When it comes to construction, woodworking, mechanical repairs, or even simple DIY projects, screws are some of the most essential fasteners you’ll use. In the United States, screw sizing has a unique system that can feel confusing if you’re not familiar with it. That’s where an American screw size chart becomes incredibly useful. It helps you quickly match screws to the correct drill bits, understand their dimensions, and avoid mistakes when working on a project.

In this guide, we’ll break down everything you need to know about American screw sizes, explain how the system works, and provide a detailed screw size chart for reference.

Why Screw Sizes Matter

Imagine building a wooden deck, fixing a cabinet, or repairing machinery. If you use the wrong screw size, a few things can go wrong:

The screw may be too loose, and the joint won’t hold.

It may be too tight, splitting the material.

You may strip the head or threads, making it unusable.

That’s why knowing the right screw size before starting your project saves time, effort, and materials. A screw size chart eliminates guesswork and ensures accuracy.

Understanding American Screw Sizes

In the U.S., screw sizes are typically defined using a gauge system or by diameter in inches. Here’s what you need to know:

1. Screw Gauge Numbers

Small screws are identified by gauge numbers (e.g., #0, #4, #8, #10, etc.).

The larger the number, the thicker the screw’s diameter.

For example, a #4 screw is thinner than a #10 screw.

2. Fractional Inch Sizes

Larger screws (typically machine bolts and lag screws) are measured in fractions of an inch (e.g., 1/4″, 3/8″, 1/2″).

These sizes specify the major diameter (the widest point of the threads).

3. Screw Length

Screw length is measured from the flat part of the head to the tip.

For flat-head screws (countersunk), the entire length is measured including the head.

For round-head or pan-head screws, length is measured excluding the head.

4. Threads Per Inch (TPI)

American screws also follow the Unified Thread Standard (UTS).

A #10 screw, for example, can have 10-24 (coarse thread) or 10-32 (fine thread).

Coarse threads are stronger for wood and general use, while fine threads are better for precision work.

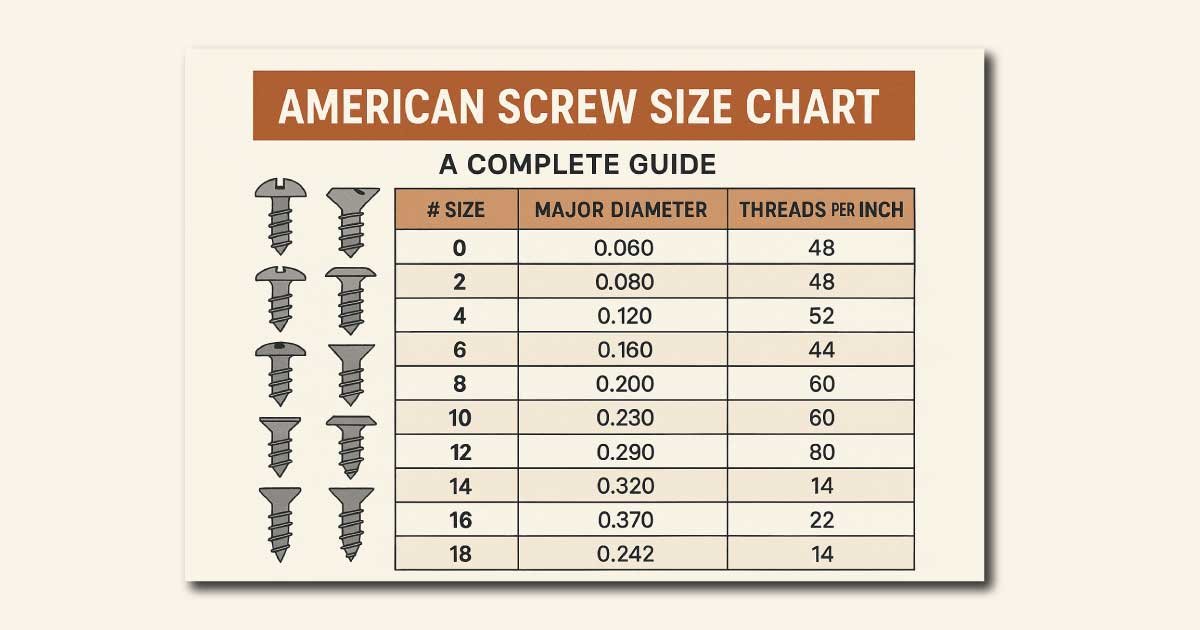

American Screw Size Chart

Here’s a quick reference chart for some of the most common screw sizes used in the U.S. This chart includes gauge sizes, diameters, and drill bit recommendations:

Common Wood and Sheet Metal Screw Sizes

| Screw Gauge | Major Diameter (inches) | Major Diameter (mm) | Recommended Drill Bit (Wood) |

|---|---|---|---|

| #0 | 0.060″ | 1.5 mm | 1/16″ |

| #2 | 0.086″ | 2.2 mm | 5/64″ |

| #4 | 0.112″ | 2.8 mm | 3/32″ |

| #6 | 0.138″ | 3.5 mm | 7/64″ |

| #8 | 0.164″ | 4.2 mm | 1/8″ |

| #10 | 0.190″ | 4.8 mm | 9/64″ |

| #12 | 0.216″ | 5.5 mm | 5/32″ |

| #14 | 0.242″ | 6.1 mm | 11/64″ |

Machine Screw Sizes (Unified Thread Standard)

| Screw Size | Major Diameter (inches) | Threads Per Inch (Coarse) | Threads Per Inch (Fine) |

|---|---|---|---|

| #2 | 0.086″ | 56 TPI | 64 TPI |

| #4 | 0.112″ | 40 TPI | 48 TPI |

| #6 | 0.138″ | 32 TPI | 40 TPI |

| #8 | 0.164″ | 32 TPI | 36 TPI |

| #10 | 0.190″ | 24 TPI | 32 TPI |

| 1/4″ | 0.250″ | 20 TPI | 28 TPI |

| 5/16″ | 0.312″ | 18 TPI | 24 TPI |

| 3/8″ | 0.375″ | 16 TPI | 24 TPI |

| 1/2″ | 0.500″ | 13 TPI | 20 TPI |

American Screw Size Chart Pdf

Also Read:

How to Read Screw Sizes (Example)

Let’s say you see a screw labeled as #10-24 x 1-1/2.

#10 = Screw gauge size

24 = Threads per inch (coarse thread)

1-1/2 = Screw length in inches

This tells you it’s a medium-size screw, 1.5 inches long, with coarse threading.

Tips for Choosing the Right Screw

Match the screw to the material

Wood → Coarse-thread screws (#6, #8, #10 are most common)

Metal → Fine-thread machine screws (e.g., #10-32, 1/4″-28)

Drywall → Drywall screws (#6 or #8 with bugle heads)

Pre-drill holes when necessary

Prevents splitting wood.

Ensures cleaner threading.

Use the right driver bit

Flathead, Phillips, Torx, or square drive.

A mismatch can strip the screw head.

Check load requirements

Larger screws or bolts provide more holding power.

For heavy-duty projects, always use lag bolts or machine bolts.

Advantages of Using an American Screw Size Chart

Saves time: No more trial and error.

Prevents damage: Protects materials from cracks and splits.

Increases accuracy: Helps select proper pilot holes.

Universal reference: Works for woodworking, construction, mechanical, and DIY projects.

Common Applications of Screw Sizes

#4 and #6 screws → Electronics, light fixtures, small wood projects.

#8 screws → The most popular for general woodworking and household projects.

#10 screws → Stronger applications like cabinetry and furniture assembly.

1/4″-20 bolts → Automotive, machinery, and metal fabrication.

3/8″-16 and larger → Heavy-duty construction and structural use.

Also Read:

Final Thoughts

The American screw size chart is an essential reference for anyone who works with screws regularly—whether you’re a professional builder, an engineer, or a DIY enthusiast. By understanding gauge sizes, threads per inch, and recommended drill sizes, you’ll save time and avoid costly mistakes.

So, next time you’re in the workshop or hardware store, keep this guide handy. With the right screw size, your project will not only be sturdier but also much easier to complete.

FAQs:

What does screw gauge size mean in the U.S.?

In the U.S., screw gauge size refers to the diameter of the screw’s shaft. Smaller numbers represent thinner screws, while larger numbers indicate thicker ones. For example, a #4 screw is thinner than a #10 screw. This system helps builders, DIYers, and mechanics choose the right screw for specific materials, ensuring proper fit, holding strength, and preventing material damage.

How do I know what drill bit to use for a screw?

To pick the right drill bit, always match it slightly smaller than the screw’s major diameter. This creates a pilot hole that allows the threads to grip securely without splitting the material. For instance, a #8 wood screw (0.164″) pairs best with a 1/8″ drill bit. Using a screw size chart ensures accuracy, reduces stripping, and gives a professional finish to your project.

What is the difference between coarse and fine screw threads?

Coarse threads have fewer, deeper grooves per inch, making them ideal for wood, drywall, and softer materials where grip strength matters. Fine threads have more, shallower grooves, providing a tighter hold in harder materials like metal or machinery. For example, a #10-24 screw is coarse-thread, while a #10-32 screw is fine-thread. Choosing correctly ensures better performance, reduced wear, and longer-lasting joints in projects.

Why are American screw sizes different from metric sizes?

American screw sizes use the gauge and inch-based system, while metric screws rely on millimeters for diameter and thread pitch. This difference exists because the U.S. predominantly follows the imperial measurement system, whereas most countries use the metric system. Understanding both is important for global projects, automotive repair, or working with imported tools and parts. Conversion charts or screw size charts help avoid confusion.

What size screw is most commonly used in woodworking?

In woodworking, the most popular screw sizes are #6, #8, and #10. The #8 screw is considered the all-purpose size, often used for cabinets, furniture, and general household projects. #6 screws are better for lighter work, while #10 screws handle heavier applications. Choosing the right size helps prevent splitting wood, ensures strong joints, and improves the overall durability of your woodworking project.

How do I read a screw size label like #10-24 x 1-1/2?

A screw labeled #10-24 x 1-1/2 breaks down as follows: “#10” is the gauge size, “24” represents threads per inch (coarse thread), and “1-1/2” is the length in inches. This means it’s a medium-thickness screw with coarse threading, measuring one and a half inches long. Understanding this system helps buyers pick exactly what they need without trial and error at the hardware store.