When it comes to construction, lifting operations, or heavy-duty fastening, I bolts (often called eye bolts) play a critical role. They are used to attach cables, ropes, or chains securely and are an essential component in material handling. Choosing the correct size of I bolt ensures both safety and performance. In this guide, we’ll cover everything you need to know about I bolts and provide a detailed I bolt size chart to help you make the right choice.

What is an I Bolt?

An I bolt (or eye bolt) is a type of fastener featuring a threaded shank with a looped head that resembles the shape of an eye. This design allows the bolt to be used for securing or lifting objects with hooks, shackles, or ropes. Depending on the type and load rating, I bolts can be used for light-duty tasks like hanging fixtures or heavy-duty jobs such as lifting industrial equipment.

Types of I Bolts

Before diving into the size chart, it’s helpful to understand the different types of I bolts available:

Shoulder Eye Bolts – Designed with a shoulder between the eye and the thread, making them suitable for angular lifting.

Plain Pattern Eye Bolts – No shoulder; suitable only for vertical lifting.

Lag Eye Bolts – Feature wood screw threads; ideal for screwing directly into timber.

Machinery Eye Bolts – Heavy-duty eye bolts designed for industrial applications and lifting machinery.

Swivel Eye Bolts – Allow rotation, reducing the risk of rope or chain twisting under load.

Each type is chosen depending on the load, angle, and material being used.

Why the I Bolt Size Chart Matters

Using the wrong I bolt size can lead to dangerous situations, including equipment failure or accidents. The I bolt size chart provides standard dimensions for different diameters, lengths, and load capacities. By referencing the chart, engineers and builders can:

Ensure proper load handling capacity.

Select the correct bolt for vertical or angular lifts.

Prevent thread stripping or structural damage.

Increase efficiency and safety in construction and rigging.

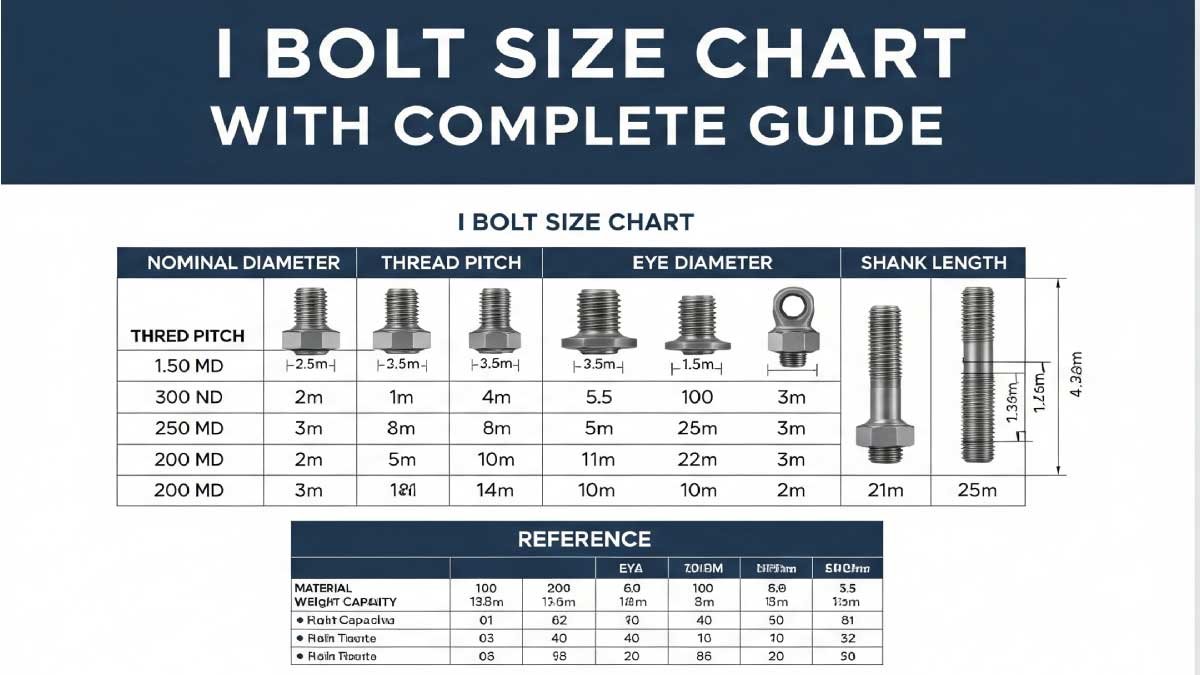

Standard I Bolt Size Chart

Below is a practical I bolt size chart that lists common dimensions and safe working load limits (SWL). Please note that exact specifications may vary by manufacturer, but this chart gives a reliable standard reference.

| I Bolt Size (Thread Dia.) | Thread Length (mm) | Inside Eye Diameter (mm) | Overall Length (mm) | Safe Working Load (kg) |

|---|---|---|---|---|

| M6 | 12 | 12 | 40 | 70 |

| M8 | 18 | 16 | 50 | 140 |

| M10 | 20 | 20 | 60 | 230 |

| M12 | 25 | 25 | 75 | 340 |

| M16 | 30 | 32 | 100 | 700 |

| M20 | 35 | 40 | 120 | 1200 |

| M24 | 40 | 50 | 140 | 1800 |

| M30 | 45 | 65 | 170 | 3200 |

| M36 | 55 | 75 | 200 | 4800 |

This chart provides the most commonly used metric sizes. For critical lifting operations, always check manufacturer specifications.

🏆 Interested in more content? Try 👉 Bolt Size Chart: A Complete Guide

Standard I Bolt Size Chart PDF

The Standard I Bolt Size Chart PDF provides clear details of common I bolt dimensions, including thread length, inside eye diameter, overall length, and safe working load limits (SWL). This handy chart serves as a reliable reference for engineers, construction workers, and rigging professionals. Always verify manufacturer specifications for critical lifting operations to ensure maximum safety and accurate performance.

Applications of I Bolts

I bolts are incredibly versatile and can be found in many industries:

Construction – Securing scaffolding, lifting beams, and handling heavy loads.

Marine – Used with ropes and rigging systems for boats and ships.

Industrial Lifting – Essential for hoisting machinery, motors, and large equipment.

Electrical Installations – Supporting conduits, cables, and overhead structures.

DIY Projects – Hanging planters, lights, or gym equipment at home.

By referencing the size chart, users can select the correct bolt for each application, ensuring safe and efficient results.

🏆 Interested in more content? Try 👉 Drill Chart: Complete Guide with PDF

How to Choose the Right I Bolt

When selecting an I bolt, consider the following:

Load Requirement – Always match the safe working load to the task. Never exceed the recommended capacity.

Material – Stainless steel I bolts are corrosion-resistant and ideal for marine use, while carbon steel provides strength for industrial applications.

Thread Type – Metric or imperial threads should match the nut or tapped hole.

Lifting Angle – Use shoulder eye bolts for angled lifts; plain eye bolts only for straight pulls.

Installation Surface – Ensure the material can withstand the load applied to the I bolt.

Safety Precautions with I Bolts

To avoid accidents and ensure longevity, always follow these safety practices:

Inspect I bolts for wear, cracks, or corrosion before use.

Tighten bolts fully so the shoulder rests against the surface.

Never exceed the rated load capacity.

For angled lifts, ensure proper orientation with shoulder bolts.

Replace damaged or bent I bolts immediately.

Following these guidelines not only enhances safety but also extends the lifespan of your hardware.

🏆 Interested in more content? Try 👉 Metric Drill and Tap Chart: A Complete Guide

Advantages of Using I Bolts

Strength – Designed to handle heavy loads safely.

Versatility – Suitable for lifting, securing, and anchoring.

Durability – High-quality steel construction ensures longevity.

Ease of Use – Simple installation with wrenches or screwdrivers.

Standardization – Available in metric and imperial sizes for compatibility worldwide.

Conclusion

The I bolt size chart is an essential reference for builders, engineers, and DIY users who need reliable fasteners for lifting and securing applications. By choosing the right size, material, and type of I bolt, you can ensure both safety and efficiency in any project.

Whether you are working on a heavy industrial task or a simple home improvement project, the chart above provides all the guidance you need. Always prioritize safety by following the manufacturer’s specifications and load ratings.

🏆 Interested in more content? Try 👉 Screw Size Chart: Complete Guide

FAQs Related to I Bolt Size:

What is an I bolt used for?

An I bolt, also called an eye bolt, is primarily used to attach ropes, chains, or cables for lifting, securing, or anchoring loads. They are widely used in construction, rigging, marine applications, and industrial machinery. Depending on size and type, I bolts can handle anything from small fixtures to several tons of weight, making them versatile and reliable for both light-duty and heavy-duty projects.

How do I read an I bolt size chart?

An I bolt size chart provides details like thread diameter, thread length, inside eye diameter, overall bolt length, and safe working load. For example, an M12 bolt has a 12mm diameter, 25mm thread length, and can safely handle around 340kg. By checking the chart, users can quickly determine which bolt size suits their lifting or fastening needs without risking overloading or mismatching components.

What is the safe working load of I bolts?

The safe working load (SWL) of I bolts varies depending on size, material, and manufacturer specifications. For instance, a small M6 I bolt has an SWL of about 70kg, while a larger M36 can handle up to 4800kg. Always reference the size chart and follow manufacturer guidelines. Overloading an I bolt can lead to dangerous failures, so never exceed the recommended capacity.

Can I bolts be used for angled lifting?

Yes, but only certain types of I bolts are suitable for angled lifting. Shoulder eye bolts are designed to handle side or angular loads safely, while plain pattern eye bolts are meant only for vertical lifting. Using the wrong type can lead to bending, breaking, or unsafe lifting conditions. Always check the chart, select the correct bolt type, and ensure proper installation for angled applications.

What materials are I bolts made of?

I bolts are commonly made from carbon steel, stainless steel, or galvanized steel. Carbon steel offers strength for industrial applications, stainless steel provides corrosion resistance for marine use, and galvanized steel offers a balance of durability and affordability. The choice depends on the environment and purpose. For long-term outdoor or marine use, stainless steel I bolts are recommended, while carbon steel suits heavy-duty indoor lifting.

How do I choose the correct I bolt size?

Choosing the correct I bolt size depends on the load requirement, lifting angle, and installation surface. Always check the I bolt size chart to match diameter and length with your task. For example, M20 bolts are suitable for loads up to 1200kg, while smaller M8 bolts handle only 140kg. Selecting the correct size prevents overloading, ensures safety, and improves performance in lifting and fastening.

Are I bolts standardized worldwide?

Yes, most I bolts follow ISO metric standards, meaning that sizes like M10 or M16 are universally recognized across countries. This standardization ensures interchangeability, so an M12 bolt from one manufacturer will fit an M12 nut or tapped hole from another. For lifting-rated bolts, additional standards such as ASME or DIN may apply. Always verify specifications in the size chart for international consistency and safety.