Drilling is a fundamental process in metalworking, woodworking, and manufacturing, where precision is key to achieving accurate and functional results. Selecting the correct drill size is essential for maintaining the strength and integrity of the workpiece. For threaded holes, engineers commonly use M drill sizes, which align with the ISO metric thread system, ensuring consistency and proper fit for bolts and screws.

Understanding M drill sizes, their applications, and tolerances helps prevent issues such as stripped threads or loose fasteners. By choosing the right drill bit, you can achieve reliable, precise, and long-lasting results in any project.

What is an M Drill Size?

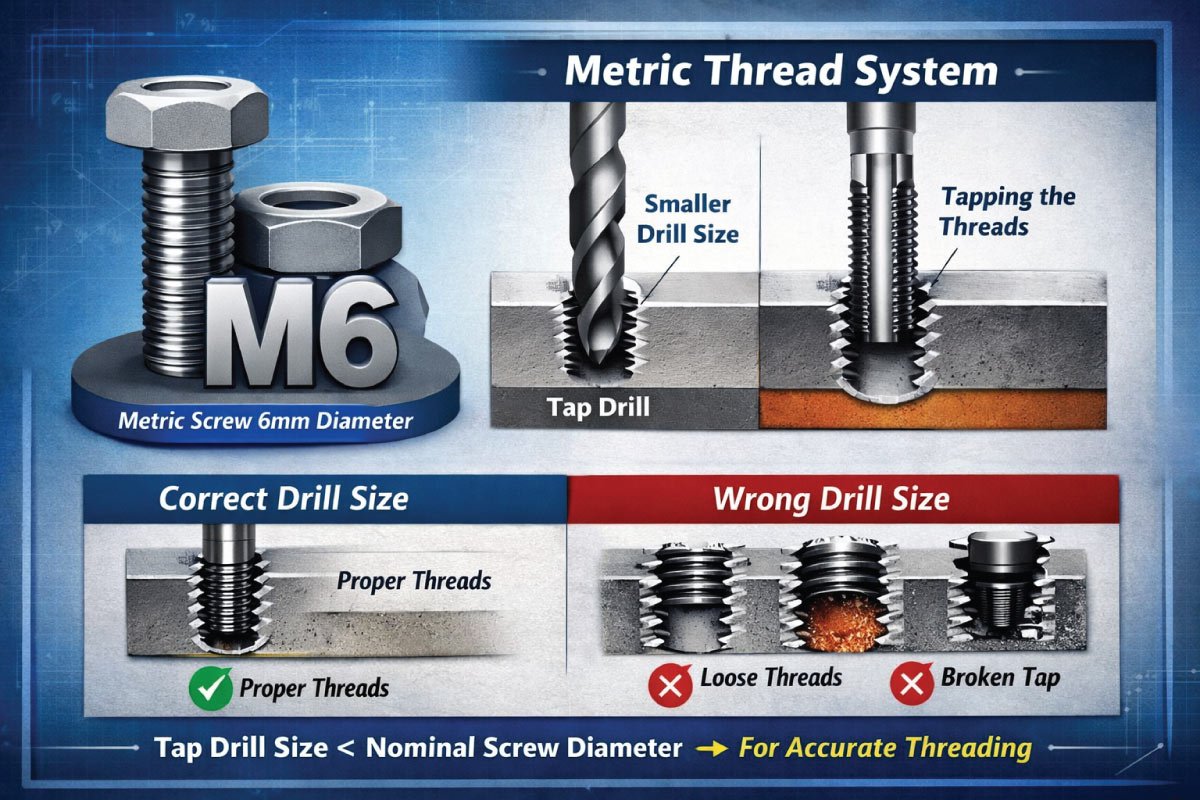

The “M” in M drill sizes refers to Metric threads. It is part of the ISO metric screw thread system, which is widely used in engineering and manufacturing worldwide. For instance, an M6 screw is a metric screw with a nominal diameter of 6 mm.

When creating a threaded hole for a bolt or screw, the drill size must match the tap drill size, which is slightly smaller than the nominal diameter of the screw. This allows the internal threads to form properly when tapped. Using the wrong drill size can result in loose threads, stripped holes, or broken taps.

How to Choose the Right Drill Size for M Threads

Selecting the correct drill bit for metric (M) threads is crucial for achieving proper thread engagement, strength, and durability. Using the wrong size can lead to stripped threads, weak joints, or assembly problems. By understanding screw size, thread pitch, recommended drill sizes, and tolerance considerations, engineers and hobbyists can ensure precise and reliable threaded holes for both standard and high-precision applications.

1- Determine the Screw Size:

The first step is identifying the screw size, such as M3, M5, or M8. The screw diameter determines the base diameter of the hole required for threading. Accurate measurement ensures compatibility with the intended bolt or fastener, avoids loose fits, and guarantees the structural integrity of the assembled components. Proper screw size selection is foundational for reliable metric threading.

2- Check the Thread Pitch:

Thread pitch defines the distance between adjacent threads and can be coarse or fine. Coarse pitch is standard unless specified otherwise in engineering designs. Choosing the correct pitch is essential because it affects the drill size, hole depth, and thread engagement. Using the wrong pitch can compromise load distribution, reduce thread strength, and create assembly difficulties.

3- Refer to an M Drill Size Chart:

M drill size charts provide recommended drill bit diameters for different metric screws. These charts are based on ISO standards and help ensure accurate thread formation. Consulting a chart simplifies the selection process, reduces errors, and guarantees that the drilled hole will accommodate the screw properly, providing a strong and durable threaded connection.

4- Consider Tolerances:

In precision engineering applications, minor adjustments may be necessary to account for material properties, machining variations, or assembly requirements. Considering tolerances ensures optimal thread engagement, prevents binding or stripping, and maintains structural integrity. Proper tolerance management allows threaded holes to meet functional and safety standards while supporting consistent performance across multiple assemblies.

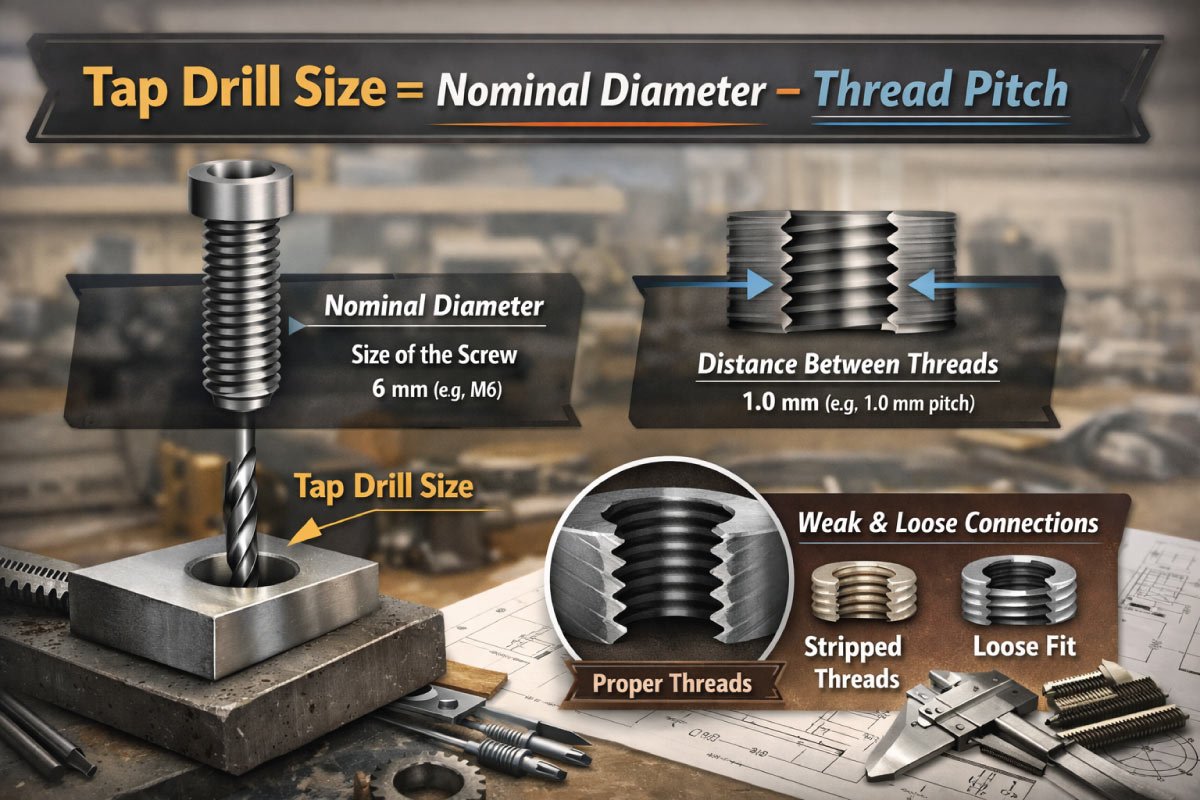

The formula to calculate the ideal tap drill size

Calculating the correct tap drill size is essential for creating properly threaded holes that ensure strong and reliable screw engagement. The ideal size depends on the screw’s nominal diameter and thread pitch. By subtracting the thread pitch from the nominal diameter, this formula provides the precise drill diameter needed to form threads accurately, preventing stripped threads, loose fits, or weakened connections

.

.

Where:

Nominal Diameter = the size of the screw (e.g., 6 mm for M6)

Thread Pitch = distance between threads (e.g., 1.0 mm for standard M6 coarse thread)

Standard M Drill Sizes (Coarse Pitch)

This table lists standard M drill sizes for coarse-pitch metric threads, showing screw nominal diameter, thread pitch, and the recommended drill bit diameter. Following these guidelines ensures accurate threading, proper fit, and strong engagement of bolts and screws. Slight adjustments may be necessary depending on material hardness or specific manufacturing standards to achieve optimal results.

| Screw Size | Nominal Diameter (mm) | Thread Pitch (mm) | Recommended Drill Size (mm) |

|---|---|---|---|

| M2 | 2 | 0.4 | 1.6 |

| M2.5 | 2.5 | 0.45 | 2.05 |

| M3 | 3 | 0.5 | 2.5 |

| M4 | 4 | 0.7 | 3.3 |

| M5 | 5 | 0.8 | 4.2 |

| M6 | 6 | 1.0 | 5.0 |

| M8 | 8 | 1.25 | 6.75 |

| M10 | 10 | 1.5 | 8.5 |

| M12 | 12 | 1.75 | 10.25 |

| M16 | 16 | 2.0 | 14.0 |

Note: Drill size recommendations may vary slightly based on material hardness and manufacturing standards.

Fine Pitch M Drill Sizes

Fine pitch threads have a smaller distance between adjacent threads, providing stronger engagement and greater resistance to loosening under vibration. This table lists recommended drill sizes for common fine-pitch metric screws, ensuring accurate threading and reliable bolt fit. Fine threads are typically used in high-precision applications such as machinery, automotive components, and aerospace assemblies where strength and precision are critical.

| Screw Size | Nominal Diameter (mm) | Fine Thread Pitch (mm) | Recommended Drill Size (mm) |

|---|---|---|---|

| M3 | 3 | 0.35 | 2.65 |

| M4 | 4 | 0.5 | 3.5 |

| M5 | 5 | 0.5 | 4.5 |

| M6 | 6 | 0.75 | 5.25 |

| M8 | 8 | 1.0 | 7.0 |

| M10 | 10 | 1.25 | 8.75 |

| M12 | 12 | 1.25 | 10.75 |

| M16 | 16 | 1.5 | 14.5 |

Fine threads are common in high-precision applications like machinery, automotive, and aerospace.

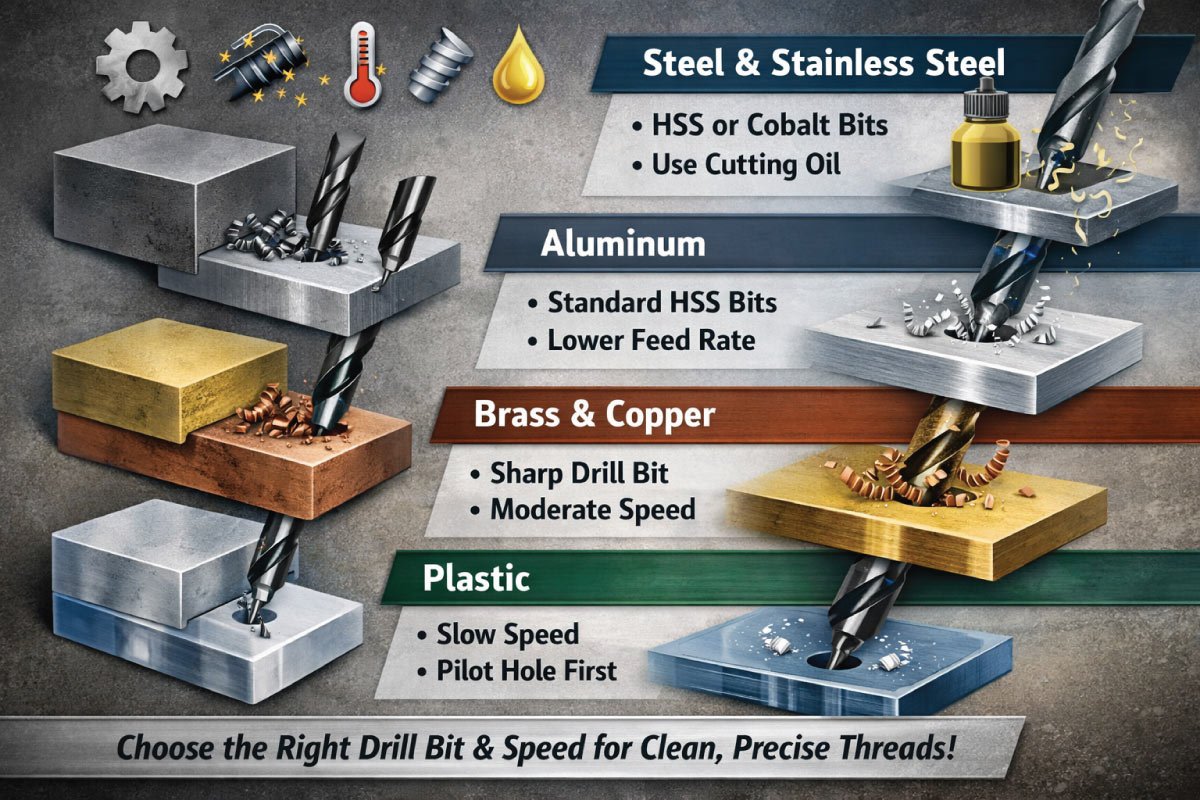

Material Considerations

The material being drilled significantly influences the choice of drill bit and cutting technique. Different materials—such as steel, aluminum, brass, copper, or plastic—have varying hardness, thermal properties, and chip formation characteristics. Selecting the correct drill bit type, speed, and lubrication ensures clean threads, prevents material damage, and extends tool life, ultimately supporting precise and reliable threaded holes in any application.

Steel & Stainless Steel: Use HSS or cobalt drill bits. Pre-lubrication with oil helps reduce heat and wear.

Aluminum: Standard HSS bits work well. Lower feed rates prevent chipping.

Brass & Copper: Use a sharp drill at moderate speed to avoid tear-out.

Plastic: Use a slower speed to prevent melting. Drill smaller pilot holes first.

Using the correct drill bit and speed ensures clean threads and prevents damage to your material or tools.

Drill Bit Material Recommendations

This table provides recommended drill bit types for various materials to ensure clean, precise holes and extend tool life. Using the correct drill for steel, aluminum, brass, copper, plastic, or titanium helps prevent overheating, chipping, or material damage. Following these guidelines ensures efficient drilling, optimal thread quality, and reliable performance across a wide range of engineering and manufacturing applications.

| Material | Recommended Drill Bit Type | Notes |

|---|---|---|

| Steel | HSS, Cobalt | Lubricate for stainless steel |

| Aluminum | HSS | Moderate speed, avoid chip buildup |

| Brass/Copper | HSS | Sharp drill, low speed |

| Plastic | HSS or Brad Point | Slow speed, pilot hole recommended |

| Titanium | Cobalt or Carbide | High hardness, use cutting fluid |

Also Read:

Tapping Tips for M Threads

Once the correct hole has been drilled, proper tapping is essential to create clean, precise threads for metric (M) screws. Using correct techniques—such as marking the drill point, securing the workpiece, applying cutting fluid, and tapping carefully—prevents damage to the material and the tap itself. Following these steps ensures strong, reliable threads and reduces the risk of breakage or misalignment.

Use a center punch to mark the drill point.

Clamp your workpiece to avoid slipping.

Use cutting fluid to reduce friction and heat.

Start tapping slowly, keeping the tap perpendicular to the hole.

Back off periodically to clear chips.

Following proper tapping techniques ensures strong, clean threads and reduces the risk of broken taps.

Also Read:

Recommended Tap Drill Sizes vs Thread Percentage

Thread engagement percentage directly affects the strength and reliability of a threaded connection. This table shows recommended tap drill sizes for various metric screws at 75% and 100% engagement. For softer metals, slightly reduced engagement helps prevent material stripping, while harder materials can achieve full engagement. Selecting the correct drill size ensures strong threads, proper fit, and long-lasting performance.

| Screw Size | Nominal Diameter (mm) | 75% Thread Engagement (mm) | 100% Thread Engagement (mm) |

|---|---|---|---|

| M3 | 3 | 2.55 | 2.5 |

| M4 | 4 | 3.3 | 3.3 |

| M5 | 5 | 4.1 | 4.2 |

| M6 | 6 | 5.0 | 5.0 |

| M8 | 8 | 6.7 | 6.8 |

| M10 | 10 | 8.5 | 8.5 |

| M12 | 12 | 10.25 | 10.25 |

Tip: For softer metals, aim for 75–80% thread engagement. For steel and harder materials, 100% engagement is ideal.

Also Read:

Common M Drill Sizes with Drill Number Equivalents (Imperial Reference)

This table lists common metric (M) drill sizes alongside their approximate U.S. drill number equivalents, providing an easy reference for converting between metric and imperial tools. It helps ensure accurate hole sizing when working in mixed-tool environments or workshops that primarily use U.S. standard drills, supporting precise threading and consistent results across different measurement systems.

| Screw Size | Nominal Diameter (mm) | Standard Drill (mm) | Approx. Drill Number (US) |

|---|---|---|---|

| M2 | 2 | 1.6 | 52 |

| M3 | 3 | 2.5 | 41 |

| M4 | 4 | 3.3 | 7 |

| M5 | 5 | 4.2 | F |

| M6 | 6 | 5.0 | 5/32 |

| M8 | 8 | 6.75 | 1/4 |

| M10 | 10 | 8.5 | 11/32 |

This table is particularly useful if you’re converting metric to imperial tools or working in a workshop that uses U.S. drill sizes.

Also Read:

Standard and Fine Pitch M Drill Sizes

Metric thread drill sizes for standard and fine pitch M threads ensure proper thread engagement and joint strength. Accurate drill selection reduces tapping torque, tool wear, and thread failure. These sizes are widely used in mechanical, structural, and industrial applications requiring reliable, high-load fastening performance.

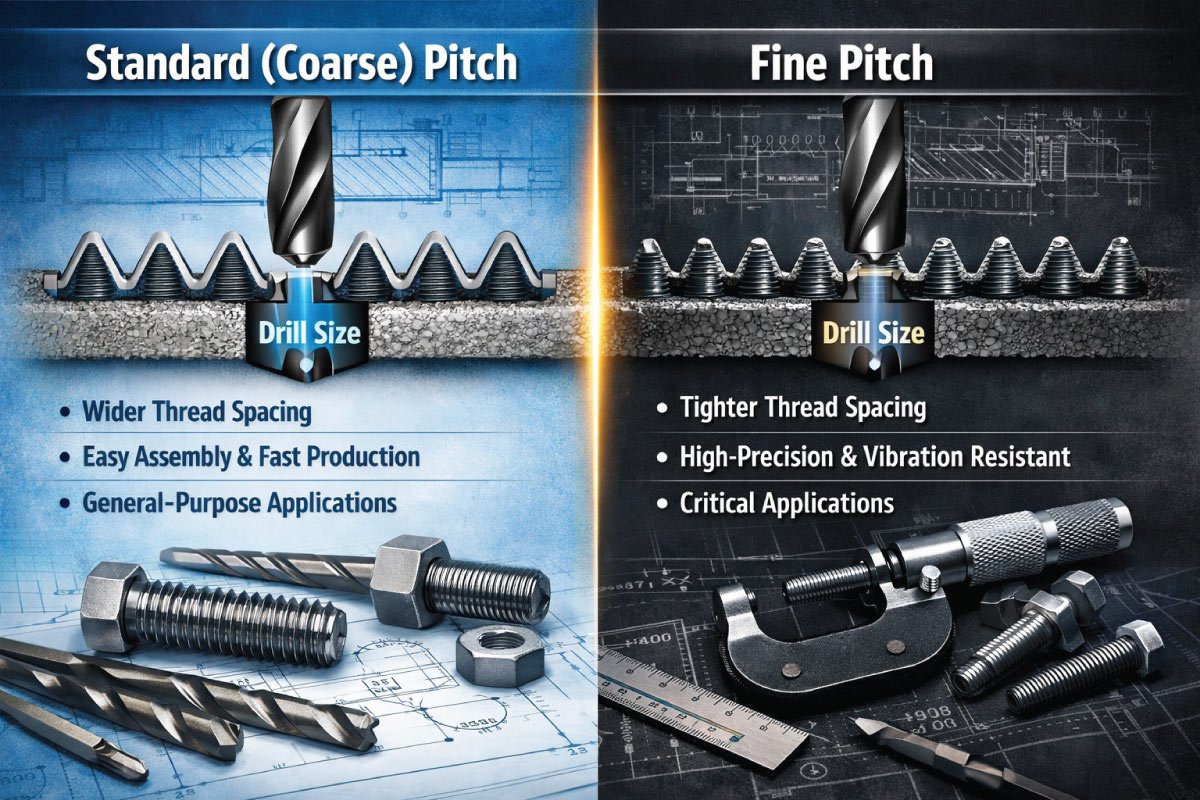

1- Standard (Coarse) Pitch

Standard, or coarse, pitch threads have larger spacing between adjacent threads and are widely used for general-purpose applications. They provide easier assembly, faster production, and adequate strength for most projects. Recommended drill sizes for coarse-pitch screws ensure accurate threading and proper bolt fit, preventing stripped threads or loose connections while maintaining reliable engagement in typical engineering and manufacturing applications.

2- Fine Pitch

Fine pitch threads have smaller spacing between threads, offering stronger engagement and improved resistance to vibration or loosening. These threads are commonly used in high-precision applications, including machinery, automotive components, and aerospace assemblies. Selecting the correct drill size for fine-pitch screws ensures precise thread formation, optimal load distribution, and durable, high-strength connections in critical or high-performance environments.

Also Read:

Thread Engagement & Drill Number Conversion

Thread engagement affects strength: 75–80% for softer metals, 100% for steel and harder materials. M drill sizes can also be converted to U.S. drill numbers for workshops using imperial tools. Correct sizing ensures strong, reliable threads across various materials and measurement systems.

1- Importance of Correct Engagement

Correct thread engagement distributes load evenly across the threads, preventing localized stress. This is especially important in softer materials, where over-tightening can strip threads. Conversely, in harder materials, full engagement maximizes strength and stability. Choosing the proper engagement percentage protects both the fastener and the material while maintaining mechanical integrity.

2- Engagement Percentage for Softer Metals

For metals like aluminum, brass, or plastic, 75–80% thread engagement is ideal. This allows strong holding power without risking stripping or material deformation. Using lower engagement percentages in softer metals reduces assembly torque requirements and provides some tolerance for variations in hole size, thread pitch, and manufacturing inconsistencies.

3- Engagement Percentage for Hard Metals

For steel, stainless steel, and other harder metals, 100% thread engagement is generally preferred. Harder materials can withstand higher torque without damage, and full engagement maximizes joint strength. This ensures that threaded connections are secure, vibration-resistant, and capable of handling heavy loads in demanding engineering applications.

4- Factors Affecting Engagement Selection

Material hardness, screw size, thread type, and load conditions all influence the optimal engagement percentage. Softer materials require reduced engagement, while harder materials allow full engagement. Engineers must also consider environmental factors, such as temperature changes and vibration, to maintain thread integrity and avoid premature failure in real-world applications.

5- Converting Metric to Imperial Drill Sizes

When working in workshops that primarily use U.S. tools, metric drill sizes can be converted to approximate U.S. drill numbers. This ensures proper hole sizing and prevents mismatched threads. Having a conversion reference allows machinists and hobbyists to maintain accuracy even when only imperial drill bits are available.

6- Common Metric-to-Imperial Drill Conversions

For example, an M3 drill (2.5 mm) is roughly equivalent to U.S. drill #41, and an M6 (5.0 mm) is about 5/32 inch. These equivalents allow consistent thread formation across different measurement systems, ensuring that both metric screws and U.S. tools can be used reliably in mixed-tool environments without compromising strength or fit.

7- Best Practices for Engagement and Conversion

Always verify engagement percentages and drill size conversions before machining. For soft metals, prioritize slightly reduced engagement; for steel, aim for full engagement. Use charts or calculators to confirm metric-to-imperial equivalences. Following these best practices ensures strong, accurate threads, reduces the risk of failure, and maintains the integrity of both the fastener and the workpiece.

Also Read:

Conclusion

A proper M drill size guide is essential for engineers, machinists, and hobbyists. Selecting the correct drill ensures strong, precise threads, prevents material damage, and maintains the structural integrity of your projects. Understanding thread pitch, screw size, and proper tapping techniques allows for accurate and reliable threaded connections across a variety of materials and applications.

Whether you are working with coarse or fine threads, or drilling into steel, aluminum, or plastic, having a reference chart at hand saves time and reduces errors. Correct drill selection improves efficiency and ensures consistent results, making even complex projects more manageable and reliable.

Always remember to lubricate appropriately, drill straight, and choose the right engagement percentage for the material. By following these best practices and consulting the provided tables, you now have a comprehensive resource for selecting M drill sizes and achieving precise, durable threads every time.

Also Read: