Angle Iron Size Chart is a vital reference in construction, manufacturing, and even DIY projects. Known for its L-shaped cross-section, angle iron is strong, versatile, and easy to work with. Whether you’re building shelves in your garage, reinforcing a structure, or working on an industrial project, choosing the right size makes all the difference.

This post is a complete guide to angle iron sizes, their applications, and how to read a size chart so you can make the best decision for your project.

What is Angle Iron?

Angle iron, also called L-angle, angle bar, or simply angle steel, is a type of steel section shaped like the letter “L.” It comes in two basic types:

Equal Angle Iron – Both legs (sides) are the same length.

Example: 2″ × 2″ × ¼”

Unequal Angle Iron – One leg is longer than the other.

Example: 3″ × 2″ × ¼”

This L-shape gives it excellent strength-to-weight ratio, allowing it to handle stress and load while staying relatively lightweight. That’s why angle iron is widely used in frames, supports, brackets, and reinforcements.

Why Size Matters in Angle Iron

Choosing the correct size of angle iron is critical because:

Strength and Load Capacity – Larger sizes with thicker legs can carry more load.

Weight Considerations – Bigger sizes mean heavier material, which may not be ideal for lighter applications.

Fit and Design – The right size ensures a clean, professional look.

Cost Efficiency – Oversizing leads to unnecessary cost, while undersizing risks failure.

This is where an angle iron size chart becomes incredibly useful.

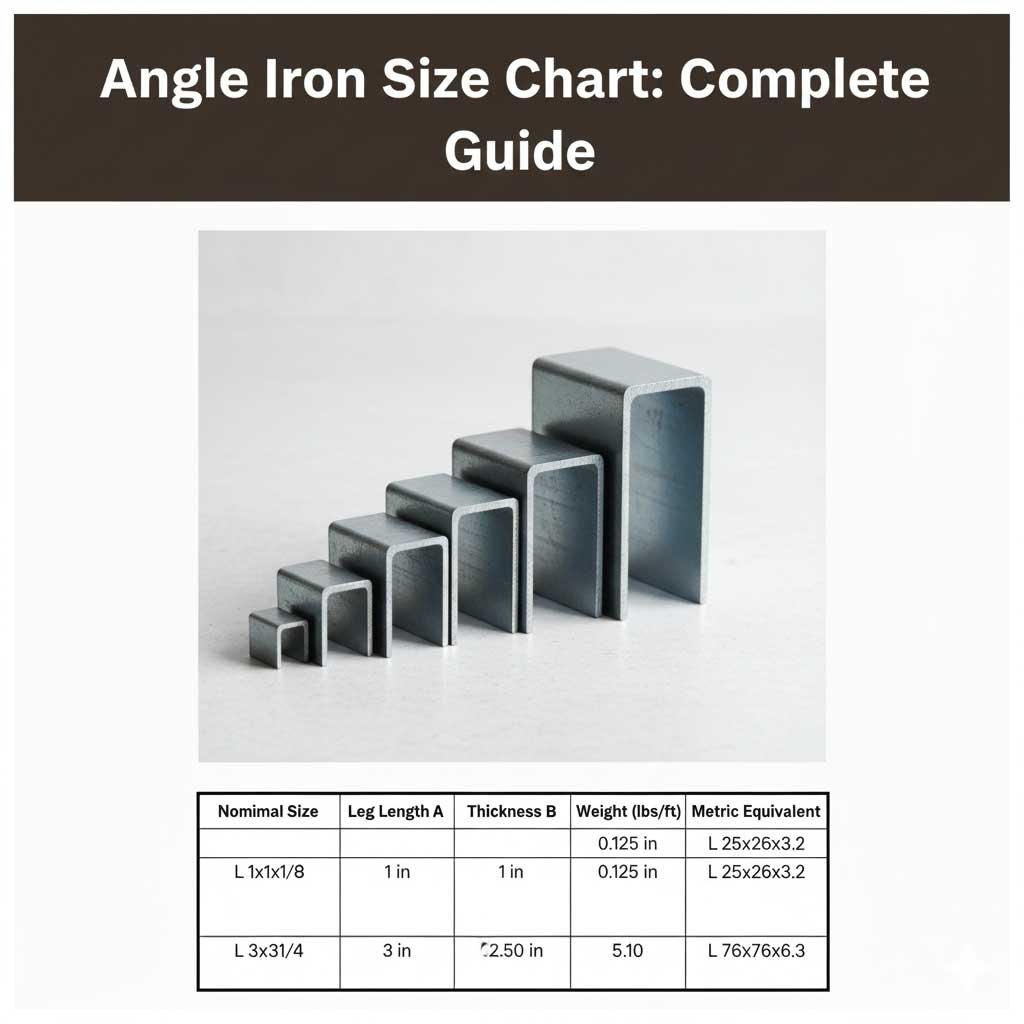

Angle Iron Size Chart

Here’s a simple reference chart showing some of the most commonly used angle iron sizes. Sizes are usually listed in inches (imperial system) or millimeters (metric system). The format is:

Leg 1 × Leg 2 × Thickness

| Size (Inches) | Size (mm) | Thickness (in) | Thickness (mm) | Weight (lbs/ft) | Common Use Case |

|---|---|---|---|---|---|

| 1″ × 1″ × 1/8″ | 25 × 25 | 0.125 | 3.2 | 0.75 | Light brackets, DIY frames |

| 1.5″ × 1.5″ × 3/16″ | 40 × 40 | 0.187 | 4.8 | 1.6 | Shelving, small reinforcements |

| 2″ × 2″ × 1/4″ | 50 × 50 | 0.25 | 6.4 | 2.9 | Medium load supports |

| 3″ × 3″ × 1/4″ | 75 × 75 | 0.25 | 6.4 | 4.3 | Structural reinforcements |

| 4″ × 4″ × 3/8″ | 100 × 100 | 0.375 | 9.5 | 7.1 | Heavy load frameworks |

| 6″ × 6″ × 1/2″ | 150 × 150 | 0.5 | 12.7 | 14.2 | Industrial construction, bridges |

| 8″ × 8″ × 1/2″ | 200 × 200 | 0.5 | 12.7 | 18.8 | High-strength columns, beams |

💡 Note: The weight values are approximate and can vary based on material type (mild steel, stainless steel, aluminum).

Angle Iron Size Chart PDF

The Angle Iron Size Chart provides quick reference for builders, engineers, and DIY enthusiasts. It lists common dimensions, thicknesses, and weights, making material selection easier. Whether you’re working on light brackets, shelves, or heavy-duty construction, this chart ensures you choose the right angle iron size for strength, stability, and cost efficiency.

🌟 Strengthen your knowledge by visiting 👉 Drill Chart: Complete Guide

How to Read the Chart

Let’s break down an example:

2″ × 2″ × ¼”

The first number (2″) is the length of the first leg.

The second number (2″) is the length of the other leg.

The third number (¼”) is the thickness of the angle iron.

So, 2″ × 2″ × ¼” angle iron means both legs are 2 inches long, and the thickness is a quarter inch.

Applications of Different Angle Iron Sizes

1. Small Sizes (1″ × 1″ × 1/8″)

Ideal for DIY projects like shelves, lightweight brackets, and decorative work.

Easy to cut, weld, and drill.

Common in home workshops.

2. Medium Sizes (2″ × 2″ × ¼”)

Strong enough for furniture, door frames, and shelving systems.

Used in automotive repairs and small construction projects.

Provides a good balance of strength and weight.

3. Large Sizes (4″ × 4″ × 3/8″ and up)

Used in bridges, building frames, industrial platforms, and heavy-duty machinery.

Provides maximum stability and load-bearing capacity.

Often used alongside I-beams and channels in construction.

Equal vs Unequal Angle Iron in Applications

Equal Angle Iron: Best for balanced load distribution, where strength is required equally in both directions. Example: support frames, shelves, trusses.

Unequal Angle Iron: Perfect for situations where one direction carries more load than the other. Example: stairways, roof framing, and reinforcements with limited space.

🌟 Strengthen your knowledge by visiting 👉 Metric Drill and Tap Chart: A Complete Guide

Materials Used in Angle Iron

Not all angle irons are made the same. Depending on your project, you can choose from:

Mild Steel – Affordable, easy to weld, suitable for most general construction.

Stainless Steel – Corrosion resistant, ideal for outdoor or marine applications.

Aluminum – Lightweight, easy to handle, used in light-duty and decorative projects.

Galvanized Steel – Coated for rust protection, good for outdoor use.

Tips for Choosing the Right Angle Iron Size

Check Load Requirements – Heavier loads need larger sizes and greater thickness.

Match with Other Materials – Ensure compatibility with beams, bolts, or structures.

Factor in Weight – Lighter applications should avoid oversized sections.

Think About Corrosion Resistance – Outdoor projects may require stainless or galvanized steel.

Cost Efficiency – Don’t overspend on a size larger than your needs.

Angle Iron in Everyday Life

Even if you are not in construction, you’ve probably seen angle iron around you:

The frame of your bed or sofa may use it.

Garage shelves often rely on angle bars.

Bridges and highways use massive angle irons for support.

Farming equipment is reinforced with angle sections.

Its versatility is why angle iron is sometimes called the “Swiss army knife of steel sections.”

🌟 Strengthen your knowledge by visiting 👉 Bolt Size Chart: A Complete Guide

How to Cut and Work with Angle Iron

Working with angle iron is relatively simple:

Cutting: Use a hacksaw for small sizes or an angle grinder for thicker sections.

Drilling: Standard drill bits work fine, but for thicker iron, use cobalt bits.

Welding: Mild steel and stainless angle irons can be welded easily.

Bolting: Angle irons are often bolted together to form frames and supports.

Always wear safety gear like gloves, goggles, and ear protection when working with steel.

Storing and Handling Angle Iron

Keep it dry to avoid rust.

Stack carefully to prevent bending.

Label sizes if you work with multiple types for quick identification.

Angle Iron Sizing Standards Around the World

While most people in the U.S. use the imperial system (inches), many industries globally rely on the metric system. For instance, in Europe and Asia, you’ll often find angle iron listed as 50 × 50 × 6 mm instead of 2″ × 2″ × ¼”. Both mean the same size, just in different units.

Imperial Standard (Inches): Common in North America.

Metric Standard (Millimeters): Common in Europe, Asia, and international engineering.

Knowing both systems can be very useful if you’re working on projects where parts are sourced from different countries. Many manufacturers publish dual charts with both inches and millimeters for convenience.

🌟 Strengthen your knowledge by visiting 👉 Drill Tap Chart: Complete Guide

Sustainability and Angle Iron

Another reason angle iron remains popular is its sustainability. Steel, the primary material, is one of the most recycled materials in the world. In fact, nearly 90% of structural steel used in construction is recycled steel.

This means when you buy angle iron, you’re often working with eco-friendly material that can be reused, melted down, and reshaped without losing its strength. This makes it not only cost-effective but also environmentally responsible.

Real-Life Examples of Angle Iron Use

To make it more practical, let’s look at some real-world scenarios:

Home Projects: A homeowner might use 1.5″ × 1.5″ × 3/16″ angle iron to build a sturdy set of garage shelves that can hold heavy tools.

Farming Equipment: Farmers often rely on 4″ × 4″ × 3/8″ angle iron to reinforce tractor attachments.

Construction: A contractor may select 6″ × 6″ × ½” angle iron for a warehouse frame because of its ability to withstand large loads.

These examples show how choosing the right size is not just a matter of preference but directly tied to performance and safety.

Final Thoughts

Angle iron is one of the most versatile and cost-effective structural materials. Whether you’re a DIY enthusiast making shelves or a builder working on industrial structures, knowing the right size through a proper size chart saves time, money, and ensures safety.

From 1-inch light brackets to 8-inch heavy-duty beams, every project has a suitable angle iron size. Use this guide as a reference the next time you are planning a project, and you’ll be well-prepared to choose the perfect material.

🌟 Strengthen your knowledge by visiting 👉 Screw Size Chart: Complete Guide

Angle Iron Size Chart – Frequently Asked Questions

What is an angle iron size chart?

An angle iron size chart is a reference table that lists available dimensions, thicknesses, and weights of angle irons. It helps engineers, builders, and DIY users pick the right size for strength, load capacity, and design requirements. The chart saves time and ensures accuracy when selecting materials for specific applications.

How do I read angle iron dimensions?

Angle iron dimensions are written as Leg 1 × Leg 2 × Thickness. For example, 2″ × 2″ × ¼” means both legs are 2 inches long, with a thickness of ¼ inch. This format helps users understand the cross-sectional size and choose the correct angle for their project needs.

What is the difference between equal and unequal angle iron?

Equal angle iron has legs of the same length, making it ideal for balanced load distribution. Unequal angle iron has one longer leg, suitable for applications where space is limited or one side bears more load. Choosing between them depends on structural requirements and the type of stress the material must handle.

Which angle iron size is best for DIY projects?

For small DIY tasks, lighter sections like 1″ × 1″ × ⅛” or 1.5″ × 1.5″ × 3/16″ work best. They are easy to cut, drill, and weld while offering enough strength for shelves, brackets, or small frames. These sizes provide a balance of strength and workability without adding unnecessary weight.

What size angle iron is used in construction?

In construction, larger sizes such as 4″ × 4″ × 3/8″ or 6″ × 6″ × ½” are common. These heavier sections provide high load capacity and structural stability, making them suitable for frameworks, columns, bridges, and industrial buildings. Engineers select sizes based on load calculations, safety standards, and specific project requirements.

How do thickness and weight affect angle iron performance?

Thicker and heavier angle irons provide greater load-bearing strength but are harder to handle and cost more. Thin sections are lightweight and easier to work with but may not withstand heavy loads. The key is choosing the right balance: sufficient thickness for safety without overspending on unnecessary strength or weight.

Can angle iron sizes vary by country?

Yes, angle iron sizes may differ between countries because of measurement systems. In the U.S., dimensions are usually in inches, while Europe and Asia use millimeters. A 2″ × 2″ × ¼” section in imperial units equals about 50 × 50 × 6 mm in metric. Charts often include both systems for clarity.