Choosing the correct conduit size is a critical part of any electrical installation. Whether you’re working on a residential project, a commercial building, or an industrial facility, the right conduit size ensures safety, code compliance, and long-term performance of your electrical system.

This conduit size guide will walk you through everything you need to know—from conduit types and sizing principles to fill calculations and practical examples. By the end, you’ll have a clear understanding of how to select the right conduit size for your wiring needs.

What Is Electrical Conduit ?

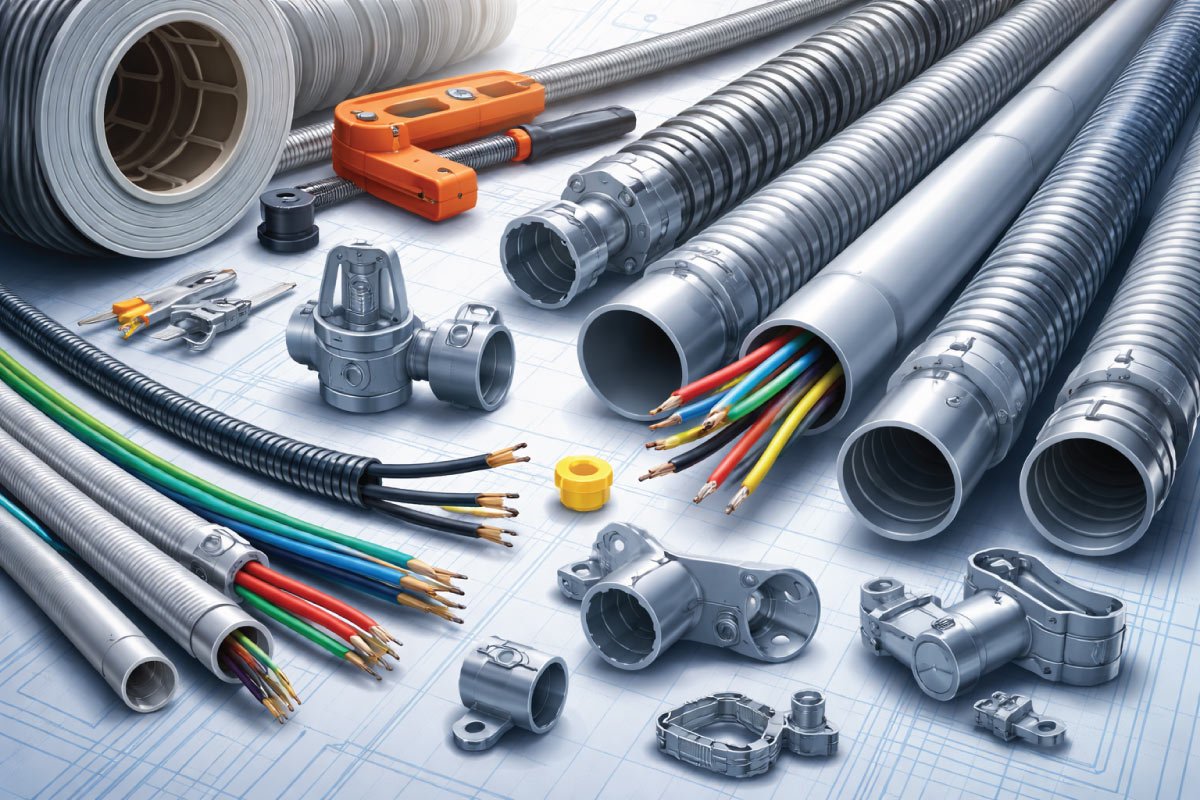

Electrical conduit is a protective tubing used to route and safeguard electrical wires. It shields conductors from physical damage, moisture, chemicals, and environmental hazards. Conduits also make future maintenance and wire replacement easier.

Conduit systems are regulated by electrical codes such as the National Electrical Code (NEC) in the United States, which specifies allowable conduit types, sizes, and fill limits.

Common Types of Electrical Conduit

Electrical conduit protects wiring, organizes circuits, and ensures safety in residential, commercial, and industrial installations. Different conduit types are made from materials suited to specific environments, such as indoor, outdoor, wet, or corrosive areas. Choosing the right type and size is essential for durability, code compliance, and ease of installation.

1- PVC Conduit

PVC (polyvinyl chloride) conduit is lightweight, non-corrosive, and ideal for indoor and outdoor use. It is resistant to moisture, chemicals, and UV exposure, making it popular for underground and exposed applications. PVC is easy to cut and join, cost-effective, and suitable for residential and commercial electrical wiring, though it requires proper support and protection from physical damage.

2- EMT

EMT is a thin-walled, galvanized steel conduit that is lightweight, strong, and cost-efficient. It is commonly used indoors for commercial and industrial applications. EMT provides excellent protection against physical damage and can be bent on-site for custom runs. It requires grounding and proper fittings but is easier to handle than rigid metal conduit.

3- RMC

RMC is a heavy-duty, thick-walled steel conduit offering maximum protection for electrical wiring. It is ideal for outdoor, underground, or high-risk areas where mechanical damage is possible. RMC is durable, fire-resistant, and can handle harsh environments. Installation requires threading and connectors, making it more labor-intensive but highly reliable.

4- IMC

IMC is a lighter, thinner alternative to RMC, offering similar protection with easier handling. It is made of galvanized steel and suitable for indoor or outdoor applications. IMC is cost-effective, corrosion-resistant, and strong enough for commercial installations. It balances durability and ease of installation, making it a popular choice in many construction projects.

5- Flexible Metal Conduit

FMC consists of interlocked metal strips, providing flexibility for installations with bends or movement. It is often used in machinery, equipment connections, and retrofit applications where rigid conduit is impractical. FMC offers protection against physical damage but is less suitable for outdoor or wet locations unless paired with proper sealing and fittings.

6- Liquidtight Flexible Metal Conduit

LFMC is a flexible metal conduit with a waterproof plastic coating, making it ideal for wet or outdoor locations. It protects wiring from moisture, corrosion, and mechanical damage while maintaining flexibility. LFMC is commonly used in industrial, commercial, and outdoor electrical systems, especially where vibration or movement is expected. Proper fittings are required to maintain a watertight seal.

7- ENT

ENT, also known as “smurf tube,” is a lightweight, corrugated plastic conduit primarily used indoors. It is easy to bend, cut, and install, making it popular for residential and commercial branch circuits. ENT is non-corrosive and cost-effective but requires proper support and cannot be used outdoors or in areas exposed to physical damage.

8- HDPE Conduit

HDPE (high-density polyethylene) conduit is a flexible, durable plastic conduit designed for underground and outdoor applications. It resists moisture, chemicals, and impact, making it ideal for telecom, data, and power cabling. HDPE is lightweight, easy to install, and available in long coils, reducing the need for joints in buried runs. Proper fittings ensure watertight connections.

Types of Electrical Conduit and Applications

| Conduit Type | Full Name | Common Applications | Indoor/Outdoor |

|---|---|---|---|

| EMT | Electrical Metallic Tubing | Residential & commercial | Indoor |

| RMC | Rigid Metal Conduit | Heavy-duty, industrial | Outdoor |

| IMC | Intermediate Metal Conduit | Commercial & industrial | Indoor/Outdoor |

| PVC | Polyvinyl Chloride | Underground, wet locations | Outdoor |

| FMC | Flexible Metal Conduit | Short flexible connections | Indoor |

| LFMC | Liquidtight Flexible Metal | Wet or damp locations | Indoor/Outdoor |

Each conduit type is available in standardized sizes, usually measured in trade sizes, not actual inner diameters.

Why Conduit Size Matters

Choosing the correct conduit size is critical for safe, efficient, and code-compliant electrical installations. Proper sizing ensures wires are protected from damage, reduces the risk of overheating, and allows for smooth installation. It also provides flexibility for future upgrades or additions, avoiding costly modifications later. Understanding the factors that influence conduit sizing helps electricians and designers maintain system reliability while meeting regulatory standards.

1- Safety

Correct conduit sizing protects electrical conductors from overheating, abrasion, and insulation damage. Overfilled or undersized conduits can trap heat, leading to insulation failure, short circuits, or even fire hazards. Ensuring the proper diameter allows conductors to maintain spacing, dissipate heat effectively, and operate safely under normal load conditions. Safety considerations are the primary reason conduit sizing is regulated in electrical codes.

2- Code Compliance

Conduit sizing is regulated by the National Electrical Code (NEC) to ensure safe and standardized installations. Adhering to conduit fill limits prevents overcrowding, reduces risk of heat buildup, and ensures inspections pass without issues. Following code guidelines also provides a consistent framework for electrical professionals, guaranteeing that wiring installations are safe, legal, and compatible with future upgrades or modifications.

3- Ease of Installation

Adequate conduit size makes wire pulling easier, reducing friction and the risk of damaging insulation during installation. Properly sized conduits minimize bends, prevent kinking, and allow multiple wires to be pulled simultaneously without excessive force. This improves installation efficiency, lowers labor costs, and ensures a neater, more organized electrical system that is easier to maintain or expand in the future.

4- Future Expansion

Selecting a slightly larger conduit than immediately necessary allows for future circuit additions or upgrades without replacing the entire run. Extra space accommodates additional conductors, reducing the need for costly retrofits or new conduit runs. Planning for expansion ensures long-term system flexibility, making it easier to adapt to changing electrical needs in residential, commercial, or industrial installations.

Oversized conduits waste space and money, while undersized conduits violate code and create hazards.

Understanding Conduit Trade Sizes

Conduit trade sizes are a standardized way to identify conduit dimensions, expressed in inches. However, the trade size does not reflect the actual internal diameter, which varies depending on the material and wall thickness of the conduit. Knowing the trade size and corresponding internal area is essential for determining how many conductors can safely fit inside, ensuring compliance with code requirements and preventing overcrowding or heat buildup.

Standard Conduit Trade Sizes and Internal Area (EMT)

Understanding conduit trade sizes and their corresponding internal areas is essential for proper wire selection and fill calculations. Each trade size represents a nominal designation rather than the exact internal diameter, which determines how many conductors can safely fit. The table below shows common EMT sizes and their usable internal area, providing a reference for planning safe and efficient electrical installations.

| Trade Size (in) | Internal Diameter (in) | Total Area (sq in) |

|---|---|---|

| 1/2″ | 0.622 | 0.304 |

| 3/4″ | 0.824 | 0.533 |

| 1″ | 1.049 | 0.864 |

| 1-1/4″ | 1.380 | 1.496 |

| 1-1/2″ | 1.610 | 2.036 |

| 2″ | 2.067 | 3.356 |

Note: Values vary slightly for PVC, RMC, and IMC.

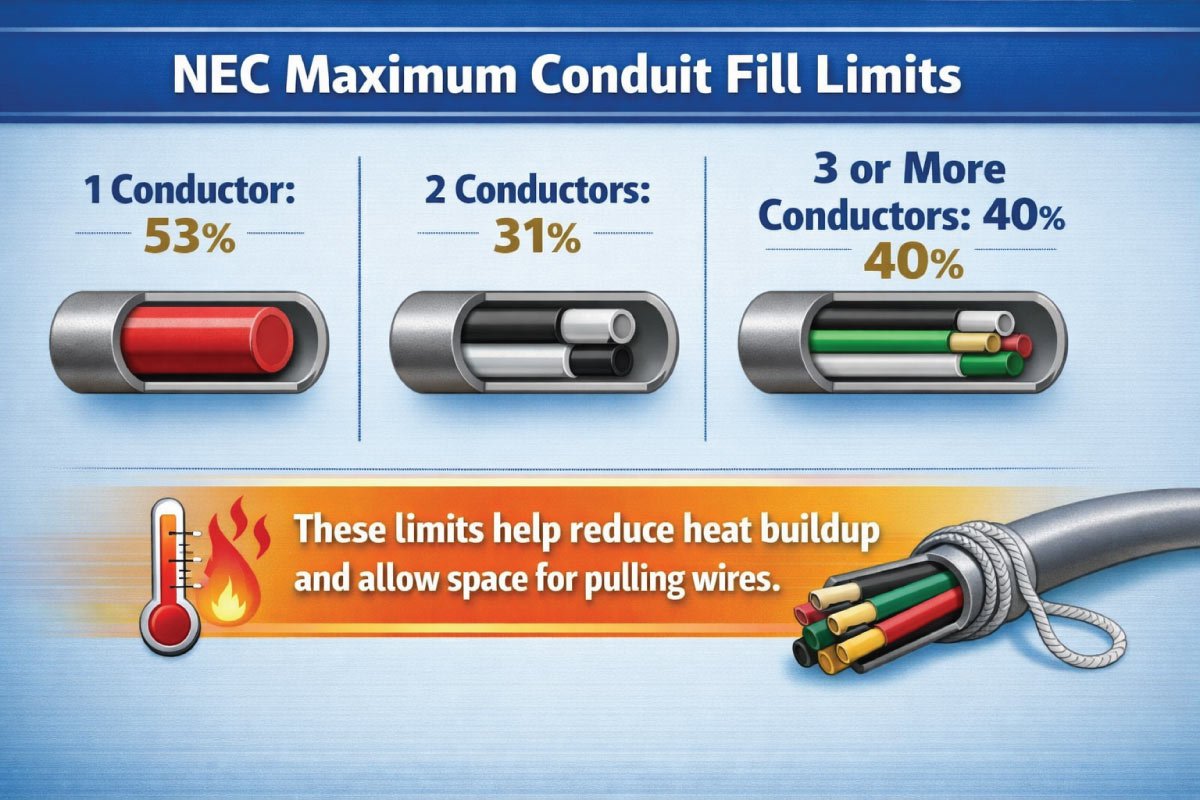

NEC Conduit Fill Rules Explained

The National Electrical Code (NEC) sets strict guidelines on how much of a conduit’s internal area can be filled with electrical conductors, a concept known as conduit fill. Proper fill ensures wires have enough space to dissipate heat, reduces the risk of insulation damage, and makes pulling or installing additional conductors easier. Following these rules is critical for safety, code compliance, and long-term system reliability.

NEC Maximum Conduit Fill Limits

1 conductor: 53%

2 conductors: 31%

3 or more conductors: 40%

These limits help reduce heat buildup and allow space for pulling wires.

How to Calculate Conduit Size

Selecting the correct conduit size ensures safe, efficient, and code-compliant wiring. Proper sizing prevents overheating, makes wire pulling easier, and allows for future expansion. Calculating conduit size involves understanding the number of conductors, their dimensions, and allowable fill limits. By following a systematic approach, electricians can determine the minimum conduit diameter required to safely accommodate all wires while maintaining compliance with NEC guidelines.

1- Identify the Number of Conductors

The first step in sizing conduit is to determine how many conductors will be installed. This includes all hot, neutral, and ground wires for the circuit. Knowing the exact count ensures accurate calculations for conduit fill, prevents overcrowding, and helps maintain proper spacing between wires, reducing heat buildup and minimizing the risk of damage or code violations.

2- Determine Wire Size (AWG or kcmil)

Next, identify the gauge (AWG) or kcmil of each conductor. Wire size affects the cross-sectional area, which is critical for conduit fill calculations. Larger wires take up more space, requiring a larger conduit, while smaller wires fit into tighter spaces. Accurate measurement of wire size ensures safety, compliance with NEC standards, and easier installation.

3- Find the Cross-Sectional Area of Each Conductor

Once wire size is known, calculate the cross-sectional area of a single conductor. This information is typically provided by the NEC tables and accounts for insulation thickness. Knowing the area helps determine how much space each conductor occupies inside the conduit, which is essential for calculating total fill and ensuring that wires are not overcrowded.

4- Add Total Conductor Area

Add the cross-sectional areas of all conductors to find the total area that needs to fit inside the conduit. This sum represents the combined space required for the wires. Accurate addition ensures that the chosen conduit will safely accommodate all conductors while complying with NEC fill limits, preventing overheating and making installation easier.

5- Divide by Allowable Conduit Fill Percentage

After calculating the total conductor area, divide it by the NEC allowable fill percentage based on the number of conductors. This step determines the minimum internal area the conduit must provide. It ensures that wires have sufficient space for heat dissipation and movement, preventing insulation damage and maintaining code compliance.

6- Select the Nearest Larger Conduit Size

Finally, choose the nearest larger conduit size that meets or exceeds the required internal area. Selecting a slightly larger conduit makes installation easier, allows for future wire additions, and ensures the system remains safe and efficient. Always verify against NEC tables to confirm compliance and optimal performance.

Wire Size and Cross-Sectional Area

Every wire gauge (AWG or kcmil) has a standardized cross-sectional area that accounts for both the conductor and its insulation. This area determines how much space the wire occupies inside a conduit, which is critical for safe installation and NEC compliance. Knowing each wire’s cross-sectional area allows electricians to calculate total conduit fill accurately, preventing overcrowding and reducing the risk of overheating or insulation damage.

Common Wire Sizes and Area (THHN)

Understanding the cross-sectional area of different wire sizes is essential for calculating conduit fill and ensuring safe electrical installations. The table below shows common THHN wire gauges and their corresponding areas, including insulation. Using these values helps determine how many conductors can safely fit within a given conduit while maintaining NEC compliance and reducing the risk of overheating or damage.

| Wire Size (AWG) | Area (sq in) |

|---|---|

| 14 AWG | 0.0083 |

| 12 AWG | 0.0133 |

| 10 AWG | 0.0211 |

| 8 AWG | 0.0366 |

| 6 AWG | 0.0507 |

| 4 AWG | 0.0824 |

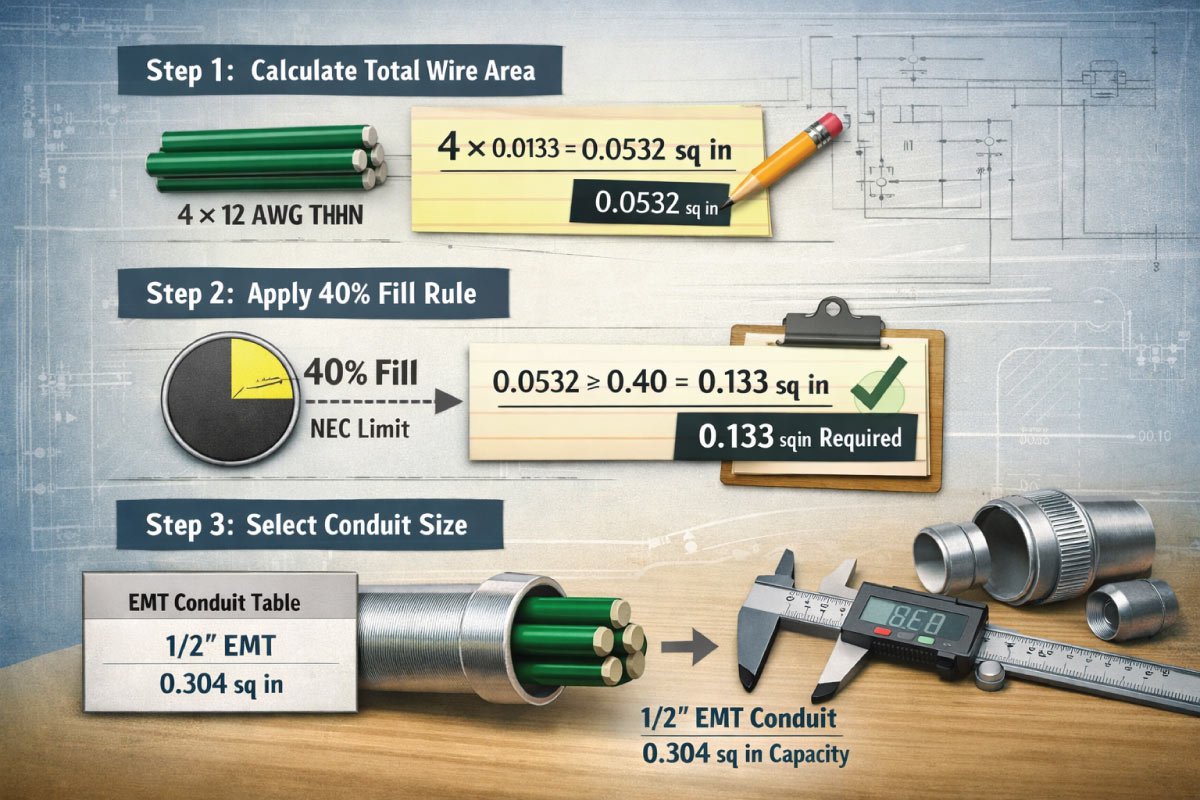

Example Conduit Sizing Calculation

Determining the proper conduit size can be straightforward when you follow a systematic approach. Let’s walk through an example to illustrate how to calculate conduit requirements for multiple conductors while adhering to NEC fill rules. Accurate calculations ensure safe, code-compliant installations and make wire pulling easier.

Scenario:

You need to run 4 × 12 AWG THHN conductors through EMT conduit.

Step 1: Calculate total wire area

4 × 0.0133 = 0.0532 sq in

Step 2: Apply 40% fill rule

0.0532 ÷ 0.40 = 0.133 sq in required

Step 3: Select conduit size

From the EMT table, 1/2″ EMT provides 0.304 sq in total area — more than sufficient.

Also Read:

Conduit Size Chart for Common Wire Configurations

The conduit size chart provides guidance for selecting the appropriate conduit dimensions based on common wire configurations. By matching the number and size of wires to the conduit’s capacity, this chart ensures safe and efficient electrical installations while maintaining proper spacing, reducing heat buildup, and complying with electrical codes.

EMT Conduit Size Guide (THHN Copper)

Selecting the right EMT conduit size depends on the number and gauge of conductors being installed. Using the NEC 40% fill rule ensures safe spacing, prevents overheating, and allows easier wire pulling. The table below provides a quick reference for the maximum number of common THHN copper conductors that can fit in standard EMT conduit sizes, helping electricians plan installations efficiently and maintain code compliance.

| Conduit Size | Max # 12 AWG | Max # 10 AWG | Max # 8 AWG |

|---|---|---|---|

| 1/2″ | 9 | 5 | 3 |

| 3/4″ | 16 | 10 | 6 |

| 1″ | 26 | 16 | 9 |

| 1-1/4″ | 45 | 28 | 16 |

| 1-1/2″ | 61 | 38 | 22 |

Based on NEC 40% fill rule

Also Read:

PVC Conduit Sizing Considerations

PVC conduit offers a larger internal diameter than EMT of the same trade size, making it ideal for long wire runs, underground installations, and situations where easier wire pulling and future expansion are needed. Proper sizing ensures compliance with fill limits and safe electrical performance.

PVC Schedule 40 Conduit Capacity (12 AWG THHN)

Table X presents the capacity of PVC Schedule 40 conduit for 12 AWG THHN wires, showing the internal area of each trade size and the corresponding maximum number of conductors. Proper sizing ensures safe wire installation, adequate spacing, and compliance with NEC fill requirements.

| PVC Trade Size | Internal Area (sq in) | Max Conductors |

|---|---|---|

| 1/2″ | 0.285 | 8 |

| 3/4″ | 0.508 | 15 |

| 1″ | 0.832 | 25 |

| 1-1/4″ | 1.453 | 43 |

| 1-1/2″ | 1.986 | 59 |

Also Read:

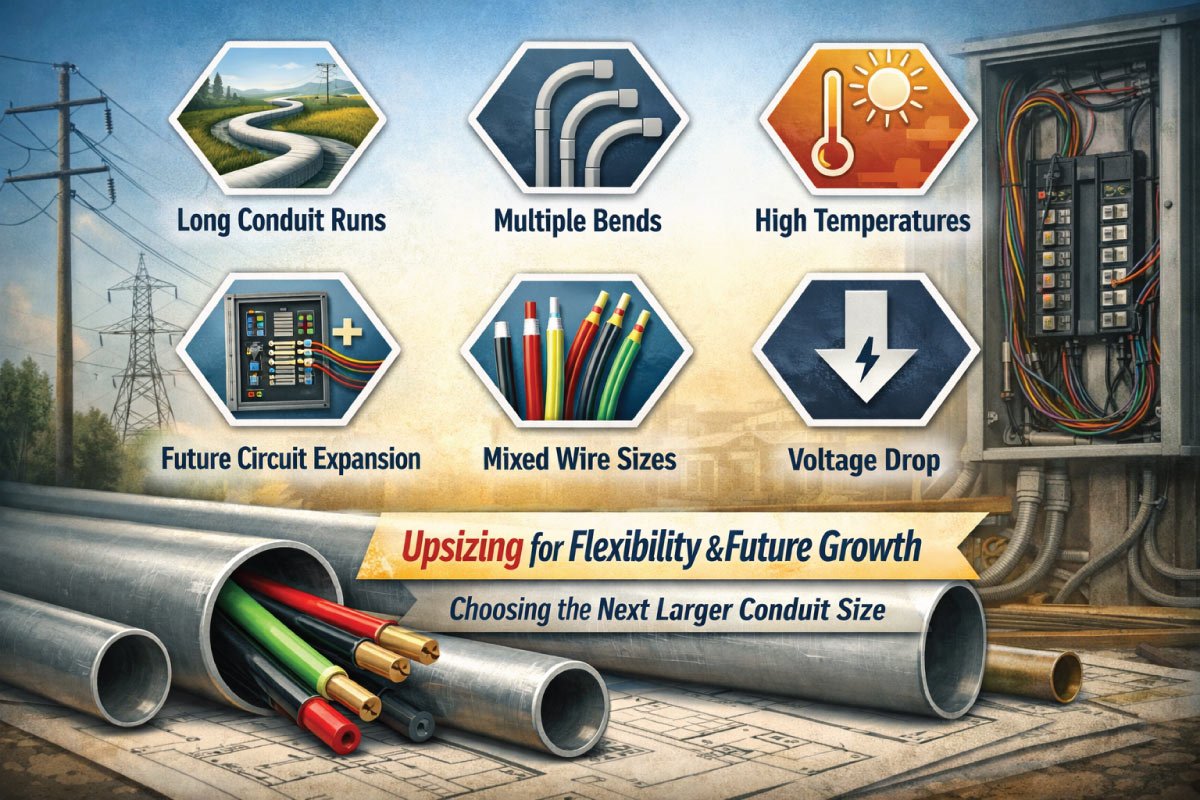

Factors That Affect Conduit Size Selection

Several factors can influence the selection of conduit size beyond standard calculations. Long runs, multiple bends, high ambient temperatures, mixed wire sizes, voltage drop considerations, and potential future circuit expansion may all require upsizing. Electricians often choose the next larger conduit size to simplify installation and provide greater flexibility for future modifications.

Long conduit runs

Multiple bends

High ambient temperatures

Future circuit expansion

Mixed wire sizes

Voltage drop considerations

In many cases, electricians intentionally choose the next larger conduit size for easier installation and flexibility.

Also Read:

Best Practices for Choosing Conduit Size

When selecting conduit size, it is essential to follow NEC or local electrical codes and use official conduit fill tables. Avoid filling conduits to their maximum capacity, clearly label conduits for future maintenance, and plan for potential expansion, particularly in commercial projects. These practices ensure safety, efficiency, and long-term flexibility.

Always follow NEC or local electrical codes

Use official conduit fill tables

Avoid filling conduits to the absolute maximum when possible

Label conduits clearly for future maintenance

Plan for expansion, especially in commercial projects

Also Read:

Conclusion

Selecting the right conduit size involves more than simply matching wire count to a chart—it directly impacts safety, efficiency, and code compliance. Proper conduit sizing ensures that wires are not overcrowded, reduces the risk of overheating, and allows for easier installation and future maintenance, supporting both the reliability and longevity of any electrical system.

Understanding the types of conduit, NEC fill rules, and wire sizes is essential for accurate planning. Practical factors such as long runs, multiple bends, high temperatures, and potential future expansion should also be considered to prevent installation issues and maintain consistent electrical performance.

This conduit size guide, with the included tables and examples, provides a strong foundation for professionals and DIY enthusiasts alike. When uncertainty arises, always refer to the NEC or consult a licensed electrician to ensure all installations meet safety standards and local regulations.

Also Read: