Starting a manufacturing business can be a game-changer for small entrepreneurs. However, choosing the right manufacturing process is crucial for efficiency, cost-effectiveness, and product quality. With the right strategies, small businesses can compete with larger companies, optimize costs, and deliver high-quality products to customers.

In this guide, we will explore the best manufacturing processes for small businesses and how to optimize them for long-term success.

1. Batch Production: Ideal for Small-Scale Manufacturing

Batch production involves producing a set quantity of products at a time rather than in continuous production. It is particularly beneficial for businesses that deal with seasonal or custom products. This method allows manufacturers to create products in limited runs, adjust designs in between batches, and reduce excessive inventory costs.

Advantages:

- Reduces waste by producing only what’s needed

- Allows for flexibility in design and materials

- Cost-effective for small production runs

- Better quality control as each batch can be reviewed before the next one starts

One of the best examples of batch production is pencil manufacturing. This process ensures that each batch of pencils meets industry standards before moving on to mass production. If you’re interested in learning more, check out this Manufacturing Process of a Pencil: From Wood to Writing Tool.

2. 3D Printing: The Future of Small Business Manufacturing

3D printing, also known as additive manufacturing, is revolutionizing small-scale production. This process involves creating products by layering materials rather than cutting from larger blocks. The ability to produce custom designs, rapid prototypes, and small-batch products makes 3D printing one of the most cost-effective and innovative methods for small businesses.

Benefits:

- Low startup costs compared to traditional manufacturing

- Ideal for prototyping and product customization

- Reduces material waste, making it a sustainable option

- Quick production turnaround, which means businesses can create products on demand

Many small businesses, from jewelry makers to custom tool manufacturers, have adopted 3D printing to reduce production costs and create unique designs. With advancements in materials, even mechanical pencil components can be made using 3D printing, offering a competitive edge. Learn more about Manufacturing Process of a Mechanical Pencil: A Step-by-Step Guide.

3. Lean Manufacturing: Maximizing Efficiency

Lean manufacturing is a production method focused on eliminating waste, improving efficiency, and maximizing productivity while maintaining high-quality standards. This strategy allows businesses to operate with minimal overhead and maximize profits.

Key Principles of Lean Manufacturing:

- Just-in-time production: Manufacturing only what is needed, when it is needed

- Continuous improvement: Regularly evaluating and optimizing processes

- Minimized waste: Using raw materials efficiently and reducing excess inventory

- Streamlined workflow: Reducing unnecessary steps to improve production speed

For small businesses, lean manufacturing can be a game-changer. Whether you are producing furniture, electronic gadgets, or even mechanical pencils, streamlining your process will save money and improve customer satisfaction. Companies that follow lean principles can reduce production costs while maintaining high product quality.

4. Sustainable Manufacturing: A Smart Choice for Small Businesses

With increasing environmental concerns, small businesses can benefit from sustainable manufacturing practices. Sustainability in manufacturing refers to the efficient use of natural resources, energy-efficient production, and reduced carbon footprints.

Strategies for Sustainability:

- Using eco-friendly materials like biodegradable plastics and recycled metals

- Energy-efficient production with solar or wind power

- Waste reduction through lean principles and smart resource management

- Water conservation by using closed-loop water recycling systems

Many companies are now transitioning to sustainable production models to align with global environmental regulations and consumer preferences. As sustainability becomes a bigger factor in consumer choices, manufacturers integrating eco-friendly methods will gain a significant advantage.

To gain a deeper understanding of sustainable manufacturing, check out this Complete Guide to Integrating Sustainability in Manufacturing.

5. Outsourcing Manufacturing: A Cost-Saving Strategy for Small Businesses

For small businesses looking to minimize investment in production facilities, outsourcing manufacturing can be a great option. Instead of setting up expensive factories, small businesses can collaborate with established manufacturers to produce their products at scale.

Benefits of Outsourcing:

- Lower production costs by avoiding large capital investments

- Access to specialized expertise from experienced manufacturers

- Flexibility to scale production based on demand

- Focus on business growth by reducing time spent on operations

Many businesses, especially in electronics, fashion, and household products, leverage outsourcing to reduce operational costs and expand their product lines quickly.

6. Automation: Enhancing Efficiency with Technology

Automation is transforming the manufacturing industry, allowing businesses to increase productivity while reducing manual labor costs. Robotics, AI-driven production lines, and automated quality control systems are making it easier for small businesses to compete with larger manufacturers.

Key Benefits of Automation:

- Increased production speed with minimal human intervention

- Improved product consistency and reduced errors

- Lower long-term costs by reducing labor expenses

- Better safety standards with fewer human-related accidents

Small businesses investing in automated solutions can significantly improve efficiency and maintain a competitive edge in their industry.

Conclusion

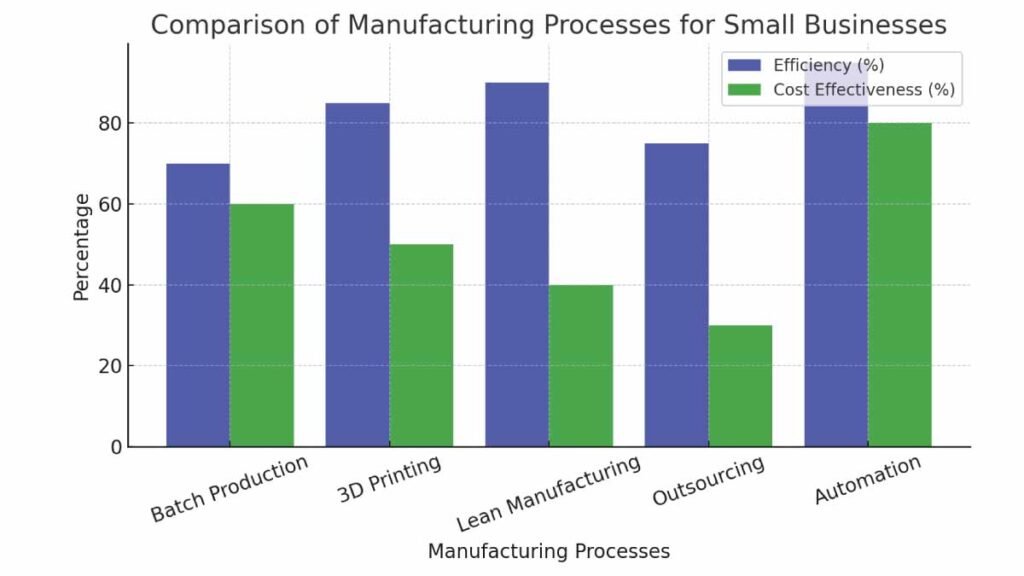

Choosing the right manufacturing process is critical for small businesses to thrive. Whether it’s batch production, 3D printing, lean manufacturing, sustainable practices, outsourcing, or automation, small businesses can find solutions that fit their budget and long-term goals.

By implementing these strategies, small manufacturers can reduce costs, increase efficiency, and create high-quality products while maintaining competitiveness in an evolving market.

As industries continue to evolve, embracing modern manufacturing processes will help small businesses scale and succeed in today’s economy.