Screws are some of the most common fasteners in any project, yet selecting the right screw size is often underestimated. Using a screw that is too short may cause joints to come apart, while a screw that is too long can damage the material or pierce through surfaces unintentionally. The wrong diameter may strip threads or fail to hold weight properly. Whether you are working on woodworking, metal fabrication, furniture assembly, or even DIY repairs, understanding screw size is crucial for durability, safety, and professional results.

This guide will take you through every aspect of screw size—from diameter and length to thread type and material compatibility. By the end, you will know how to measure, select, and install screws with confidence, avoiding common mistakes and ensuring your projects hold together perfectly.

Understand Screw Anatomy

Before you can choose the right screw size, you need to understand the anatomy of a screw. A screw has several key parts: the head, the shank, the threads, and the tip. The head type determines the tool needed for installation, whether it’s a flathead, Phillips, or hex. The shank is the smooth portion that may sit in unthreaded material, while the threaded portion grips the material for holding power. The tip type, whether pointed or blunt, affects how the screw penetrates the material.

Knowing the function of each part helps you understand why size and type matter. For example, a screw with too thin a shank may bend under pressure, while one with a sharp tip can easily split wood if pre-drilling isn’t considered.

Screw Anatomy Overview Table

| Part | Description | Importance |

|---|---|---|

| Head | Top of the screw | Determines tool needed and surface contact |

| Shank | Smooth section | Provides grip and alignment |

| Threads | Spiral ridges | Secure the screw in material |

| Tip | End of screw | Facilitates penetration and prevents splitting |

Metric vs. Standard Screws

Screws are manufactured in both metric and standard (imperial) systems. Metric screws are measured in millimeters, while standard screws use inches. This distinction affects diameter, length, and thread pitch. Using the wrong system can lead to poor fit, stripped threads, or unstable connections.

For instance, an M6 screw (6mm diameter) may appear similar to a 1/4″ screw, but the thread pitch differs and could cause stripping if used incorrectly. Knowing which system your project uses is the first step in accurate screw selection.

Metric vs. Standard Screw Sizes Table

| System | Example | Diameter | Thread Pitch/TPI | Typical Use |

|---|---|---|---|---|

| Metric | M4 | 4mm | 0.7mm | Electronics, small machinery |

| Metric | M6 | 6mm | 1.0mm | Furniture, bicycles |

| Standard | 1/4″-20 | 0.25″ | 20 TPI | Furniture, construction |

| Standard | 3/8″-16 | 0.375″ | 16 TPI | Medium-duty projects |

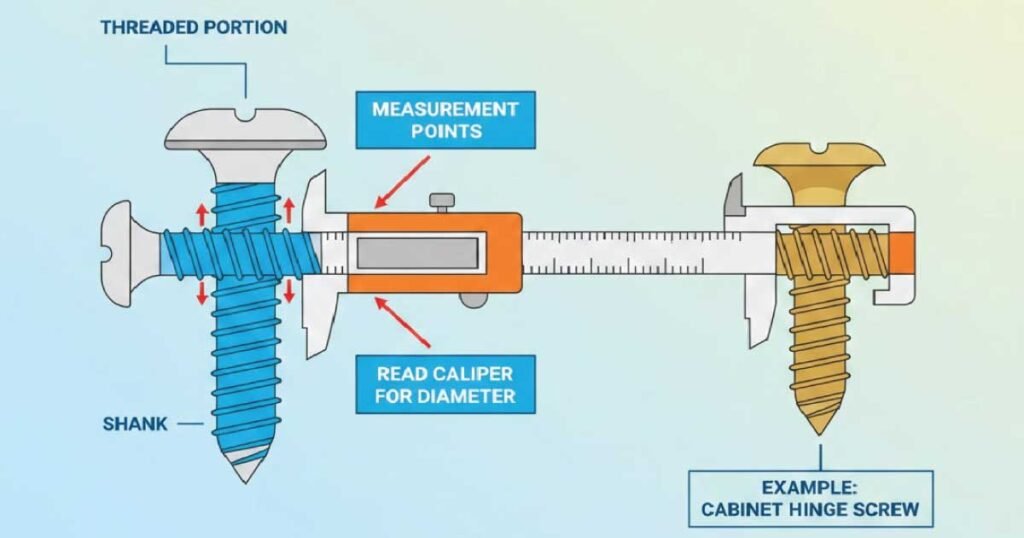

Measuring Screw Diameter

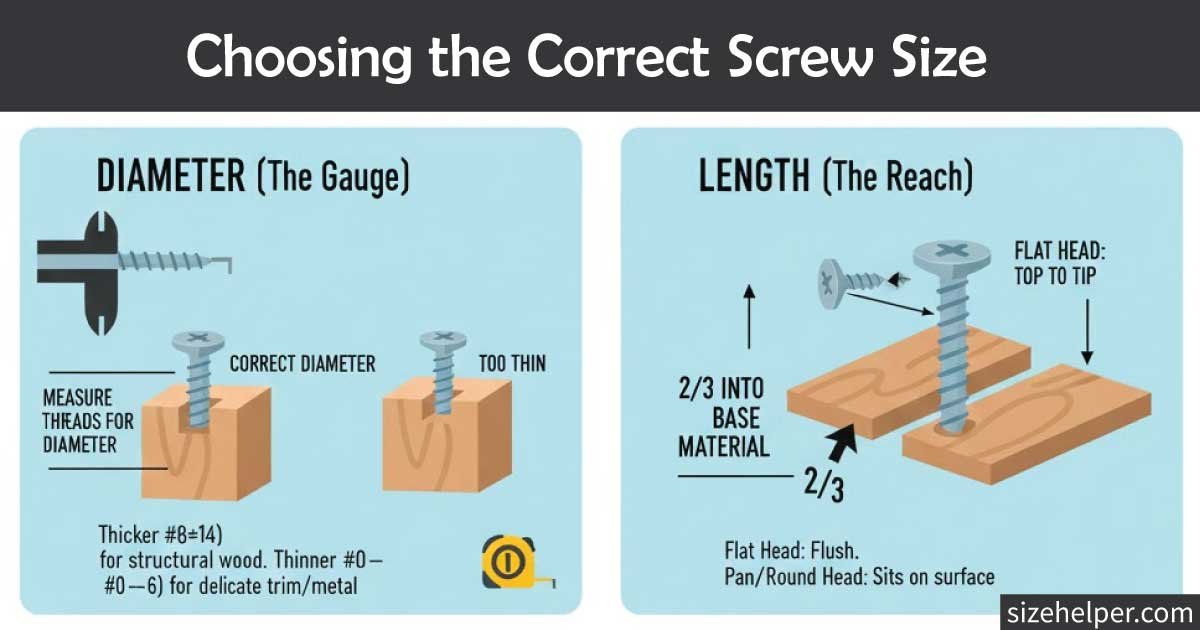

The screw diameter is one of the most critical measurements. It is measured across the threaded portion, not the shank, to ensure a proper fit with nuts or pre-drilled holes. Using calipers gives the most accurate measurement, but a measuring tape can work for larger screws.

For example, when replacing a screw on a cabinet hinge, measuring the diameter ensures that the new screw fits snugly without damaging the wood or leaving the hinge loose. Choosing the wrong diameter is one of the most common mistakes beginners make.

Common Screw Diameters Table

| Screw Size | Metric Diameter | Standard Diameter | Typical Application |

|---|---|---|---|

| Small | M3 | #4 | Electronics, light fastening |

| Medium | M5 | 10 | Woodwork, bicycles |

| Large | M8 | 5/16″ | Furniture, automotive |

| Extra Large | M12 | 1/2″ | Heavy machinery, construction |

Determining Screw Length

Screw length is measured from the bottom of the head to the tip. For countersunk screws, the head sits flush with the material, so the total length may include the head. For raised-head screws, the shank length is the key measurement.

A simple guideline is that screws should penetrate at least half the thickness of the second material for a secure hold. For example, when attaching a wooden bracket to a wall, a screw that penetrates too shallowly will not hold weight, while one that is too long may damage internal wiring or plumbing.

Understand Thread Pitch and Type

Thread pitch determines how tightly a screw grips the material. Metric screws use pitch in millimeters (distance between threads), while standard screws use threads per inch (TPI). Coarse threads are easier to install and grip softer materials like wood, while fine threads are stronger in metal and thin materials.

The thread type also matters—wood screws, machine screws, sheet metal screws, and self-tapping screws all have different thread profiles designed for specific materials. Using the wrong thread type can strip the hole or fail to hold weight.

Common Thread Types Table

| Screw Type | Typical Pitch/TPI | Best Use |

|---|---|---|

| Wood Screw | Coarse | Wood, soft materials |

| Machine Screw | Fine | Metal, machinery |

| Sheet Metal Screw | Medium | Thin metal, plastic |

| Self-Tapping | Variable | Wood, metal, plastics without pre-drilling |

Matching Screw to Material

Different materials require different screw sizes and types. Wood, metal, plastic, and composite materials have unique properties that affect screw selection. A screw too thick may split wood, while a screw too thin in metal may strip threads under torque.

For instance, installing a metal bracket on drywall requires a screw with sufficient length to reach studs or anchors, while a short screw may not provide any structural support. Matching diameter, length, and thread type to the material ensures a secure and durable connection.

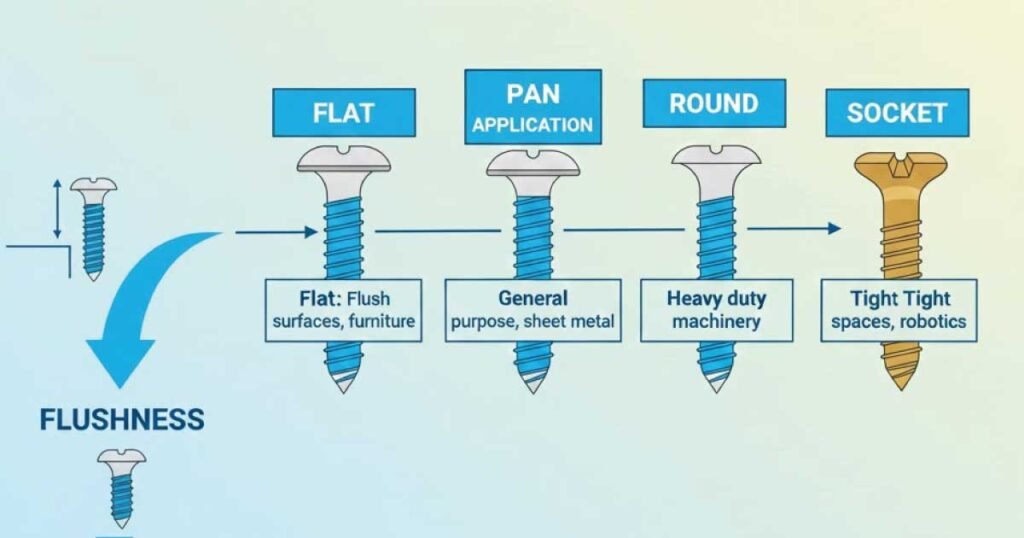

Head Types and Their Impact on Size Selection

Screw head types affect installation and surface finish. Flat heads sit flush with the material, making them ideal for furniture or countersunk surfaces. Pan and round heads protrude and provide extra strength. Hex and socket heads allow higher torque applications in machinery.

The head type also interacts with screw length, as countersunk screws need slightly longer shanks to accommodate flush mounting, while raised heads add thickness to the visible surface.

Common Screw Head Types

| Head Type | Characteristics | Typical Use |

|---|---|---|

| Flat | Countersunk, flush | Woodwork, furniture |

| Pan | Rounded top, flat underside | Medium-duty fastening |

| Round | Fully rounded | Decorative, light fastening |

| Hex | Six-sided | Machinery, automotive |

Practical Tips for Beginners:

Choosing the right screw may seem simple, but small details make a big difference. Selecting the correct size, material, and thread type ensures strong, secure, and long-lasting joints. Proper screw choice prevents material damage, reduces wasted effort, improves installation efficiency, and helps avoid costly mistakes or rework during projects of any scale.

7 Practical Tips for Beginners

Measure screw diameter and length accurately before buying.

Match the thread type to wood, metal, or plastic.

Choose the correct head style for the tool and finish.

Select material and coating for corrosion resistance.

Check compatibility with nuts, anchors, or tapped holes.

Start screws straight to avoid cross-threading or stripping.

Test fit on scrap material before final installation.

Also Read:

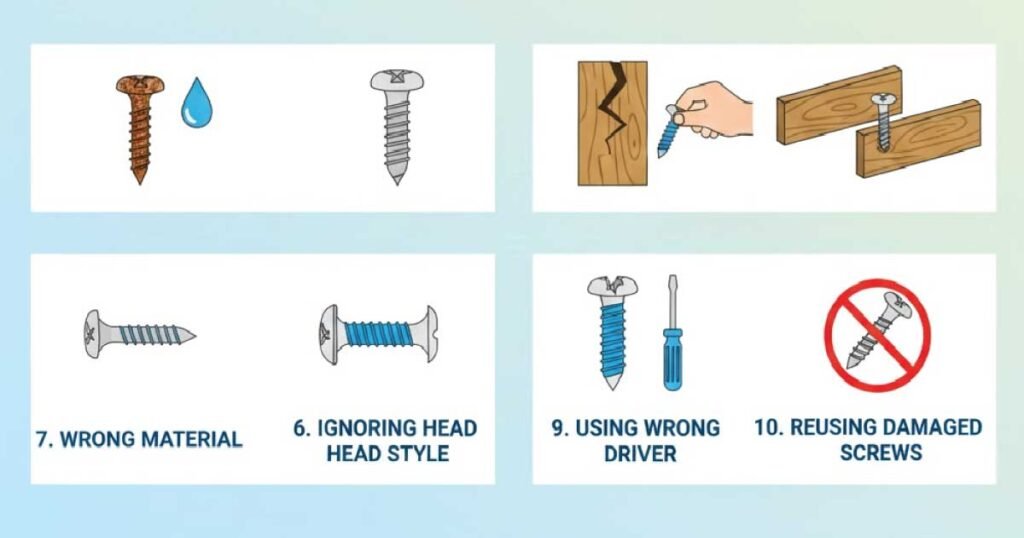

Common Mistakes to Avoid

Using the wrong screw diameter for the application

Selecting an incorrect screw length

Choosing the wrong thread type for the material

Mixing metric and standard screws

Ignoring the screw head type and surface fit

Using the wrong screw material or coating

Over-tightening and stripping threads

Example: Selecting Screws for Furniture Assembly

Imagine assembling a kitchen cabinet. Using screws that are too short leaves shelves unstable, while screws that are too long can puncture back panels or damage adjacent surfaces. Choosing the right screw type for the wood material is crucial.

Wood screws with coarse threads and flat heads provide a flush, neat finish, while ensuring the screw penetrates deep enough into studs or supports guarantees stability.

Always test screw fit on a scrap piece of wood before final installation. Paying attention to these small details prevents mistakes, improves durability, and ensures professional, long-lasting results in any woodworking project.

Also Read:

Conclusion: Confidently Choosing the Right Screw Size

Choosing the correct screw size is a skill that combines measurement, material knowledge, and practical experience. By understanding screw anatomy, diameter, length, thread type, head style, and material compatibility, you can select screws that provide secure, durable, and professional-quality connections.

Whether you’re assembling furniture, repairing machinery, or working on DIY projects, mastering screw selection improves both safety and project quality. By applying the principles outlined in this guide, measuring accurately, and testing fit before final installation, you’ll gain confidence and efficiency in every project, ensuring your fasteners perform as intended.

Also Read: