Chainsaws are essential tools for homeowners, landscapers, and forestry professionals. However, choosing the right chainsaw chain size is crucial for safety, efficiency, and optimal performance. Many people overlook the importance of the correct chain, often leading to poor cutting performance or even accidents. In this guide, we will dive deep into everything you need to know about chainsaw chain sizes, including measurement methods, types of chains, maintenance tips, and more.

Why Chainsaw Chain Size Matters

Imagine you are trying to cut a large tree for your backyard firewood. You pick up your chainsaw, start it, and immediately notice that it’s struggling. The cut is uneven, and you have to push harder than usual. This is often caused by using the wrong chainsaw chain size. The correct chain size ensures smooth cutting, prevents damage to the saw, and reduces the risk of kickback or injury.

Chainsaw chains are not universal. Each chainsaw model is designed to work with a specific chain length, gauge, and pitch. Using the wrong chain can reduce cutting efficiency, increase wear and tear, and even void your warranty.

How Choosing the Right Chain Saved a Day

Last winter, my neighbor faced a big problem when a tree had fallen across his driveway. He borrowed a chainsaw from a friend, eager to clear the debris quickly, but he skipped one crucial step: checking the chain size. As he started cutting, the chainsaw worked for a few minutes before the chain suddenly slipped off the bar and jammed. We tried to fix it immediately, but it took hours to remove the jam, adjust the tension, and get the saw running again.

After several attempts, we realized the chain didn’t match the bar properly, and the only solution was to replace it with the correct size. That simple oversight had turned a task that should have taken an hour into a frustrating half-day project.

This experience was a valuable lesson: always confirm your chainsaw’s chain size before starting any cutting job. It may seem minor, but using the right chain ensures smooth operation, prevents damage to the saw, and saves both time and money. From that day on, my neighbor never skips checking chain size, and his chainsaw jobs have been safer and more efficient ever since.

Chainsaw Chain Size Basics

Choosing the correct chainsaw chain is crucial for both safety and performance. Using the wrong chain can cause poor cutting, excessive wear, or even damage to your chainsaw. To select the right chain, you need to understand three key measurements that define its size and compatibility.

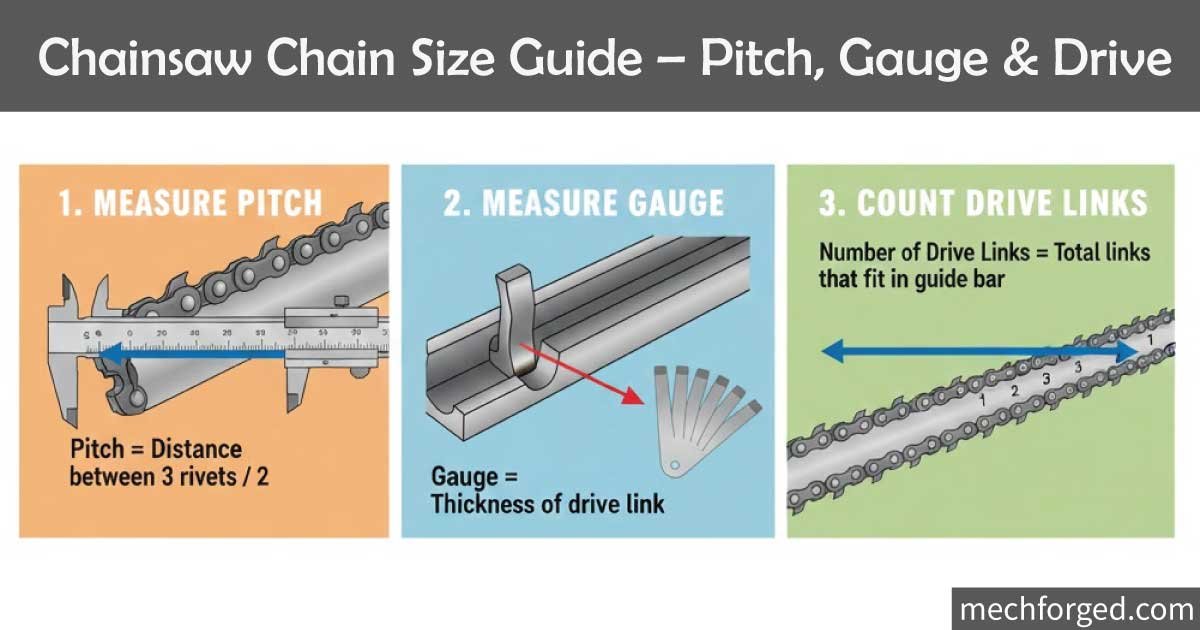

Chain Pitch – This is the distance between three consecutive rivets divided by two. The pitch affects how the chain fits the sprocket and the smoothness of the cut. Chains with the wrong pitch can slip or bind, making cutting inefficient and potentially dangerous.

Gauge – The gauge refers to the width of the chain’s drive links that slide into the guide bar. Choosing the correct gauge ensures that the chain sits securely in the bar groove, preventing wobbling or derailment during operation.

Number of Drive Links – This determines the chain’s overall length. A chain with too few or too many links won’t fit properly, causing tension issues or incomplete coverage of the bar.

Understanding these three factors guarantees that your chainsaw operates efficiently, safely, and with minimal wear on both the bar and chain. Always double-check these measurements before purchasing a new chain.

Common Chainsaw Chain Sizes

Choosing the right chainsaw chain ensures safe and efficient cutting. Chains differ in pitch, gauge, and bar length, which determine compatibility and performance. The following table highlights the most common chain sizes, their typical bar lengths, and the types of chainsaws or tasks they are best suited for.

| Chain Pitch | Gauge | Typical Bar Length | Usage |

|---|---|---|---|

| 1/4″ | .043″ | 12″ – 14″ | Small chainsaws, hobby use |

| .325″ | .050″ | 14″ – 18″ | Mid-range chainsaws, yard work |

| 3/8″ | .050″ | 16″ – 20″ | Standard homeowner chainsaws |

| 3/8″ | .058″ | 18″ – 24″ | Heavy-duty chainsaws, professional use |

| .404″ | .063″ | 20″ – 36″ | Commercial logging, large trees |

How to Measure Your Chainsaw Chain

Measuring your chainsaw chain correctly is essential for safety, efficiency, and proper cutting performance. Using the wrong chain size can lead to poor cutting, excessive wear, or even damage to your chainsaw. By checking the pitch, gauge, and number of drive links, you can ensure the perfect fit for your bar and motor.

1. Check the Pitch

The pitch of a chainsaw chain refers to the distance between three consecutive rivets divided by two. It affects how the chain engages with the sprocket and ensures smooth operation. Common pitches include 1/4″, .325″, 3/8″, and .404″. Always measure carefully, as the wrong pitch can cause slipping or uneven cuts.

2. Measure the Gauge

The gauge is the width of the drive link that fits into the guide bar. It ensures the chain sits snugly in the bar groove for stable cutting. Common gauges are .043″, .050″, .058″, and .063″. Using the wrong gauge may lead to the chain binding, slipping, or wearing out prematurely.

3. Count the Drive Links

The total number of drive links determines the overall chain length and ensures it fits the bar correctly. Most chainsaw manuals list compatible chains by the number of drive links. For example, a 16-inch bar typically requires 66 drive links. Counting carefully avoids tension problems and ensures smooth, efficient cutting.

Signs You Need a New Chainsaw Chain

Recognizing when your chainsaw chain needs replacement is crucial for safety and performance. Worn or damaged chains reduce cutting efficiency and increase the risk of accidents. Look out for these common signs to know when it’s time for a new chain.

Dull or chipped teeth

Difficulty cutting through wood

Increased vibration during operation

Chain skipping or jumping off the bar

Replacing a worn-out chain improves cutting performance, prevents damage to the saw, and ensures safety.

Types of Chainsaw Chains

Choosing the right chainsaw chain is just as important as picking the correct size. Chains come in different types, each designed for specific tasks, wood conditions, and skill levels. Understanding the differences ensures efficient cutting, longer chain life, and safer operation.

1. Full-Chisel Chains

Full-chisel chains are built for fast and aggressive cutting, especially in softwood. Their square-cornered teeth remove large wood chips quickly, making them ideal for professional loggers or heavy-duty tasks. While they cut efficiently, they require regular maintenance and sharpening to prevent dulling, especially when used in dirty or abrasive conditions.

2. Semi-Chisel Chains

Semi-chisel chains have rounded teeth, which allow them to stay sharp longer under tough conditions. They are excellent for cutting dirty, frozen, or knotty wood and are more forgiving for general-purpose use. This makes them a popular choice for homeowners and casual users who need reliable performance with less frequent sharpening.

3. Low-Profile Chains

Low-profile chains are designed for safety and ease of control, typically found on small, consumer-grade chainsaws. They feature reduced kickback and smoother operation, making them perfect for beginners or light-duty tasks. While not as fast as full- or semi-chisel chains, they are easier to handle and safer for inexperienced users.

Table: Chain Types and Best Uses

| Chain Type | Tooth Shape | Best For | Maintenance |

|---|---|---|---|

| Full-Chisel | Square | Fast cutting, softwood | Sharpen frequently |

| Semi-Chisel | Rounded | Hardwood, dirty wood | Sharpen moderately |

| Low-Profile | Rounded, smaller | Beginners, light duty | Minimal |

👉 Band Saw Blade Size Chart: Comprehensive Guide gives you a clear breakdown of blade sizes, widths, lengths, and tooth configurations for different cutting needs. Discover how choosing the right blade improves accuracy, efficiency, and tool life. Explore the full post to access detailed charts, practical tips, and expert recommendations.

Choose the Right Chain for Your Chainsaw

Selecting the right chainsaw chain is essential for efficient cutting, safety, and longer chain life. A mismatched chain can cause poor performance, increased wear, or accidents. Consider the following factors carefully to ensure your chain suits both your saw and the type of work you plan to do.

1. Bar Length Compatibility

The chain must match the length of your chainsaw bar exactly. Using a chain that is too short or too long can cause tension issues, uneven cuts, and potential damage to both the bar and motor. Always check the manufacturer’s guide or measure the bar before purchasing a new chain.

2. Cutting Purpose

Different chains are designed for specific types of wood. Full-chisel chains work best for softwood and fast cutting, while semi-chisel chains handle hardwood and frozen timber effectively. Choosing a chain suited for your cutting task improves efficiency, reduces wear, and ensures cleaner, safer cuts.

3. Frequency of Use

How often you use your chainsaw influences chain choice. Professionals who cut daily may prefer durable, easy-to-sharpen chains, while occasional users can opt for low-maintenance chains that last longer without frequent sharpening. Matching chain durability to usage frequency prevents premature wear and enhances safety.

4. Local Wood Conditions

The environment matters. Cutting dirty, frozen, or abrasive wood requires semi-chisel or low-profile chains, which resist dulling and maintain performance. Softwood in clean conditions can use full-chisel chains for fast cutting. Understanding local conditions ensures your chain remains efficient and safe over time.

Maintaining Your Chainsaw Chain

A well-maintained chainsaw chain not only lasts longer but also ensures cleaner cuts and safer operation. Neglecting maintenance can lead to inefficient cutting, increased wear, and even accidents. By following these essential tips, you can maximize your chain’s performance and extend the life of both the chain and your chainsaw.

1. Regular Sharpening

Sharpening your chainsaw chain regularly is crucial for smooth and efficient cutting. Use a properly sized round file and maintain the correct angle for each tooth. A dull chain requires more effort, generates excessive heat, and increases the risk of kickback. Regular sharpening keeps the chain cutting safely and effectively.

2. Proper Lubrication

Chainsaw chains need constant lubrication to reduce friction and prevent overheating. Always use high-quality bar and chain oil before and during operation. Adequate lubrication prevents premature wear on both the chain and guide bar, ensuring smoother performance and reducing the risk of chain breakage or motor strain.

3. Correct Tension

Maintaining the right chain tension is essential for safety and efficiency. A properly tensioned chain should snap back when pulled away from the bar but should not sag. Loose chains can derail or cause uneven cuts, while overly tight chains increase friction and wear. Always check tension before each use.

4. Clean After Use

After every use, clean your chainsaw to remove sawdust, resin, and debris. This prevents corrosion, buildup, and unnecessary wear on both the chain and the bar. Using a brush or compressed air ensures that all parts remain free of debris, keeping the chainsaw ready for the next cutting task.

👉 M Key Size Chart: Complete Guide for Beginners explains standard M key sizes, measurements, and common applications in a simple, beginner-friendly way. Learn how to identify the correct size quickly and avoid fitting errors in mechanical work. Read the full guide for clear charts, practical examples, and helpful tips.

Safety Considerations

Safety should always be your top priority when operating a chainsaw. Using the correct chain size not only improves cutting efficiency but also prevents accidents and protects both the operator and the tool. Awareness of common risks and proper precautions is essential for every chainsaw user.

1. Kickback Accidents

Kickback occurs when the tip of the chainsaw bar contacts an object, causing the saw to jerk back suddenly. Using the wrong chain size or a dull chain increases the likelihood of kickback. Always maintain proper chain tension and sharpness, and hold the saw firmly to minimize the risk of injury.

2. Chain Breakage

Chains that do not match the bar or are worn out are prone to breaking under pressure. A broken chain can fly off at high speed, posing a serious safety hazard. Regular inspections, proper tensioning, and using the correct chain type prevent chain breakage and ensure safer operation.

3. Bar Damage

Incorrect or mismatched chains can damage the guide bar, leading to uneven cuts or expensive repairs. Bars may warp, wear unevenly, or develop grooves if the chain is too loose, too tight, or incompatible. Ensuring the chain fits properly protects your equipment and maintains cutting accuracy.

4. Protective Gear

No chainsaw task should be attempted without proper safety gear. Always wear gloves, chainsaw chaps, safety glasses, ear protection, and sturdy footwear. Protective equipment reduces the risk of injury from kickback, flying debris, and accidental contact with the chain. Safety and preparation go hand in hand.

Tips for Buying Chainsaw Chains Online

Buying chainsaw chains online can save time and money, but it requires careful attention to ensure you get the right fit and quality. By considering key factors such as compatibility, specifications, and user feedback, you can make an informed purchase and avoid costly mistakes.

1. Check Brand Compatibility

Not all chains are compatible with every chainsaw. Always confirm that the chain brand and model match your chainsaw’s make and specifications. Using an incompatible chain can lead to poor cutting performance, excessive wear, or even damage to your saw, so double-check the manufacturer’s guidelines before purchasing.

2. Verify Pitch, Gauge, and Drive Links

Before ordering, carefully check the pitch, gauge, and number of drive links to ensure proper fit. These measurements determine how the chain fits on your bar and sprocket. A mismatch can cause chain derailment, uneven cuts, and potential safety hazards. Accurate measurements are essential.

3. Read Customer Reviews

Customer reviews provide valuable insights into a chain’s durability, cutting performance, and reliability. Look for feedback on how the chain performs over time, its sharpening needs, and how well it handles different types of wood. Honest reviews help you choose high-quality chains from trusted sellers.

4. Consider Buying Replacement Chains in Packs

Purchasing chains in packs can save money and ensure you always have a replacement ready. Frequent chainsaw users benefit from having spares on hand to avoid downtime during projects. Just ensure all chains in the pack match your chainsaw’s specifications for pitch, gauge, and drive links.

👉 Exhaust Pipe Size Chart: Complete Guide helps you understand different pipe diameters, measurements, and their impact on engine performance and sound. Learn how choosing the correct size improves airflow, efficiency, and overall vehicle performance. Read the full post to explore detailed charts, expert insights, and practical selection tips.

Common Chainsaw Chain Problems

Even the best chainsaw chains can encounter problems over time. Recognizing and addressing these issues early helps maintain cutting efficiency, safety, and chain longevity. Regular inspections and proper maintenance are key to avoiding costly repairs and keeping your chainsaw performing at its best.

1. Chain Stretching

Chains naturally stretch with use, especially after heavy cutting sessions. A stretched chain may sag or derail, reducing cutting efficiency and increasing wear on the guide bar. Regularly check chain tension and adjust as needed. Replacing severely stretched chains prevents uneven cuts and ensures safe operation.

2. Tooth Damage

Hitting rocks, debris, or knots can chip or break teeth, making cutting slower and uneven. Damaged teeth can also increase the risk of kickback. Inspect your chain before each use, sharpen or replace damaged teeth, and avoid cutting in areas with hidden obstacles to maintain smooth performance.

3. Rust and Corrosion

Chains are prone to rust and corrosion if stored improperly. Moisture can weaken the metal, making it more likely to break during use. Always clean your chain after use and store it in a dry environment with a light coat of bar and chain oil to prevent oxidation.

Upgrade Your Chainsaw Chain

For advanced users, upgrading to a specialized chain can improve performance:

Low-Vibration Chains – Reduce fatigue during long sessions.

Micro-Chisel Chains – Ideal for precise cutting.

Carbide-Tipped Chains – Extremely durable, perfect for frozen or dirty wood.

Conclusion: Choosing the Right Chainsaw Chain

Selecting the correct chainsaw chain size is essential for efficiency, safety, and longevity of your chainsaw. By understanding chain pitch, gauge, drive links, and chain types, you can make an informed choice. Regular maintenance, sharpening, and lubrication ensure your chainsaw continues to perform optimally.

Investing time in selecting and caring for your chainsaw chain not only saves money but also ensures a safer and more productive cutting experience. Always remember the story of my neighbor – a small mistake in chain size can lead to hours of frustration. Choosing the right chain is a small step that makes a big difference.

👉 Jigsaw Blade Size: Complete Guide helps you understand blade lengths, widths, T-shank vs U-shank types, and their best uses for wood, metal, and plastic cutting. Choosing the right blade improves cut quality and tool safety. Read the full guide to access detailed charts, expert tips, and a free downloadable PDF.

FAQs:

How do I know my chainsaw chain size?

To determine your chainsaw chain size, check three key factors: chain pitch, gauge, and the number of drive links. Measure the distance between three consecutive rivets for pitch, the width of drive links for gauge, and count all drive links. Your chainsaw manual also lists compatible sizes.

What does 72 mean on a chainsaw chain?

The number 72 on a chainsaw chain usually refers to the number of drive links. Drive links determine the overall chain length and must match the guide bar. A chain with 72 drive links is designed for a specific bar length, ensuring proper fit and smooth operation.

How to tell what size file for chainsaw chain?

The correct file size depends on your chain’s pitch. Common pitches like 1/4″, .325″, 3/8″, or .404″ require matching round file diameters. Using the right file ensures proper sharpening angles, maintains cutting efficiency, and prolongs chain life. Always check the chain manufacturer’s specifications before filing.

What size are chainsaw chains?

Chainsaw chains vary based on pitch, gauge, and drive links. Pitch is usually 1/4″, .325″, 3/8″, or .404″, gauges range from .043″ to .063″, and drive links depend on bar length. Proper sizing ensures safety, smooth cutting, and prevents chain derailment or bar damage.

What are the different types of chainsaw chains?

Chainsaw chains include full-chisel, semi-chisel, and low-profile chains. Full-chisel chains cut fast in softwood, semi-chisel chains handle dirty or frozen wood, and low-profile chains are safer for beginners or light-duty use. Each type is designed for specific tasks, wood types, and user experience levels.