How Do Hydraulic Locks Work? Hydraulic locks are essential components in many industries, where they play a crucial role in ensuring the safety and efficiency of various machines and equipment. From construction to aerospace, hydraulic locks are trusted for their ability to secure positions and control movement with precision. But how exactly do hydraulic locks work? This article delves into the science, components, types, and applications of hydraulic locks, providing a comprehensive understanding of their functionality.

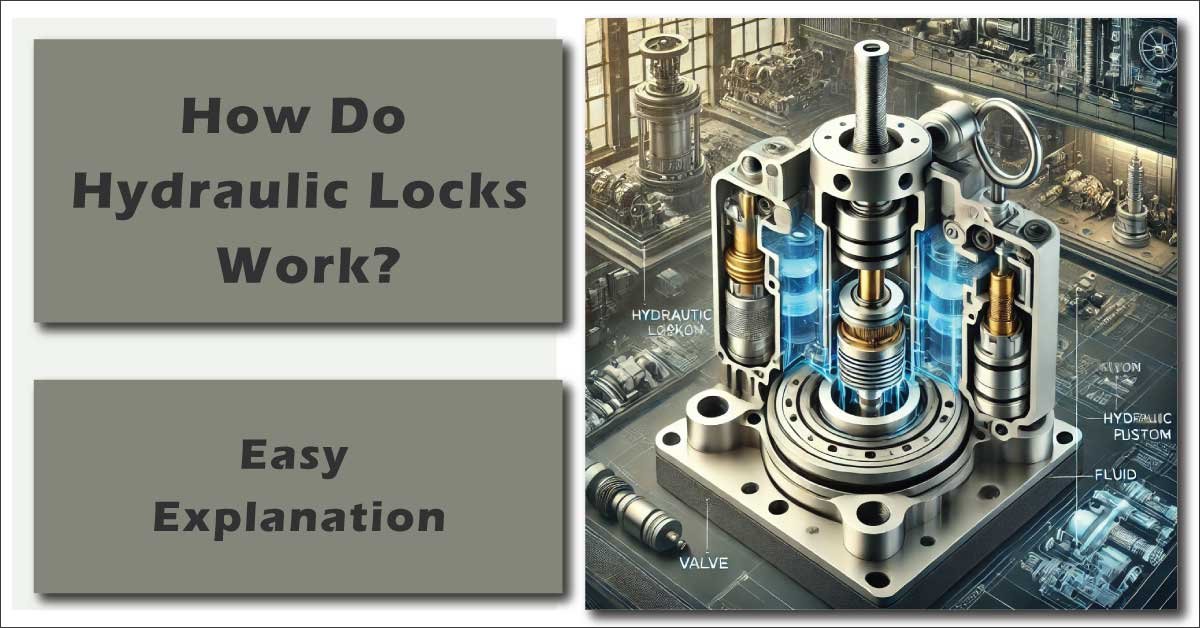

A hydraulic lock system consists of several vital components that ensure efficient and reliable operation. Cylinders provide the housing for pistons, facilitating controlled motion. Pistons transfer force within the system to perform work. Valves regulate hydraulic fluid flow for precision. Hydraulic fluids transmit power, while seals prevent leaks, maintaining system integrity. Together, these components ensure smooth performance and durability under various operating conditions.

To understand how hydraulic locks work, it’s important to know their key components:

1. Cylinders: Act as the Primary Housing for the Hydraulic Piston

Cylinders are robust, sealed structures designed to house and guide the movement of pistons. They withstand high pressures and provide a stable environment for hydraulic processes. By ensuring precise piston motion, cylinders facilitate smooth and controlled force transfer, making them a fundamental part of any hydraulic lock system.

2. Pistons: Transferring Force Within the Cylinder in Hydraulic Locks

Pistons are movable components inside the cylinder that convert hydraulic energy into mechanical motion. When pressurized fluid acts on the piston, it moves to generate force. This motion is crucial for transferring energy effectively, enabling the hydraulic lock to maintain stability and perform its intended function with precision.

3. Valves: Regulating Hydraulic Fluid Flow in Hydraulic Locks

Valves regulate the flow and direction of hydraulic fluid within the system, ensuring precise control and stability. By opening, closing, or throttling fluid paths, valves enable the hydraulic lock to engage or disengage as needed. Their functionality is essential for maintaining the lock’s reliability and accurate positional control.

4. Hydraulic Fluids: Transmitting Power in Hydraulic Locks

Hydraulic fluids are specialized liquids that carry force through pressurization in the system. They are carefully formulated to resist temperature changes, contamination, and wear. These fluids ensure smooth operation, efficient energy transfer, and consistent performance, playing a crucial role in the effectiveness and longevity of hydraulic lock systems.

5. Seals: Preventing Leakage and Ensuring Efficiency in Hydraulic Locks

Seals are critical for maintaining a leak-free hydraulic system. They prevent fluid from escaping and contaminants from entering the system. Properly functioning seals enhance the efficiency and reliability of hydraulic locks by preserving pressure levels and ensuring smooth operation, even under demanding conditions or high-pressure environments.

Each of these parts works in harmony to ensure the system’s functionality and reliability.

Also Read:

Hydraulic Fluids: The Driving Force Behind Hydraulic Locks

Hydraulic fluid is essential to the operation of hydraulic locks, acting as the medium that transmits power throughout the system. Beyond power transmission, it lubricates moving components, minimizes wear, and protects against corrosion. The quality and type of hydraulic fluid significantly influence system efficiency and durability. Maintaining proper fluid levels and conducting regular inspections ensure consistent performance and prevent potential failures. Selecting the right fluid for specific operating conditions is critical to maximizing the hydraulic lock’s reliability and lifespan.

The Science Behind Hydraulic Locks: How Hydraulic Locks Work

Hydraulic locks operate on the principle of fluid pressurization within a closed system. When fluid is pressurized, it generates a force that either moves or stabilizes the piston. Valves play a pivotal role by controlling fluid flow, allowing the system to lock the piston in a desired position. This mechanism enables precise motion control and positional stability, making hydraulic locks essential for applications requiring high accuracy and load-holding capabilities. Their efficient and reliable design underpins their widespread use in heavy machinery and industrial systems.

Step-by-Step Process: How do Hydraulic Locks Work

Hydraulic locks are essential components in many industrial applications, providing reliable and secure locking mechanisms for machinery and equipment. These systems work by utilizing the power of hydraulic fluid to generate pressure and control the movement of pistons. Whether for heavy machinery, vehicles, or automated systems, hydraulic locks ensure that critical parts stay in place under high pressure or load. This step-by-step guide explores the detailed process of how hydraulic locks operate, from activation to release, highlighting the essential functions and maintenance required for optimal performance.

Hydraulic Pressure and Its Role in Locking Systems

Hydraulic pressure is the fundamental force that drives hydraulic systems, including locks. By controlling and regulating this pressure, hydraulic locks can effectively hold or release mechanical parts, providing precise movement. The pressure is carefully managed to ensure that the lock remains secure even under significant external forces or heavy loads. This ensures the stability and reliability of equipment and machinery that rely on hydraulic systems. Hydraulic pressure enables the lock to maintain its position, providing a safe and efficient solution for various mechanical and industrial applications.

Different Types of Hydraulic Locks Explained

Hydraulic locks come in different designs to cater to specific needs and applications:

1. Single-Acting Hydraulic Locks:

These operate in one direction only, making them ideal for simpler applications. They rely on the pressure in one direction to move the piston and lock the position. When the pressure is released, the piston returns to its starting position, making them cost-effective and easy to maintain.

2. Double-Acting Hydraulic Locks:

Unlike single-acting locks, these locks function in both directions, allowing for more control and versatility. They can provide locking in both extension and retraction, making them suitable for applications requiring more precision and flexibility, such as in industrial machinery.

3. Pilot-Operated Check Valves:

These valves are used in hydraulic locking systems to control fluid flow with precision. They enable the hydraulic system to hold a locked position and provide enhanced control by using a pilot signal to control valve operation. They are ideal for complex hydraulic systems requiring higher accuracy and performance.

Also Read:

Maintenance Technician Tool List: Essential Tools for Every Job

Applications of Different Hydraulic Lock Types

Each type of hydraulic lock serves specific applications, depending on the needs of the machinery:

1. Single-Acting Systems:

These are commonly used in simple, cost-effective applications like automotive lifts, presses, or jacks. Since they operate in only one direction, they are ideal for situations where the load remains in a stable position after being locked.

2. Double-Acting Systems:

Used in more complex machinery, double-acting hydraulic locks provide control in both directions. These systems are essential in applications that require both extension and retraction, such as construction equipment, hydraulic cranes, and industrial presses that require flexibility in motion and precise control.

3. Pilot-Operated Valves:

These locks are crucial in high-precision fields like aerospace and robotics, where the demands for accuracy and reliability are stringent. Pilot-operated valves allow for highly controlled locking and unlocking mechanisms in systems where minute adjustments are necessary to ensure safety and performance.

Why Choose Hydraulic Locks Over Mechanical Systems?

Hydraulic locks are favored over mechanical systems for several compelling reasons:

1. Precision:

Hydraulic locks provide superior control over the movement and positioning of machinery components. By regulating the flow and pressure of hydraulic fluid, they offer fine-tuned adjustments that mechanical systems often cannot match, ensuring high accuracy in locking mechanisms.

2. Strength:

Hydraulic locks can handle significantly higher loads than mechanical locks. The pressure generated within the hydraulic system allows these locks to operate under extreme conditions, easily securing heavy machinery and equipment without compromising their structural integrity.

3. Durability:

Designed to withstand harsh environments, hydraulic locks are built with materials and components that ensure long-term reliability. They can perform under extreme temperatures, vibration, and other challenging conditions, making them ideal for industries where durability is a priority.

4. Safety:

Hydraulic locks have a built-in safety advantage due to their controlled pressure mechanisms. Unlike mechanical systems, which may fail under excessive load or stress, hydraulic systems are less prone to failure, reducing the risk of accidents and ensuring the security of the entire system.

Also Read:

Enhanced Safety Features of Hydraulic Lock Systems

Safety is a key consideration in the design and operation of hydraulic locks. These systems come with several features to enhance reliability and minimize risks:

1. Overload Protection:

Hydraulic locks are designed to manage high-pressure conditions, with overload protection mechanisms that prevent excessive pressure build-up. This feature ensures that the system operates within safe limits, preventing damage to components and the risk of system failure.

2. Fail-Safe Designs:

Many hydraulic lock systems incorporate fail-safe designs that automatically release pressure or engage safety measures if the system experiences malfunction. This reduces the risk of catastrophic failures, ensuring the continued safety of the machinery and personnel operating it.

3. Pressure Release Mechanisms:

Built-in pressure release mechanisms allow for safe and controlled discharge of pressure when needed. These mechanisms ensure that the system remains operational under fluctuating pressure conditions, providing a fail-safe in case of sudden pressure surges or loss of control.

These enhanced safety features make hydraulic locks an essential choice in critical industries, including aerospace, construction, and manufacturing, where the integrity of the equipment and safety of personnel are paramount.

Common Issues in Hydraulic Locks and How to Troubleshoot Them

Hydraulic locks are generally reliable, but like any mechanical system, they can encounter issues. Here are some common problems and solutions:

1. Leaks:

Leaks are one of the most common problems in hydraulic locks, typically caused by damaged seals or loose connections. When fluid leaks, it can affect the pressure and performance of the system.

Solution: Inspect all seals and connections regularly. Replace any damaged seals and tighten connections to prevent further leaks. Ensure proper sealing materials are used to withstand high pressure.

2. Pressure Loss:

A loss of pressure can occur if components such as valves or cylinders become worn or damaged. Without sufficient pressure, the hydraulic lock may fail to hold the piston securely in place.

Solution: Regularly check the condition of valves and cylinders. If there are signs of wear or damage, replace the affected components. Ensuring the system is free of debris and contaminants also helps maintain proper pressure levels.

3. Contaminated Fluid:

Contaminants in hydraulic fluid, such as dirt or moisture, can degrade the performance of the hydraulic lock and cause inefficiencies in operation.

Solution: To prevent contamination, regularly flush the hydraulic system and replace the fluid according to the manufacturer’s recommendations. Use high-quality filters to prevent particles from entering the fluid system, and keep the system sealed to avoid contamination from external sources.

Proper maintenance and troubleshooting are essential for ensuring the smooth operation of hydraulic locks, prolonging their lifespan, and maintaining system performance.

Also Read:

Maintenance Tips for Long-Lasting Hydraulic Locks

Proper maintenance is crucial to ensuring the longevity and optimal performance of hydraulic locks:

1. Regular Inspections:

Consistently inspect all components of the hydraulic lock system to identify potential issues such as leaks, wear, or damage before they become major problems. Early detection helps prevent costly repairs and downtime.

2. Clean Hydraulic Fluid:

Contaminants in hydraulic fluid can cause the system to lose efficiency or even fail. Regularly check and clean the hydraulic fluid to prevent buildup of dirt, moisture, or other impurities that could damage internal components.

3. Seal Replacement:

Over time, seals can wear out or become brittle, leading to leaks or pressure loss. Regular seal replacement ensures that hydraulic locks remain airtight, preserving system pressure and preventing fluid leakage.

4. System Calibration:

Properly calibrating the system’s pressure settings is essential for smooth operation. Ensure that the pressure levels are accurately set according to manufacturer specifications to maintain the lock’s holding capacity and safety.

By following these maintenance tips, you can extend the life of hydraulic locks, minimize downtime, and keep your systems running smoothly.

Also Read:

Real-World Applications: Where Hydraulic Locks Are Used

Hydraulic locks play a crucial role in many industries due to their reliability and precision:

1. Automotive:

Hydraulic locks are often used in braking systems, where they help secure brake components in place under pressure. They are also found in vehicle lifts, where they ensure the lift stays stable while lifting or lowering vehicles.

2. Construction:

In construction, hydraulic locks are essential in cranes, excavators, and other heavy machinery. These locks prevent boom collapse or ensure that heavy loads are safely secured when lifting or moving materials.

3. Manufacturing:

Hydraulic locks are commonly used in manufacturing settings, such as presses and assembly lines, where precise control and stability are needed to secure parts and tools during the manufacturing process.

4. Aerospace:

In the aerospace industry, hydraulic locks are critical for providing precise control in aircraft systems, such as landing gear and flight control systems. The ability to lock and secure parts under varying pressure conditions ensures safe and reliable operation.

Hydraulic Locks in Heavy Machinery and Equipment

Heavy machinery and equipment rely heavily on hydraulic locks for stability and control. These locks are especially crucial for ensuring safe operation in environments with high loads or moving parts:

Cranes: Hydraulic locks in cranes prevent the boom from collapsing under heavy loads by securely locking the position of the boom during operation. This enhances the safety of both operators and bystanders.

Loaders: Hydraulic locks are used to secure the bucket or other lifting components of loaders. This helps ensure that the load is safely held in place during loading and unloading, reducing the risk of accidents and improving operational efficiency.

By using hydraulic locks, these machines can safely operate under high-pressure conditions, providing stability and safety when handling large and heavy materials.

Also Read:

Future Innovations in Hydraulic Lock Technology

As technology evolves, so does the design and functionality of hydraulic locks. Several innovations are shaping the future of hydraulic lock systems:

1. Digital Pressure Control:

The introduction of digital pressure control systems allows for real-time adjustments and monitoring of hydraulic pressure. This offers greater accuracy and efficiency in controlling the locking mechanism and ensures smoother operation.

2. Advanced Materials:

New materials are being developed to make hydraulic locks more durable and resistant to wear and tear. These materials can withstand extreme conditions such as high temperatures and corrosive environments, increasing the lifespan of hydraulic locks.

3. Integrated Sensors:

The integration of sensors into hydraulic lock systems provides better monitoring and feedback on the system’s performance. Sensors can detect changes in pressure, fluid levels, or temperature, alerting operators to potential issues before they lead to system failure.

These innovations promise to further enhance the precision, safety, and durability of hydraulic locks, ensuring that they continue to play an indispensable role in modern machinery and industrial applications.

Also Read:

Conclusion

Hydraulic locks are marvels of engineering, combining simplicity and power to provide reliable control and stability in various applications. Understanding their components, operation, and maintenance can help industries maximize their potential. With ongoing advancements, hydraulic locks are set to become even more versatile, paving the way for safer and more efficient machinery.