Anchor bolts are the unsung heroes of construction and structural engineering. While often hidden beneath concrete, they play a critical role in ensuring buildings, bridges, machinery, and other structures remain secure under heavy loads and extreme conditions. Choosing the right anchor bolt size isn’t just about grabbing the largest bolt you can find; it’s about balancing diameter, length, material strength, and installation method to match the demands of your project.

In this guide, we will explore anchor bolt sizes in detail, explain how to select the strongest option for your needs, and share practical tips for installation and common pitfalls to avoid. By the end, you will have a solid understanding of how anchor bolts work, how they are sized, and how to choose the best option for both safety and durability.

What Are Anchor Bolts?

Anchor bolts are threaded fasteners used to attach structures or machinery to concrete or masonry. They differ from standard bolts because one end is embedded into concrete, while the other protrudes above the surface to secure steel plates, wood, or equipment. This anchoring provides structural stability and resistance to shear and tensile forces.

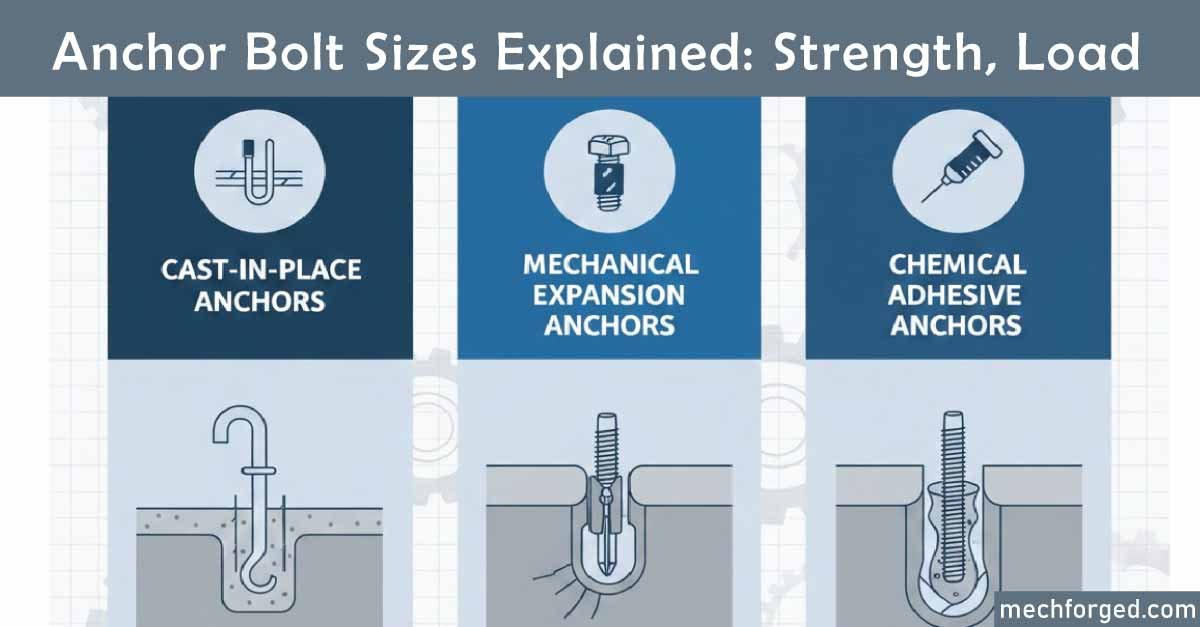

Depending on the project, anchor bolts may be cast into concrete during pouring (cast-in-place) or installed afterward (post-installed) using chemical adhesives or mechanical expansion.

| Type of Anchor Bolt | Installation Method | Common Use |

|---|---|---|

| Cast-in-place | Embedded during concrete pour | Buildings, columns, heavy machinery |

| Mechanical | Expansion or wedge inserted afterward | Retrofitting structures, bridges |

| Chemical | Adhesive-based post-installation | Concrete repair, high-strength attachments |

Why Bolt Size Matters

Anchor bolt size is critical because it directly affects load-bearing capacity. Too small a bolt may fail under stress, while an oversized bolt may be unnecessary and costly. Engineers consider both diameter and length to ensure that the bolt can safely transfer loads from the attached structure into the concrete.

Additionally, proper sizing reduces the risk of concrete cracking and ensures long-term stability. When selecting an anchor bolt, you should consider the type of load it will support—whether it’s vertical weight (tensile load) or horizontal stress (shear load)—as this affects the required dimensions.

| Bolt Size Factor | Importance |

|---|---|

| Diameter | Determines shear and tensile strength |

| Length | Ensures proper embedment in concrete |

| Thread Length | Allows secure attachment of nuts and plates |

| Material | Affects durability and corrosion resistance |

Common Anchor Bolt Sizes

Anchor bolts come in a variety of diameters, lengths, and thread lengths. Standard diameters range from 1/2 inch to over 2 inches, while lengths can vary from a few inches for light-duty applications to several feet for heavy structural elements.

Smaller bolts are typically used for attaching machinery or light fixtures to concrete slabs, whereas larger diameters support columns, steel beams, and heavy equipment. Threaded portions generally extend above the concrete to accommodate washers and nuts, providing secure attachment points.

| Diameter (inches) | Common Lengths (inches) | Typical Use |

|---|---|---|

| 1/2 | 6–12 | Light fixtures, small equipment |

| 5/8 | 8–16 | Medium machinery, structural anchors |

| 3/4 | 12–24 | Heavy machinery, steel columns |

| 1 | 18–36 | Industrial equipment, large structural connections |

| 1-1/4 to 2 | 24–48 | Bridges, high-rise structures |

Material Considerations

Anchor bolts are usually made from carbon steel, stainless steel, or alloy steel. The material affects both strength and corrosion resistance. Carbon steel bolts are strong and cost-effective but may corrode if exposed to moisture. Stainless steel is ideal for outdoor or coastal applications due to its corrosion resistance. Alloy steel offers higher strength for heavy-duty industrial applications. Coatings such as hot-dip galvanizing or epoxy can further enhance durability.

| Material | Strength | Corrosion Resistance | Best Use |

|---|---|---|---|

| Carbon Steel | High | Low | Indoor, dry environments |

| Stainless Steel | Medium | High | Outdoor, coastal areas |

| Alloy Steel | Very High | Medium | Heavy machinery, industrial structures |

| Galvanized Steel | High | High | Exterior applications, wet areas |

Understand Load Capacity

Anchor bolts must withstand two main types of loads: tensile and shear. Tensile load refers to the bolt’s ability to resist being pulled out of concrete, while shear load refers to resistance against lateral forces. Engineers use charts and calculations to determine the minimum bolt size required for a specific load, factoring in concrete strength, bolt material, and embedment depth.

| Bolt Diameter | Tensile Load Capacity (lbs) | Shear Load Capacity (lbs) |

|---|---|---|

| 1/2 inch | 3,000–4,000 | 2,500–3,500 |

| 5/8 inch | 5,000–6,500 | 4,500–5,500 |

| 3/4 inch | 8,000–10,000 | 7,000–9,000 |

| 1 inch | 12,000–16,000 | 10,000–14,000 |

| 1-1/4 inch | 18,000–22,000 | 16,000–20,000 |

Understanding these numbers helps in selecting a bolt that provides a safety margin beyond the expected load.

👉 Get a clear understanding of gas pipe sizing to ensure safe flow, proper pressure, and efficient installation. This guide breaks down diameters, capacity limits, and matching the right pipe to your system. For smoother projects and safer setups, make sure to read the full detailed post!

Cast-in-Place vs. Post-Installed Bolts

Cast-in-place bolts are set during the concrete pour. They allow precise alignment and provide excellent strength because the bolt becomes an integral part of the concrete. Post-installed bolts, on the other hand, are drilled into cured concrete using expansion anchors or chemical adhesives. These are convenient for retrofits but may require careful selection of bolt type and embedment depth to achieve comparable strength.

| Type | Strength | Installation Difficulty | Best Use |

|---|---|---|---|

| Cast-in-place | Very High | Moderate | New construction, structural beams |

| Mechanical Expansion | High | Easy | Retrofitting, medium loads |

| Chemical Adhesive | Very High | Moderate | High-strength retrofits, industrial equipment |

Thread Length and Nut Engagement

The threaded portion of an anchor bolt must be sufficient to engage washers and nuts securely. Short threads may fail to provide adequate clamping force, while excessively long threads can interfere with installations or cause alignment problems.

A general guideline is that the threaded portion should extend at least twice the thickness of the material being clamped. For example, if mounting a steel plate that’s 1 inch thick, a thread length of 2 inches or more is recommended.

Embedment Depth: How Deep Should Bolts Go?

Proper embedment depth ensures that the anchor bolt can transfer loads to the surrounding concrete without pulling out. Deeper embedment increases tensile and shear capacity but may require longer bolts and more precise installation.

For standard concrete (3,000–4,000 psi), embedment depths vary based on bolt diameter. Larger diameters require deeper embedment to distribute stress evenly.

| Bolt Diameter | Recommended Embedment Depth |

|---|---|

| 1/2 inch | 4–5 inches |

| 5/8 inch | 5–6 inches |

| 3/4 inch | 6–8 inches |

| 1 inch | 8–10 inches |

| 1-1/4 inch | 10–12 inches |

👉 Learn how to pick the correct drill bit, tap size, and thread match with this essential tap-and-die drill reference. This guide simplifies thread measurements, drill diameters, and tool selection so your projects stay accurate and smooth. For anyone who wants cleaner threads and fewer mistakes, dive into the full detailed post now!

Common Installation Mistakes

Even experienced installers can make errors when working with anchor bolts. Common mistakes include selecting the wrong diameter, underestimating required embedment depth, overtightening nuts, or using inappropriate materials for the environment.

Other frequent issues involve misalignment during cast-in-place installation, which can complicate attachment of steel plates, and failing to follow manufacturer specifications for post-installed anchors. Always double-check bolt specifications and load requirements before installation.

Practical Tips for Choosing the Strongest Option

When selecting anchor bolts, consider several factors. First, evaluate the load type—shear or tensile—and select a bolt size with an adequate safety margin. Next, match the bolt material to the environment. Stainless steel or coated bolts are ideal for outdoor or corrosive conditions. Third, ensure proper embedment depth, thread length, and alignment to maximize strength.

Some additional tips include lightly lubricating threads during installation for smoother torque application, using calibrated torque wrenches for consistency, and keeping a reference chart of bolt sizes and capacities for quick decision-making. A mini-list of key considerations would be: evaluate load, select diameter, match material, check embedment, and verify alignment.

Comparing Bolt Strengths

Understanding the relative strength of anchor bolts helps in selecting the best option for a project. Larger diameter bolts naturally carry higher loads, but material and installation type also significantly influence strength. For example, a 3/4 inch stainless steel bolt may outperform a 1/2 inch carbon steel bolt in tensile capacity despite smaller diameter due to material properties.

| Bolt Size & Material | Tensile Load (lbs) | Shear Load (lbs) | Recommended Use |

|---|---|---|---|

| 1/2 inch Carbon Steel | 3,500 | 2,800 | Light fixtures |

| 5/8 inch Stainless | 6,000 | 5,000 | Medium machinery |

| 3/4 inch Alloy Steel | 9,500 | 8,000 | Heavy equipment |

| 1 inch Galvanized | 15,000 | 12,000 | Industrial beams |

Tools and Equipment for Installation

Installing anchor bolts correctly requires the right tools. Cast-in-place bolts require careful placement during concrete pouring, while post-installed bolts need drill bits, torque wrenches, and sometimes chemical adhesives. Using the right tools ensures proper torque, alignment, and load transfer.

For large-scale projects, alignment jigs, templates, or laser guides can help ensure multiple bolts are positioned accurately. In addition, torque wrenches help prevent overtightening, which could damage both the bolt and the concrete substrate.

| Tool Type | Best Use |

|---|---|

| Torque Wrench | Ensures correct clamping force |

| Drill with Bit | Post-installed anchors |

| Alignment Jig | Cast-in-place positioning |

| Chemical Dispenser | Adhesive anchors |

Conclusion: Choosing the Right Anchor Bolt

Selecting the right anchor bolt size is essential for structural safety and long-term stability. Diameter, length, material, thread engagement, and embedment depth all contribute to the bolt’s ability to withstand tensile and shear loads. By carefully evaluating the project’s requirements, using reference charts, and following best practices during installation, you can ensure that your anchor bolts perform optimally.

Remember, the strongest option isn’t always the largest bolt—it’s the bolt that fits the load, material, and environmental conditions while being installed correctly. With careful planning, attention to detail, and the tips provided here, you can confidently select anchor bolts that keep your structures secure and durable for years to come.

| Quick Reference: Anchor Bolt Guide | Diameter | Length | Embedment | Material | Load Capacity (lbs) |

|---|---|---|---|---|---|

| Light fixtures | 1/2 inch | 6–12 | 4–5 in | Carbon Steel | 3,500 tensile |

| Medium machinery | 5/8 inch | 8–16 | 5–6 in | Stainless Steel | 6,000 tensile |

| Heavy equipment | 3/4 inch | 12–24 | 6–8 in | Alloy Steel | 9,500 tensile |

| Industrial beams | 1 inch | 18–36 | 8–10 in | Galvanized Steel | 15,000 tensile |

👉 Get a clear overview of I-bolt dimensions, load ratings, and thread sizing with this easy-to-follow reference. This guide helps you understand how different I-bolt measurements impact strength and safety in lifting or anchoring applications. For accurate hardware selection and safer projects, don’t miss the full, detailed post!

FAQs:

What sizes do anchor bolts come in?

Anchor bolts come in a wide range of sizes, typically from 1/4 inch to 1 inch in diameter, and lengths from 4 inches to over 24 inches depending on the project. Larger commercial or structural applications often require thicker, longer anchor bolts for added strength and secure load-bearing capacity.

How to check the size of an anchor bolt?

To check an anchor bolt’s size, measure its diameter using a caliper and its length from the end to the start of the threads. You can also read any markings on the bolt head for grade and size information. Always compare your measurements with a bolt size chart for accuracy.

What size is a M12 anchor bolt?

An M12 anchor bolt has a 12-millimeter diameter and usually comes in lengths ranging from 50 mm to 300 mm or more. “M12” only refers to diameter, so you must check the length and thread type separately. It is commonly used for medium-duty structural and machinery installations.

How to know what anchor size?

Choosing the right anchor size depends on the load requirement, material strength, and thickness of the surface you’re fastening into. A simple rule: the anchor should be equal to or longer than the fastener and thick enough to handle the load. Manufacturer instructions usually provide recommended anchor-to-fastener sizing.

Can you install anchor bolts after concrete is poured?

Yes, you can install anchor bolts after concrete is poured using post-installed anchors like epoxy anchors, wedge anchors, or sleeve anchors. These anchors are drilled into cured concrete and provide strong holding power. Proper drilling depth, cleaning, and manufacturer-specified curing time ensure safe and reliable installation.

How many types of anchor bolts are there?

Anchor bolts come in many types, but the most common include L-shaped bolts, J-bolts, wedge anchors, sleeve anchors, expansion anchors, and epoxy anchors. Each type serves different load and material conditions. Understanding their unique strengths helps you select the right bolt for concrete, masonry, or structural applications.