Engines power the world around us — from the car you drive to the lawn mower in your backyard, and even the massive ships crossing oceans. If you’ve ever wondered how engines work but felt overwhelmed by technical jargon, you’re not alone. Understanding engines doesn’t have to be complicated. With a clear, step-by-step approach, you can grasp the basics and even appreciate the engineering genius behind them.

In this 10-step easy guide, we’ll walk you through the fundamentals, breaking down complex concepts into simple explanations anyone can follow. By the end, you’ll have a solid understanding of how engines function, the main components involved, and why they’re designed the way they are.

Step 1: Understand What an Engine Actually Is

At its core, an engine is a machine designed to convert one form of energy into mechanical power. Most common engines — like those in cars — convert chemical energy from fuel into kinetic energy (movement).

Engines can be classified into many types:

Internal Combustion Engines (ICE) – Found in most cars, motorcycles, and boats; they burn fuel inside the engine’s cylinders.

External Combustion Engines – Such as steam engines, where fuel is burned outside the engine, and steam powers movement.

Electric Motors – Technically not “engines” in the traditional sense, but they convert electrical energy into motion.

Think of the engine as the heart of a vehicle. Just like the heart pumps blood to keep the body alive, the engine generates power to keep a machine moving.

Step 2: Learn the Basic Principle of How an Engine Works

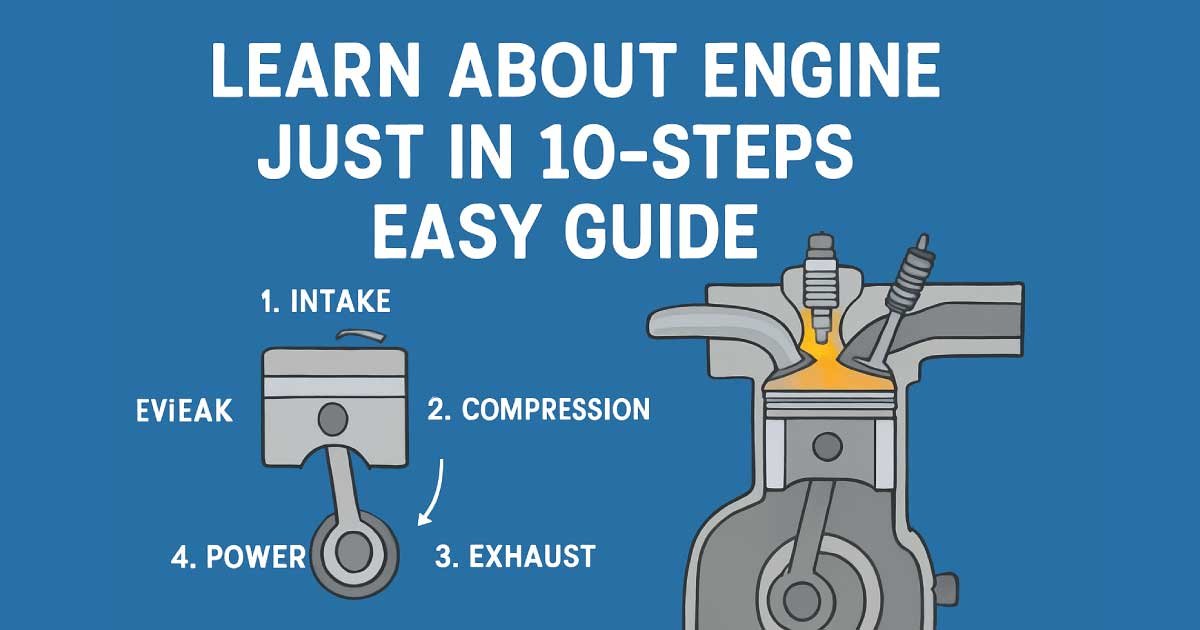

For an internal combustion engine, the process is surprisingly straightforward:

Fuel and air mix inside the engine cylinder.

A spark plug ignites this mixture.

The explosion forces a piston downward.

The crankshaft converts this motion into rotation.

The rotation is sent to the wheels (in cars) or propellers (in boats).

This cycle repeats hundreds of times per minute, producing continuous movement. The process is known as the four-stroke cycle (intake, compression, power, exhaust).

If you understand these four strokes, you already grasp the foundation of how most car engines work.

Step 3: Identify the Main Parts of an Engine

An engine may seem like a maze of metal and wires, but it’s really a collection of essential parts working together:

Cylinder – The chamber where the fuel-air mix burns.

Piston – Moves up and down inside the cylinder.

Crankshaft – Converts piston motion into rotation.

Valves – Control the intake of air/fuel and release of exhaust gases.

Spark Plug – Ignites the fuel-air mixture.

Camshaft – Controls the timing of the valves.

Oil System – Lubricates parts to reduce friction.

Cooling System – Prevents overheating using coolant or air.

If you can point to each part and know its function, you’ve taken a big step toward engine literacy.

Step 4: Learn About Different Types of Engines

Engines come in different shapes, sizes, and designs depending on their purpose. The most common ones include:

Petrol (Gasoline) Engines – Light, fast, and common in cars and motorcycles.

Diesel Engines – More fuel-efficient and durable, often used in trucks, buses, and heavy equipment.

Rotary Engines – Compact and lightweight, but less common today.

Electric Motors – Used in electric vehicles, powered by batteries instead of fuel.

Hybrid Engines – Combine fuel-powered engines with electric motors for efficiency.

Knowing the differences will help you understand why certain vehicles use certain engines. For example, trucks often use diesel engines because they provide high torque for pulling heavy loads.

Step 5: Understand the Role of Fuel and Air

Engines can’t run on fuel alone — they need the right mixture of fuel and air for combustion. Air brings oxygen, which reacts with fuel to produce energy. The balance is crucial:

Too much fuel (rich mixture) → Wastes fuel, causes smoke, and reduces efficiency.

Too much air (lean mixture) → Can overheat the engine and cause damage.

Modern engines use fuel injection systems to ensure the perfect mix, replacing older carburetors. Some high-performance engines even use turbochargers or superchargers to force more air in, creating more power.

A good way to imagine it: Think of a campfire. If you don’t have enough oxygen, the fire dies. If you add too much wood without airflow, it smokes. The same principle applies to engines.

Step 6: Ignition and Timing

The ignition system is what starts the combustion process inside the engine. In petrol engines, spark plugs create a spark at the precise moment the fuel-air mixture is compressed inside the cylinder. Diesel engines, however, work a bit differently — they rely on the high pressure inside the cylinder to ignite the fuel without a spark plug.

Why timing matters:

If the spark occurs too early or too late, the engine loses efficiency, burns more fuel, or even causes damage. This is known as ignition timing, and modern vehicles use computers (ECUs) to control it with incredible precision.

A good example: Imagine clapping in sync with music — if your clap comes too soon or too late, it throws off the rhythm. Engines work the same way: perfect timing keeps everything smooth.

Step 7: Lubrication and Cooling Systems

Engines operate under intense pressure and heat. Without proper lubrication, the moving parts would grind against each other and wear out almost instantly.

Lubrication system key points:

Engine oil coats moving parts to reduce friction.

The oil pump circulates oil through the engine.

Oil filters keep out dirt and debris.

Cooling system key points:

Most modern engines use a liquid cooling system with coolant flowing through the engine block.

A radiator transfers heat from the coolant to the air.

Some smaller engines (like motorcycles) use air cooling instead.

If lubrication is the “skin cream” for your engine, cooling is the “fan” keeping it from overheating. Both systems must work together to ensure a long engine life.

Step 8: Exhaust and Emissions

After combustion, the burned gases must leave the engine. This is where the exhaust system comes in. It channels exhaust gases safely away from the engine and reduces harmful emissions before they reach the atmosphere.

Main exhaust components:

Exhaust manifold – Collects gases from cylinders.

Catalytic converter – Breaks down harmful pollutants.

Muffler – Reduces noise from the exhaust.

Tailpipe – Releases gases outside the vehicle.

Modern engines are designed to meet strict emission standards, meaning they burn fuel more cleanly. Some even use EGR (Exhaust Gas Recirculation) systems to re-burn certain gases for improved efficiency.

Think of it as your car’s way of “breathing out” — the cleaner the breath, the healthier the environment.

Step 9: Common Engine Problems and Maintenance

Even the best engines face issues if not maintained properly. Learning to recognize early signs can save you costly repairs.

Common engine problems:

Overheating – Often due to coolant leaks or radiator issues.

Knocking sounds – Can mean poor fuel quality or timing issues.

Oil leaks – May indicate worn seals or gaskets.

Loss of power – Could be caused by clogged fuel injectors or air filters.

Basic maintenance tips:

Regular oil changes – Every 3,000–7,000 miles depending on your vehicle.

Replace air filters – Keeps airflow clean and efficient.

Check coolant levels – Prevents overheating.

Inspect spark plugs – Ensures smooth ignition.

Listen for unusual noises – Early detection prevents bigger issues.

Think of engine maintenance like brushing your teeth — skip it for too long, and you’ll pay for it later.

Step 10: How to Keep Learning and Practicing

Understanding engines doesn’t end with reading a guide — real learning comes from hands-on experience. Even if you’re not planning to become a mechanic, basic skills can be useful for troubleshooting and saving money.

Ways to keep learning:

Watch tutorials – Many mechanics share detailed repair videos online.

Read repair manuals – Learn the exact specifications for your vehicle.

Join car forums – Ask questions and read about others’ experiences.

Try small projects – Start with oil changes, spark plug replacements, or air filter swaps.

Attend workshops – Local colleges or community centers often offer automotive classes.

The more you explore, the more these concepts will stick. And remember, even experienced mechanics started with curiosity and small steps.

Final Thoughts

Engines might seem intimidating at first, but breaking them down into 10 simple steps makes them easier to understand. You now know:

What an engine is and how it works

The main components and their functions

How fuel, air, ignition, and timing work together

The importance of lubrication, cooling, and exhaust systems

Common issues and how to prevent them

How to continue your engine education

Whether you are a curious beginner or someone looking to understand their vehicle better, these steps give you a strong foundation. And who knows — today’s curiosity might lead to tomorrow’s passion for engineering or automotive repair.

Also Read: