Grub screws—also known as set screws—are small but critical fastening components used across mechanical, industrial, and DIY applications. Among the most commonly used are metric (M) grub screws, which follow standardized ISO dimensions and are widely available in sizes ranging from M1 to M24 and beyond.

Choosing the correct M grub screw size is essential for ensuring secure fastening, proper torque application, and long-term reliability of assemblies such as gears, pulleys, collars, bearings, and rotating shafts. This guide provides a comprehensive breakdown of M grub screw sizes, dimensions, thread standards, materials, and use cases—along with three detailed size charts to help you make the right selection.

What Is an M Grub Screw?

An M grub screw is a headless, fully threaded fastener designed to sit flush inside a component, providing a clean and compact fixing solution. Unlike standard screws, it has no external head and is tightened using an internal drive such as a hex socket, slotted drive, or Torx. The “M” denotes metric threading, measured in millimeters and manufactured to ISO standards for precision and compatibility.

Hex socket (Allen key)

Slotted drive

Torx (less common)

The “M” designation refers to metric threading, measured in millimeters according to ISO standards.

Why Grub Screw Size Matters

Choosing the correct grub screw size is essential for reliable, long-term performance in mechanical assemblies. The right size ensures secure fastening, protects mating components, and maintains alignment under load or vibration. Incorrect sizing can lead to slippage, thread damage, or premature failure. Because grub screws are often hidden once installed, getting the size right from the start prevents costly rework and downtime later.

1- Proper Holding Strength

Using the correct grub screw size provides the holding strength needed to resist axial movement and rotational forces. A properly sized screw applies adequate pressure to the shaft or component without overstressing the material. This is especially important in power transmission and precision assemblies, where insufficient holding force can cause slippage, misalignment, or loss of torque during operation.

2- Correct Thread Engagement

Correct sizing ensures optimal thread engagement between the grub screw and the tapped hole. Adequate engagement distributes load evenly across the threads, improving strength and durability. If the screw is too small, thread contact is reduced; if too large, threads may bind or deform. Proper engagement minimizes wear, improves load transfer, and supports repeated tightening if maintenance is required.

3- Reduced Risk of Stripping or Loosening

A correctly sized grub screw significantly lowers the risk of stripped threads or loosening over time. Oversized screws can damage internal threads, while undersized screws may not generate enough friction to stay secure. Matching the screw size to the application helps maintain consistent clamping force, even in environments exposed to vibration, temperature changes, or cyclic loading.

4- Compatibility with Shafts, Hubs, and Tapped Holes

Grub screw size directly affects compatibility with shafts, hubs, and tapped holes. The right diameter and length ensure proper contact without distorting components or interfering with surrounding parts. Oversized screws can damage shafts or hubs, while undersized ones may fail to locate components accurately. Proper sizing ensures smooth assembly, reliable positioning, and long-term mechanical integrity.

An undersized screw may slip, while an oversized screw can damage threads or distort components.

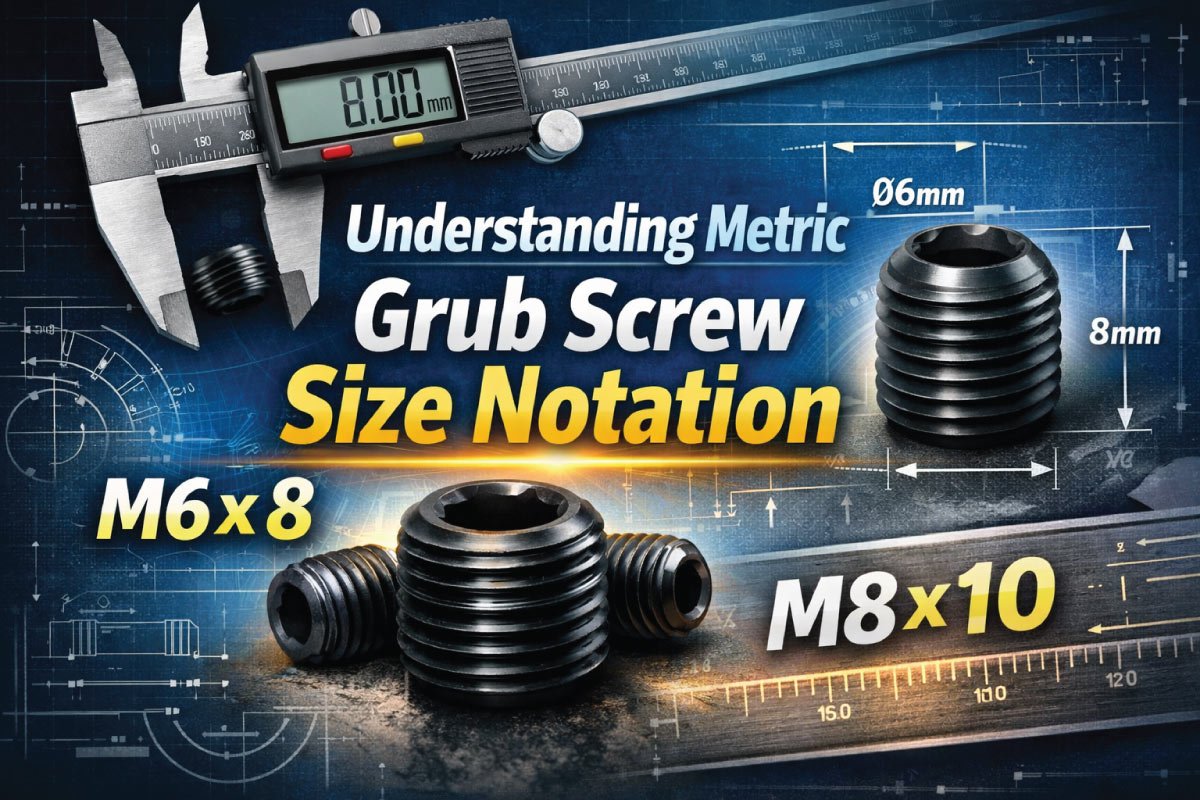

Understanding Metric Grub Screw Size Notation

Metric grub screw sizes follow a simple, standardized format that makes identification straightforward and consistent across applications. The notation helps engineers, technicians, and buyers quickly determine whether a screw will fit a specific threaded hole and provide the required holding depth. Understanding this sizing system reduces errors during selection, improves compatibility, and ensures the grub screw performs reliably once installed in mechanical assemblies.

M[d] × [L]

Where:

M = Metric thread

d = Nominal thread diameter (mm)

L = Length of the screw (mm)

Example:

M6 × 10 → 6 mm thread diameter, 10 mm length

Standard M Grub Screw Thread Sizes and Pitch

The table below outlines commonly used metric grub screw sizes along with their nominal thread diameters and standard thread pitches. These dimensions follow ISO metric standards and are widely used in general engineering, manufacturing, and maintenance applications. Knowing the correct diameter and pitch helps ensure proper thread matching, secure fastening, and compatibility with tapped holes across different components.

| Grub Screw Size (M) | Thread Diameter (mm) | Standard Pitch (mm) |

|---|---|---|

| M1.6 | 1.6 | 0.35 |

| M2 | 2.0 | 0.40 |

| M2.5 | 2.5 | 0.45 |

| M3 | 3.0 | 0.50 |

| M4 | 4.0 | 0.70 |

| M5 | 5.0 | 0.80 |

| M6 | 6.0 | 1.00 |

| M8 | 8.0 | 1.25 |

| M10 | 10.0 | 1.50 |

| M12 | 12.0 | 1.75 |

| M16 | 16.0 | 2.00 |

| M20 | 20.0 | 2.50 |

Tip: Fine-pitch threads are available for certain sizes but are less common for general-purpose grub screws.

Common M Grub Screw Lengths

Grub screw length refers to the full threaded portion of the screw, as there is no head above the surface. Choosing the correct length is critical to ensure sufficient thread engagement and effective holding power. The ideal length depends on the depth of the tapped hole, the holding force required for the application, and the shaft diameter and material being secured, ensuring strength without risking bottoming out or damage.

Depth of tapped hole

Required holding force

Shaft diameter and material

Typical M Grub Screw Length Ranges

This table highlights commonly available length options for standard metric grub screw sizes. While exact availability may vary by manufacturer, these ranges cover most general-purpose applications. Selecting an appropriate length ensures adequate thread engagement, reliable holding strength, and avoids bottoming out in blind holes or overloading the threads during tightening.

| Grub Screw Size | Common Lengths (mm) |

|---|---|

| M2 | 2, 3, 4, 5, 6 |

| M3 | 3, 4, 5, 6, 8, 10 |

| M4 | 4, 6, 8, 10, 12 |

| M5 | 6, 8, 10, 12, 16 |

| M6 | 6, 8, 10, 12, 16, 20 |

| M8 | 8, 10, 12, 16, 20 |

| M10 | 10, 12, 16, 20, 25 |

| M12 | 12, 16, 20, 25, 30 |

Best practice: The screw should engage at least 1 to 1.5× the thread diameter for optimal strength.

Types of M Grub Screw Points

M grub screws are available with different point styles to suit a wide range of mechanical applications. Each point type affects how the screw contacts the mating surface, influencing holding strength, ease of adjustment, and whether the connection is temporary or permanent. Selecting the correct point style improves performance, reduces wear on components, and ensures reliable positioning under load or vibration.

1- Flat Point

Flat point grub screws are the most commonly used type and are ideal for applications involving soft materials or components that require frequent adjustment. The flat end distributes pressure evenly across the contact surface, minimizing damage to shafts. This makes them suitable for assemblies where repositioning or removal is expected without leaving permanent marks.

2- Cup Point

Cup point grub screws provide strong holding power by slightly biting into the shaft surface. The concave tip creates increased friction and resistance to loosening, making it well suited for general-purpose and high-vibration applications. They are commonly used where a secure grip is needed but complete permanence is not required.

3- Cone Point

Cone point grub screws offer maximum grip by penetrating the mating surface with a sharp, pointed tip. This creates a very secure, almost permanent connection, ideal for heavy-duty or high-torque applications. However, the cone point can damage shafts, so it is best used where removal or repositioning is unlikely.

4- Dog Point

Dog point grub screws feature an extended cylindrical tip designed to fit into a pre-drilled hole or slot. This allows for precise positioning and alignment of components. They are commonly used in assemblies that require accurate location rather than high clamping force, such as indexing or locating parts.

Grub Screw Point Type vs Application

This table compares common grub screw point types based on holding strength, reusability, and typical applications. Understanding these differences helps in selecting the most suitable point style for your assembly, whether the priority is adjustability, maximum grip, or precise positioning. Choosing the right point type improves reliability, reduces component damage, and ensures the fastener performs as intended in service.

| Point Type | Holding Strength | Reusability | Typical Applications |

|---|---|---|---|

| Flat Point | Medium | High | Adjustable components |

| Cup Point | High | Medium | Gears, pulleys |

| Cone Point | Very High | Low | Permanent fixtures |

| Dog Point | High | Medium | Precision alignment |

Materials Used in M Grub Screws

The material of an M grub screw plays a major role in its performance, durability, and suitability for different environments. Selecting the right material helps balance strength, corrosion resistance, and service life, especially when factors such as moisture, temperature, load, or electrical conductivity are involved.

Common Materials

Alloy Steel – High strength, often black oxide coated

Stainless Steel (A2 / A4) – Corrosion-resistant

Brass – Non-magnetic, softer

Nylon / Plastic – Electrical insulation, light-duty

Standard Grades and Hardness

Grub screw performance is closely linked to mechanical grade and hardness, which determine strength, wear resistance, and how aggressively the screw grips the mating surface. International standards help ensure consistency and reliability across manufacturers, making it easier to select the right fastener for a given application.

ISO 898-5 specifies the mechanical properties of metric set screws, including hardness requirements. Alloy steel grub screws typically have a hardness range of 45–53 HRC, offering excellent strength and holding power. Stainless steel versions are softer, usually around 25–35 HRC, providing better corrosion resistance with reduced risk of damaging shafts. Higher hardness improves grip but also increases the likelihood of surface indentation or shaft damage.

ISO 898-5 specifies mechanical properties

Typical hardness:

Alloy steel: 45–53 HRC

Stainless steel: ~25–35 HRC

Higher hardness improves grip but increases the risk of shaft damage.

Read More:

How to Choose the Right M Grub Screw Size

Selecting the correct M grub screw ensures reliable performance, prevents damage, and maintains component alignment. Key factors include shaft diameter, load, material compatibility, and adjustment frequency. Considering these aspects helps you choose a screw that provides sufficient holding power, fits the application precisely, and balances strength with ease of maintenance or repositioning. Proper selection avoids premature wear or failure in assemblies.

1- Shaft Diameter

The grub screw diameter should be proportional to the shaft it secures. A screw that is too large can deform or damage the shaft, while one that is too small may slip or fail under load. Correct sizing ensures proper thread engagement and reliable clamping without compromising component integrity.

2- Load and Torque Requirements

Applications with high torque or axial loads require grub screws that can handle the forces involved. Larger diameters or point types like cup or cone points offer stronger grip and reduce the risk of loosening. Proper selection ensures the assembly remains secure under operational stresses.

3- Material Compatibility

Choose a grub screw material suited to the environment. Stainless steel is ideal for corrosive or humid conditions, alloy steel for high-strength requirements, and brass or nylon for specialized uses. Matching material properties with environmental demands improves longevity and reduces maintenance needs.

4- Adjustment Frequency

If frequent adjustments are needed, flat-point grub screws are preferred for easy repositioning without damaging the shaft. For permanent or heavy-duty fixtures, cup or cone points provide stronger, more lasting engagement but are harder to remove. Selecting the point type based on adjustment needs enhances usability and protects components.

Read More:

Common Applications of M Grub Screws

M grub screws are versatile fasteners used across a wide range of industries and applications. Their headless, compact design allows them to secure components in tight spaces where traditional screws or bolts might not fit. From industrial machinery to DIY projects, they provide reliable holding power while maintaining a clean, flush surface.

Typical applications include electric motors, gearboxes, conveyor systems, robotics, automotive components, furniture fittings, and hobby projects.

Electric motors

Gearboxes

Conveyor systems

Robotics

Automotive components

Furniture fittings

DIY and hobby projects

Their compact design makes them ideal for tight spaces where traditional fasteners won’t fit.

Read More:

Installation Tips for M Grub Screws

Proper installation is crucial to ensure M grub screws perform reliably and avoid damaging components. Following best practices improves grip, prevents stripping, and extends the life of both the screw and the assembly. Paying attention to thread condition, torque, and surface preparation helps maintain secure, long-lasting connections.

1- Use the Correct Allen Key Size

Always select the proper hex key or driver for the grub screw’s internal drive. Using an incorrect size can round out the socket, making the screw difficult to tighten or remove. Proper fit ensures even torque distribution and reduces the risk of damage.

2- Clean Threads Before Installation

Remove dirt, debris, or old lubricant from both the grub screw and tapped hole. Clean threads allow smooth engagement, improve torque accuracy, and prevent galling or cross-threading during installation.

3- Apply Thread Locker for Vibration Resistance

For applications exposed to vibration or movement, a medium-strength thread locker helps prevent the screw from loosening over time. Apply sparingly to avoid excess adhesive that could make removal difficult.

4- Do Not Overtighten

Grub screws, especially smaller sizes, are prone to stripping if overtightened. Apply only the recommended torque for the diameter and point type to secure the component without damaging threads or the shaft.

5- Consider Shaft Surface Preparation

A flat or dimpled contact area on the shaft improves grip, especially for flat- or cup-point screws. This reduces slippage and allows the screw to maintain a secure hold without excessive torque.

Read More:

Final Thoughts

Mastering the M grub screw size guide is essential for engineers, machinists, maintenance professionals, and DIY enthusiasts. Every decision—from diameter and length to point style and material—directly impacts the screw’s holding strength, durability, and overall performance. Understanding these factors ensures your assemblies remain secure and function reliably under varying loads and operating conditions.

Standardized metric sizing makes M grub screws versatile and precise. Using the correct size ensures proper fit and alignment, reducing the risk of stripped threads, loose parts, or mechanical failure. This consistency allows for easier maintenance, replacement, and interoperability across tools and components in industrial, automotive, and home projects.

By following the tables, formulas, and guidance provided, you can confidently select or replace M grub screws. Accurate selection guarantees strong, long-lasting assemblies, simplifies project planning, and saves time and effort. With this knowledge, you are equipped to achieve precise, secure, and reliable fastening in any application.

Read More: