Rivets are small, yet incredibly powerful fasteners used in countless applications, from construction and manufacturing to aerospace and automotive industries. Choosing the right rivet size may seem like a minor detail, but it can make a significant difference in the strength, durability, and overall performance of a project. In this guide, we’ll explore everything you need to know about rivet sizes, types, and how to select the perfect rivet for your work.

A Story About Choosing the Wrong Rivet

Before diving into the technical details, let me share a story. A few years ago, my friend Ahmed was helping a small workshop assemble a custom metal structure for a garden gazebo. Excited to get started, he grabbed some rivets that “looked about right” without checking their exact size.

Halfway through the assembly, the structure started wobbling, and a few rivets sheared off under pressure. After hours of trial and error, he realized the rivets were too short and too thin for the metal’s thickness. The experience was frustrating but eye-opening. From that day forward, Ahmed always measures carefully, refers to rivet size charts, and ensures he selects the correct rivet for the job.

This story shows that even experienced DIYers can face serious problems if rivet sizes are ignored, highlighting the importance of choosing the right size for safety, strength, and durability in any metal project.

Understand Rivet Sizes

Rivet size is determined mainly by diameter and length. These two factors define how strong the rivet will hold materials together and how suitable it is for your specific application.

Diameter: Refers to the thickness of the rivet shaft. Larger diameters provide more strength but require bigger holes.

Length: Determines how much material the rivet can hold together. Too short and it won’t secure properly; too long and it may protrude unnecessarily.

Here’s a simple table for reference:

| Rivet Diameter | Typical Material Thickness | Use Case |

|---|---|---|

| 3/32 inch (2.4 mm) | Up to 1/8 inch | Light-duty metal, aluminum sheets |

| 1/8 inch (3.2 mm) | 1/8 to 1/4 inch | General-purpose light metal fastening |

| 5/32 inch (4 mm) | 1/4 to 3/8 inch | Medium-duty metal and thin steel |

| 3/16 inch (4.8 mm) | 3/8 to 1/2 inch | Structural steel, heavy-duty connections |

| 1/4 inch (6.4 mm) | 1/2 inch and above | Large industrial or aerospace applications |

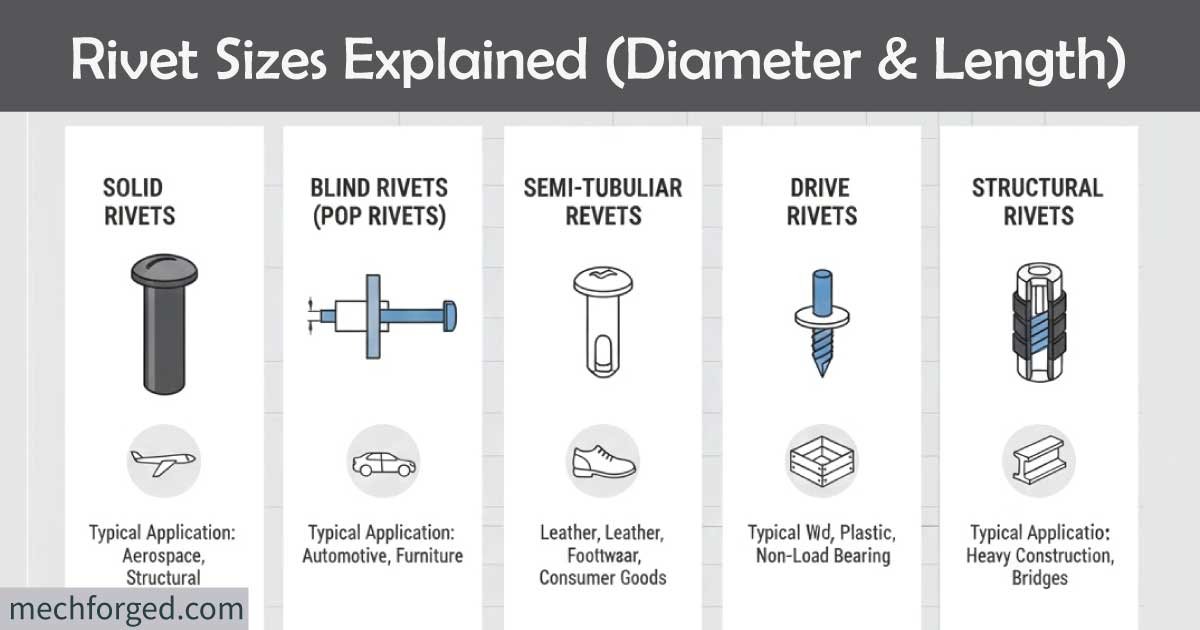

Types of Rivets

Rivets come in various types, each designed for specific applications and strength requirements. Choosing the right rivet type ensures a secure and durable connection. Whether you are working on metal structures, furniture, or DIY projects, understanding rivet types helps you select the correct size, material, and installation method for your task.

1. Solid Rivets

Solid rivets are the strongest type of rivets, commonly used in aircraft, heavy machinery, and structural steel work. They provide maximum holding strength and reliability. Solid rivets are installed using a hammer or rivet gun, and the tail end is deformed to create a permanent, tight joint suitable for heavy-duty applications.

2. Blind Rivets (Pop Rivets)

Blind rivets, also known as pop rivets, can be installed from one side, making them ideal for applications where access to the backside is limited. They are widely used in DIY projects, automotive repairs, and household fixtures. Blind rivets expand as the pin is pulled, securing materials quickly and efficiently.

3. Semi-Tubular Rivets

Semi-tubular rivets feature a partial hollow at the end, allowing easier deformation during installation. They are lightweight yet strong enough for applications like furniture assembly, small machinery, and metal brackets. Semi-tubular rivets save time and reduce installation effort while providing a reliable fastening solution for medium-strength projects.

4. Drive Rivets

Drive rivets are installed by driving a pin directly into the rivet body. This action expands the rivet, locking materials together. They are mostly used in sheet metal, plastic assemblies, and light-duty applications. Drive rivets offer a quick and simple fastening solution where vibration resistance is not the primary concern.

5. Structural Rivets

Structural rivets are designed for high-strength, load-bearing applications such as bridges, ships, and heavy construction projects. Made from durable materials like steel or alloy, these rivets provide maximum joint integrity. They are ideal for projects where safety and structural performance are critical, and selecting the correct rivet size is essential.

🔧 Confused about drill sizes? This complete Drill Size Guide explains conversion charts, drill types, and real-world uses in a simple, practical way. Whether you’re a DIYer or professional, this guide helps you choose the right drill every time. Read the full post to avoid costly mistakes.

Choose the Right Rivet for Your Project

Selecting the correct rivet ensures a strong, durable connection. Factors like material thickness, hole size, and rivet material type all affect performance. Paying attention to these details prevents weak joints, reduces failures, and ensures your project is secure and long-lasting.

1. Material Thickness

When choosing a rivet, the length should be at least 1.5 times the combined thickness of the materials being joined. This ensures the rivet fully passes through both layers, creating a tight, secure hold. Incorrect length can lead to weak connections or rivet failure under stress.

2. Hole Size

Always match the rivet diameter to the pre-drilled hole. A hole that’s too small prevents proper installation, while a hole that’s too large results in a loose fit. Correct hole sizing ensures maximum strength and stability for your assembled parts.

3. Material Type

Different materials require specific rivet types. Aluminum, steel, and copper each need compatible rivets for proper fastening and corrosion resistance. Choosing the wrong material can lead to rust, reduced strength, and premature failure, especially in outdoor or high-stress applications.

Here’s a quick chart to match rivet size with material type:

| Rivet Material | Compatible Base Material | Ideal Diameter |

|---|---|---|

| Aluminum | Aluminum, light steel | 1/8 to 3/16 inch |

| Steel | Steel, stainless steel | 5/32 to 1/4 inch |

| Copper | Copper, soft metals | 3/32 to 1/8 inch |

| Stainless Steel | Corrosion-prone areas | 5/32 to 1/4 inch |

Step-by-Step Guide to Measuring for Rivets

Accurate measurement is absolutely crucial when selecting the right rivet for any project. Following these steps carefully ensures a secure, durable connection, minimizes installation errors, and guarantees that your rivet provides maximum strength, longevity, and reliable performance during use.

1. Measure Material Thickness

Use a caliper, ruler, or thickness gauge to measure the combined thickness of all materials you plan to join. Accurate measurement ensures you select a rivet long enough to pass through every layer, creating a secure fastening that won’t leave gaps or weak points in the joint.

2. Determine Rivet Diameter

Consult a rivet size chart to match the thickness of your materials to the correct rivet diameter. The diameter must fit snugly in the pre-drilled hole to prevent wobbling, maintain joint integrity, and allow the rivet to properly expand or deform during installation for a strong, lasting hold.

3. Check Rivet Length

Select a rivet with sufficient length to extend fully through all material layers, leaving enough tail for proper deformation. Choosing the correct length ensures a tight hold, prevents failure under stress, and guarantees that your joint remains strong and stable over time, even under heavy loads or vibrations.

4. Verify Hole Size

Drill holes slightly larger than the rivet diameter to allow smooth installation. Proper hole sizing ensures the rivet slides in easily while still holding materials firmly, avoiding loose or misaligned joints. Correct sizing also reduces installation difficulty, whether using a hand hammer, rivet gun, or pneumatic tool.

🔩 Stud bolts play a critical role in industrial fastening. This guide explains stud bolt sizes, thread types, lengths, and real-world industrial uses in a clear, practical way. If you want stronger, safer, and more reliable connections, read the full post for complete details and expert insights.

Common Mistakes When Choosing Rivets

Choosing the right rivet is more important than most people realize. A small misstep can compromise the strength and durability of your project. From selecting the wrong size to ignoring material compatibility, even experienced DIYers can make these errors. Understanding common mistakes helps ensure a secure, long-lasting connection for any application.

1. Too Short or Too Long

Rivets that are too short may not fully engage both materials, leading to weak joints that could fail under stress. On the other hand, excessively long rivets can protrude, causing safety hazards or interference with moving parts. Measuring material thickness carefully and selecting the right rivet length is crucial for reliable assembly.

2. Wrong Diameter

Using a rivet with the wrong diameter can have serious consequences. A rivet that is too thin may shear under pressure or fail in high-stress applications. Conversely, a rivet that is too thick can damage the materials you are joining, creating cracks or splitting softer metals. Accurate sizing ensures durability and stability.

3. Ignoring Material Compatibility

Not all rivets are compatible with all materials. For example, using steel rivets with aluminum components can result in galvanic corrosion over time, weakening the joint and potentially damaging both parts. Considering material types and their interactions is essential for long-lasting, corrosion-resistant assemblies, especially in outdoor or high-moisture environments.

4. Neglecting Load Requirements

Rivets are not one-size-fits-all when it comes to load-bearing applications. Ignoring the load requirements can lead to structural failures or unsafe assemblies. Some rivets are only suitable for light-duty tasks, while others are engineered for heavy-duty or structural applications. Always match the rivet type to the intended load and stress conditions.

Practical Tips for Rivet Installation

Always de-burr holes before installing rivets to avoid stress points.

Use proper rivet tools – hand rivets for light work, pneumatic rivet guns for heavy-duty jobs.

For outdoor applications, choose corrosion-resistant materials like stainless steel or aluminum.

Test a sample rivet before full installation to ensure it fits and holds correctly.

Rivet Size Conversion Table

For international users, rivet sizes often come in metric measurements. Here’s a simple conversion table:

| Imperial Size | Metric Equivalent |

|---|---|

| 3/32 inch | 2.4 mm |

| 1/8 inch | 3.2 mm |

| 5/32 inch | 4 mm |

| 3/16 inch | 4.8 mm |

| 1/4 inch | 6.4 mm |

⚓ Anchor bolts are the foundation of structural strength. This guide covers anchor bolt sizes, types, load capacities, installation methods, and materials used in construction. Learn how to choose the right anchor bolt for safety and durability—read the full post to get complete, practical guidance.

Rivet vs. Bolt: Understand the Difference

Rivets and bolts might appear similar at first glance, but they serve very different purposes in mechanical and structural applications. Understanding how each fastener works helps you choose the right option for durability, strength, and maintenance needs.

1. Rivets

Rivets are permanent fasteners designed to create a strong, long-lasting joint between thin sheets of metal or similar materials. Once installed, they cannot be removed without drilling them out. This makes rivets ideal for projects where vibration resistance, stability, and tamper-proof connections are required.

2. Bolts

Bolts are removable fasteners typically used for thicker materials or assemblies that may require future disassembly or maintenance. They offer flexible use because they can be tightened, removed, or replaced as needed. Bolts are perfect for structures, machinery, and components that demand adjustability and regular inspection.

Choose Between a Rivet and a Bolt

Deciding whether to use a rivet or a bolt depends on how permanent you need the joint to be and the type of materials you’re working with. Rivets offer lasting strength without maintenance, while bolts provide the convenience of removal and adjustment whenever required.

Specialized Rivets for Unique Applications

Different industries rely on specialized rivets because each environment demands specific strength, durability, and material compatibility. From lightweight aircraft panels to corrosion-resistant marine structures, choosing the right rivet type ensures long-term performance, safety, and efficiency in professional manufacturing, repair, and assembly work.

1. Aerospace

The aerospace industry commonly uses 1/8-inch aluminum rivets because they provide the perfect balance of strength and lightweight performance. These rivets securely fasten thin metal panels without adding unnecessary weight, helping improve fuel efficiency and maintain structural integrity in high-stress, high-altitude conditions.

2. Automotive

In automotive manufacturing, blind rivets are widely used for attaching interior panels, trims, and small assemblies where one-sided access is required. These rivets allow quick installation, reduce labor time, and deliver consistent strength, making them ideal for complex vehicle designs and tight assembly spaces.

3. Shipbuilding

Shipbuilding typically relies on stainless steel rivets because they resist corrosion, rust, and moisture damage in harsh marine environments. These rivets provide long-lasting durability for metal hulls, decks, and fittings, ensuring that vessels remain safe and structurally sound even after years of exposure to seawater.

4. Furniture

Furniture makers often choose semi-tubular rivets because they are easier to install and require less force, making them perfect for assembling decorative or lightweight metal components. They create neat, clean joints while maintaining good strength, supporting both functionality and aesthetic appeal in furniture design.

How to Inspect Rivet Quality

Inspecting rivets after installation is essential for ensuring long-term safety, durability, and structural integrity. A proper inspection helps identify installation errors early, prevents unexpected failures, and guarantees that each rivet is performing as intended, especially in load-bearing or high-vibration applications.

1. Visual Check

Start by examining the rivet head and tail to confirm proper deformation. The tail should be evenly expanded without cracks or bending, and the head must sit flush against the material. A clean, uniform appearance indicates a correctly installed and secure rivet connection.

2. Tug Test

A gentle pull on the joined materials helps verify that the rivet is firmly seated. If there is any movement, looseness, or unexpected flexing, the rivet may be improperly sized, incorrectly installed, or weakened. A secure rivet will hold tightly without shifting.

3. Alignment Check

Inspect the row of rivets to ensure they are straight, evenly spaced, and properly positioned. Poor alignment can weaken the joint, affect load distribution, or signal installation mistakes. Consistent spacing and correct placement help maintain the strength and appearance of the assembly.

4. Importance of Regular Inspection

Rivets used in structural or high-load applications must be inspected regularly to avoid potential failures. Over time, vibration, weather exposure, or material stress may affect rivet performance. Routine checks ensure continued safety and reliability, especially in aircraft, vehicles, machinery, and building structures.

DIY Rivet Projects for Beginners

Rivets are versatile and beginner-friendly. Some projects include:

Building metal shelves or storage racks.

Fixing broken garden tools.

Assembling lightweight metal frames for furniture or décor.

DIY car or bike panel repairs.

Tips for Long-Term Durability

Ensuring long-term durability of riveted joints requires choosing the right materials, installing rivets properly, and protecting them from environmental damage. Small preventive steps greatly increase the lifespan of your assemblies, especially in outdoor or heavy-duty applications where moisture, vibration, and temperature changes can weaken fasteners over time.

1. Use the Right Rivet Material

Selecting the correct rivet material is one of the simplest ways to improve durability. Aluminum rivets work well in lightweight applications, while stainless steel offers excellent corrosion resistance for outdoor or moisture-prone environments. Matching rivet material with the base material helps prevent galvanic reactions and long-term damage.

2. Avoid Over-Tightening

Over-tightening rivets can cause unnecessary deformation, weaken the joint, or damage the surrounding materials. A properly set rivet should expand just enough to create a secure hold without crushing the workpiece. Controlled installation ensures strength, reduces wear, and prevents early failure caused by stressed or distorted components.

3. Protect Rivet Joints

For outdoor structures, adding a protective layer such as anti-corrosion spray, sealant, or paint helps safeguard rivets from moisture, salt, or harsh weather. These protective coatings slow down rust formation and maintain the integrity of both the rivet and the material, extending the life of the entire assembly.

Conclusion

Choosing the right rivet size may seem like a small step, but it has a huge impact on the overall strength, durability, and safety of any assembly. When you fully understand rivet diameters, lengths, types, and material compatibility, you naturally avoid common issues—just like the mistakes highlighted in Ahmed’s story. The right sizing ensures the joint can handle load, vibration, and long-term wear without loosening or failing. Whether you’re working on a simple home repair or a demanding industrial project, always measure carefully, use reliable tools, and refer to accurate size guides. These small habits guarantee every rivet holds securely and performs as expected.

Choosing the right wood screw size makes all the difference. This guide explains screw lengths, gauges, and best uses for secure, long-lasting joints. Perfect for DIYers and professionals alike—read the full post to avoid common mistakes and build with confidence.

FAQs:

How do I know what size rivet to use?

Choosing the right rivet size depends on the combined thickness of the materials being joined and the type of load they will bear. Measure material thickness accurately, then select a rivet long enough to pass through all layers while allowing proper deformation for a secure hold

What size is a number 10 rivet?

A number 10 rivet typically has a diameter of 0.190 inches (approximately 4.8 mm). This standard size is commonly used for light to medium-duty applications, including sheet metal work and general assembly. Always verify compatibility with material thickness and hole size for a reliable, permanent connection.

What size hole for a 3.2 mm rivet?

For a 3.2 mm rivet, drill a hole slightly larger than the rivet diameter, usually around 3.3 mm. This ensures the rivet fits comfortably without excessive looseness, allowing proper deformation during installation while maintaining a strong, durable joint. Always measure carefully for precision and safety.

What are rivet sizes?

Rivet sizes are defined by diameter and length. Diameter determines the rivet’s thickness and shear strength, while length depends on the combined thickness of materials to be joined. Standard sizes range from tiny fractions of an inch to larger industrial sizes, each suited for specific load requirements and applications.

How to calculate rivet size?

To calculate rivet size, measure the total thickness of the materials being joined. Add approximately 1.5 times the rivet diameter to determine the proper rivet length. The diameter should match the load requirements. Correct sizing ensures secure fastening without damaging the materials or compromising joint strength.

How to get rivet diameter?

Rivet diameter can be measured using a caliper or by referencing standard size charts. Choose a diameter based on the material thickness and expected load. Using the correct diameter ensures that the rivet can handle shear and tensile forces effectively while providing a strong, long-lasting connection.