What Does “M” Mean in Set Screw Sizes?

The letter “M” in set screw sizes stands for metric thread, which means the screw is measured using the metric system. The number that follows the “M” indicates the nominal outer diameter of the thread in millimeters.

For example, M4 means the screw has a 4 mm thread diameter, while M8 indicates an 8 mm thread diameter. Metric set screws are manufactured according to ISO (International Organization for Standardization) standards, which ensures consistent sizing, precise fit, and global compatibility across tools, machinery, and fasteners.

What Is a Set Screw?

A set screw is a fully threaded fastener used to secure one object within or against another by applying pressure at its tip. Unlike bolts or cap screws, it has no head and is designed to sit flush with or below the surface. Set screws are commonly used to lock gears, pulleys, collars, and knobs onto shafts.

Common Applications of M Set Screws

M set screws are essential fastening components used to securely lock parts in position without protruding heads. Thanks to their metric sizing and ISO standardization, they are widely adopted across mechanical, industrial, and precision-based systems where compact, reliable holding power is required.

1-Shaft and Pulley Assemblies

In shaft and pulley assemblies, M set screws prevent slipping and rotational movement by tightly gripping the shaft surface. They ensure accurate alignment and torque transmission, making them ideal for conveyor systems, motors, and power transmission setups where stable motion and positioning are critical.

2-Gears and Couplings

M set screws are commonly used in gears and couplings to lock components firmly onto shafts. They help maintain precise positioning under load and vibration, ensuring smooth power transfer. Their compact, headless design makes them perfect for tight spaces in mechanical assemblies.

3-Bearings and Collars

In bearings and shaft collars, M set screws secure components in fixed axial positions. This prevents unwanted movement during operation and improves overall system stability. Metric set screws provide consistent clamping force, which is essential for maintaining alignment and reducing wear in rotating parts.

4-Automotive Components

Automotive systems rely on M set screws for securing small but critical components such as sensors, knobs, and shaft-mounted parts. Their resistance to vibration and precise metric sizing make them suitable for engines, transmissions, and interior mechanisms where reliability and space efficiency matter.

5-Industrial Machinery

Industrial machinery uses M set screws to lock moving and stationary parts in place under heavy loads. They are commonly found in manufacturing equipment, pumps, and compressors, offering durability, easy installation, and compliance with international standards for global machine compatibility.

6-Electronics and Robotics

In electronics and robotics, M set screws are valued for their precision and compact size. They help secure motors, joints, and control components without adding bulk, ensuring accurate movement and positioning in reminder-sensitive systems like robotic arms, automation units, and electronic assemblies.

Also Read:

Metric Set Screw Standards (ISO & DIN)

ISO 4026 – 4029

DIN 913 – DIN 916

These standards define:

Thread pitch

Length tolerances

Drive types

Tip styles

Understand Metric Thread Pitch

Metric thread pitch refers to the distance between adjacent threads, measured in millimeters. It plays a key role in how tightly a set screw engages with a threaded hole.

For example, M6 × 1.0 means the screw has a 1.0 mm thread pitch, while M6 × 0.75 represents a fine pitch thread. Unless specifically stated, coarse pitch is considered the standard for most metric set screws due to its strength and ease of installation.

Example:

M6 × 1.0 → 1.0 mm pitch

M6 × 0.75 → fine pitch

Coarse pitch is standard unless otherwise specified.

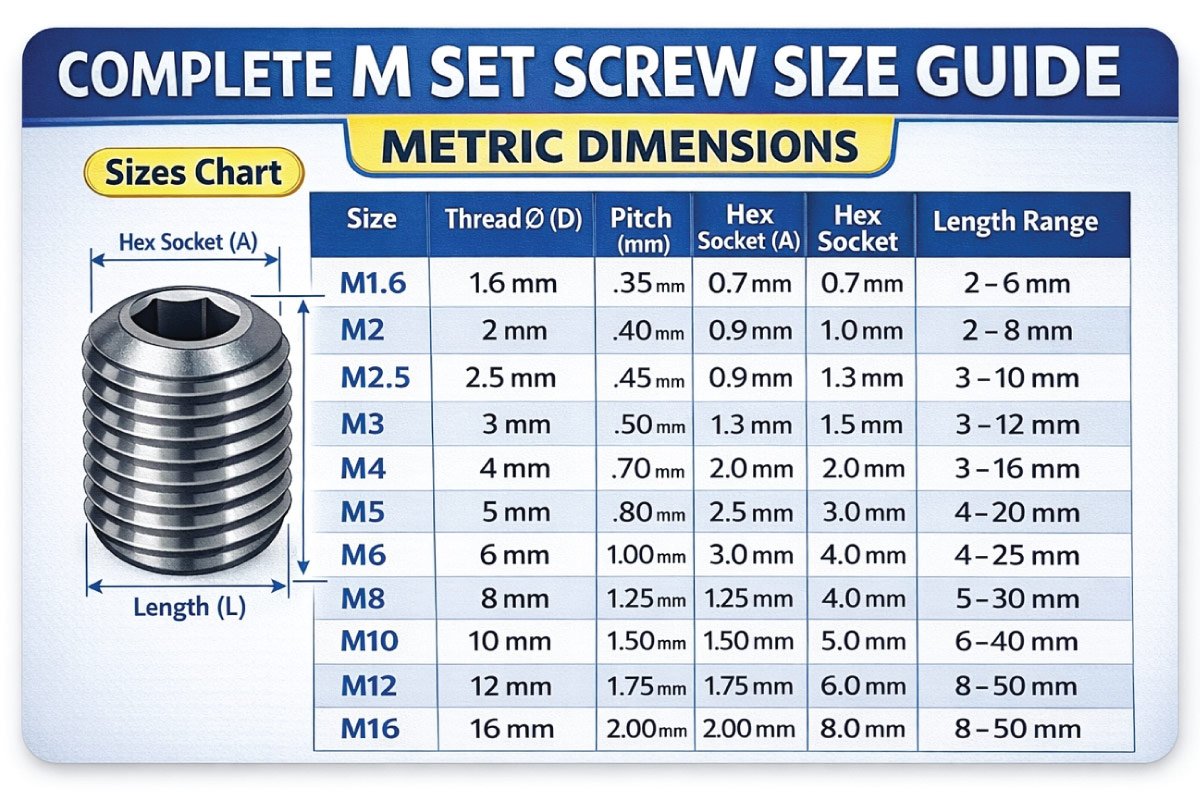

Standard M Set Screw Size Chart (Diameter & Pitch)

This chart shows the most commonly used metric (M) set screw sizes, including their nominal thread diameters and both standard (coarse) and fine thread pitches. Coarse pitch is typically used for general applications, while fine pitch is preferred where higher precision or vibration resistance is required.

Metric Set Screw Thread Sizes

| M Size | Nominal Diameter (mm) | Standard Pitch (mm) | Fine Pitch (mm) |

|---|---|---|---|

| M2 | 2.0 | 0.40 | 0.25 |

| M3 | 3.0 | 0.50 | 0.35 |

| M4 | 4.0 | 0.70 | 0.50 |

| M5 | 5.0 | 0.80 | 0.50 |

| M6 | 6.0 | 1.00 | 0.75 |

| M8 | 8.0 | 1.25 | 1.00 |

| M10 | 10.0 | 1.50 | 1.25 |

| M12 | 12.0 | 1.75 | 1.50 |

Metric Set Screw Length Explained

Metric set screw length is measured from one end to the other because set screws do not have a head. This ensures accurate sizing for proper engagement inside the threaded hole. Common lengths typically range from 3 mm to 50 mm, with the exact length selected based on the screw’s diameter, application load, and required holding depth.

Also Read:

Standard Lengths for M Set Screws

Metric set screws are available in a range of standardized lengths to suit different holding depths and load requirements. Choosing the correct length ensures proper thread engagement without bottoming out or protruding beyond the surface.

Typical Length Ranges

| M Size | Common Lengths (mm) |

|---|---|

| M3 | 3, 4, 5, 6, 8, 10 |

| M4 | 4, 6, 8, 10, 12 |

| M5 | 6, 8, 10, 12, 16 |

| M6 | 8, 10, 12, 16, 20 |

| M8 | 10, 12, 16, 20, 25 |

| M10 | 12, 16, 20, 25, 30 |

Types of Set Screw Drive Styles

Set screw drive styles determine how torque is applied during installation and removal. Choosing the right drive type improves grip, reduces tool slippage, and prevents damage to the screw or surrounding material. Each drive style offers different advantages based on torque needs and accessibility.

1-Hex Socket (Allen) Drive

Hex socket, commonly known as Allen drive, is the most widely used set screw drive style. It allows higher torque transfer, better tool engagement, and minimal risk of stripping. This drive is ideal for precision assemblies, tight spaces, and applications requiring frequent adjustment.

2-Slotted Drive

Slotted drive set screws feature a single straight slot and are typically used in light-duty or older applications. While easy to install with a flat-head screwdriver, they offer limited torque control and are more prone to slipping or cam-out under higher loads.

3-Torx Drive

Torx drive set screws use a star-shaped recess that provides excellent torque transmission and strong tool engagement. This design reduces cam-out and wear, making Torx drives suitable for high-torque, vibration-prone applications such as automotive components and industrial machinery.

4-Square Socket Drive

Square socket drive set screws provide solid contact between the tool and fastener, allowing reliable torque application. They are less common than hex sockets but are valued in specific industrial and mechanical setups where durability and resistance to stripping are important.

Also Read:

Common Screw Tip Types and Their Uses

Set screw tips are designed to balance holding strength and surface protection. Selecting the right tip type ensures secure fastening while minimizing damage to the shaft or component. Each style serves specific applications, from temporary positioning to high-vibration environments.

Set Screw Tip Styles

| Tip Type | Description | Best Use Case |

|---|---|---|

| Flat Point | Flat end, minimal damage | Temporary positioning |

| Cup Point | Concave tip | General purpose, shafts |

| Cone Point | Sharp point | Permanent locking |

| Dog Point | Extended tip | Precise alignment |

| Knurled Cup | Serrated edge | High vibration |

Material Options for M Set Screws

Common materials include:

Carbon steel – Strong and economical

Alloy steel – High strength

Stainless steel (A2, A4) – Corrosion resistant

Brass – Non-marring, electrical uses

Nylon – Lightweight, non-conductive

Strength Grades and Hardness

Metric set screws are classified by strength grades that indicate their tensile capacity and hardness. Common grades include Class 12.9, which offers high tensile strength for most mechanical applications, and Class 14.9, designed for heavy-duty industrial use. Higher class numbers correspond to greater load-bearing capability and durability, ensuring reliable performance under stress.

Class 12.9 – High tensile strength

Class 14.9 – Heavy-duty industrial use

Higher class numbers mean greater load capacity.

Also Read:

Complete Coupling Size Guide 2026 with Charts

How to Choose the Right M Set Screw Size

Coarse vs Fine Thread Set Screws

Metric set screws come in coarse and fine thread options, each suited for specific applications. Understanding the differences helps in choosing the right screw for strength, precision, and ease of installation. Coarse threads are ideal for quick assembly and softer materials, while fine threads offer higher holding power and better resistance to vibration.

1-Coarse Threads

Coarse thread set screws have fewer threads per millimeter, allowing faster installation and easier assembly. They are ideal for softer materials like aluminum or plastic, as they reduce the risk of stripping. Coarse threads are generally preferred for general-purpose applications where speed and simplicity are more important than precision.

2-Fine Threads

Fine thread set screws feature closely spaced threads, providing higher holding strength and better vibration resistance. They are ideal for applications requiring precise adjustments, such as machinery alignment or instrumentation. Fine threads distribute load more evenly along the shaft, improving stability and reducing the likelihood of loosening under stress.

Metric vs Imperial Set Screws

Metric and imperial (inch-based) set screws differ in key specifications, and understanding these differences is essential for proper assembly. Metric screws use millimeters for diameter and pitch, while imperial screws use inches and threads per inch (TPI). Thread angles and pitch calculations also vary. Mixing the two systems can cause poor fit, stripping, or component damage.

1-Measurement System

Metric set screws are measured in millimeters, specifying both diameter and thread pitch, whereas imperial screws are measured in inches, with threads per inch (TPI) indicating thread density. Using the correct measurement system ensures proper fit and engagement between screw and threaded hole, preventing loosening or mechanical failure.

2- Thread Angle

Metric and imperial screws have different thread angles, affecting how the threads engage and hold. Metric threads typically have a 60° angle, while some imperial threads use 55° or other standards. Mismatched thread angles can lead to poor grip, stripping, and uneven load distribution, compromising the assembly.

3-Pitch Calculation

Pitch, the distance between threads, is calculated differently for metric and imperial screws. Metric screws use millimeters per thread, while imperial screws use threads per inch (TPI). Confusing the two can result in a loose fit, thread damage, or difficulty during installation, making it crucial to match the screw system to the application.

3-Mixing Systems Warning

Never mix metric and imperial set screws in the same assembly. Differences in diameter, pitch, and thread angle can cause improper engagement, stripping, and potential failure. Always use screws and threaded components from the same measurement system to ensure reliable performance and maintain mechanical integrity.

Also Read:

Installation Tips for M Set Screws

Proper installation of M set screws ensures secure holding, long-lasting performance, and minimal damage to components. Following a few key practices can prevent common issues like loosening, stripping, or misalignment.

1-Clean Threads Before Installation

Always clean both the set screw and the threaded hole before installation. Remove debris, dirt, or grease to ensure smooth engagement and consistent torque application. Clean threads reduce the risk of cross-threading, improve holding strength, and help the screw seat properly against the shaft or component.

2-Use Thread Locker for Vibration Resistance

Applying a thread-locking compound enhances resistance to vibration and prevents the screw from loosening over time. Thread lockers are especially useful in rotating machinery, automotive components, or high-vibration environments, ensuring the set screw maintains firm contact without frequent retightening.

3-Avoid Over-Torquing

Over-tightening a set screw can strip threads, damage the shaft, or break the screw. Always follow recommended torque values for the specific size and material. Using a calibrated torque wrench or carefully applying hand pressure ensures secure fastening without compromising the components.

4-Use Correct Hex Key Size

Using the correct hex key (Allen wrench) size prevents rounding off the drive recess or damaging the screw. A snug-fitting tool ensures maximum torque transfer, smooth installation, and reduces the risk of stripping, especially for small-diameter screws in tight spaces.

5-Align Tip Properly with Shaft Flat

For maximum holding strength, align the screw tip with a shaft flat or groove. Proper alignment ensures even pressure distribution, prevents slipping, and minimizes surface damage. Misaligned tips can reduce holding power and lead to vibration-related loosening over time.

Common Mistakes to Avoid

When using M set screws, several common mistakes can compromise performance and safety. Selecting the wrong thread pitch, using a soft material for high-torque applications, over-tightening cone point screws, or neglecting corrosion resistance can lead to loosening, damage, or premature failure. Awareness of these pitfalls ensures reliable and long-lasting assemblies.

Choosing incorrect pitch

Using soft material for high torque

Over-tightening cone point screws

Ignoring corrosion requirements

Maintenance and Replacement Guidelines

Proper maintenance of M set screws is essential for safe and reliable operation. Regularly inspect screws for wear, thread stripping, corrosion, or loosening due to vibration. Any damaged or compromised screws should be replaced immediately to prevent mechanical failure, ensure secure fastening, and maintain optimal performance in machinery and assemblies.

Wear

Thread stripping

Corrosion

Loosening under vibration

Replace damaged screws immediately to prevent mechanical failure.

Final Thoughts

Understanding M set screw sizes ensures proper fit, maximum holding power, and long-term reliability. Whether you’re a mechanical engineer, technician, or DIY enthusiast, using the correct metric set screw can prevent costly failures and improve performance.

Keep this M set screw size guide as a reference for selecting the right diameter, pitch, length, and tip style for any application.

Also Read:

Complete Shoulder Bolt Size Guide and Measurement Chart

FAQs:

What are M screw sizes?

M screw sizes follow the metric thread system, where the letter “M” stands for metric and the number indicates the screw’s nominal diameter in millimeters. For example, M5 means a 5 mm thread diameter. These sizes follow ISO standards and are widely used worldwide.

How to determine M screw size?

To determine an M screw size, measure the outside diameter of the threads using a caliper; this gives the M value in millimeters. Then check the thread pitch by measuring the distance between threads or using a thread gauge. Length is measured from the head to the tip.

Which is bigger, M6 or M8 screws?

M8 screws are bigger than M6 screws. The number represents the thread diameter in millimeters, so an M6 screw has a 6 mm diameter while an M8 screw has an 8 mm diameter. M8 screws are stronger and used for heavier loads.

What size is M5?

An M5 screw has a nominal thread diameter of 5 millimeters. The most common thread pitch for M5 is 0.8 mm, although fine pitches also exist. M5 screws are commonly used in machinery, electronics, and automotive assemblies.

What are the different types of set screws?

Set screws come in several types based on their tip design, including cup point, flat point, cone point, and dog point. Each type is designed for specific holding needs, such as maximum grip, minimal surface damage, or precise alignment in mechanical assemblies.

How to measure M screws?

To measure M screws, first measure the outer thread diameter to identify the M size. Next, measure the thread pitch using a gauge or ruler. Finally, measure the length from the head underside or top, depending on the screw type, to the tip.