Concrete blocks are one of the most widely used construction materials in residential, commercial, and industrial building projects. Their strength, durability, cost-effectiveness, and versatility make them ideal for walls, foundations, partitions, and load-bearing structures. However, choosing the correct concrete block size is essential for structural integrity, cost control, and construction efficiency.

This Concrete Block Size Guide explains standard dimensions, types, applications, weight considerations, and international sizing standards to help you select the right block for your project.

What Is a Concrete Block?

Why Concrete Block Size Matters

Structural strength

Wall thickness and insulation

Material costs

Construction speed

Load-bearing capacity

Incorrect sizing can lead to material waste, weak structures, or code violations.

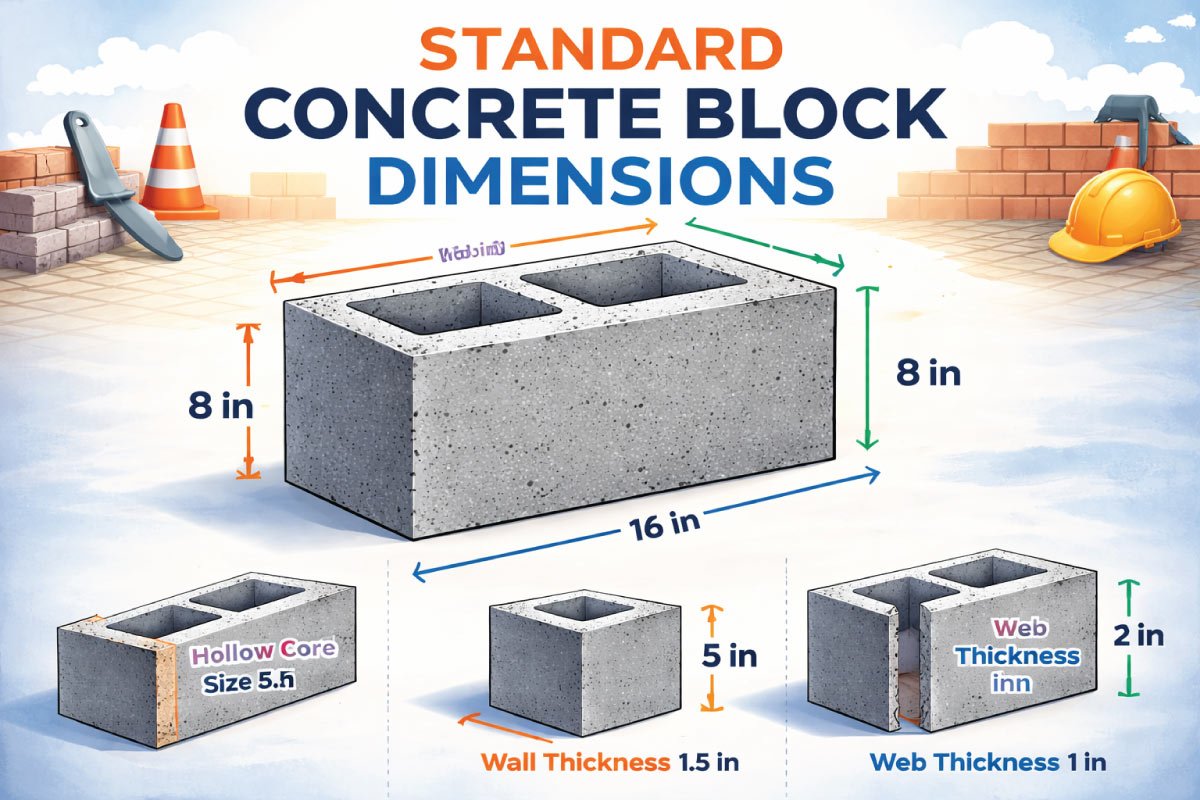

Standard Concrete Block Dimensions Explained

Length

Height

Width (thickness)

The most common nominal length is 16 inches (400 mm), which includes mortar joints.

Nominal Size vs Actual Size

Understanding the difference between nominal and actual concrete block sizes is essential for accurate planning and construction. Builders and designers rely on nominal dimensions for layout and estimating, while actual dimensions determine the true physical fit of blocks. Confusing the two can result in misalignment, uneven walls, or improper mortar joints during construction.

1-Nominal Size

The nominal size of a concrete block includes the block itself plus the standard mortar joint, usually 3/8 inch thick. This sizing convention simplifies wall layout, spacing, and material calculations. Nominal dimensions allow blocks to fit neatly into modular construction systems, making it easier to plan courses, openings, and overall wall dimensions accurately.

2-Actual Size

The actual size refers to the physical dimensions of the concrete block alone, excluding mortar. These dimensions are slightly smaller than the nominal size to allow space for mortar joints. For example, a nominal 16 × 8 × 8 inch block typically measures about 15⅝ × 7⅝ × 7⅝ inches, ensuring proper alignment and bonding when laid.

Standard Concrete Block Sizes (Imperial)

Standard Concrete Block Size Chart – Imperial

| Nominal Size (inches) | Actual Size (inches) | Common Use |

|---|---|---|

| 16 × 8 × 4 | 15⅝ × 7⅝ × 3⅝ | Partition walls |

| 16 × 8 × 6 | 15⅝ × 7⅝ × 5⅝ | Medium-load walls |

| 16 × 8 × 8 | 15⅝ × 7⅝ × 7⅝ | Load-bearing walls |

| 16 × 8 × 10 | 15⅝ × 7⅝ × 9⅝ | Foundation walls |

| 16 × 8 × 12 | 15⅝ × 7⅝ × 11⅝ | Structural walls |

Standard Concrete Block Sizes (Metric)

Metric-sized concrete blocks are widely used in Europe, Asia, and many international construction projects. They are manufactured to standardized dimensions that simplify modular design, improve construction accuracy, and ensure compatibility with metric-based building codes, mortar joint thicknesses, and structural design requirements across different regions.

Standard Concrete Block Size Chart – Metric

| Nominal Size (mm) | Actual Size (mm) | Typical Application |

|---|---|---|

| 400 × 200 × 100 | 390 × 190 × 90 | Partition walls |

| 400 × 200 × 150 | 390 × 190 × 140 | Residential walls |

| 400 × 200 × 200 | 390 × 190 × 190 | Load-bearing walls |

| 400 × 200 × 250 | 390 × 190 × 240 | Retaining walls |

| 400 × 200 × 300 | 390 × 190 × 290 | Heavy structural use |

Hollow vs Solid Concrete Blocks

Concrete blocks come in two main types—hollow and solid—each suited for specific construction needs. Hollow blocks feature cavities that reduce weight and improve insulation, making them ideal for walls and partition structures. Solid blocks provide higher compressive strength and are used in foundations or applications requiring maximum load-bearing capacity, offering stability and durability.

1-Hollow Concrete Blocks

Hollow concrete blocks have internal cavities that make them lighter and easier to handle. The cavities improve thermal and sound insulation, reduce material usage, and speed up construction. They are commonly used for walls, partitions, and non-load-bearing structures where moderate strength and energy efficiency are desired.

2-Solid Concrete Blocks

Solid concrete blocks are fully dense, offering maximum compressive strength and durability. They are ideal for foundations, load-bearing walls, and heavy structural applications where stability and strength are critical. While heavier and more labor-intensive to install, solid blocks provide long-lasting support and can withstand substantial structural loads.

Concrete Block Thickness and Structural Role

Load-bearing capability

Fire resistance

Sound insulation

Thin blocks (100 mm / 4″) are suitable for partitions, while thicker blocks (200 mm / 8″) are used for structural walls.

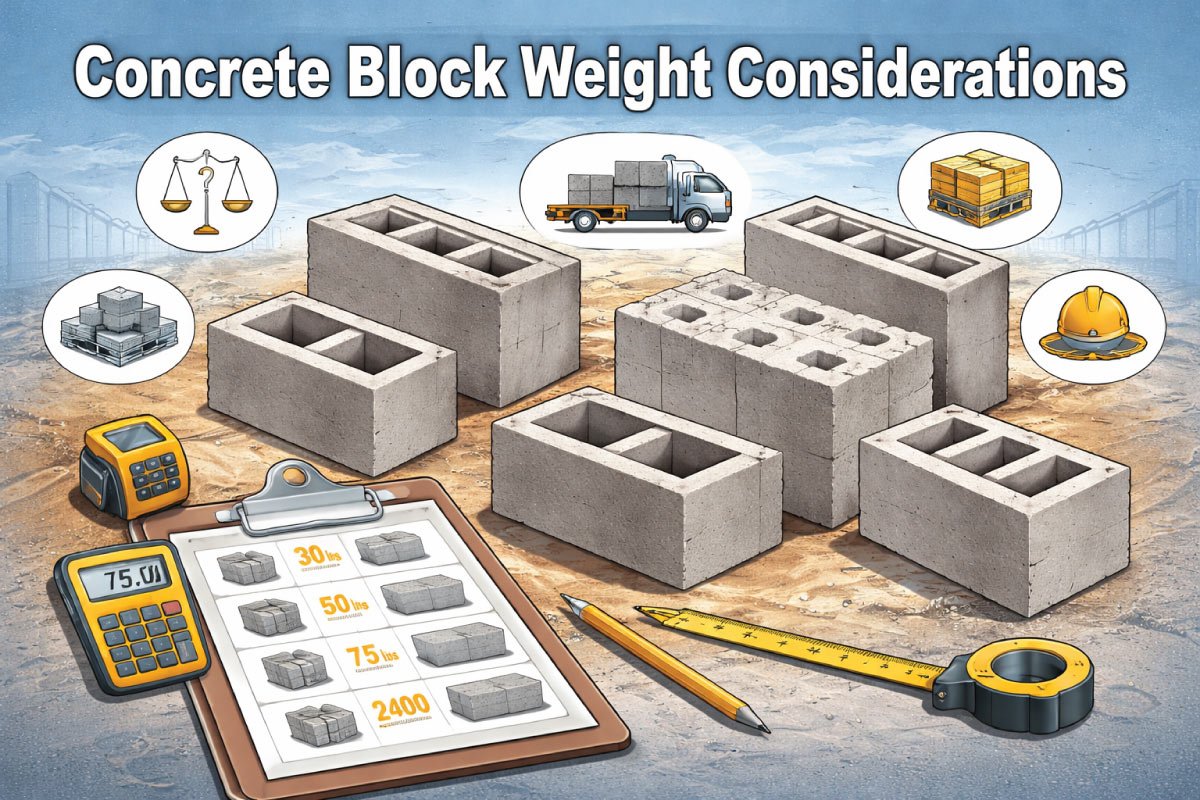

Concrete Block Weight Considerations

The weight of a concrete block depends on its size, whether it is solid or hollow, and the density of the aggregates used. Block weight influences handling, transportation, and labor requirements, as well as structural load calculations. Properly accounting for weight ensures safe construction practices, efficient workflow, and accurate design of supporting structures.:

Size

Solid or hollow design

Aggregate density

Weight affects handling, labor cost, and structural load calculations.

Concrete Block Weight Chart

This chart provides approximate weights for common concrete block sizes, helping builders and engineers plan for handling, transportation, and structural load considerations. Weight varies based on block dimensions and whether the block is hollow or solid, ensuring accurate calculations for labor requirements, equipment needs, and safe construction practices.

| Block Size | Type | Approximate Weight |

|---|---|---|

| 16 × 8 × 4 in | Hollow | 18–20 kg (40–44 lb) |

| 16 × 8 × 6 in | Hollow | 22–24 kg (48–53 lb) |

| 16 × 8 × 8 in | Hollow | 28–30 kg (62–66 lb) |

| 16 × 8 × 8 in | Solid | 35–38 kg (77–84 lb) |

| 400 × 200 × 200 mm | Hollow | 25–30 kg |

Load-Bearing vs Non-Load-Bearing Blocks

Understanding the distinction between load-bearing and non-load-bearing concrete blocks is essential for safe and efficient construction. Load-bearing blocks carry structural loads such as floors, roofs, or upper walls, while non-load-bearing blocks are primarily used for partitions or infill. Selecting the appropriate type ensures structural integrity, proper wall function, and compliance with building standards.

1-Load-Bearing Blocks

Load-bearing concrete blocks are designed to support structural loads from floors, roofs, and upper wall sections. They typically have greater thickness, higher compressive strength, and solid or reinforced construction. These blocks are used in foundations, structural walls, and other critical areas where strength and durability are essential for building stability and safety.

2-Non-Load-Bearing Blocks

Non-load-bearing blocks are used for partitions, infill walls, or decorative applications where structural support is not required. They are often thinner, lighter, and easier to handle than load-bearing blocks. While they provide separation, insulation, and aesthetic function, they do not contribute to the overall structural load capacity of the building.

Load-bearing blocks typically require greater thickness and higher compressive strength.

Concrete Block Sizes for Foundations

Foundation walls require concrete blocks that provide maximum strength and stability. Typically, blocks are 200–300 mm (8–12 inches) thick and may be solid or reinforced hollow units. Using blocks with high compressive strength and proper dimensions ensures the foundation can safely support structural loads and resist soil pressure, settling, and other ground forces over time.:

200–300 mm (8–12 inch) thick blocks

Solid or reinforced hollow blocks

High compressive strength

Proper sizing ensures stability and resistance to soil pressure.

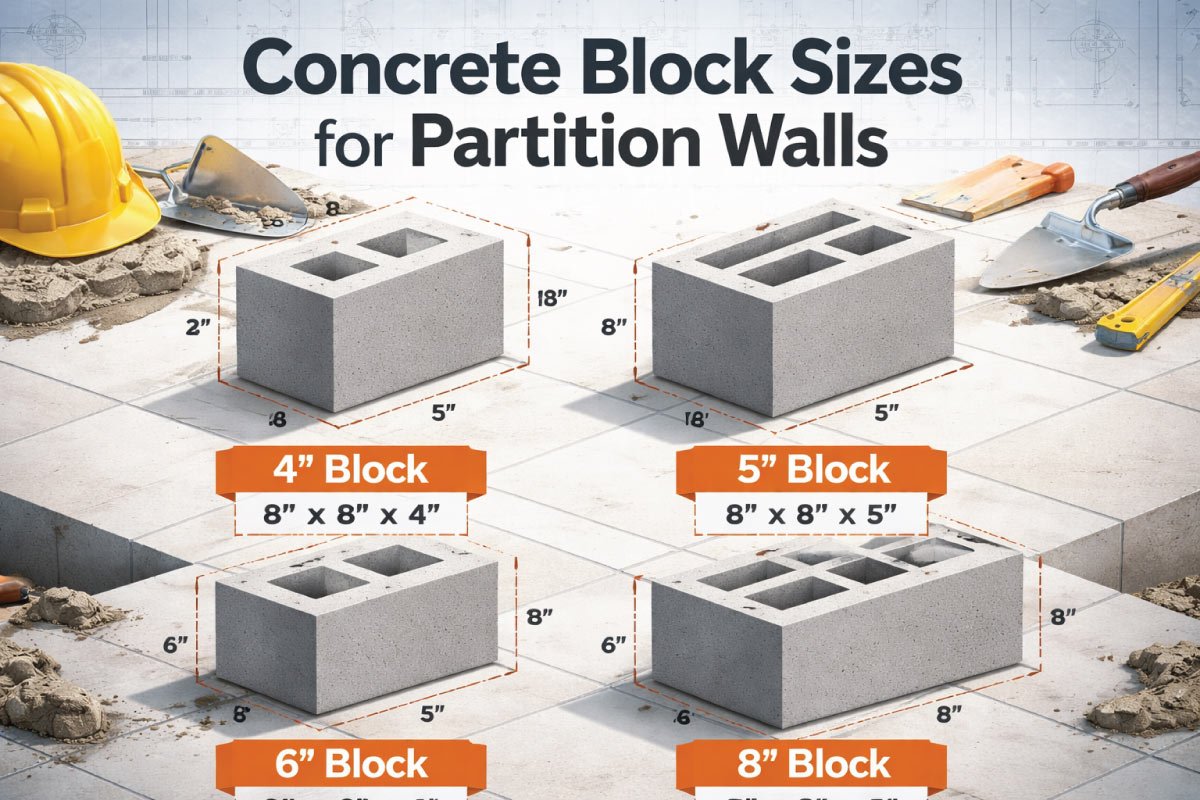

Concrete Block Sizes for Partition Walls

Partition walls commonly use 100–150 mm (4–6 inch) thick concrete blocks, often in a hollow design. These lightweight blocks are easier to handle and install, reducing labor effort, material costs, and construction time. While not intended for structural loads, they provide effective separation, insulation, and space division in residential, commercial, and industrial buildings.

100–150 mm (4–6 inch) blocks

Hollow design

Lightweight blocks for easier installation

These reduce material cost and construction time.

Special Concrete Block Sizes and Shapes

Special-purpose concrete blocks are designed to meet specific construction needs while maintaining modular compatibility with standard blocks. These include blocks for corners, openings, reinforced sections, and aesthetic finishes. Using these specialized blocks simplifies construction, ensures proper alignment, and allows for seamless integration into walls, lintels, and structural elements without compromising strength or design consistency.

1-Lintel Blocks

Lintel blocks are specially shaped to form horizontal support above openings such as doors and windows. They often feature a U-shaped groove to accommodate reinforcing steel and concrete infill, providing added strength. Lintel blocks maintain modular sizing for easy integration with standard blocks, ensuring proper load distribution and structural stability in walls.

2-Corner Blocks

Corner blocks are designed to create neat, strong corners in walls without cutting standard blocks. They have precise angles and dimensions that match modular systems, allowing seamless interlocking. Using corner blocks simplifies construction, maintains alignment, and ensures consistent wall thickness and strength at junctions.

3-Bullnose Blocks

Bullnose blocks feature rounded edges, often used for aesthetic purposes on exposed wall corners or edges. They provide a finished appearance while maintaining compatibility with standard block sizes. Bullnose blocks enhance safety by reducing sharp edges and improve the overall visual appeal of partition walls and facades.

4-U-Shaped Blocks for Reinforcement

U-shaped blocks, or channel blocks, are designed to accommodate steel reinforcement and concrete filling. They are commonly used in lintels, bond beams, and structural walls to increase strength and stability. These blocks maintain modular sizing, allowing seamless construction while providing enhanced load-bearing capacity and durability.

Discover More:

M Dowel Pin Size Chart: Complete 2026 Guide with PDF Reference

Concrete Block Sizes by Application

Different construction applications require specific concrete block sizes to ensure strength, stability, and efficiency. Interior partitions use thinner blocks, while residential walls, load-bearing walls, foundations, and retaining walls require progressively thicker units. Selecting the appropriate block size for each application ensures structural integrity, proper load distribution, and faster, more cost-effective construction.

| Application | Recommended Block Size |

|---|---|

| Interior partitions | 100 mm / 4″ |

| Residential walls | 150–200 mm / 6–8″ |

| Load-bearing walls | 200–250 mm / 8–10″ |

| Foundations | 250–300 mm / 10–12″ |

| Retaining walls | 200–300 mm / 8–12″ |

Discover More:

International Concrete Block Standards

Concrete blocks are manufactured and tested according to international standards to ensure consistent quality, strength, and durability. Common standards include ASTM C90 in the USA, BS EN 771-3 in the UK and Europe, IS 2185 in India, and CSA A165 in Canada. These standards establish size tolerances, compressive strength requirements, and performance criteria for safe, reliable construction worldwide.

ASTM C90 (USA)

BS EN 771-3 (UK & Europe)

IS 2185 (India)

CSA A165 (Canada)

These standards define block size tolerances, strength, and durability.

Discover More:

How to Choose the Right Concrete Block Size

Selecting the correct concrete block size is essential for safe, efficient, and cost-effective construction. Proper block selection ensures adequate structural strength, wall performance, and compliance with local regulations. Builders must consider factors such as load requirements, wall thickness, insulation, budget, and block availability to achieve durable, high-quality walls and foundations.

1-Structural Load Requirements

The intended load on a wall or structure determines the block thickness and type. Load-bearing walls and foundations require thicker, stronger blocks to safely support floors, roofs, and upper stories. Non-load-bearing partitions can use thinner, lighter blocks. Choosing the right block based on structural load ensures stability and long-term performance.

2-Wall Thickness and Insulation Needs

Wall thickness affects both structural integrity and thermal or acoustic insulation. Thicker blocks provide greater strength and better insulation, while thinner blocks are suitable for interior partitions or non-load-bearing walls. Considering insulation needs alongside block thickness helps maintain energy efficiency and comfort within the building.

3-Local Building Codes

Building codes dictate minimum structural requirements, block dimensions, and construction practices. Selecting blocks that comply with local regulations ensures legal approval, safety, and long-term durability. Always verify that the chosen concrete block size meets the standards required for the specific application and region.

4-Construction Budget

Budget considerations influence the choice between solid and hollow blocks, as well as block thickness and material type. Thinner, hollow blocks are cost-effective and easier to handle, while thicker or solid blocks provide higher strength but at a higher material and labor cost. Balancing budget and performance is key to efficient construction.

5-Availability in Your Region

Concrete block availability varies by region, manufacturer, and standard sizes. Choosing sizes that are readily available locally reduces lead times, transportation costs, and construction delays. Always confirm local supply options before finalizing block selection for your project.

Consult a structural engineer for load-bearing designs.

Discover More:

Common Mistakes When Selecting Concrete Block Sizes

Selecting the wrong concrete block size can compromise structural integrity, increase costs, and cause construction delays. Common errors include using blocks unsuited for their application, miscalculating dimensions, overlooking weight and handling requirements, neglecting mortar joints, and failing to comply with local building codes. Awareness of these pitfalls ensures safer and more efficient construction.

1-Using Partition Blocks for Load-Bearing Walls

A frequent mistake is using thin, hollow partition blocks in load-bearing walls. These blocks lack the necessary strength and can lead to structural failure. Always select blocks designed for the intended load to ensure wall stability and safety.

2-Ignoring Nominal vs Actual Sizes

Confusing nominal and actual block sizes can result in misalignment and uneven walls. Nominal size includes mortar joints, while actual size is the block’s physical dimension. Accurate planning requires using the correct measurement to maintain proper spacing and fit.

3-Underestimating Block Weight

Block weight affects handling, labor requirements, and structural load calculations. Using heavier blocks than anticipated can increase construction difficulty and stress on supporting structures. Always account for block weight during planning and material handling.

4-Not Accounting for Mortar Joints

Mortar joints add thickness to walls and affect overall dimensions. Failing to include them in calculations can cause misalignment, uneven courses, and gaps. Always incorporate standard mortar joint thickness when planning wall layouts.

5-Failing to Follow Local Building Codes

Ignoring local building codes can lead to unsafe structures and legal issues. Codes often specify minimum block sizes, strength requirements, and wall thicknesses. Compliance ensures structural safety, durability, and regulatory approval.

Avoiding these mistakes improves safety and durability.

Discover More:

Final Thoughts

Understanding concrete block sizes is essential for efficient, safe, and cost-effective construction. By choosing the correct block dimensions, thickness, and type, builders can ensure structural integrity, reduce material waste, and meet building standards. This Concrete Block Size Guide provides a reliable reference for selecting the right blocks for any construction project.

Discover More: