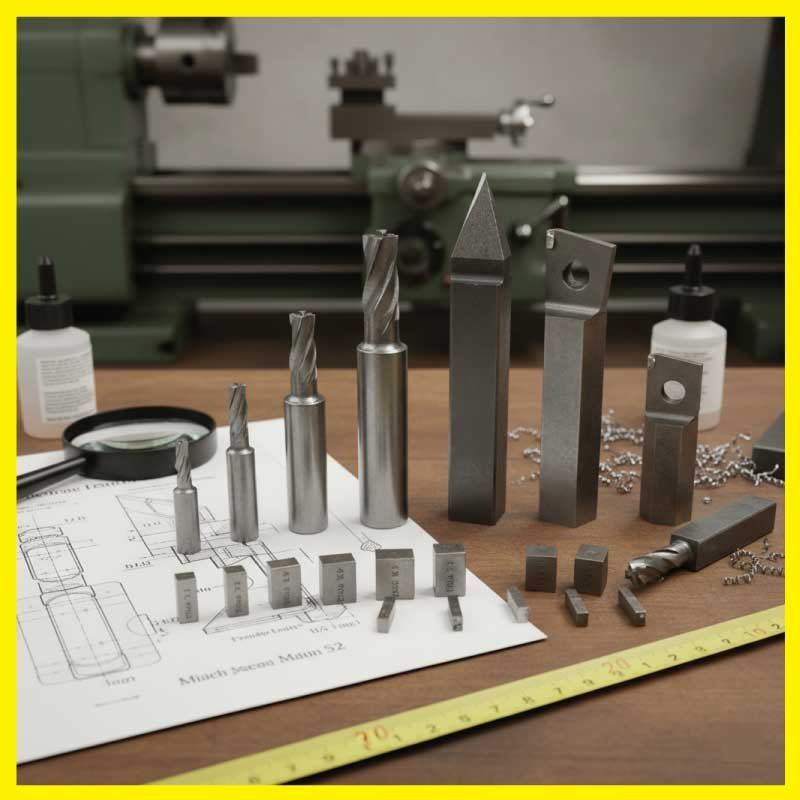

If you have ever stepped into a machine shop or worked around a lathe, you’ve likely heard people talk about tool bit sizes—3/8″, 1/2″, 5/16″, and so on. But what exactly do these sizes mean? And how do you know which one to use for your project?

That’s where this lathe tool bit size chart comes in handy. Whether you are a beginner learning the ropes or an experienced machinist fine-tuning your setup, understanding the right lathe tool bit size can make all the difference in achieving clean, accurate cuts.

In this guide, we will go over everything you need to know from tool bit dimensions and materials to how to choose the right size for your lathe. You’ll also find a detailed lathe tool bit size chart below to make your selection quick and easy.

What Is a Lathe Tool Bit?

A lathe tool bit is a small piece of hardened metal (usually high-speed steel or carbide) that’s used to remove material from a workpiece as it spins on the lathe. Think of it as the “blade” that shapes, cuts, or finishes your metal, wood, or plastic parts.

Tool bits are mounted in a tool holder, and the cutting edge is shaped (or “ground”) for specific types of cuts—like turning, facing, threading, or parting off.

Why Tool Bit Size Matters

Choosing the right size tool bit is not just about what fits in your tool post. It affects:

Cutting performance: A tool bit that’s too small might chatter or deflect.

Surface finish: The wrong height can cause poor surface quality.

Tool life: Using the correct size reduces wear and prevents breakage.

Machine compatibility: Your lathe’s tool post size determines the maximum tool bit height it can hold safely.

In short, the size of your tool bit directly impacts the precision and efficiency of your turning operation.

Lathe Tool Bit Size Chart

Let’s look at the standard sizes available and which lathe type or application they’re most suitable for.

| Tool Bit Size (Inches) | Tool Bit Size (mm) | Common Lathe Type | Recommended Use / Application |

|---|---|---|---|

| 1/4″ × 1/4″ | 6 × 6 mm | Mini Lathe / Hobby Lathe | Light turning, soft materials (aluminum, brass) |

| 5/16″ × 5/16″ | 8 × 8 mm | Small Bench Lathe | General small-part turning, fine finishing |

| 3/8″ × 3/8″ | 10 × 10 mm | Medium Lathe | Most common size for home workshops |

| 1/2″ × 1/2″ | 12 × 12 mm | Medium to Large Lathe | Heavy cuts, steel, and tough alloys |

| 5/8″ × 5/8″ | 16 × 16 mm | Industrial Lathe | For roughing operations and high torque jobs |

| 3/4″ × 3/4″ | 20 × 20 mm | Heavy Duty Lathe | Deep cutting, heavy material removal |

| 1″ × 1″ | 25 × 25 mm | Industrial / CNC Lathe | Heavy-duty, precision machining tasks |

Lathe Tool Bit Size Chart PDF

Lathe Tool Bit Size Chart helps machinists and hobbyists choose the right tool for precision cutting. Each size suits different lathes, from mini to industrial models, ensuring accurate, smooth, and efficient performance. Understanding the correct bit size improves cutting stability, surface finish, and tool life — making it an essential reference for every turning operation.

Understanding Tool Bit Dimensions

Each size (like 1/2″ × 1/2″) represents the square cross-section of the tool bit.

That means it’s ½ inch wide and ½ inch high, while the length can vary (usually around 2–3 inches).

Here’s why the height matters:

Your lathe tool post needs the cutting edge to be at the same height as the workpiece centerline. If your bit is too tall or too short, it won’t cut properly — it might rub, dig in, or leave a poor finish.

How to Choose the Right Lathe Tool Bit Size

When choosing your tool bit size, keep these four main factors in mind:

1. Lathe Size

Each lathe has a maximum tool bit capacity.

For example:

- Mini lathes (7×10, 8×12) usually handle up to 3/8″ tool bits.

- Mid-size lathes (9×20 or 10×22) can take 1/2″ bits comfortably.

- Larger industrial machines go up to 3/4″ or 1″ tool bits.

👉 Tip: Check your tool post slot size. If it’s 1/2″, you can’t fit a 5/8″ bit without modifying the tool post or shimming.

2. Material of Workpiece

Different materials require different cutting strengths:

Soft metals (aluminum, brass) → smaller bits (¼” or 5/16″) are fine.

Steel or cast iron → medium to large bits (3/8″ or ½”).

Hardened alloys → use carbide-tipped or 5/8″+ bits for rigidity.

3. Type of Operation

What you’re doing on the lathe also matters:

Roughing: Use larger tool bits for stability and strength.

Finishing: Use smaller bits for finer cuts.

Threading or grooving: Choose the tool shape, not just the size, carefully.

Rigidity and Clearance

A bigger tool bit usually means more rigidity, which helps reduce vibration and chatter. But make sure the bit doesn’t interfere with the chuck or tailstock, especially on smaller machines.

Types of Lathe Tool Bits

Besides size, tool bits come in different shapes and materials. Let’s take a quick look:

1. High-Speed Steel (HSS) Tool Bits

Pros: Easy to grind, inexpensive, ideal for small lathes.

Cons: Dulls faster at high speeds.

Best For: Beginners, general-purpose turning.

2. Carbide Tool Bits

Pros: Hard, heat-resistant, stays sharp longer.

Cons: More brittle and expensive.

Best For: Hard metals and high-speed cutting.

3. Cobalt Tool Bits

Pros: Between HSS and carbide in toughness; good heat resistance.

Best For: Medium-hard steels, stainless steel.

4. Brazed Carbide Tool Bits

These have carbide tips brazed onto a steel shank — a good balance of durability and affordability.

Common Lathe Tool Bit Shapes

Tool bits are ground into different shapes depending on the type of cut needed. The main ones include:

| Shape Type | Purpose | Common Application |

|---|---|---|

| Right-Hand Tool | Cuts from right to left | General turning |

| Left-Hand Tool | Cuts from left to right | Reverse cuts |

| Round Nose | Finishing tool for smooth surfaces | Light cuts |

| Threading Tool | Cuts screw threads | Internal/external threads |

| Parting Tool | Cuts off the workpiece | Grooving or separating |

| Boring Tool | Enlarges internal holes | Internal cutting |

Understanding these shapes helps you grind and select your tool bits correctly for the job at hand.

Lathe Tool Bit Height Setup

Even with the right size bit, tool height adjustment is critical.

Here’s how to set it up:

- Mount the tool bit in the holder.

- Bring it close to the workpiece or tailstock center.

- Adjust with shims or the tool post screw until the cutting edge aligns with the centerline of the workpiece.

✅ Pro Tip: If the tool is above center, it can rub instead of cut. If it’s below center, it can dig in or cause chatter.

Example: Choosing a Tool Bit for a 9×20 Lathe

Let’s say you have a 9×20 bench lathe. The tool post slot typically fits up to ½” tool bits.

If you mostly turn mild steel and occasionally aluminum:

- Use 3/8″ HSS bits for fine finishing.

- Keep ½” carbide bits for tougher jobs or roughing passes.

This gives you flexibility and ensures both smooth finishes and durability.

Detailed Lathe Tool Bit Size Reference (Imperial and Metric)

| Imperial Size (Inches) | Metric Equivalent (mm) | Length (approx.) | Typical Use |

|---|---|---|---|

| 1/8″ × 1/8″ | 3 × 3 mm | 1.5″ | Mini hobby lathes, very light work |

| 3/16″ × 3/16″ | 5 × 5 mm | 2″ | Small parts, model making |

| 1/4″ × 1/4″ | 6 × 6 mm | 2.5″ | Small lathes, soft metals |

| 5/16″ × 5/16″ | 8 × 8 mm | 2.5″ | Small to mid lathes |

| 3/8″ × 3/8″ | 10 × 10 mm | 2.75″ | General purpose |

| 1/2″ × 1/2″ | 12 × 12 mm | 3″ | Medium lathes, steel cutting |

| 5/8″ × 5/8″ | 16 × 16 mm | 3″ | Heavy cuts |

| 3/4″ × 3/4″ | 20 × 20 mm | 3.5″ | Industrial work |

| 1″ × 1″ | 25 × 25 mm | 4″ | CNC / Large lathe operations |

Maintaining and Sharpening Lathe Tool Bits

No matter the size, a dull tool bit can ruin your surface finish and damage your workpiece.

Here’s how to keep them in shape:

Regular Grinding: Use a bench grinder or tool grinder.

Maintain Proper Angles:

Rake angle: 8°–15°

Relief angle: 6°–12°

Nose radius: Small for fine cuts, larger for roughing.

Cool During Grinding: Dip in water to avoid overheating.

Hone with a Stone: Finish the edge for a smoother cut.

Final Thoughts

Choosing the correct lathe tool bit size is one of those small details that make a huge difference in machining quality.

If your tool bit matches your lathe size, material, and operation type, you will notice:

- Smoother finishes

- Reduced chatter

- Longer tool life

- Better overall control

Use the lathe tool bit size chart above as your quick reference, and always focus on matching size and rigidity to the job. With the right setup, even a small bench lathe can produce professional-level results.

Summary Table – Quick Reference

| Lathe Type | Recommended Tool Bit Size | Common Material Cut |

|---|---|---|

| Mini Lathe (7×10, 8×12) | 1/4″ to 5/16″ | Aluminum, brass |

| Medium Lathe (9×20, 10×22) | 3/8″ to 1/2″ | Mild steel, bronze |

| Large Lathe (12″+ swing) | 5/8″ to 3/4″ | Cast iron, stainless steel |

| CNC / Industrial Lathe | 3/4″ to 1″ | Hardened steel, alloys |

A Quick Tip Before You Go

If you’re just starting out, invest in a lathe tool bit set that includes multiple sizes (¼”, ⅜”, ½”). It’s the best way to experiment and learn which size works best for your machine and material type.

Once you get familiar with how different bit sizes behave, you’ll start to notice subtle improvements in every cut — and that’s the real joy of precision machining.

📏 Collet Sizes Chart helps machinists and tool users find the perfect collet for their machine or workpiece. Understanding different collet sizes ensures accurate gripping, smooth machining, and better performance. Whether you’re working with ER, R8, or 5C collets, this guide makes selection easy — keep reading the full post to choose the ideal size for your project!

FAQs:

What are the kinds of lathe tool bits?

Lathe tool bits come in several types based on their cutting purpose and shape. The main kinds are right-hand, left-hand, round-nose, threading, parting, and boring tools. They’re made from materials like High-Speed Steel (HSS), carbide, or cobalt, depending on the job. Each tool type performs a specific function—whether it’s shaping, cutting, finishing, or grooving the workpiece.

What is the size of a lathe?

The size of a lathe is usually described by two measurements — the swing (the maximum diameter of material it can turn) and the distance between centers (the maximum length of material it can hold). For example, a 9×20 lathe means a 9-inch swing and 20-inch length capacity. These measurements help users choose the right machine for their project size.

What size are mini lathe tools?

Mini lathes typically use smaller tool bits, usually around 1/4-inch (6 mm) or 5/16-inch (8 mm) square shank size. These compact tools are perfect for hobby projects, aluminum, brass, and small steel parts. Their smaller size provides more control for fine detailing while still being strong enough for light machining tasks on compact benchtop lathes.

How do I know what size tool post for my lathe?

To find the right tool post size, measure your lathe’s center height (from the bed to the spindle centerline). Then, match it to the tool post manufacturer’s chart, which lists recommended post sizes for different lathe heights. Generally, smaller lathes use AXA, medium ones BXA, and larger industrial lathes CXA or higher. Always ensure your tool bit aligns with the workpiece centerline.

What is a BT-40 tool holder?

A BT-40 tool holder is a type of precision tool holder used mainly in CNC milling machines, not manual lathes. It has a 40-taper shank that fits into the machine spindle and securely holds cutting tools. The “BT” design offers balanced performance for high-speed machining, providing excellent rigidity and accuracy — making it ideal for modern industrial manufacturing.

What is the size of lath?

The size of a lathe can vary widely depending on its purpose. Small mini lathes may be 7×10 inches, suitable for hobbyists. Bench lathes are often around 9×20 or 10×22 inches, while industrial floor lathes can reach 16×40 inches or larger. These measurements refer to swing and distance between centers, which determine the maximum workpiece size.

What is a lath tool?

A lathe tool (or tool bit) is a cutting tool used on a lathe machine to shape, cut, or finish rotating material. It’s typically made from HSS, carbide, or cobalt and comes in various shapes like right-hand, left-hand, or round-nose. The tool removes material layer by layer, producing smooth surfaces, precise dimensions, or threads on the workpiece.

What size lathe is most common?

For home workshops and small businesses, the most common lathe size is around 9×20 inches or 10×22 inches. These medium-sized bench lathes offer a great balance between power, precision, and affordability. They can handle most metalworking jobs, from turning and threading to facing and boring, making them ideal for both beginners and experienced machinists.

How do I know if my lathe is MT1 or MT2?

To determine if your lathe is MT1 or MT2 (Morse Taper size), measure the inside diameter of the spindle or tailstock taper. MT1 usually has a smaller diameter (about 12 mm at the large end), while MT2 measures around 18 mm. You can also check the manufacturer’s manual — it lists the correct taper size for your machine’s headstock and tailstock.