If you are planning to invest in a CNC router machine, it’s important to understand what you’re buying. CNC routers have transformed the way we work with materials like wood, plastic, and metal. From hobbyists to industrial manufacturers, CNC routers offer precision, automation, and versatility. But with so many models, features, and price ranges available, how do you pick the right one? In this detailed CNC router machines buying guide, we will break down everything you need to know before making a purchase.

What is a CNC Router Machine?

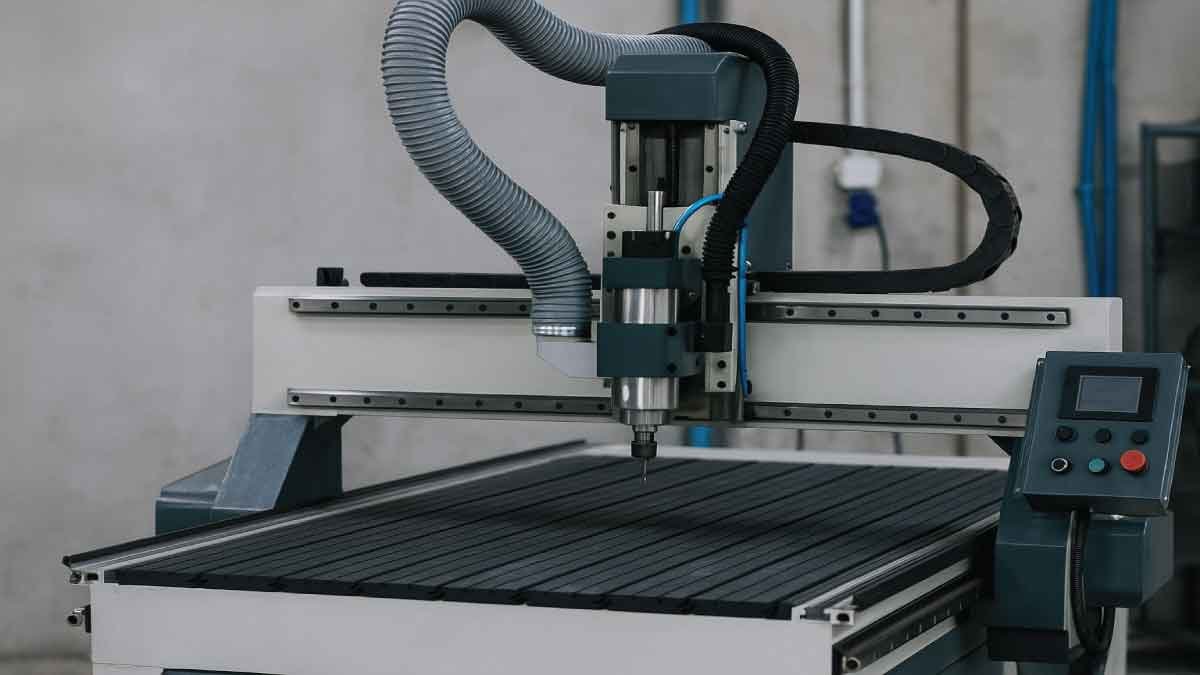

A CNC (Computer Numerical Control) router is a computer-controlled cutting machine used for cutting, carving, and engraving a variety of materials. It operates based on coded instructions, allowing for accurate and repeatable cuts.

CNC routers are commonly used in woodworking, signage, furniture making, and even in metal and plastic fabrication. Whether you’re a hobbyist looking to upgrade your workshop or a business aiming to improve production, a CNC router can be a game-changer.

Why You Need a Buying Guide

Purchasing a CNC router is a significant investment, and making the wrong choice can lead to frustration and wasted money. This guide will help you:

- Understand the different CNC router machine types

- Learn how to choose a CNC router that fits your needs

- Compare CNC router machine prices and features

- Identify what to look for in terms of software compatibility, spindle options, and more

Let’s get started.

👉 Want to become a CNC expert? Read our complete guide: CNC Machining 101: Beginner-to-Expert Guide to explore everything from basic principles to advanced CNC techniques and boost your real-world skills.

Types of CNC Router Machines

CNC router machines come in several types, each designed to meet different user needs and project requirements. Whether you’re a hobbyist or an industrial manufacturer, understanding the types of CNC routers available helps you choose the right machine for your applications.

1. Desktop CNC Routers

Desktop CNC routers are small, lightweight machines perfect for hobbyists, students, and small businesses. They’re ideal for working on wood, plastic, and other soft materials. With a compact footprint and affordable pricing, these routers are excellent for light-duty projects like signs, engravings, and prototypes. Great for learning and experimentation.

2. Mid-Size CNC Routers

Mid-size CNC routers offer a balance between capability and cost. These machines are commonly used in small workshops, schools, and growing manufacturing operations. They provide a larger work area and more powerful spindles than desktop models, making them suitable for furniture production, cabinetry, and other moderate-scale cutting tasks.

3. Industrial CNC Routers

Industrial CNC routers are high-performance machines built for heavy-duty and continuous use. They can process a wide range of materials including hardwoods, plastics, composites, and even metals. Found in large factories, they feature robust construction, powerful motors, and automation options. These machines are ideal for high-volume production environments.

4. 3-Axis vs. 4-Axis vs. 5-Axis CNC Routers

CNC routers are classified by their number of axes, which impacts movement and complexity.

3-axis machines cut in three linear directions.

4-axis routers add rotation around one axis.

5-axis routers allow multi-directional movement, enabling intricate, detailed work.

More axes mean greater flexibility but also increased cost and complexity.

Key Features to Consider Before Buying a CNC Router

When selecting a CNC router, it’s crucial to evaluate specific features that match your project needs, workspace, and skill level. Below are the key aspects you should carefully assess before making a purchase:

1. Working Area Size

The working area refers to the maximum dimensions of material the router can handle. If you regularly work on large panels or sheets, a larger working area is necessary. However, keep in mind that bigger machines require more space. Match the router size with your typical project requirements and workspace limitations.

2. Spindle Options

The spindle is the heart of your CNC router. It determines how fast and how deeply the machine can cut into different materials. Spindles vary by power, measured in horsepower (HP) or kilowatts (kW), and by cooling type—air or water. Choose based on your material type and workload frequency.

3. Software Compatibility

A CNC router is only as good as the software it runs on. Ensure the machine supports popular and user-friendly CAD/CAM software like Fusion 360, VCarve, or Mach3. Proper software compatibility ensures efficient design translation, precise cutting instructions, and a smoother learning curve for both beginners and professionals.

4. Frame Material

A CNC router’s frame significantly affects its durability and cutting accuracy. Steel and aluminum frames are common; they offer strong structural integrity and help reduce vibration during operation. A stable frame leads to cleaner cuts and less wear on components. Always check for rigidity when evaluating build quality.

5. Control System

The control system is how you operate and program your CNC router. Beginner-friendly interfaces are ideal for new users, while advanced systems offer more features for experienced operators. Look for systems that support manual, USB, and PC control options. A good control system enhances usability and reduces setup time.

6. Dust Collection

CNC routers generate a lot of dust and debris, especially when cutting wood. A built-in or attachable dust collection system keeps your workspace cleaner and safer. It also protects internal machine components from clogging or damage. Efficient dust collection is essential for maintaining air quality and machine longevity.

7. Drive System

The drive system moves the cutting head across the material. Ball screw systems offer high precision and are ideal for detailed work, though they’re typically more expensive. Rack-and-pinion drives are more affordable and better for larger machines but may sacrifice some accuracy. Choose based on your project needs and budget.

Best CNC Router for Beginners

If you’re just getting started, look for models that are:

- Easy to assemble

- User-friendly

- Well-supported by online communities and tutorials

- Equipped with basic features without being overly complex

Brands like BobsCNC, Genmitsu, and FoxAlien offer great entry-level options. These machines often appear in searches for the best CNC router for beginners.

CNC Router Machine Price Comparison

Prices for CNC routers vary widely:

- Desktop models: $300 to $1,500

- Mid-size machines: $2,000 to $10,000

- Industrial CNC routers: $10,000 to over $100,000

When doing a CNC router machine price comparison, remember to factor in the cost of:

- Software

- Tool bits

- Replacement parts

- Maintenance

Sometimes spending a little more upfront saves a lot in the long run.

CNC Router for Woodworking

One of the most popular applications of CNC routers is in woodworking. A CNC router for woodworking can create intricate designs, signs, furniture, and cabinetry. Look for features such as:

- High-speed spindles for clean cuts

- Vacuum tables for holding wood sheets in place

- Compatibility with woodworking design software

Whether you’re making signs, cabinets, or art, a CNC router can take your woodworking to the next level.

Industrial CNC Router vs. Hobby CNC Router

Understanding the differences between industrial and hobby CNC routers is crucial for selecting the right machine. Each type is designed for specific users, workloads, and environments.

Industrial CNC Router

Industrial CNC routers are built for durability, precision, and high-volume production. They feature powerful motors, large work tables, and robust construction to handle heavy-duty tasks. These machines are designed to run continuously in demanding environments like manufacturing facilities. They’re ideal for cutting metals, plastics, hardwoods, and composites with extreme accuracy and speed.

Hobby CNC Router

Hobby CNC routers are compact, affordable, and user-friendly machines. They’re perfect for beginners, DIYers, and small business owners working on wood, foam, or plastic projects. These routers are best suited for light-duty tasks and creative applications like custom signs, model-making, and engraving. They offer a cost-effective way to start CNC machining.

Which One Should You Choose?

Your choice depends on your project size, material types, and production goals. For occasional use or small-scale crafting, a hobby CNC router offers excellent value. If you’re running a business with high output or need precision across tough materials, an industrial CNC router is the smarter long-term investment.

Desktop CNC Router Buying Tips

Here are some quick tips when considering a desktop CNC router:

- Prioritize build quality over flashy features

- Make sure the machine comes with support or a warranty

- Check for active user forums or community groups

- Ensure it has all necessary accessories like bits and clamps

A good desktop router is often the first step toward mastering CNC work.

CNC Router Maintenance Checklist

Keeping your machine in top shape ensures longevity and performance. Here’s a simple CNC router maintenance checklist:

- Clean the machine daily

- Lubricate moving parts weekly

- Check spindle runout regularly

- Inspect belts and gears monthly

- Update firmware and software

Regular maintenance can prevent major issues and save on repair costs.

Top Features in CNC Router Machines

Some of the top features in CNC router machines include:

- Auto tool changers

- Vacuum tables

- Enclosures for noise and dust

- Touch screen controllers

- Wi-Fi connectivity

While not all are necessary for beginners, they can be useful as your needs grow.

Pros and Cons of CNC Routers

Understanding the pros and cons of CNC routers can help you make a better decision:

Pros:

- High precision and repeatability

- Saves time and labor

- Versatile across materials

- Customization options

Cons:

- Initial cost can be high

- Learning curve for software and operation

- Maintenance requirements

CNC Router Machine for Metal and Plastic

Not all CNC routers are suitable for hard materials. If you plan to work with metals or plastics, choose a CNC router machine for metal and plastic with:

- A high-torque spindle

- Rigid frame

- Appropriate bits and cooling systems

Many industrial-grade routers can easily handle aluminum, acrylic, and even brass.

Affordable CNC Router Machines for Small Business

Small businesses often seek affordable CNC router machines for small business needs. Look for:

- Machines under $5,000

- Reliable customer support

- Expandability and upgradability

Brands like Shapeoko and Onefinity offer machines tailored for small businesses. They balance cost and performance, making them ideal for startups.

Final Thoughts

Choosing the right CNC router machine depends on your budget, material, and project needs. Whether you’re a beginner exploring the best CNC router for beginners or a business owner comparing CNC router machine prices, this guide gives you the tools to make an informed decision.

By considering factors like spindle options, software compatibility, maintenance, and whether you need a desktop CNC router or an industrial CNC router, you can select the perfect machine for your workshop or factory floor.

Invest wisely, and your CNC router will serve you for years to come.

Tags: CNC router machines, CNC router buying guide, CNC for beginners, woodworking CNC, affordable CNC routers

FAQs:

What is a CNC router machine used for?

A CNC router machine is used for cutting, carving, engraving, and shaping various materials like wood, plastic, metal, and foam. It’s widely used in woodworking, sign-making, furniture design, and even metal fabrication. The machine uses computer-controlled movements to create precise and repeatable designs, making it ideal for both custom and production work.

How do I choose the right CNC router?

To choose the right CNC router, consider your project size, material type, budget, and experience level. Beginners may benefit from desktop models, while businesses might need industrial-grade machines. Check for software compatibility, spindle power, and available features. Always balance quality with price and ensure good support from the manufacturer.

What is the best CNC router for beginners?

The best CNC router for beginners is usually a desktop model that’s easy to set up and operate. Brands like Genmitsu, BobsCNC, and FoxAlien offer user-friendly options. Look for one with good online tutorials, active community support, and simple control software to help you learn quickly and efficiently.

How much does a CNC router machine cost?

CNC router machines range in price from $300 for entry-level desktop models to over $100,000 for industrial machines. Mid-range options for small businesses usually fall between $2,000 and $10,000. Pricing depends on size, spindle power, software, and additional features like auto tool changers or vacuum tables.

Can a CNC router cut metal?

Yes, some CNC routers can cut metal, especially softer types like aluminum or brass. You’ll need a rigid machine with a powerful spindle and proper bits. It’s also important to use coolant or lubrication to prevent overheating. Not all routers can handle metal, so check specs before buying.

What software is used for CNC routers?

Popular software for CNC routers includes VCarve, Fusion 360, Easel, and Mach3. These programs help you design your project and convert it into code the machine understands. Make sure the CNC router you choose is compatible with your preferred software to ensure smooth and accurate operation.

Do CNC routers require a lot of maintenance?

CNC routers need regular but manageable maintenance. You should clean dust and debris daily, lubricate moving parts weekly, and check belts, gears, and spindles monthly. Staying consistent with upkeep helps your machine last longer and perform better, avoiding costly repairs or downtime in the future.

What materials can a CNC router cut?

CNC routers can cut a wide range of materials including wood, plywood, MDF, acrylic, plastic, aluminum, brass, and foam. The type of material depends on the router’s spindle power and bit quality. Always ensure your machine is rated to handle the specific material you plan to work with.

Is a CNC router worth it for small businesses?

Absolutely. CNC routers can improve precision, save time, and boost productivity, making them a smart investment for small businesses. With affordable options now available, even startups can benefit. Whether you’re crafting custom furniture, signage, or prototypes, a CNC router can give you a competitive edge.

What’s the difference between a CNC router and a laser cutter?

A CNC router uses a spinning bit to cut or carve materials, while a laser cutter uses a high-powered laser beam to cut or engrave. CNC routers are better for thick materials and 3D shaping, whereas laser cutters excel at precision engraving and cutting thin materials like acrylic and wood sheets.