If you are diving into the world of CNC router bits, you might be wondering what exactly they are and how to choose the right ones for your projects. In this blog post, I’ll explain everything you need to know about what are CNC router bits and guide you through the types of CNC router bits: a complete guide for beginners. Whether you’re working with wood, aluminum, metal, or even stone, understanding what bits to use for a CNC router is essential for getting clean, precise cuts every time.

I’ll also cover practical questions like where to buy CNC router bits from trusted sources, and address some common concerns such as can you use CNC bits in a router? plus how long do CNC router bits last? To help you keep your tools in top shape, I’ll share tips on how to sharpen CNC router bits effectively. Along the way, you’ll get a detailed look at specialized bits for different materials, including CNC router bits for wood, CNC router bits for aluminum, CNC router bits for metal, and CNC router bits for stone.

By the end of this post, you’ll feel confident selecting the perfect CNC router bits for your specific needs and know how to maintain them to ensure long-lasting performance.

What Are CNC Router Bits?

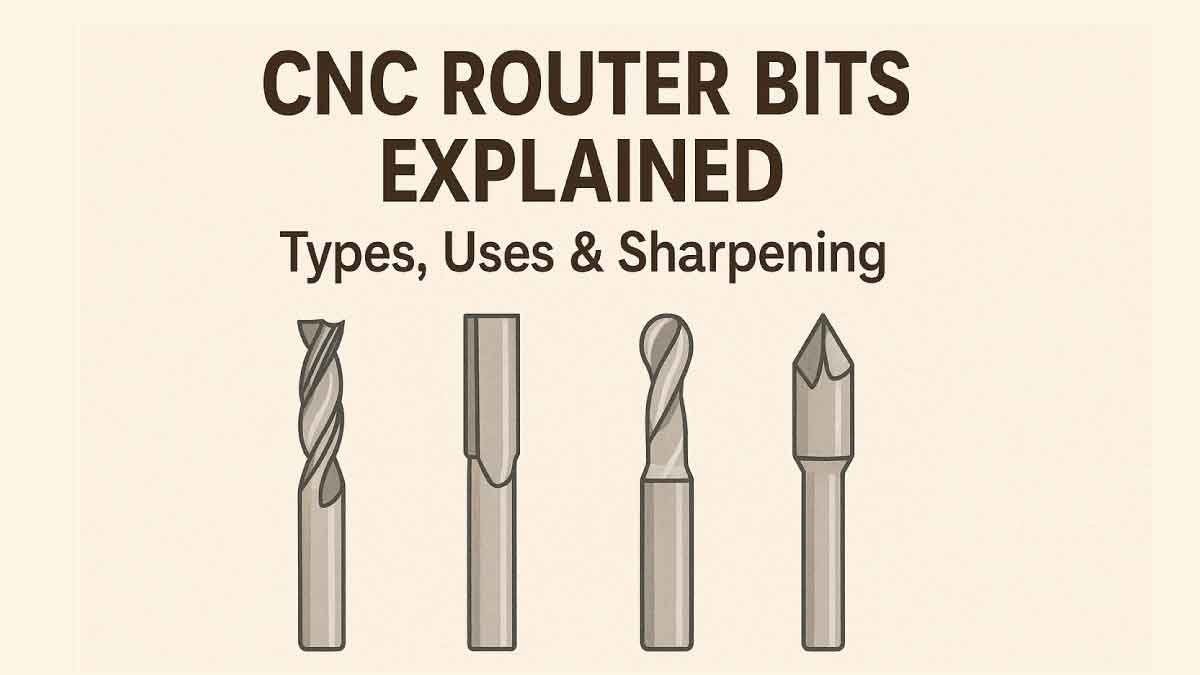

CNC router bits are cutting tools specifically designed to be used with CNC (Computer Numerical Control) routers. These bits come in various shapes and sizes, each tailored for specific tasks like cutting, carving, engraving, drilling, and shaping materials such as wood, plastic, foam, or even soft metals. Unlike standard router bits, CNC bits are built for precision and durability to handle the high-speed, automated movements of CNC machines. Common types include straight bits, ball nose bits, V-bits, and end mills. Each bit serves a different purpose—for example, V-bits are great for engraving, while end mills are perfect for smooth, detailed cuts. Choosing the right bit depends on the material and the desired finish.

Types of CNC Router Bits: A Complete Guide for Beginners

CNC router bits are essential tools used in computer-controlled cutting machines. These bits come in a wide variety of shapes and sizes, and each type is designed for a specific task or material. Choosing the right CNC router bit can make a big difference in the quality of your project, whether you’re working with wood, plastic, foam, or metal. Here’s a detailed guide to help you understand the most common types of CNC router bits and when to use them.

1. Straight Bits

Straight bits are some of the most basic and commonly used CNC bits. They are ideal for making straight cuts in materials like wood, MDF, and plywood. These bits are often used for routing grooves, dados, and rabbets. While they’re simple in design, they are not the best for chip removal, which can affect cut quality if not managed properly.

2. Spiral Up-Cut Bits

Spiral up-cut bits are designed to pull chips upward, away from the cutting surface. This results in cleaner bottoms on cuts and better chip evacuation, making them great for deep or aggressive cuts. However, because they pull upward, they may cause fraying or tear-out on the top surface of the material, especially on plywood or laminated boards.

3. Spiral Down-Cut Bits

In contrast to up-cut bits, spiral down-cut bits push chips down into the material. This produces clean top edges and is especially useful for cutting plywood or veneer where you want to avoid top-edge tear-out. However, because they push chips downward, they’re not great for deep cuts as chip buildup can occur.

4. Compression Bits

Compression bits are a hybrid design that combines both up-cut and down-cut flutes. The lower part of the bit pulls chips up, while the upper part pushes them down. This unique design produces clean edges on both the top and bottom surfaces of the material. Compression bits are ideal for cutting laminated plywood, MDF, or any two-sided material where edge quality matters.

5. Ball Nose Bits

Ball nose bits have a rounded tip and are mainly used for 3D carving and contour work. They allow smooth curves and flowing lines, making them perfect for sculpted surfaces, signs, or artistic work. While they don’t create sharp corners, their smooth finishing ability makes them a favorite for 3D CNC projects.

6. V-Bits (V-Groove Bits)

V-bits are designed for carving fine details, especially for engraving text, decorative patterns, or chamfering edges. They come in various angles, such as 30°, 60°, or 90°, and are commonly used in sign making. The angle determines the width and depth of the engraving, with sharper angles creating finer details.

7. End Mills (Flat End Bits)

Flat end mills are versatile and commonly used for general-purpose cutting, slotting, and pocketing. These bits cut flat-bottomed grooves and are great for applications requiring sharp edges or corners. They are commonly used in woodworking, plastics, and even soft metals.

Each type of CNC router bit is designed for a specific purpose, and using the right one can greatly improve the quality, speed, and efficiency of your work. Whether you’re cutting simple shapes or doing detailed engraving, understanding the function of each bit will help you get the best results in your CNC projects.

Please check out our detailed guide about:

What Bits to Use for a CNC Router

Choosing the right bits for your CNC router depends on the material you’re cutting and the type of work you’re doing—whether it’s carving, cutting, engraving, or shaping. Here’s a simple guide to help you pick the right bit for the job:

1. Straight Bits

Best for: Grooves, dados, rabbets, and simple cuts in wood or MDF.

Why use it: They make clean, straight cuts and are great for basic routing tasks.

2. Spiral Up-Cut Bits

Best for: Deep cuts and materials that require good chip removal (wood, plastic).

Why use it: Pulls chips up and out, giving you cleaner bottom edges.

3. Spiral Down-Cut Bits

Best for: Plywood, veneer, or projects that need clean top edges.

Why use it: Pushes chips down, reducing tear-out on the top surface.

4. Compression Bits

Best for: Laminated boards, plywood, and double-sided materials.

Why use it: Cuts cleanly on both the top and bottom surfaces.

5. Ball Nose Bits

Best for: 3D carving, sculpting, and contours.

Why use it: Rounded tip allows smooth, flowing curves and shapes.

6. V-Bits

Best for: Engraving, lettering, and detailed designs.

Why use it: Creates fine lines and sharp angles with adjustable depth.

7. End Mills (Flat End)

Best for: Slots, pockets, sharp edges, and precise cutting.

Why use it: Versatile bit that’s ideal for detailed and accurate work.

Tip:

Always match the bit’s shank size to your router’s collet and consider material compatibility (wood, plastic, foam, aluminum). Also, choose a bit with the proper flute length and cutting diameter based on your project’s depth and precision needs.

Using the right bit not only improves cut quality but also extends the life of your tool and reduces wear on your CNC machine.

Please check out our detailed guide about:

Where to Buy CNC Router Bits

You can buy CNC router bits from a variety of trusted sources, both online and in-store. Here are some popular and reliable options:

🛒 Online Retailers

Amazon – Huge selection of bits for all budgets and materials. Great for quick delivery and user reviews.

eBay – Good for finding deals, but quality can vary. Stick to reputable sellers.

ToolsToday – Specializes in high-quality CNC bits from brands like Amana Tool. Ideal for professionals.

Inventables – Great for CNC beginners. Offers bundled kits and individual bits.

Rockler – Offers woodworking-focused bits and accessories. Trusted by hobbyists and pros.

Carbide 3D – Known for premium bits designed specifically for CNC machines like Shapeoko.

BitsBits.com – Offers a wide range of precision CNC bits, including coated and specialty tools.

🏬 Physical Stores

Home Depot / Lowe’s – Limited selection, mostly woodworking bits. Good for quick local access.

Woodcraft / Rockler Retail Stores – Best for hands-on shopping and expert advice.

Local tool suppliers or CNC equipment shops – Often carry professional-grade bits and offer personalized service.

💡 Tip:

When buying bits, look for details like:

Shank size (to match your router)

Material type (carbide is preferred for durability)

Coating (TiN, TiAlN for extended life)

Flute type and count (affects cut quality and chip removal)

Stick with trusted brands like Amana Tool, Freud, Whiteside, and Yonico for consistent performance.

Please check out our detailed guide about:

Can You Use CNC Bits in a Router?

Yes, you can use CNC bits in a router, but it depends on the type of router you have. Many handheld or table-mounted routers can accept bits designed for CNC machines, especially if the shank size matches your router’s collet. CNC bits are often designed for precision and durability, making them great for woodworking, engraving, or even light metal work. However, keep in mind that routers typically move manually, while CNC machines are automated. So, while the bits can work, you may not achieve the same accuracy as with a CNC setup. Always check the bit’s specifications and ensure it’s compatible with your router’s speed and power to avoid damage or safety issues.

How Long Do CNC Router Bits Last?

The lifespan of CNC router bits depends on how often you use them, the material you’re cutting, and the bit’s quality. On average, a good-quality bit used on wood may last 3 to 6 months with regular use. For heavy-duty jobs or hard materials like aluminum, it might wear out faster. Carbide bits last longer than high-speed steel (HSS) and are better for frequent use. Proper maintenance—like cleaning, sharpening, and storing them correctly—can extend their life. Watch for signs of wear, such as burning, chipping, or rough cuts. Replacing bits before they become too dull helps maintain clean cuts and protects your CNC machine from extra strain.

Please check out our detailed guide about:

How to Sharpen CNC Router Bits

Sharpening your CNC router bits helps you save money by extending their life and keeps your cuts smooth and accurate. Proper sharpening requires care and the right tools. Here’s a step-by-step guide to help you sharpen your bits effectively:

1. Inspect the Bit

Before sharpening, carefully examine the bit under good lighting or a magnifier. Look for signs of dullness, chipped edges, or damage. If the bit is badly worn, chipped, or cracked, sharpening won’t help — it’s safer and more effective to replace it. Only sharpen bits that are slightly dull to maintain proper cutting performance.

2. Use a Diamond File or Sharpening Stone

Carbide router bits require special care. Use a fine diamond file or diamond sharpening stone to sharpen them because carbide is extremely hard and regular sharpening stones won’t work. These diamond tools gently grind the carbide without damaging the bit’s shape or coating, ensuring a precise sharpen.

3. Sharpen the Cutting Edges

Focus on filing the flat cutting edge inside each flute of the bit. Use light, even strokes and avoid altering the bit’s original angle or profile. Filing too aggressively or unevenly can ruin the bit’s geometry, causing poor cuts or vibrations. Sharpen each flute equally for balanced performance.

4. Clean the Bit

Before sharpening, clean your bit thoroughly. Use a bit cleaner, solvent, or degreaser to remove any built-up resin, pitch, or debris. A clean edge reveals the true cutting surface and allows the sharpening tool to work effectively. This also helps prevent contamination during the sharpening process.

5. Check Balance

After sharpening, check that the bit spins evenly and smoothly on your router or CNC machine. An unbalanced bit can cause excessive vibration, damage your workpiece, and reduce accuracy. If the bit is off-balance, minor adjustments may be needed, or you might consider professional sharpening for best results.

Professional Sharpening

For complex-shaped bits like V-bits or ball nose bits, or if you frequently need sharpening, consider sending your bits to a professional sharpening service. These experts use precision equipment to restore bit geometry perfectly, ensuring long-lasting, high-quality performance.

This careful approach to sharpening CNC router bits will keep your tools in top shape and help you achieve clean, precise cuts every time.

Please check out our detailed guide about:

CNC Router Bits for Wood

When working with wood, choosing the right CNC router bits is key to getting clean, precise cuts without damaging your material. Here are some of the best types of bits specifically designed for wood:

Straight Bits — Perfect for making straight cuts, grooves, and dados in hardwood, softwood, or plywood. They create clean, flat-bottomed cuts.

Spiral Up-Cut Bits — Great for deep cuts in wood because they pull chips up and away, preventing clogging. However, they may cause some tear-out on the surface.

Spiral Down-Cut Bits — Push chips downward, reducing splintering on the wood surface, ideal for veneer or delicate wood projects.

Compression Bits — Combine up-cut and down-cut action for smooth edges on both top and bottom surfaces of laminated wood or plywood.

V-Bits — Used for engraving wood, lettering, and decorative carving, creating sharp, detailed designs.

Ball Nose Bits — Ideal for 3D carving and sculpting wood surfaces with smooth, rounded edges.

Using high-quality carbide bits designed for wood will give you cleaner cuts and longer bit life. Always match the bit size and shape to your project’s needs for the best results.

CNC Router Bits for Aluminum

When cutting aluminum with a CNC router, you need specialized bits designed to handle metal’s hardness and softness without causing damage or excessive wear. Here are the key types of CNC router bits best suited for aluminum:

Carbide End Mills: Solid carbide bits are the best choice for aluminum due to their strength and durability. They maintain sharp edges longer and resist heat better than HSS bits.

Single-Flute or Two-Flute Bits: Aluminum chips are sticky and can clog multi-flute bits. Single or two-flute bits provide larger chip clearance, helping to evacuate material efficiently and prevent clogging.

Up-Cut Spiral Bits: These bits pull chips upward, improving chip removal and cooling. Good chip evacuation prevents the bit from overheating and extends its life.

Compression Bits: For laminated or coated aluminum sheets, compression bits can reduce burrs and give a cleaner edge on both surfaces.

Coated Bits: Look for bits with coatings like TiAlN (Titanium Aluminum Nitride) or ZrN (Zirconium Nitride), which reduce friction and improve wear resistance.

Tips:

Use proper cutting speeds and feeds to avoid melting or gumming up aluminum.

Use lubrication or air blast to cool the cutting area and clear chips.

Always choose bits specifically labeled for aluminum for best results and longer tool life.

Using the right CNC router bits helps produce smooth, precise cuts while protecting both the material and your machine.

Please check out our detailed guide about: