly the screw engages with the nut or threaded hole.

For beginners, a simple method is to compare the screw with a gauge or a chart of standard sizes, ensuring both diameter and thread pitch match perfectly.

Common Machine Screw Sizes Table

| Screw Size | Metric Diameter | Standard Diameter | Common Applications |

|---|---|---|---|

| Small | M2 | #2 | Electronics, precision components |

| Medium | M4 | #8 | Furniture, small machinery |

| Large | M6 | 1/4″ | Medium-duty assemblies |

| Extra Large | M8 | 5/16″ | Heavy machinery, metal fabrication |

Understand Thread Pitch and TPI

Thread pitch is the distance between threads for metric screws, while TPI (threads per inch) is used for standard screws. Fine threads provide stronger engagement in metal, while coarse threads are easier to install and grip softer materials like plastic or aluminum. Choosing the correct thread pitch is crucial to prevent stripping and ensure a secure fit.

For example, a fine-thread M6 screw works well in machinery with tapped holes, whereas a coarse-thread M6 screw might strip a soft aluminum component.

Metric vs. Standard Thread Pitch Table

| Screw Diameter | Metric Pitch | Standard TPI | Best Use |

|---|---|---|---|

| M3 / #2 | 0.5mm | 48 | Electronics |

| M4 / #8 | 0.7mm | 32 | Light machinery |

| M6 / 1/4″ | 1.0mm | 20 | Furniture, medium-duty |

| M8 / 5/16″ | 1.25mm | 18 | Automotive, heavy-duty |

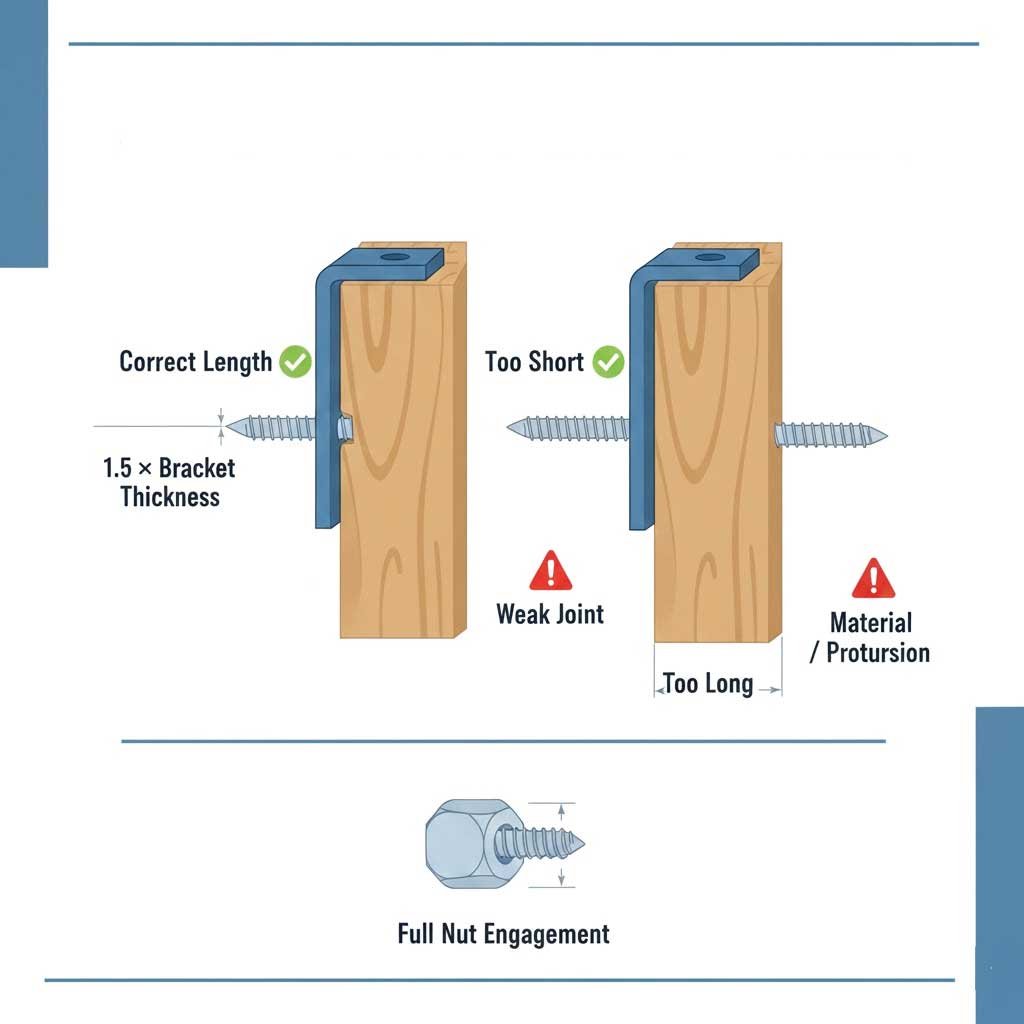

Choose the Right Screw Length

The correct screw length depends on the materials being fastened and whether nuts are used. A screw should penetrate at least half the thickness of the receiving material or fully engage a nut. Overly long screws may damage the material or protrude undesirably, while short screws risk weak joints.

For example, when fastening a metal bracket to a wooden post, a screw long enough to enter the wood at least 1.5 times the thickness of the bracket ensures a strong hold without splitting the wood.

Head Types and Applications

Machine screws come with different head types: flat, pan, round, oval, and hex. Flat heads are ideal for countersunk applications, pan and round heads are common for raised surfaces, and hex heads allow higher torque installations. The head type affects the overall screw length and how the fastener interacts with the surface.

For instance, installing a flush-mounted metal panel requires flat-head screws, while assembling a small machine frame may benefit from hex heads for added torque.

Common Head Types and Uses Table

| Head Type | Characteristics | Typical Use |

|---|---|---|

| Flat | Countersunk | Flush surfaces, furniture |

| Pan | Rounded, flat bottom | Medium-duty fastening |

| Round | Fully rounded | Decorative, light assembly |

| Hex | Six-sided | High torque, machinery |

Material and Coating Considerations

Machine screws are made from various materials including steel, stainless steel, brass, and nylon. The choice affects strength, corrosion resistance, and application suitability. Steel screws are strong but may rust unless plated; stainless steel offers high corrosion resistance, ideal for outdoor or moist environments. Brass screws are decorative and corrosion-resistant but weaker, while nylon screws are non-conductive and lightweight, suitable for electronics.

Considering both material and coating is essential for long-term durability and preventing material damage.

Machine Screw Materials & Applications Table

| Material | Coating/Finish | Best Use |

|---|---|---|

| Steel | Zinc-plated | Indoor, general use |

| Stainless Steel | Polished | Outdoor, corrosive environments |

| Brass | Natural | Decorative, light loads |

| Nylon | Natural | Electronics, lightweight, insulated |

Matching Machine Screws to Nuts

A common mistake is assuming any nut will fit a machine screw. The screw diameter and thread pitch must match exactly. Using a mismatched nut can strip threads, loosen under vibration, or fail under load. Beginners should always measure both the screw and the nut and test-fit before final assembly.

For example, pairing an M6 screw with a 1/4″-20 nut might seem close, but the threads do not match, risking stripped connections.

Also Read:

Practical Tips for Beginners

Choosing the right machine screw can be confusing for beginners, but a few basic checks make the process much easier. Accurate measurement, proper material selection, and compatibility with nuts or tapped holes are essential for a secure fit. Following simple, step-by-step guidelines helps prevent installation errors and ensures long-lasting, reliable fastening results.

Measure the screw diameter first using a caliper or gauge

Check thread pitch carefully to ensure a proper match

Select the correct length to avoid bottoming out

Choose a suitable head type for access and appearance

Match screw material to strength and environment needs

Consider coatings for corrosion resistance

Confirm compatibility with nuts or tapped holes

Avoid overtightening to prevent thread damage

Test fit on scrap material before final use

Keep common sizes organized for quick access

Common Mistakes to Avoid

When working with machine screws, beginners often face problems due to simple but avoidable mistakes. Choosing incorrect sizes, ignoring thread standards, or overlooking material quality can weaken joints and cause installation issues. Learning basic screw anatomy and measuring carefully helps ensure strong, reliable, and corrosion-resistant connections.

Using the wrong screw diameter or length

Mixing metric and standard (imperial) screws

Ignoring thread pitch compatibility

Choosing an incorrect head type for the application

Overlooking material and coating requirements

Conclusion: Confidently Selecting Machine Screws

Mastering machine screw sizes is essential for both DIY enthusiasts and professional builders. By understanding anatomy, measuring diameter and length, selecting the correct thread pitch, choosing appropriate head type, and considering material and coating, you can achieve strong, secure, and long-lasting assemblies.

From assembling machinery to building furniture or repairing electronics, choosing the right machine screw ensures durability, safety, and professional-quality results. Applying the principles outlined in this guide, testing fit, and paying attention to material compatibility will make your projects not only successful but also enjoyable to complete.

Also Read: