Choose the right jigsaw blade size can feel confusing, especially if you are new to woodworking or DIY projects. Walk into any hardware store, and you will see dozens of blades that look almost identical but promise very different results. Many people assume that all jigsaw blades work the same way, but that assumption often leads to rough cuts, broken blades, and frustration.

The truth is, jigsaw blade size plays a major role in how clean, accurate, and safe your cut will be. The length, width, and tooth structure of a blade decide whether your cut glides smoothly or fights you the entire way. In this complete guide, we will go deep into how jigsaw blade sizes work, how to choose the right one for your project, and how small size differences can completely change your cutting experience.

This guide is written for beginners, DIYers, and even experienced users who want a clearer understanding—without unnecessary jargon.

Understand What “Jigsaw Blade Size” Actually Means

When people hear “blade size,” they often think it refers only to length. In reality, jigsaw blade size is a combination of three key dimensions:

Blade length – how deep the blade can cut

Blade width – how straight or curved the cut can be

Tooth density (TPI) – how smooth or aggressive the cut is

All three work together. A long blade with the wrong tooth pattern can still give poor results, while a short blade with the correct size and teeth can outperform it on thinner material.

Blade Length: The Foundation of a Successful Cut

Blade length is the most basic and most important size factor. It determines how thick a material you can cut through safely.

A jigsaw blade must always be longer than the material thickness. If it’s not, the blade will struggle, overheat, or snap. Many beginners unknowingly use short blades on thick wood, wondering why the saw vibrates or burns the surface.

Standard Jigsaw Blade Lengths and Uses

| Blade Length | Material Thickness Range | Typical Use |

|---|---|---|

| 1.5″ – 2″ | Up to 1″ | Thin plywood, laminates, plastics |

| 2″ – 2.5″ | 1″ – 2″ | General woodworking |

| 2.5″ – 3″ | 2″ – 3″ | Thick boards, hardwood |

| 3″+ | 3″ and above | Construction lumber, beams |

A good rule is to choose a blade that is at least ¼ inch longer than the material thickness. This extra length allows the blade to move freely without bottoming out during the cut.

Standard_Jigsaw_Blade_Lengths PDF

The Standard_Jigsaw_Blade_Lengths PDF provides a clear and concise reference for selecting the right jigsaw blade. It lists standard blade lengths, corresponding material thickness ranges, and typical uses, helping DIYers and professionals choose blades for wood, laminates, plastics, and construction materials, ensuring accurate and efficient cutting every time.

🛠️ Understanding wood screw sizes is crucial for any DIY or woodworking project. This post explains the right lengths, gauges, and uses of wood screws, helping you avoid mistakes and achieve stronger, cleaner joins. Read the full guide to master wood screw size basics and work like a pro!

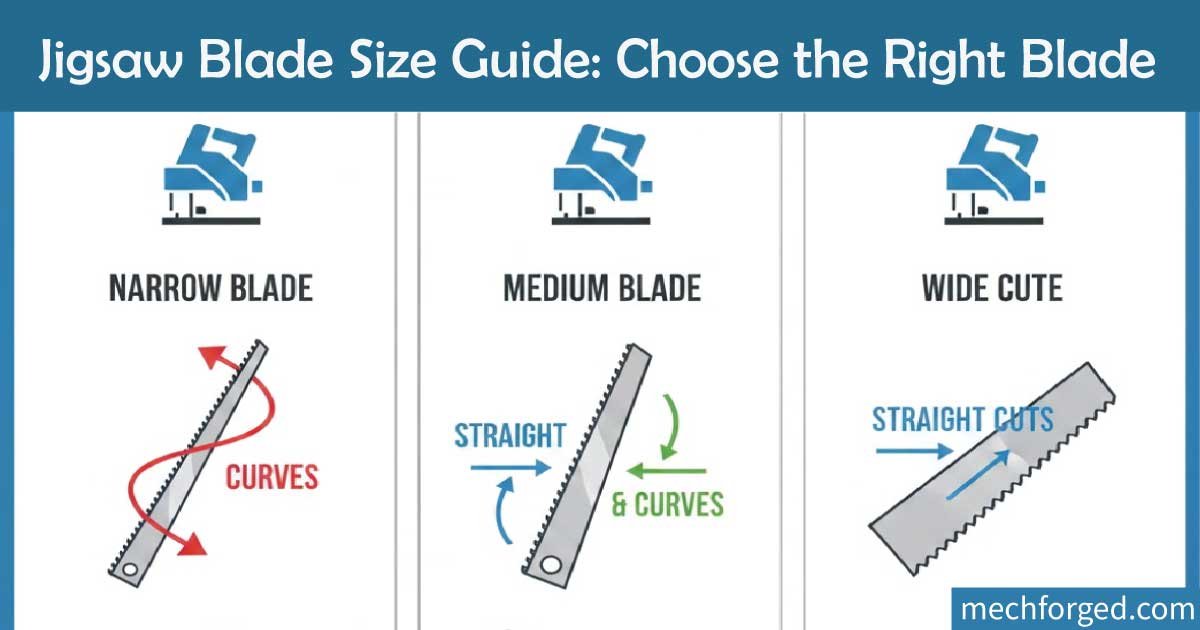

Blade Width: Straight Cuts vs Curves

Blade width determines how flexible the blade is during cutting. This directly affects whether you can cut tight curves or long straight lines.

Narrow blades bend easily, making them perfect for curves and detailed shapes. Wide blades resist bending, which helps them stay straight and stable during long cuts.

Blade Width and Cutting Behavior

| Blade Width | Cutting Style | Best Applications |

|---|---|---|

| Narrow | Tight curves | Patterns, circles, artistic cuts |

| Medium | Balanced | Everyday woodworking |

| Wide | Straight cuts | Long, straight edges |

If you’re cutting shapes or circles, a narrow blade gives you control. If you’re cutting cabinet panels or shelves, a wider blade keeps the cut straight and clean.

Tooth Density (TPI): Speed vs Smoothness

TPI stands for Teeth Per Inch, and it controls how aggressive or smooth your cut will be.

Low TPI blades have larger teeth that remove material quickly, but they leave rough edges. High TPI blades cut more slowly but leave smooth, polished edges.

TPI Guide by Cutting Result

| TPI Range | Cutting Speed | Finish Quality | Best For |

|---|---|---|---|

| 3–6 | Very fast | Rough | Softwood, demolition |

| 7–10 | Medium | Clean | Hardwood, general use |

| 10–14+ | Slow | Very smooth | Metal, plywood, laminates |

If you want speed, go low TPI. If appearance matters, go higher TPI. For thin materials, high TPI also prevents the blade from grabbing and tearing the surface.

🔧 Learn how to choose the right pipe thread size for any plumbing or DIY project. This guide includes a clear chart and PDF for quick reference. Read the full post to understand pipe thread size standards, avoid leaks, and ensure accurate, hassle-free connections every time!

Choose the Right Blade Size for Wood

Wood is the most common material used with jigsaws, but not all wood behaves the same way. Softwood, hardwood, plywood, and MDF all require slightly different blade sizes.

For softwood, shorter blades with fewer teeth work well because the material cuts easily. For hardwood, you need a longer blade and more teeth to prevent burning and splintering. Plywood and MDF benefit from finer teeth to protect surface layers.

A mistake many people make is using a fast-cut blade on plywood. This almost always causes tear-out on the top layer. A finer blade takes longer but gives professional-looking results.

Choose Blade Size for Metal Cutting

Cutting metal with a jigsaw is completely different from cutting wood. Metal is harder, thinner, and more sensitive to heat.

Metal blades are usually shorter and have very high TPI. This prevents snagging and reduces vibration. Longer blades are helpful when cutting thicker metal sections, but speed must always be kept slow.

When cutting metal, blade size works together with technique. Using the correct size but forcing the cut can still destroy the blade. Slow, steady pressure is key.

Blade Size for Plastic, Laminate, and Specialty Materials

Plastics and laminates can melt or chip if the blade size is wrong. High-speed cutting creates heat, which causes plastic edges to fuse back together.

For these materials, a medium-length blade with fine teeth works best. The goal is control, not speed. Specialty blades with reverse teeth are excellent for laminates because they reduce surface chipping.

Tile and ceramic materials require a completely different approach. These do not use traditional teeth at all, but abrasive grit edges. Blade “size” here refers mainly to length and rigidity rather than teeth.

How Blade Size Affects Accuracy and Control

Blade size has a direct influence on how accurately and smoothly your jigsaw performs. Length and width determine how stable the blade feels during cutting, how easily it follows your line, and how much vibration you experience. Even a powerful jigsaw cannot compensate for an incorrectly sized blade.

1. Short Blades

Short jigsaw blades are ideal for thin materials such as plywood, laminates, and plastic sheets. Because less blade extends below the material, there is reduced flex during cutting. This gives you better control, especially for detailed work or precise straight cuts. Short blades also reduce vibration, making it easier to guide the saw steadily without the blade drifting off course.

2. Long Blades

Long blades are designed for cutting thick wood, dense boards, and stacked materials. The extra length allows the blade to move freely through the entire thickness without bottoming out. This added reach improves stability during deep cuts and prevents overheating. However, on thin material, long blades can flex excessively, reducing accuracy and making control more difficult.

3. Wide Blades

Wide jigsaw blades are stiffer by design, which helps them resist twisting during cutting. This rigidity is especially useful for long, straight cuts where accuracy matters most, such as cutting shelves or panels. Because wide blades are less likely to bend sideways, they maintain a straight cutting path and reduce the chance of angled or uneven edges.

4. Narrow Blades

Narrow blades are excellent for curved cuts, tight turns, and intricate shapes. Their slim profile allows them to pivot easily inside the cut. However, this flexibility also makes them more prone to wandering during straight cuts. Without careful guidance, narrow blades may drift off the line, especially in thicker or harder materials.

If you have ever noticed your jigsaw drifting away from the cut line, the issue is usually not your technique. In most cases, it’s the blade length or width that isn’t suited to the material or type of cut you’re making. Choosing the correct blade size restores control instantly.

Project Examples (Practical Guidance)

Imagine you are building a wooden shelf using ¾-inch plywood. In this case, a short to medium-length jigsaw blade with fine teeth is the best choice. It cuts smoothly through the layered wood without tearing the surface veneer, leaving clean edges that require very little sanding. This not only saves time but also improves the final appearance of the shelf.

Now imagine cutting a curved opening in a countertop for a sink or fixture. A narrow blade becomes essential here. Its slim profile allows it to follow tight curves easily without binding inside the cut. Wider blades would resist turning and could cause rough edges or force you to stop and restart the cut.

For cutting metal brackets, blade size becomes even more critical. A short blade with very fine teeth reduces vibration, prevents chatter, and delivers controlled, accurate cuts. These examples clearly show that blade size is not about personal preference, it is about choosing the right blade for the specific task at hand.

Blade Material and Size: How They Work Together

Blade size alone does not guarantee good cutting performance. The material of the blade plays an equally important role in flexibility, strength, and heat resistance. When blade size and material work together correctly, cuts become smoother, safer, and more reliable across different materials.

1. High-Carbon Steel Blades for Wood Cutting

High-carbon steel blades are flexible and forgiving, making them ideal for cutting wood and soft materials. When paired with the correct blade length and width, they handle curves and straight cuts smoothly. Their flexibility helps prevent snapping, especially in narrow or medium-length blades used for general woodworking tasks.

2. High-Speed Steel Blades for Metal Cutting

High-speed steel blades are designed to handle heat and friction, which makes them suitable for cutting metal. When combined with shorter blade lengths and fine teeth, they provide clean cuts without overheating. Using the correct blade size ensures stability and prevents premature dulling during metal cutting projects.

3. Bi-Metal Blades for Versatile Projects

Bi-metal blades combine a flexible steel body with hardened teeth, offering both strength and durability. When matched with the proper blade size, they perform well across wood, metal, and plastic. This balance makes bi-metal blades an excellent choice for users who work with mixed materials.

Why the Wrong Material Fails Faster

Using the wrong blade material, even in the correct size, leads to quick wear and failure. A long blade made from an unsuitable material may bend, overheat, or break. A properly chosen blade material, even in a shorter size, always delivers better performance and longer blade life.

🔩 Find the perfect J-bolt size for your construction or DIY projects with this guide. Includes a detailed chart, measurements, and free PDF for quick reference. Read the full post to understand J-bolt sizes, ensure accurate installation, and secure strong, reliable connections every time!

Common Blade Size Mistakes (and How to Avoid Them)

Even experienced users sometimes make simple mistakes when selecting jigsaw blades. These errors can cause rough cuts, broken blades, or wasted material. Understanding the most common pitfalls and learning how to avoid them ensures cleaner cuts, better control, and longer blade life, no matter the project.

Choosing the longest blade by default: Long blades on thin materials can flex and vibrate, reducing accuracy and control.

Using wide blades for curves: Wide blades resist turning, making detailed cuts difficult and causing rough edges.

Ignoring TPI: Selecting the wrong tooth density can result in rough or slow cuts, even if the blade length is correct.

Using the wrong blade material: A blade not suited to the material can wear quickly or break.

Forcing the saw: Pushing too hard stresses the blade, regardless of size.

Neglecting material thickness: A blade shorter than the material can’t complete the cut cleanly.

Overlooking blade flexibility: Using a rigid blade for intricate or thin material can cause binding or wandering cuts.

Tips to Get the Best Results from Any Blade Size

Even with the correct blade size, technique and preparation play a crucial role in achieving smooth, accurate cuts. Following simple best practices improves control, prevents mistakes, and extends blade life. These tips ensure your jigsaw performs consistently, whether you’re cutting wood, metal, or plastic.

Let the blade do the work: Forcing the saw bends the blade and reduces precision.

Clamp your material securely: Movement during cutting can ruin even the best blade’s performance.

Replace dull blades promptly: Worn blades behave like the wrong size and create rough cuts.

Use test cuts on scrap: This helps confirm the blade size and tooth pattern for the material.

Maintain steady feed pressure: Pushing too fast can cause burning, splintering, or bending.

Keep the blade perpendicular: Tilting the saw can affect cut accuracy and wear the blade unevenly.

Match blade material to the project: Wood, metal, and plastic require different blade compositions for optimal performance.

Final Thoughts

Choosing the right jigsaw blade size is not complicated once you understand what each dimension does. Blade length controls depth, blade width controls direction, and TPI controls finish quality. When all three are matched correctly to your material, cutting becomes smoother, safer, and far more enjoyable.

Instead of guessing, use blade size as a tool—just like the jigsaw itself. The right blade transforms your project from frustrating to satisfying.

With this knowledge, you’ll spend less time fixing mistakes and more time building with confidence.

FAQs:

What size blade do I need for my jigsaw?

The right jigsaw blade depends on material thickness, type, and cut style. Short blades work best for thin materials, while long blades handle thicker boards. Consider blade width and tooth count (TPI) as well. Matching all three ensures smooth, accurate cuts without blade bending or tearing the material.

What length are jigsaw blades?

Jigsaw blades come in various lengths, typically ranging from 1.5″ to over 3″. Short blades are ideal for thin materials, medium lengths suit general woodworking, and longer blades handle thick boards and construction lumber. Always choose a blade slightly longer than your material to prevent bottoming out and improve cutting control.

Are jigsaw blades standard?

Most modern jigsaw blades follow either T-shank or U-shank standards, ensuring compatibility with specific jigsaw models. However, blade length, width, and tooth pattern vary depending on material and cut type. While the mounting is standard, the actual blade size and teeth configuration must be chosen carefully for the project.

What size is a standard saw blade?

For circular saws, the “standard” blade is usually 7 ¼ inches with a 5/8-inch arbor, suitable for most woodworking tasks. For jigsaws, there isn’t one universal size, as length, width, and TPI vary by application. Always check the saw type and material requirements before selecting a blade.

How to identify the blade size?

Measure three key dimensions: blade length (tip to base), blade width (side-to-side), and tooth density (TPI). Check the manufacturer’s markings if present. Material compatibility is also important. Combining these factors ensures you select the correct blade for smooth, accurate, and safe cuts.

What are the three types of saw blades?

Saw blades are generally categorized as: (1) Crosscut blades for cutting across wood grain, (2) Rip blades for cutting along the grain, and (3) Combination or general-purpose blades for versatile use. Other specialized blades exist, but these three cover most woodworking and DIY projects effectively.