What Is a Drill Chuck?

Why Drill Chuck Size Matters

The range of drill bit diameters you can use

Compatibility with your drill machine

Accuracy and runout performance

Torque transfer and safety

Using the wrong chuck size can lead to slippage, poor drilling accuracy, damaged bits, or even operator injury.

Understanding Drill Chuck Size Terminology

Before selecting a drill chuck, it is important to understand common sizing terms that affect compatibility and performance. Chuck capacity defines the minimum and maximum bit sizes the chuck can grip. Mount type describes how the chuck attaches to the drill, either threaded or tapered. Arbor size specifies the interface between the chuck and spindle, while jaw count—typically three jaws—determines how securely and evenly the tool is held.

Chuck Capacity – Minimum and maximum bit size the chuck can hold

Mount Type – How the chuck attaches to the drill (threaded or tapered)

Arbor Size – The interface between chuck and spindle

Jaw Count – Typically 3 jaws for most drills

How Drill Chuck Sizes Are Measured

1.5–10 mm

3–16 mm

1/16″–1/2″

This range indicates the smallest and largest drill bit shank the chuck can securely grip.

Common Drill Chuck Size Ranges

Most drills are designed around a few standard chuck size ranges. Small drills typically use chucks up to 10 mm (3/8″) for light-duty work, medium drills commonly use 13 mm (1/2″) chucks for general-purpose applications, and heavy-duty drills use 16 mm (5/8″) or larger chucks for high-torque, demanding tasks. The correct size depends on drill power and intended use.

Small drills: up to 10 mm (3/8″)

Medium drills: up to 13 mm (1/2″)

Heavy-duty drills: up to 16 mm (5/8″) or larger

The right size depends on the drill’s power and intended application.

Drill Chuck Sizes by Application

Light DIY work: 6–10 mm chuck

General construction: 10–13 mm chuck

Metalworking and industrial use: 13–16 mm chuck

Selecting the correct size improves efficiency and extends tool life.

Drill Chuck Size Chart – Metric (Table)

This metric drill chuck size chart provides a clear reference for matching chuck capacity with drill type and application. It helps users quickly identify the appropriate chuck size for tasks ranging from precision electronics work to heavy-duty industrial drilling. Using the correct size ensures better accuracy, improved safety, and optimal drilling performance.

| Chuck Size Range (mm) | Typical Drill Type | Common Applications |

|---|---|---|

| 0.5 – 6 mm | Mini / Precision Drill | PCB drilling, electronics |

| 1.5 – 10 mm | Light-duty Drill | DIY, wood, plastic |

| 1.5 – 13 mm | Standard Drill | Construction, metal drilling |

| 3 – 16 mm | Heavy-duty Drill | Steel fabrication |

| 5 – 20 mm | Industrial Drill Press | Machining, production |

Drill Chuck Sizes by Power Tool Type

Different power tools are designed to work with specific drill chuck sizes based on their torque, speed, and intended use. Understanding typical chuck sizes for cordless drills, corded hand drills, and drill presses helps ensure compatibility, safe operation, and optimal performance across a wide range of drilling applications.

1- Cordless Drills

Cordless drills typically use 10 mm or 13 mm chucks, offering a balance between versatility, portability, and weight. These sizes allow the use of common drill bits for wood, plastic, and light metal while keeping the tool compact. Proper chuck sizing helps maintain battery efficiency and reduces strain on the motor during operation.

2- Corded Hand Drills

Corded hand drills are commonly equipped with 13 mm chucks, enabling them to handle higher torque and larger drill bits than most cordless models. This size supports a wide range of general-purpose drilling tasks, including masonry and metalwork, while providing stable bit retention and consistent power delivery for continuous use.

3- Drill Presses

Drill presses often use 16 mm or larger chucks to provide greater rigidity, precision, and load capacity. Larger chuck sizes support heavier drill bits and demanding materials while minimizing runout. This makes them ideal for machining, fabrication, and production environments where accuracy, repeatability, and stability are essential.

Inch-Based Drill Chuck Size Chart (Table)

This inch-based drill chuck size chart provides a quick reference for matching chuck capacity to typical applications. It shows the equivalent metric sizes and helps users select the right chuck for tasks ranging from precision drilling to heavy-duty industrial work. Using the correct size improves accuracy, safety, and overall drilling performance.

| Chuck Size Range (Inches) | Equivalent Metric | Typical Use |

|---|---|---|

| 1/32″ – 1/4″ | 1 – 6 mm | Precision drilling |

| 1/16″ – 3/8″ | 1.5 – 10 mm | DIY and light work |

| 1/16″ – 1/2″ | 1.5 – 13 mm | General-purpose drilling |

| 1/8″ – 5/8″ | 3 – 16 mm | Heavy-duty drilling |

| 1/4″ – 3/4″ | 6 – 20 mm | Industrial use |

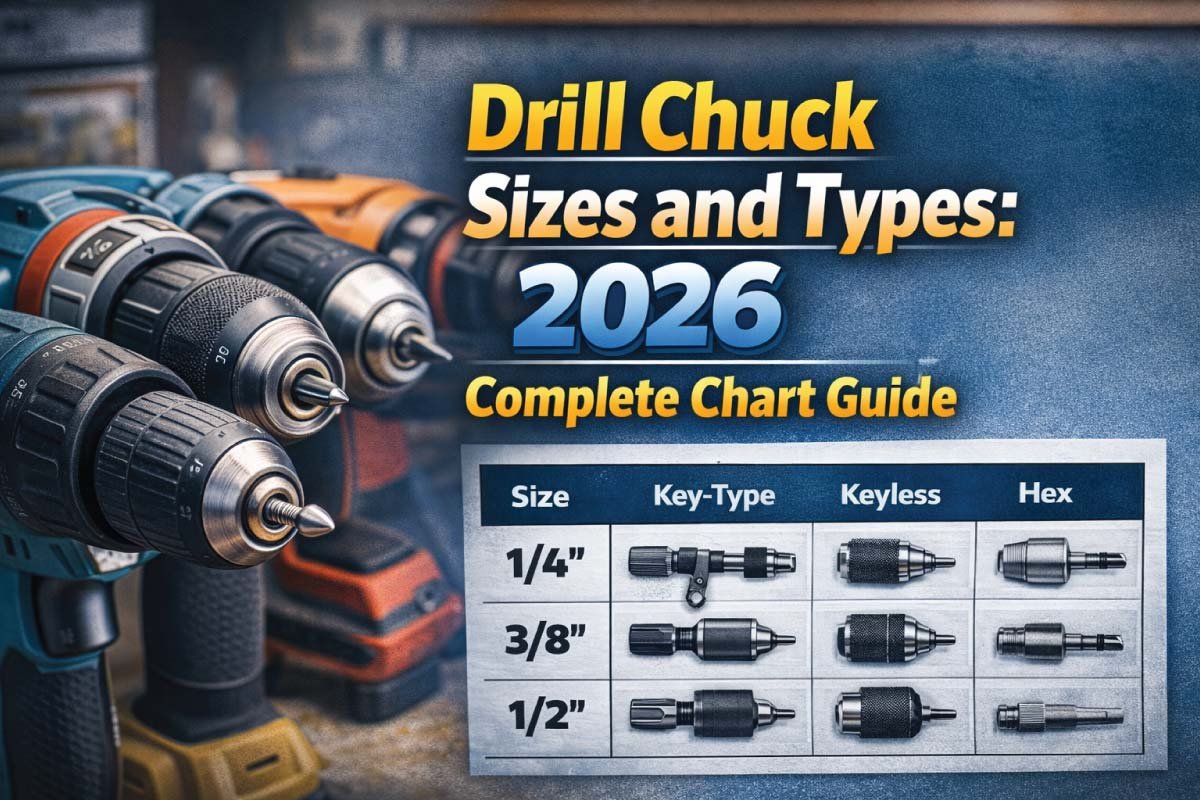

Keyed vs Keyless Drill Chucks

Choosing between keyed and keyless drill chucks affects grip strength, convenience, and application suitability. Keyed chucks use a chuck key to tighten and provide a stronger, more secure hold, ideal for high-torque drilling. Keyless chucks can be tightened by hand for faster bit changes, making them better suited for light to medium-duty tasks.

1 Keyed Drill Chucks

Use a chuck key for tightening

Offer stronger grip

Ideal for high-torque drilling

2 Keyless Drill Chucks

Hand-tightened

Faster bit changes

Best for light to medium-duty work

Chuck size availability is similar for both types, but gripping strength differs.

Drill Chuck Mounting Types

Selecting the correct drill chuck requires considering not only size but also mounting type to ensure compatibility with the drill or machine. Mount type affects stability, torque transfer, and ease of installation. Common mounting options include threaded mounts for handheld drills and taper mounts for drill presses and industrial machines.

1- Threaded Mount

Threaded mounts are commonly used on handheld drills, such as 1/2″-20 UNF. The chuck screws directly onto the drill spindle, providing a secure connection suitable for general-purpose drilling. This mount type is easy to install and remove, making it convenient for changing chucks or performing maintenance on portable drills.

2- Taper Mount

Taper mounts, such as Jacobs or Morse tapers, are used on drill presses and industrial machines. The chuck fits snugly onto the tapered spindle, offering high stability and precise alignment. This mounting method provides excellent torque transfer and runout accuracy, making it ideal for heavy-duty, high-precision drilling operations.

Common Arbor and Taper Sizes

Drill chucks are designed to fit specific arbor and taper sizes, which determine how the chuck mounts to the spindle. Popular Jacobs taper sizes include JT0, JT1, JT2, and JT33, while common Morse tapers include MT1, MT2, and MT3. Selecting the correct taper ensures secure mounting, proper alignment, and reliable torque transfer during drilling operations.

JT0, JT1, JT2, JT33 (Jacobs Taper)

MT1, MT2, MT3 (Morse Taper)

Each chuck size is designed to work with specific taper sizes.

Chuck Size vs Drill Bit Shank Size

Drill bits come in different shank types and sizes, affecting chuck compatibility. Small bits typically have straight shanks, larger bits may use reduced shanks, and specialty bits often feature hex shanks for better grip. Using a larger drill chuck increases flexibility, allowing you to accommodate a wider range of bit types and sizes for various drilling applications.

Small bits: straight shank

Large bits: reduced shank

Specialty bits: hex shank

A larger chuck allows more flexibility in bit selection.

Drill Chuck Size vs Torque Capacity

The size of a drill chuck affects the torque it can handle and the range of drill bit sizes it supports. Larger chucks are capable of managing higher torque and accommodating bigger bits, but they require more powerful drills. Using a large chuck on a low-power drill risks overloading the motor and reducing performance or causing damage.

Handle higher torque

Support larger drill bits

Require more powerful drills

Using a large chuck on a low-power drill can overload the motor.

Drill Chuck Size and Runout Accuracy

Runout refers to the wobble of a drill bit during rotation, which affects precision and hole quality. Smaller, high-quality chucks typically exhibit lower runout, making them ideal for precision work. Larger chucks can have higher runout if not properly matched to the spindle, potentially reducing accuracy and causing uneven or oversized holes.

Smaller, precision chucks usually have lower runout

Larger chucks may have higher runout if poorly matched

Precision work benefits from smaller, high-quality chucks.

Drill Chuck Size by Material Type

The material being drilled influences the choice of drill bit and chuck size. Different materials require specific capacities to ensure proper grip, torque transfer, and drilling efficiency. Selecting the right chuck for wood, metal, or masonry improves performance, prevents bit damage, and ensures accurate, clean holes while maintaining safety and extending the tool’s lifespan.

1-Wood

Drilling wood allows for a wide range of bit sizes, from small precision bits to large spade or auger bits. Chucks for wood drilling often accommodate larger bits to handle the softer material efficiently. Proper chuck selection ensures a secure grip, prevents bit slippage, and allows fast, clean drilling for both DIY and professional woodworking applications.

2-Metal

Metal drilling requires controlled bit sizes and a strong, secure chuck to handle higher torque and resist bit wandering. Using the correct chuck size ensures consistent alignment, reduces runout, and prevents overheating or wear on the bit. A well-matched chuck improves drilling accuracy and prolongs tool life when working with steel, aluminum, or other metals.

3-Masonry

Drilling into masonry, concrete, or stone demands heavy-duty chucks capable of gripping robust, often larger-diameter bits. These chucks withstand high impact and vibration from hammer drills or rotary hammers. Selecting the appropriate chuck ensures efficient material removal, reduces the risk of bit damage, and maintains operator safety during demanding masonry drilling tasks.

Drill Chuck Selection Table by Material (Table)

This table provides recommended drill chuck sizes based on the material being drilled and the type of drill used. Matching chuck size to material ensures proper bit grip, torque transfer, and drilling efficiency. Following these guidelines helps achieve accurate holes, reduces tool wear, and improves safety across woodworking, metalworking, masonry, and precision drilling applications.

| Material Type | Recommended Chuck Size | Drill Type |

|---|---|---|

| Wood | 10 – 13 mm | Cordless / Corded |

| Aluminum | 10 – 13 mm | Corded |

| Steel | 13 – 16 mm | Heavy-duty |

| Masonry | 13 – 16 mm | Hammer drill |

| Precision Work | 6 – 10 mm | Bench drill |

Common Drill Chuck Size Mistakes

Frequent errors in selecting drill chucks can lead to poor performance, tool damage, and safety risks. Common mistakes include choosing a chuck based solely on bit size, ignoring mounting compatibility, using oversized chucks on low-power drills, assuming all 13 mm chucks are interchangeable, and neglecting runout requirements. Avoiding these errors saves time, reduces costs, and protects equipment.

Choosing chuck size based only on bit size

Ignoring mounting compatibility

Using oversized chucks on low-power drills

Assuming all 13 mm chucks are interchangeable

Neglecting runout requirements

Avoiding these mistakes saves time, money, and equipment damage.

How to Upgrade or Replace a Drill Chuck

When upgrading or replacing a drill chuck, start by identifying the current chuck size and checking the spindle’s thread or taper type. Ensure the new chuck’s capacity matches the drill’s power, and decide between a keyed or keyless design. Follow manufacturer installation guidelines carefully to ensure proper fit, secure operation, and safe drilling performance.

Identify current chuck size

Check spindle thread or taper

Match chuck capacity to drill power

Choose keyed or keyless type

Install using manufacturer guidelines

Proper installation ensures safe operation.

Drill Chuck Size for Professional vs DIY Users

Choosing the right drill chuck depends on the user’s needs and application. DIY users, professionals, and industrial operators each require different capacities and types to balance ease of use, grip strength, and precision. Matching chuck size to skill level and workload ensures efficiency, safety, and optimal drilling performance across all tasks.

1-DIY Users

DIY users typically benefit from 10–13 mm keyless chucks. These chucks are lightweight, easy to hand-tighten, and versatile enough for common household projects such as wood, plastic, or light metal drilling. They provide sufficient grip for most tasks while simplifying bit changes, making them ideal for casual or home-use drilling applications.

2-Professionals

Professional users often prefer 13–16 mm keyed chucks. These chucks deliver superior grip strength and durability, making them suitable for high-torque, frequent drilling in construction, metalworking, or general contracting. Keyed chucks ensure secure bit retention, reduce slippage, and maintain accuracy during demanding, repetitive tasks.

3-Industrial Users

Industrial operators typically use larger, taper-mounted chucks for drill presses or machining applications. These chucks provide maximum rigidity, precision, and load capacity, supporting heavy-duty drilling, long bits, or specialized tooling. Proper sizing ensures accuracy, repeatability, and safe operation in production and high-precision industrial environments.

Maintenance Tips for Drill Chucks

Proper care of drill chucks helps maintain performance, accuracy, and longevity. Clean the jaws regularly to remove debris, avoid overtightening to prevent wear or damage, apply light lubrication if recommended, and replace worn or damaged chucks promptly. Regular maintenance ensures secure bit grip, reduces runout, and extends the overall life of your drill chuck.

Clean jaws regularly

Avoid over tightening

Lubricate lightly if recommended

Replace worn chucks promptly

Good maintenance extends chuck life and preserves accuracy.

Final Thoughts

electing the right drill chuck size goes beyond simply matching a drill bit. It requires understanding chuck capacity, mounting type, torque limits, and the specific demands of your application. By following this Drill Chuck Size Guide, you can confidently choose a chuck that enhances performance, ensures safety, and maximizes efficiency for everything from home DIY projects to industrial machining tasks.

FAQs:

What is a Drill Chuck Sizes Chart?

A drill chuck sizes chart shows the standard chuck capacities used in drilling machines. It usually lists size ranges such as 1–10 mm, 1–13 mm, or 1–16 mm. These charts help users select compatible drill bits and ensure proper grip, accuracy, and safe drilling performance.

What Are the Types of Chucks for Drilling?

There are several types of chucks used for drilling, including keyed chucks, keyless chucks, SDS chucks, and magnetic chucks. Each type is designed for specific drilling needs, such as high torque, quick bit changes, or heavy-duty industrial applications, improving efficiency and control.

What Are the Different Types of Drill Chucks?

Different types of drill chucks include keyed drill chucks for strong grip, keyless chucks for quick bit changes, SDS chucks for hammer drills, and hex chucks for impact drivers. Each type varies in holding strength, convenience, and compatibility with drilling machines.

What Is a Drill Chuck Chart Used For?

A drill chuck chart is used to compare chuck sizes, mounting types, and bit capacity ranges. It helps users identify the correct chuck for their drill machine, ensuring compatibility and preventing slippage or damage during drilling operations in workshops, construction, and manufacturing environments.

What Is the Definition of a Drill Chuck?

A drill chuck is a mechanical device used to hold and secure drill bits or cutting tools in a drilling machine. It tightens around the bit using jaws, allowing smooth rotation and accurate drilling. Drill chucks are essential for precision, safety, and consistent drilling performance.

What Are the Main Types of Drill Chucks?

The main types of drill chucks include keyed chucks, keyless chucks, SDS chucks, and self-tightening chucks. These types differ in tightening method, grip strength, and application. Choosing the right chuck improves drilling accuracy, tool stability, and operator convenience.

What Are Common Chuck Sizes for Drills?

Common chuck sizes for drills include 6 mm, 10 mm, 13 mm, and 16 mm capacities. These sizes indicate the maximum drill bit diameter the chuck can hold. Selecting the correct size ensures proper bit fit, reduced vibration, and safer drilling operations.

What Is a Heavy Duty Drill Chuck?

A heavy duty drill chuck is designed for high-torque and industrial drilling applications. It features stronger jaws, hardened steel construction, and higher gripping force. These chucks are commonly used in metalworking, construction, and manufacturing where durability and precision are critical.