Types of Drill Presses

Drill presses are available in several configurations, each tailored to meet specific application needs. Understanding the different types of drill presses can help you choose the right one for your workshop or project requirements.

Benchtop Drill Press

Benchtop drill presses are an excellent choice for small workshops or hobbyists seeking a compact yet powerful drilling solution. These presses offer the convenience of portability without sacrificing performance. Their smaller footprint makes them ideal for workbenches or limited workspace environments. Despite their compact size, benchtop drill presses typically feature sufficient power and versatility to tackle a wide range of drilling tasks. Whether you are working on woodworking projects, crafting DIY furniture, or performing light metalworking tasks, a benchtop drill press provides the precision and control you need.

Floor Drill Press

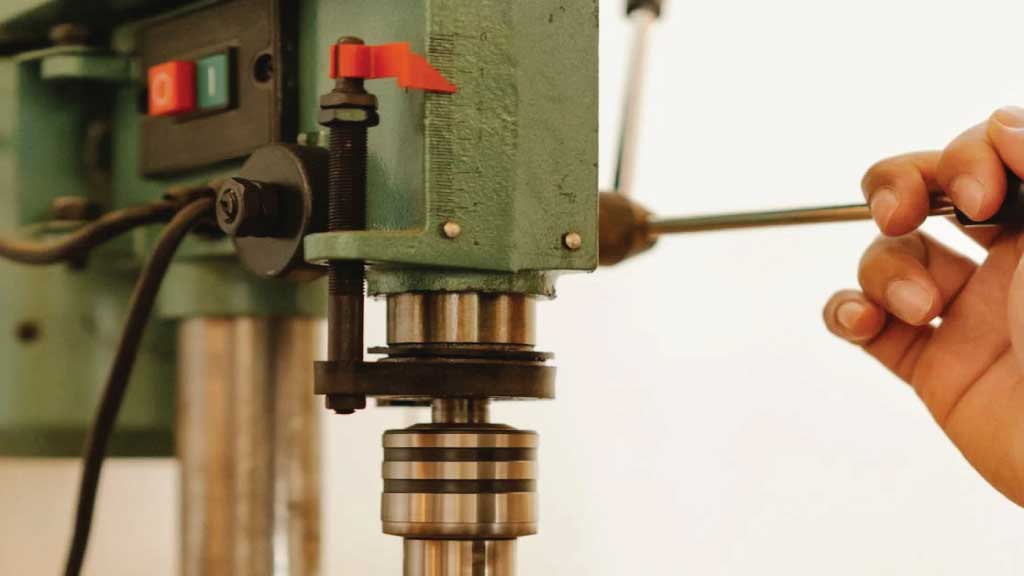

For larger projects and professional applications, floor drill presses are the preferred choice. These robust machines offer enhanced stability and larger drilling capacities compared to their benchtop counterparts. Floor drill presses are designed to handle heavy duty drilling tasks with ease, making them indispensable tools in industrial settings, fabrication shops, and construction sites. Their sturdy construction and powerful motors allow for efficient drilling of larger workpieces and thicker materials. Whether you are drilling precise holes in steel beams or fabricating metal components for structural projects, a floor drill press delivers the performance and reliability required for demanding applications.

Magnetic Drill Press

Magnetic drill presses are specialized tools designed for drilling on vertical, inclined, or overhead surfaces. Unlike traditional drill presses that rely on clamps or vises to secure workpieces, magnetic drill presses utilize powerful magnets to attach directly to ferrous materials, providing unparalleled stability and flexibility in unconventional drilling situations. These presses are commonly used in industries such as metalworking, construction, and manufacturing, where drilling on steel structures or machinery is frequent. The magnetic base ensures secure attachment to the workpiece, allowing for precise drilling in challenging positions or confined spaces.

Whether you are installing pipelines, fabricating steel frames, or performing maintenance on industrial equipment, a magnetic drill press offers the versatility and efficiency needed to get the job done safely and accurately.

In summary, the choice of drill press depends on your specific application requirements, workspace limitations, and desired level of portability. Whether you opt for a benchtop, floor, or magnetic drill press, each type offers unique features and benefits to suit a variety of drilling tasks and environments. By selecting the right drill press for your needs, you can enhance productivity, efficiency, and precision in your workshop or job site.

Conclusion

FAQs about Drill Presses

What safety precautions should I take when using a drill press?

Always wear appropriate personal protective equipment (PPE) such as safety glasses and hearing protection. Ensure the workpiece is securely clamped to the table to prevent movement during drilling. Avoid wearing loose clothing or jewelry that could get caught in the drill press. Familiarize yourself with the emergency stop button and always disconnect power before making adjustments or changing drill bits.

How do I choose the right drill press for my needs?

Consider factors such as the type of projects you will be working on, available space in your workshop, and your budget. Determine the desired horsepower, spindle speed range, and drilling capacity based on the materials you’ll be drilling. Evaluate additional features like table adjustability, depth stops, and chuck size to ensure they align with your specific requirements and preferences.

Can I drill different materials with the same drill press?

Yes, most drill presses are capable of drilling a wide range of materials including wood, metal, plastic, and more. However, it’s important to use the appropriate drill bits and settings for each material to achieve optimal results. For example, use high speed steel (HSS) bits for metal and carbide tipped bits for hardwoods to minimize wear and ensure clean, precise holes.

How do I maintain and care for my drill press?

Regularly inspect and clean the drill press, removing any debris or buildup that could affect performance. Lubricate moving parts as recommended by the manufacturer to prevent friction and wear. Check and adjust alignment as needed to ensure accurate drilling. Replace worn or damaged parts promptly to avoid compromising safety and functionality. Following a routine maintenance schedule will prolong the lifespan of your drill press and ensure consistent performance.

Can a drill press be used for tasks other than drilling holes?

Yes, drill presses can be adapted for a variety of tasks beyond drilling. Attachments such as sanding drums, mortising attachments, and rotary sanding discs can transform your drill press into a multipurpose workstation. With the right accessories and setup, you can use your drill press for tasks such as sanding, polishing, mortising, and even light milling operations, expanding its versatility and utility in your workshop.

ZAK Engineer is an experienced engineer with 15 years in the mechanical and industrial sectors. Holding advanced degrees and multiple certifications in engineering, he combines technical expertise with a passion for writing to provide valuable insights into engineering innovations and business strategies. His content empowers professionals to excel in their fields and stay updated with the latest industry trends.