ER Collet Size Chart is one of the most important references for machinists, engineers, and CNC operators who rely on precision tool-holding systems. Among the many options available, the ER collet stands out for its versatility, accuracy, and strong grip—making it a preferred choice in machining, milling, drilling, and other high-precision operations.

But here’s the challenge: ER collets come in multiple sizes, and each size has a specific clamping range. If you don’t know which collet to use, you risk tool breakage, vibration, or reduced machining quality.

That is why having an ER collet size chart is essential. With the correct chart in front of you, you can easily match your tool shank diameter with the right collet, ensuring maximum precision and performance.

In this complete guide, we’ll cover:

What an ER collet is

Why ER collets are so widely used

Different ER collet series (ER8, ER11, ER16, ER20, ER25, ER32, ER40, ER50)

A complete ER collet size chart with dimensions

How to choose the right ER collet

Common applications of ER collets

- Tips for collet maintenance and care

What is an ER Collet?

An ER collet is a standardized tool-holding device, designed to grip round-shank tools such as end mills, drills, taps, and reamers. Developed in the 1970s in Switzerland, the ER collet system quickly became the industry standard due to its flexibility and precision.

Key features of ER collets include:

Tapered design – fits into a matching collet chuck nut.

Slits along the body – allow the collet to compress and grip different tool diameters.

High clamping force – provides tool stability during high-speed machining.

Wide clamping range – each collet can hold tools within about 1mm of its nominal size.

Why ER Collets Are Popular

ER collets are preferred over other collet systems because of their:

Versatility – A single ER collet can clamp multiple tool diameters.

High Accuracy – Runout (deviation) is typically less than 0.015 mm.

Wide Range of Sizes – Suitable for both very small and very large tools.

Affordability – More cost-effective than shrink-fit or hydraulic holders.

Compatibility – Works with most CNC machines and toolholders.

Types of ER Collets (Series)

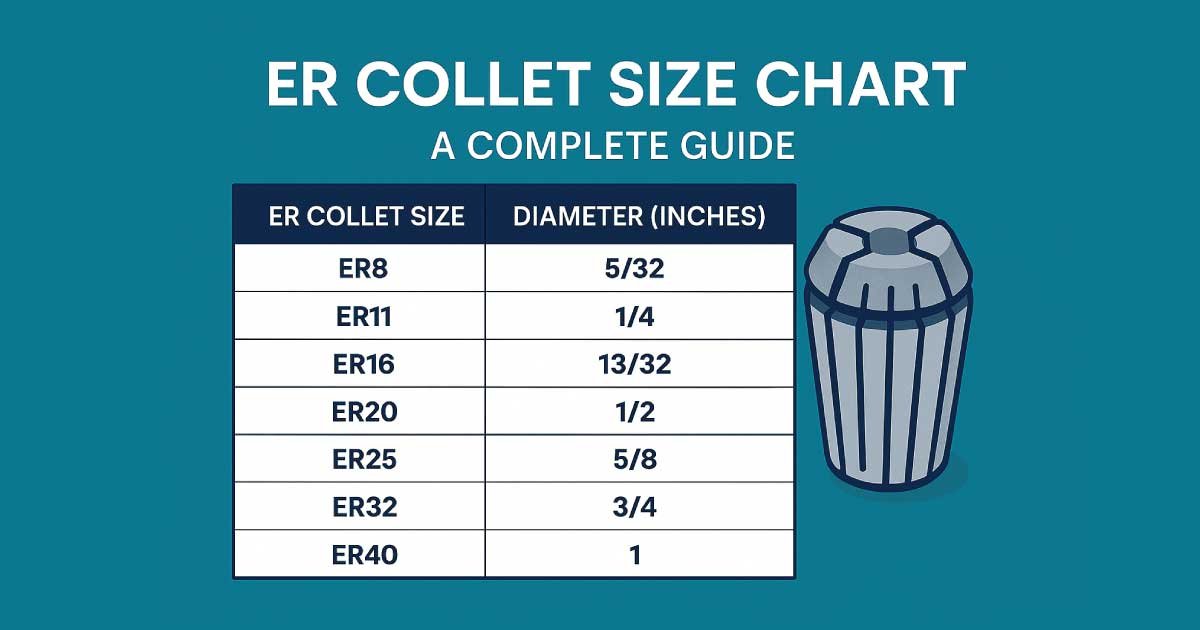

ER collets come in different series sizes, each defined by its outer diameter in millimeters. The most common are:

ER8 – for very small tools, micromachining.

ER11 – small drills, engraving tools.

ER16 – general small-to-medium machining.

ER20 – very popular in CNC milling.

ER25 – medium tool sizes.

ER32 – heavy-duty milling and drilling.

ER40 – large shank tools.

ER50 – industrial heavy machining, very large tools.

Complete ER Collet Size Chart

Here is the ER Collet Size Chart showing clamping ranges:

| ER Series | Clamping Range (mm) | Common Tool Shank Sizes (mm) | Typical Applications |

|---|---|---|---|

| ER8 | 0.5 – 5 mm | 1, 2, 3, 4 mm | Engraving, precision drilling |

| ER11 | 1 – 7 mm | 1.5, 2, 3, 4, 5, 6 mm | Small drills, PCB machining |

| ER16 | 1 – 10 mm | 2, 4, 6, 8, 10 mm | Light milling, tapping |

| ER20 | 1 – 13 mm | 3, 6, 8, 10, 12 mm | CNC milling, drilling |

| ER25 | 1.5 – 16 mm | 4, 6, 10, 12, 16 mm | Medium machining |

| ER32 | 2 – 20 mm | 6, 8, 12, 16, 20 mm | Heavy milling, reaming |

| ER40 | 3 – 26 mm | 8, 12, 16, 20, 25 mm | Large shank cutting tools |

| ER50 | 6 – 34 mm | 10, 16, 20, 25, 32 mm | Heavy-duty machining |

👉 Each collet covers about 1mm range below its nominal size. For example, an ER20 collet marked “10mm” can usually hold tools from 9mm to 10mm.

Also Read:

How to Choose the Right ER Collet

Check your tool shank diameter – Always match the size correctly.

Choose the correct ER series – ER16 for small jobs, ER32 for heavy cutting.

Avoid over-compression – Never force a tool smaller than the collet range.

Use quality collets – Cheap collets often have poor runout and wear quickly.

Consider your machine – Some machines are limited to certain ER series.

Applications of ER Collets

ER collets are used in a wide range of industries:

CNC Machining – Milling, drilling, tapping, and boring.

Engraving – Jewelry, PCB manufacturing, fine detailing.

Woodworking – Router tool holding.

Metal Fabrication – Precision boring and reaming.

Medical Manufacturing – Small-diameter tool holding for implants and devices.

Maintenance & Care of ER Collets

To get the best life and accuracy from your collets:

Keep collets clean – Dirt and chips reduce accuracy.

Inspect regularly – Look for cracks or wear.

Lubricate threads – A drop of oil on the nut threads reduces wear.

Replace worn collets – A damaged collet can ruin expensive tools.

Store properly – Use collet racks or cases to avoid damage.

Final Thoughts

The ER collet size chart is a vital reference for anyone using CNC machines or precision milling tools. Whether you are a machinist, hobbyist, or engineer, knowing which collet fits your tool ensures accuracy, safety, and efficiency.

By choosing the right collet, maintaining it properly, and using the correct series, you’ll achieve better machining results and extend the life of both your tools and your collets.

Also Read: