Drilling seems like a simple task, attach the bit, pull the trigger, and make a hole. But anyone who has worked with wood, metal, concrete, or even plastic knows that selecting the correct drill size can make or break your entire project. A wrong drill size can leave you with a loose screw, a cracked material, or a hole far bigger than you planned.

Whether you are a DIY beginner, a machinery enthusiast, a mechanic, or an engineering professional, understanding drill sizes is essential. This guide breaks down everything you need from conversion charts to drill bit types and real-world applications.

A Quick Story Before We Begin:

Sometimes the smallest mistake teaches the biggest lesson. A few months ago, I was helping a friend organize and install new shelves in his small workshop. He had recently bought new tools, a fresh set of screws, and a shiny cordless drill. He was excited, confident, and ready to get the job done quickly.

We measured the shelf height, marked the drilling points, and he grabbed his drill. Without a second thought, he picked a drill bit that “looked close enough” to the screw size. This is a habit many people have—choose the bit based on guesswork instead of measurement.

The moment he started drilling, I noticed something wrong. The drill bit dug into the wooden plank far too easily. It wobbled slightly and removed more material than necessary. When he tried inserting the screw, it slid in with no resistance and began spinning freely. The screw wasn’t gripping anything—it was too loose.

He stepped back, confused and annoyed.

“Why don’t my screws ever fit properly? I think these screws are low quality,” he said.

But the screws weren’t the problem.

The drill size was.

I picked up the bit and showed him how the diameter was wider than the screw’s core. That meant there was nothing left for the threads to hold onto. We opened a drill size conversion chart, matched the exact screw size, and selected the correct bit.

This time, when he drilled the hole, it was clean and precise. The screw slid in perfectly, tightened smoothly, and the shelf felt solid. His eyes widened in surprise.

He said,

“I wish someone had explained drill sizes in simple words. It always felt more complicated than it should be.”

And he was absolutely right. Many beginners, DIYers, and even some professionals lose screws, break materials, or damage projects simply because they don’t understand drill sizing. That moment made me realize how important clear guidance is.

And that’s exactly why this guide exists—to simplify drill sizes and make drilling mistakes a thing of the past.

What Is a Drill Size?

A drill size simply refers to the diameter of the drill bit you are using. But even though the concept is simple, people often get confused because drill sizes come in different measurement systems. The drill size defines how wide your drilled hole will be and determines how well screws, bolts, anchors, dowels, or fasteners will fit. A correct drill size makes your project strong, neat, and safe. A wrong drill size can make screws loose, damage materials, or ruin the entire assembly.

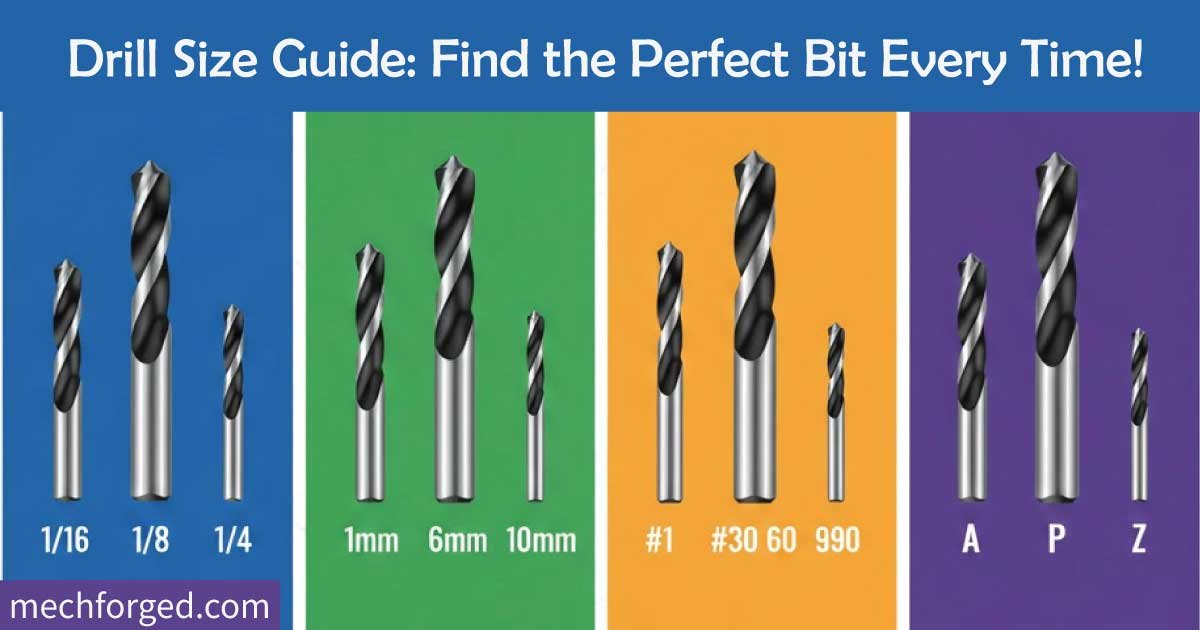

There are four main drill size systems used worldwide:

1. Inch-Based (Fractional) Sizes

These are written as fractions like 1/4”, 3/16”, or 5/32”.

They are widely used in the United States and common in woodworking, DIY projects, and general home repairs.

2. Metric Sizes (mm)

These are written in millimeters—4 mm, 6 mm, 10 mm, etc.

They are used internationally, especially in engineering, machinery, automobiles, and metal fabrication. Metric drill sizes offer more precision and are easier to understand for beginners.

3. Number Gauge Drill Sizes (#1 to #80)

These run in reverse order—#1 is large and #80 is extremely tiny.

They are used where precision is required, such as electronics, engineering tools, and aircraft components.

4. Letter Gauge Drill Sizes (A to Z)

These sizes fill the gaps between number drills and fractional drills.

Letter drills are popular in industrial settings, manufacturing, and precision machining.

When you look at a drill bit, the size stamped on it tells you exactly how wide the hole will be. Matching that size with your screw or fastener is the key to a strong connection.

Choosing the correct drill size means your screw threads engage perfectly, preventing cracks, avoiding loose fittings, and ensuring your work looks professional.

Read This Latest Guide: Stud Bolt, Sizes, Threads, Lengths & Industrial Uses

Why Drill Size Matters

Most people underestimate how important drill size is—until something goes wrong. Using the wrong size can damage your project, weaken a structure, or make the screw completely useless. Understanding drill sizes is important because it affects the strength, safety, and overall quality of whatever you are building.

1. Prevent Loose or Oversized Holes

Using a drill bit even slightly larger than the screw’s core diameter can cause serious problems. The screw may spin freely, wobble, or fail to hold the material properly, resulting in weak joints and reduced durability over time.

2. Avoid Material Cracking

A drill bit that is too small forces screws to push the material apart as they enter. This pressure can split wood, deform metal, or crack plastic, compromising the strength and appearance of your project and making assembly difficult.

3. Increase Joint Strength

Selecting the correct drill size allows screw threads to bite securely into the material. This ensures maximum holding power, long-lasting stability, and prevents loosening over time, making your assembled furniture, cabinetry, or fixtures far more durable.

4. Improve Accuracy and Professional Finish

Proper drill sizing reduces rough edges, tear-outs, and uneven holes. By using the right bit, your project maintains clean lines, a polished appearance, and professional-quality results, making it safer, visually appealing, and easier to complete.

5. Work Faster and More Safely

Drilling with the correct bit size requires less effort, reduces friction, and prevents binding or slipping. This speeds up the work process, lowers the risk of accidents, and ensures a smoother, safer experience, especially with hardwoods or metals.

6. Match Screws and Fasteners Correctly

Different screws and fasteners have specific diameter and thread requirements. Wood screws, metal screws, and masonry anchors each need properly matched drill bits to perform effectively, ensuring secure attachment and preventing damage to the material or fastener.

From building shelves and assembling furniture to working on automotive engines or machinery, the correct drill size ensures everything fits securely and functions as it should.

Using the wrong drill size doesn’t just cause frustration—it can ruin the entire project.

Drill Size Conversion Chart (Metric to Inch)

Different projects use different measurement systems. Sometimes you may have screws in metric (like M6 or M8), but your drill set is in inches. Or you may be following a guide that uses fractional sizes while your toolbox has metric bits.

This is where a conversion chart becomes essential.

Below is a simple and practical conversion chart that helps you match metric drill sizes with their closest fractional and decimal inch equivalents.

Drill Size Conversion Chart (Metric ↔ Fractional Inches)

| Metric (mm) | Fractional Inch | Decimal Inch |

|---|---|---|

| 1.0 mm | 3/64″ | 0.039″ |

| 1.5 mm | 1/16″ | 0.059″ |

| 2.0 mm | 5/64″ | 0.078″ |

| 3.0 mm | 1/8″ | 0.125″ |

| 4.0 mm | 5/32″ | 0.156″ |

| 5.0 mm | 3/16″ | 0.187″ |

| 6.0 mm | 15/64″ | 0.234″ |

| 6.5 mm | 1/4″ | 0.250″ |

| 8.0 mm | 5/16″ | 0.312″ |

| 10 mm | 3/8″ | 0.375″ |

This chart is extremely useful when switching between measurement systems or working on engineering, construction, or fabrication tasks where accuracy is important. The ability to convert between metric and fractional sizes helps ensure you pick the right bit every time.

Whether you are installing hardware, drilling pilot holes, or working with machinery, this chart saves time and prevents errors.

Read This Latest Guide: Anchor Bolt Size: Types, Loads, Installation and Material

Types of Drill Sizes:

Understanding drill sizes begins with understanding the measurement systems used to define them. Although a drill bit is simply a small metal tool meant to create a hole, the system used to label its size can vary depending on the country, industry, and application. To avoid confusion and mistakes, you must know the four major drill size systems used worldwide: fractional, metric, number, and letter. Each system has its own purpose, advantages, and industries where it is commonly used.

1. Fractional Drill Sizes

Fractional drill sizes are measured in inches, and they are most commonly used in the United States, Canada, and some woodworking industries globally. These sizes appear as fractions such as 1/4”, 3/16”, 5/32”, and so on. Fractional bits usually increase in steps of 1/64” or 1/32”, giving users a wide range of hole diameters.

Fractional sizes are extremely popular because they are easy to recognize and widely used in DIY projects, home repairs, cabinetry, construction, and carpentry. If you work with screws, bolts, or anchors bought from U.S. hardware stores, you will often find that their recommended drill sizes are in fractional inches.

Many carpenters and home improvement workers prefer fractional bits because they are versatile, widely available, and easy to remember. In addition, fractional sizes blend well with common screw dimensions used in wood and metal projects.

2. Metric Drill Sizes

Metric drill sizes are measured in millimeters (mm), and they represent the worldwide standard used in most countries outside the United States. Metric sizes such as 4 mm, 6 mm, 8 mm, and 10 mm are especially popular in machinery, automotive engineering, construction, fabrication, electronics, and metalworking.

Metric drill bits are considered more precise because the metric system is based on powers of ten, which makes calculations and measurements simpler. That is why engineers, machinists, and industrial technicians prefer metric bits—everything is predictable, consistent, and easier to convert.

Metric drill bits are the backbone of mechanical industries. From automotive bolts to CNC machining to electrical panel wiring, almost everything in technical fields uses metric sizing. If you work with bolts labeled M4, M6, M8, or M10, you will need metric drill sizes.

3. Number Drill Sizes (#1 to #80)

Number drill sizes, also known as wire gauge drill bits, range from #1 (largest) to #80 (smallest). The sequence appears reversed, but there is a reason behind it: historically, these sizes were based on the wire thickness used in early manufacturing, where thicker wires had smaller gauge numbers.

Number drill bits are used in precision engineering, machine shops, electronics, instrument fabrication, and technical applications where extremely specific hole sizes are required. For example:

#1 drill size is around 5.8 mm

#80 drill size is around 0.343 mm (extremely tiny)

These bits are rarely used for regular home projects but are essential in industries where accuracy matters more than convenience.

4. Letter Drill Sizes (A to Z)

Letter drill bits are another measurement system mostly used in industrial and mechanical environments. Letters run from A (smallest) to Z (largest) and fill the sizing gaps between fractional and number bits.

For example:

A drill bit ≈ 0.234 inches

Z drill bit ≈ 0.413 inches

Letter bits are helpful in machining holes where standard sizes don’t give an exact fit. They are often used in metal fabrication, machinery repair, automotive workshops, and manufacturing plants, where engineers need precise intermediate hole sizes for bolts, bearings, bushings, and mechanical components.

Overall, understanding the four size systems helps you choose the correct drill bit every time. Fractional is ideal for woodworking and general tasks, metric for global and engineering projects, number gauge for precision work, and letter gauge for industrial applications that require intermediate sizing. When you know which system your project uses, drilling becomes faster, safer, and more accurate.

Read This Latest Guide: Master Sheet Metal Screws: Sizes, Types & DIY Tips

Drill Size Table for Common Screw Sizes

Matching screws with the correct drill bit size is one of the most important steps in woodworking and metalworking. The table below shows recommended drill bit sizes for common screw diameters, and the explanation after the table helps beginners understand how to apply this information in real projects.

Recommended Drill Bit Size for Screw Diameters

| Screw Size | Pilot Hole (Soft Wood) | Pilot Hole (Hard Wood) | Clearance Hole |

|---|---|---|---|

| #4 | 3/32″ | 1/16″ | 1/8″ |

| #6 | 7/64″ | 3/32″ | 9/64″ |

| #8 | 1/8″ | 7/64″ | 11/64″ |

| #10 | 9/64″ | 1/8″ | 13/64″ |

| #12 | 5/32″ | 9/64″ | 7/32″ |

This chart is more important than most beginners realize. When you insert a screw into wood, three things matter:

1. Pilot Hole Size

A pilot hole is drilled before driving the screw.

It helps:

Guide the screw straight

Prevent wood from splitting

Reduce friction

Make the screw sit tightly

If you don’t drill a pilot hole, especially in hardwood, the screw will act like a wedge and crack the wood.

Softwood vs Hardwood

Softwoods (like pine) compress easily, so they need a slightly bigger pilot hole. Hardwoods (like oak) are dense, so they need a smaller pilot hole to grip properly.

2. Clearance Hole

A clearance hole allows the screw’s shank (the smooth part under the head) to pass through the top board freely. This ensures that the screw pulls two boards together tightly.

For example: If you are joining two wooden planks, drilling a clearance hole in the top plank makes the screw pull both pieces together with maximum strength.

3. Why Matching Screw Sizes Matters

Using the wrong pilot hole size can lead to:

Stripped screw heads

Cracked wood

Loose joints

Weak structural strength

Misaligned holes

Using a drill size table eliminates guesswork and ensures professional results every time. Whether you’re installing cabinets, building furniture, assembling decks, or doing crafts, matching screws and drill bits is the key to success.

Types of Drill Bits and Their Uses

Choosing the correct drill size is only half the job—using the right type of drill bit is equally important. Each drill bit is designed for a specific material and purpose. Using the wrong bit can lead to slow drilling, poor results, overheating, or even tool damage.

Below are the most common drill bit types and their uses, explained in detail.

1. Twist Drill Bits

Twist drill bits are the most common type found in every toolbox.

They are used for:

Wood

Metal

Plastic

PVC

General-purpose drilling

They come in all sizing systems, including metric, fractional, number, and letter types. If you have only one set of bits, twist bits are the most versatile.

2. Brad-Point Drill Bits

These bits are specially designed for woodworking. The pointed tip at the center prevents the bit from wandering and helps you drill precise holes exactly where you marked. They make cleaner, sharper holes compared to twist bits.

Perfect for:

Cabinetry

Furniture making

Carpentry

Wooden crafts

3. Masonry Drill Bits

Masonry bits are made with carbide tips, allowing them to cut through tough materials like:

Concrete

Brick

Tiles

Stone

They are used with hammer drills for maximum impact. Without the right masonry bit, drilling into concrete becomes almost impossible.

4. Forstner Bits

Forstner bits are premium woodworking bits used to create flat-bottom holes, commonly needed in:

Cabinet hinges

Furniture joints

Decorative woodworking

Drilling large, clean holes

These bits make extremely smooth cuts and are preferred by professional woodworkers.

5. Step Drill Bits

These bits look like a stepped cone and are mainly used for sheet metal. One bit can drill multiple hole sizes because each step increases the diameter.

Used in:

Electrical panels

Car bodywork

Thin metal sheets

DIY metal fabrication

6. Spade Bits

Spade bits are perfect for drilling large holes in wood quickly. They remove material at high speed but often leave rough edges.

Ideal for:

Running pipes

Creating wiring holes

Rough carpentry

7. Countersink Bits

Countersink bits create a cone-shaped hole so the screw head sits flush with the surface. They are used in:

Furniture

Door frames

Cabinetry

Any project requiring clean finish

Countersinking prevents wood from bulging around the screw.

Read This Latest Guide: Wood Screw Size Basics: Lengths, Gauges & Best Uses

How to Choose the Right Drill Size

Choosing the right drill bit size can make the difference between a clean, professional-looking project and one filled with cracks, loose screws, or damaged material. Luckily, the process becomes simple once you understand what to look for. Follow the steps below to confidently pick the correct drill size every time.

1. Identify the Screw or Fastener Size

Begin by checking the size printed on the screw or bolt package. You might see something like #8 × 1”, M6 × 20, or 1/4” × 2” bolt. In these examples, the first number indicates the diameter of the screw or bolt. This diameter is the main detail used to select the matching drill bit size. Without knowing the exact diameter, choosing a drill bit becomes guesswork.

2. Match the Pilot Hole Size

A pilot hole is essential because it guides the screw into the material and prevents splitting or unnecessary resistance. The rule of thumb is simple: choose a drill bit that is slightly smaller than the screw’s diameter. This ensures the threads bite into the material while still allowing the screw to slide in smoothly. If the pilot hole is too big, the screw will not hold properly; if it’s too small, the material may crack.

3. Consider the Material Type

Different materials react differently when drilled, so adjust your drill size based on what you are working with:

Hardwood: Use a smaller bit to create a tighter pilot hole.

Softwood: A slightly larger bit works well because softwood compresses easily.

Metal: Always use the exact recommended bit size for clean, precise holes and proper thread engagement.

4. Use Conversion Charts

If your screws are metric and your drill bits are in inches, or vice versa, rely on a conversion chart. These charts match each screw size to the nearest drill bit, helping you avoid mistakes.

5. Test on Scrap Material

Before committing to the final hole, test the drill size on a scrap piece of the same material. A quick test hole allows you to check the fit, make adjustments, and avoid damaging your main project.

Common Mistakes to Avoid When Choosing Drill Sizes

Even with the right tools, small mistakes in drill size selection can cause major problems in your project. Understanding these common errors will help you drill cleaner, safer, and more accurate holes every time.

1. Eyeballing the Size

One of the most frequent mistakes is simply guessing the drill bit size by eye. Although it may seem quick, eyeballing usually leads to choosing a bit that is either too large or too small. As a result, screws may become loose, holes can widen, or the material may crack under pressure. Always compare sizes properly or consult a drill chart instead of relying on visual guesses.

2. Ignoring Material Properties

Every material reacts differently to drilling. A bit perfect for soft pine might cause hardwood to split instantly or struggle to cut through metal. If you don’t consider whether the material is soft, hard, dense, or brittle, the hole size can become inaccurate, and damage becomes more likely. Adjust your bit size and drilling approach based on the specific material.

3. Using Worn-Out Drill Bits

Dull or damaged bits affect precision. They require more force, heat up quickly, and often create oversized or rough holes. This not only compromises the fitting of screws but also increases the chance of burning or chipping the work surface. Replacing worn bits keeps your drilling accurate and clean.

4. Drilling Too Fast

High speed creates friction and heat, especially in metal. Excess heat can dull the bit faster and distort the hole. Using a slower RPM helps maintain control and prevents overheating.

5. Not Using a Pilot Hole

Skipping a pilot hole, especially in hardwood or metal—leads to wandering bits, cracked surfaces, and inaccurately sized holes. A pilot hole guides the screw properly and ensures a clean, secure fit.

When to Use Metric vs Inch Drill Sizes

Choosing between metric and inch drill sizes depends on the type of project, materials, and fasteners you are working with. Using the wrong system can lead to poorly fitting screws, loose connections, or even damaged materials. Understanding when to use each system ensures precision and professional results.

Choose Metric Drill Sizes When:

✔ You are working with machinery, engines, or automotive projects.

✔ Bolts and screws are labeled with the “M” system, such as M4, M6, or M10.

✔ You are involved in engineering, industrial fabrication, or technical assembly.

Metric drill bits are precise and match the standardized dimensions used in industrial and mechanical applications.

Choose Fractional (Inch) Sizes When:

✔ You are doing woodworking or furniture assembly.

✔ You work on general DIY projects around the home.

✔ Screws are labeled in inches, such as 1/4”, 3/8”, or 1/2”.

Fractional sizes are common in construction and woodworking, providing ease of use with materials and fasteners widely available in inch measurements.

Choose Number/Letter Sizes When:

✔ You need precision drilling for small, detailed work.

✔ Working in electronics, aviation, or high-precision industrial fabrication.

✔ Projects require tiny, exact holes where fractional or metric sizes may not offer the accuracy needed.

Number and letter sizes allow fine adjustments in diameter for specialized applications.

Read This Latest Guide: Pipe Thread Size Chart: Simple Guide + PDF

Examples of Drill Size Applications

Understanding which drill size to use in different situations helps ensure precision, safety, and strong fittings. From home projects to industrial work, applying the right drill bit makes your tasks easier and prevents costly mistakes.

1. Installing Home Shelves

When mounting shelves, the right drill bit ensures wall anchors fit snugly and support the weight. Choosing a bit that is too small or large can damage the wall or cause shelves to become unstable.

Use: 6 mm masonry bit for wall plugs

Use: 8 mm for heavy-duty anchors

2. Automotive Work

Cars, motorcycles, and other machinery often use metric bolts. Using the correct drill size for these bolts ensures fasteners fit perfectly, maintaining structural integrity and preventing damage to threads or surrounding components.

Use: M6 and M8 bolts require matching metric drill sizes

3. Wood Furniture Assembly

Wood screws need properly sized pilot holes to prevent splitting and ensure a tight grip. Selecting the right bit size based on the screw diameter improves assembly quality and increases the furniture’s durability.

Use: Pilot hole sizes based on screw diameter (as shown in table)

4. CNC and Fabrication

Precision work like CNC machining or metal fabrication demands exact drill sizes. Using number or letter drill bits guarantees accurate holes for assembly, alignment, and component fit, which is critical in industrial and manufacturing applications.

Use: Number or letter drill sizes for precision

5. Electrical Work

Small-scale electrical projects require careful drilling for wires, conduits, and mounting hardware. Using appropriately sized gauge bits prevents damage to delicate components and ensures neat, professional installations.

Use: Small number gauge bits for wire routing

Drill Size Tips for Perfect Results

- Always start with a smaller pilot hole

- Use sharp, high-quality bits

- Mark hole points clearly

- Use correct RPM for the material

- Keep bits cool when drilling metal

- Practice on scrap material

Conclusion

Choosing the correct drill size is essential for any project, yet often overlooked. Whether working with wood, metal, plastic, or concrete, the right drill bit ensures precision, strong joints, and professional-quality results. This guide provides conversion charts, tables, and clear explanations to help you drill perfect holes every time. For added convenience, you can request an alternate version, more detailed tables, or a ready-to-use PDF format, all generated instantly for easy reference.

FAQs:

What do drill sizes mean?

Drill sizes refer to the diameter of a drill bit, determining how wide a hole it will create. Correct drill size ensures screws, bolts, or fasteners fit properly. Using the right size prevents loose fittings, material cracking, and ensures a secure, professional-quality result in woodworking, metal, or other materials.

What are the four systems of drill sizes?

Drill sizes are measured using four main systems: Fractional (inches), Metric (millimeters), Number Gauge (#1–#80), and Letter Gauge (A–Z). Fractional is common in woodworking, metric in engineering, number and letter sizes for precision work. Knowing the system ensures correct hole sizes and secure fastener installation.

What is a #7 drill bit in inches?

A #7 drill bit has a diameter of approximately 0.201 inches (around 5.1 mm). Numbered drill bits range from #1 (largest) to #80 (smallest), primarily used in precision work, electronics, and machinery. The #7 size is ideal for creating pilot holes for screws that require a snug, secure fit.

What does 10mm drill mean?

A 10mm drill bit has a diameter of 10 millimeters. It is used to create holes that match the size of bolts, screws, or dowels in metric measurement systems. Proper selection ensures the fastener fits snugly, prevents material damage, and guarantees strong, durable joints in wood, metal, or machinery projects.