When working with hydraulic systems, one of the most important factors that ensures efficiency and safety is choosing the right hydraulic hose size. Selecting a hose that is too small restricts flow, while one that is too large can increase costs and reduce flexibility. This is where a hydraulic hose size chart comes in handy.

In this guide, we’ll explore everything you need to know about hydraulic hose sizing, factors that affect it, and provide a comprehensive size chart to simplify the process.

Why Hydraulic Hose Size Matters

Hydraulic hoses act like arteries in a hydraulic system. They carry pressurized fluid from one component to another, powering machines such as excavators, forklifts, tractors, and industrial presses.

If the hose size doesn’t match the system’s requirements, you may encounter:

Pressure drops that reduce efficiency.

Overheating due to increased fluid velocity.

Premature wear of hoses and fittings.

Safety hazards from leaks, bursts, or failures.

Correct sizing ensures your system runs at its best while avoiding costly downtime.

Key Factors in Hose Sizing

Before jumping to the chart, let’s look at the main elements you need to understand when selecting hydraulic hose size.

1. Inside Diameter (ID)

The ID determines the flow capacity. If the hose is too small, velocity increases, creating excessive pressure loss and heat. If it’s too large, the hose becomes bulkier and more expensive.

2. Outside Diameter (OD)

This matters when routing hoses in tight spaces. It also affects what fittings can be attached.

3. Hose Dash Size

In hydraulics, hoses are often measured in dash sizes, which are 1/16th of an inch increments of the inside diameter. For example:

Dash 4 = 4/16″ = 1/4″ ID

Dash 8 = 8/16″ = 1/2″ ID

4. Flow Rate & Velocity

Hydraulic systems usually maintain fluid velocities within recommended ranges to reduce turbulence and friction loss. For pressure lines, a velocity of 20 ft/s is common, while return lines may allow up to 10 ft/s.

5. Pressure Rating

The hose must withstand both the working pressure and potential spikes without failure.

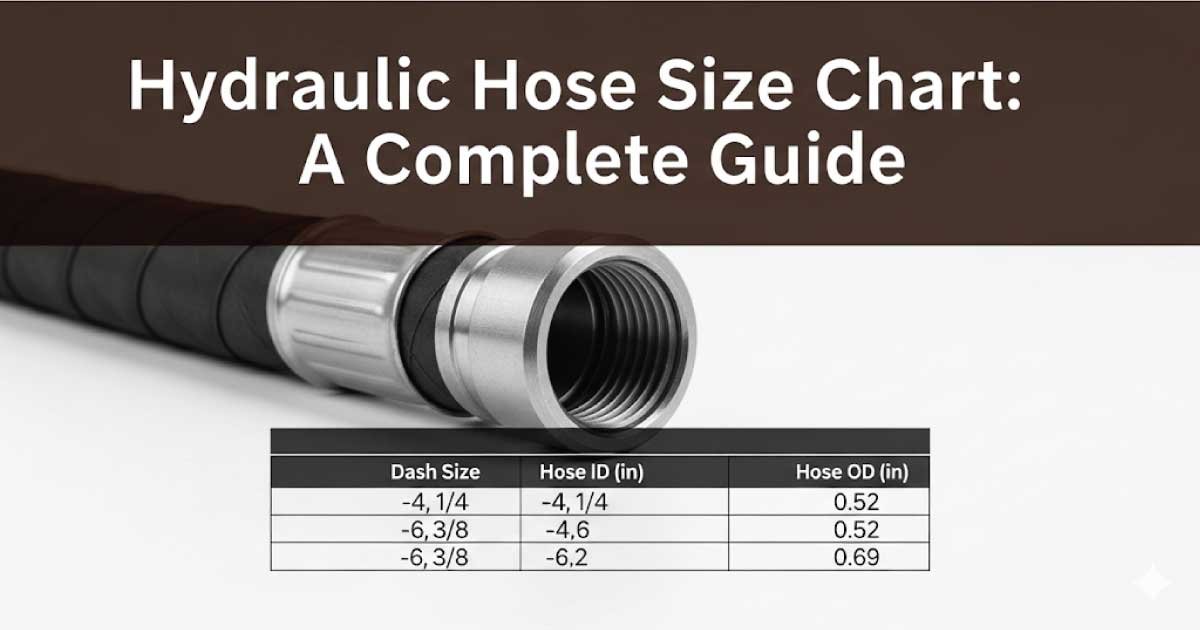

Hydraulic Hose Size Chart

Here’s a reference chart that links dash size, hose ID, and recommended flow capacities.

Hydraulic Hose Size Reference

| Dash Size | Hose ID (inches) | Hose ID (mm) | Recommended Flow (GPM) | Typical Applications |

|---|---|---|---|---|

| -2 | 1/8″ | 3.2 mm | 0.5 – 1.0 | Pilot lines, light-duty hydraulics |

| -3 | 3/16″ | 4.8 mm | 1.0 – 1.5 | Small equipment, instrumentation |

| -4 | 1/4″ | 6.4 mm | 2.0 – 3.0 | Low-pressure return lines |

| -6 | 3/8″ | 9.5 mm | 3.5 – 6.0 | Mobile equipment, steering |

| -8 | 1/2″ | 12.7 mm | 6.5 – 12.0 | Construction machinery |

| -10 | 5/8″ | 15.9 mm | 11 – 17 | Agricultural machines |

| -12 | 3/4″ | 19.1 mm | 17 – 27 | Excavators, loaders |

| -16 | 1″ | 25.4 mm | 28 – 45 | Industrial systems, high-flow return |

| -20 | 1-1/4″ | 31.8 mm | 46 – 70 | Large hydraulic circuits |

| -24 | 1-1/2″ | 38.1 mm | 71 – 100 | Heavy-duty industrial hydraulics |

| -32 | 2″ | 50.8 mm | 101 – 150+ | High-volume return lines |

Hydraulic Hose Size PDF Chart

If you want a printable version of the chart, here’s a Hydraulic Hose Size Chart PDF. It’s useful for mechanics, engineers, or field technicians who need quick reference during installation or troubleshooting.

How to Use the Hose Size Chart

Determine flow requirement: Check how many gallons per minute (GPM) your hydraulic pump delivers.

Match with velocity: Ensure the hose size allows recommended velocities (not too fast or too slow).

Select dash size: Use the chart to find the dash size that meets your GPM requirement.

Check fittings and routing: Verify that the hose OD works with your fittings and space.

Example: Choosing the Right Size

Let’s say you have a system delivering 20 GPM.

A 1/2″ hose (-8) would only handle about 12 GPM efficiently, which would overheat.

A 3/4″ hose (-12) can handle 27 GPM, making it the correct choice.

This demonstrates how undersized hoses can restrict performance and why charts are critical.

Also Read: Metric Drill and Tap Chart: A Complete Guide

Common Mistakes in Hydraulic Hose Sizing

Ignoring flow velocity – Many users just pick hoses by diameter without checking velocity.

Oversizing – Larger hoses cost more and reduce flexibility.

Using wrong fittings – Even if the hose ID is correct, mismatched fittings cause leaks.

Not considering future upgrades – If you expect higher flow in the future, plan ahead with hose sizing.

Hose Routing and Installation Tips

Choosing the right size is step one, but proper installation ensures long service life.

Avoid sharp bends that reduce flow.

Use clamps and protective sleeves to prevent abrasion.

Leave enough slack to handle pressure surges.

Never twist hoses during installation.

Final Thoughts

A hydraulic hose size chart is more than just a table of numbers—it’s a critical tool for system performance and safety. By understanding flow rate, velocity, and dash sizes, you can make informed choices that prevent failures and extend the life of your hydraulic equipment.

Whether you are maintaining a small tractor or designing an industrial system, the correct hose size ensures maximum efficiency and reliability.

Also Read: Drill Chart 2025: Complete Guide with PDF

FAQs

What is a hydraulic hose size chart used for?

A hydraulic hose size chart helps users match the correct hose diameter to their system’s flow requirements. It provides reference values for dash sizes, inside diameters, and recommended flow rates. By using the chart, engineers and technicians can ensure the hose supports optimal fluid velocity, prevents excessive pressure drop, and reduces the risk of overheating. It’s a critical tool for designing safe and efficient hydraulic systems.

How do dash sizes relate to hydraulic hose sizing?

Dash sizes are a standard way of describing hydraulic hose diameters in 1/16-inch increments. For example, a dash 4 (-4) indicates a hose with a 1/4-inch inside diameter, while dash 8 (-8) equals 1/2 inch. Understanding dash sizes makes it easier to choose the right hose when working with charts, fittings, or catalogs. They provide a universal language in hydraulics that simplifies hose identification and replacement.

Why does inside diameter matter in hydraulic hoses?

The inside diameter (ID) of a hydraulic hose directly affects the flow capacity of the system. A smaller diameter increases fluid velocity, which can cause turbulence, heat buildup, and pressure loss. Conversely, an oversized hose may waste resources and reduce system flexibility. Matching the correct ID ensures smooth flow, prevents energy loss, and supports long equipment life. This is why proper ID selection is essential for hydraulic efficiency.

What happens if you choose the wrong hydraulic hose size?

Using the wrong hose size can create several issues. If the hose is too small, it restricts flow, leading to overheating, higher energy use, and pressure drops. This can cause premature hose wear or even system failure. If the hose is too large, it may be bulky, more expensive, and harder to route properly. Both extremes impact safety, efficiency, and long-term maintenance costs. Correct sizing prevents these problems.

How can I calculate the right hydraulic hose size for my system?

To calculate the correct hose size, you need to know the flow rate (GPM) and allowable fluid velocity. Use the hydraulic hose size chart to match these values with the proper inside diameter. For example, pressure lines typically run at 20 feet per second, while return lines allow 10 feet per second. Once you determine flow and velocity, you can select the dash size that ensures reliable performance.

Can hydraulic hose size affect energy efficiency?

Yes, hydraulic hose sizing plays a major role in system energy efficiency. An undersized hose forces the pump to work harder due to increased friction and pressure loss, wasting energy. On the other hand, oversized hoses may increase fluid volume unnecessarily, reducing overall responsiveness. Choosing the correct hose size balances velocity and pressure, minimizing energy losses. This not only improves efficiency but also reduces operating costs over time.

Are larger hydraulic hoses always better?

Not necessarily. While larger hoses can carry more fluid, they are not always the best choice. Oversized hoses may add unnecessary cost, reduce flexibility in tight installations, and make the system bulkier. Moreover, fluid velocity may drop too low, affecting performance. The goal is not to go bigger but to size hoses correctly according to flow rate and application needs. Proper sizing ensures both efficiency and durability.