Mechanical pencils are an essential tool for students, artists, engineers, and professionals. Unlike traditional wooden pencils, mechanical pencils offer a reusable and precise writing experience. But have you ever wondered how these innovative writing instruments are made? In this in-depth guide, we will explore the manufacturing process of a mechanical pencil, covering the materials, production steps, and quality control measures.

Understanding Mechanical Pencils

A mechanical pencil consists of multiple components, including a plastic or metal body, lead mechanism, eraser, and clip. Unlike regular pencils that need sharpening, mechanical pencils use a refillable lead system, making them a long-lasting and convenient option.

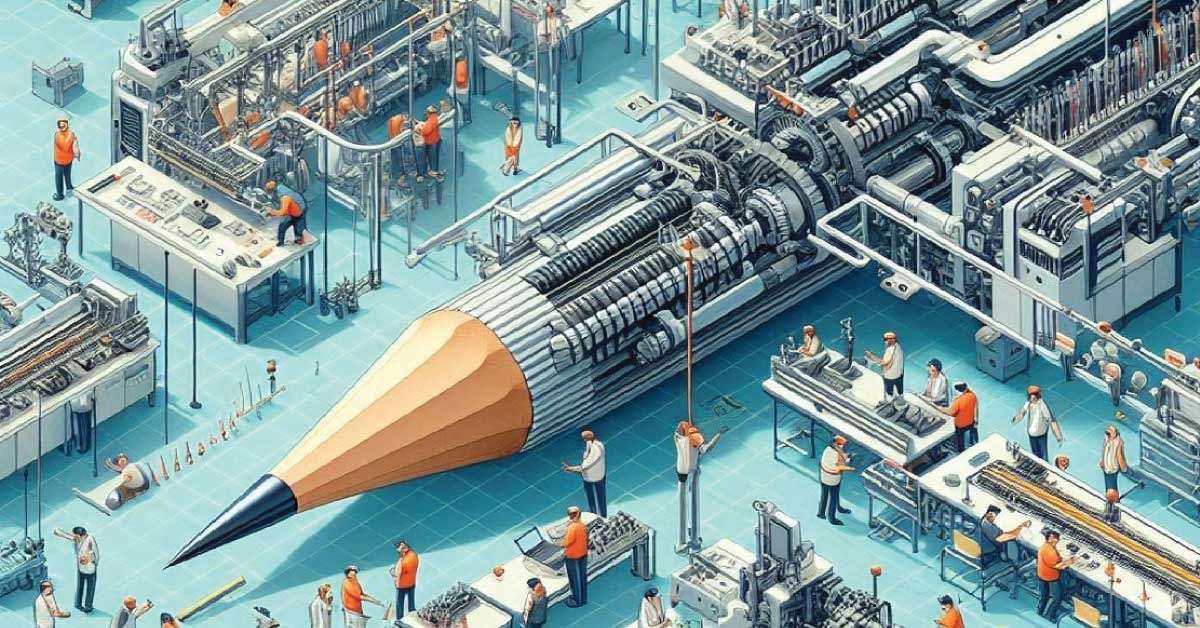

The manufacturing process of a mechanical pencil involves precise engineering and quality materials to ensure smooth operation and durability. Let’s dive into the step-by-step process.

Raw Materials Used in Mechanical Pencil Manufacturing

Before production begins, manufacturers gather high-quality materials to create a durable and efficient mechanical pencil. The main materials include:

- Plastic or Metal Casing – The body of the pencil is made from ABS plastic or lightweight metal like aluminum or stainless steel.

- Lead (Graphite Core) – The lead used in mechanical pencils is made from graphite and clay, available in different thicknesses like 0.5mm, 0.7mm, and 0.9mm.

- Spring Mechanism – A spring-loaded clutch or a twist mechanism is used to advance the lead smoothly.

- Rubber or Vinyl Eraser – Some mechanical pencils come with an attached eraser.

- Metal Clips – Used for securing the pencil to a pocket or notebook.

Each of these materials undergoes a series of manufacturing processes to create the final product.

Also Read:

Step-by-Step Manufacturing Process of a Mechanical Pencil

1. Designing the Mechanical Pencil

Before production begins, engineers design the pencil using CAD (Computer-Aided Design) software. The design process ensures that the pencil is comfortable to hold, lightweight, and durable.

The design team focuses on:

- Ergonomics for a comfortable grip

- Lead advancement mechanism efficiency

- Aesthetic appeal and functionality

Once the design is finalized, the production phase begins.

2. Injection Molding for the Pencil Body

The outer casing of a mechanical pencil is usually made of ABS plastic or metal. The process involves:

- Melting the raw plastic pellets at high temperatures.

- Injecting molten plastic into molds to form the pencil body.

- Cooling and hardening the plastic in the mold.

- Removing the pencil casing from the mold.

For metal-bodied mechanical pencils, the casing is created through metal extrusion and precision machining.

3. Manufacturing the Graphite Lead

The lead used in mechanical pencils is a combination of graphite and clay, mixed to achieve the desired hardness level (e.g., HB, 2B, 4H).

The process includes:

- Grinding graphite and clay into a fine powder.

- Mixing with water to create a smooth paste.

- Extruding the paste into thin rods of 0.5mm, 0.7mm, or other standard sizes.

- Baking at high temperatures to remove moisture and harden the lead.

- Cutting the lead into standard refill lengths.

The finished graphite leads are inspected for consistency before assembly.

4. Assembling the Mechanical Pencil Components

Once the individual parts are ready, they are assembled into a working mechanical pencil. The assembly process includes:

✅ Inserting the lead advancement mechanism – A spring-loaded clutch or twist mechanism is placed inside the casing.

✅ Placing the graphite lead – A piece of graphite lead is inserted into the lead tube.

✅ Attaching the eraser – If the pencil has an eraser, it is fitted at the top.

✅ Adding a metal clip – The clip is attached for better portability.

Also Read:

5. Quality Control and Testing

Each mechanical pencil undergoes rigorous quality control testing to ensure functionality and durability. The quality checks include:

✅ Lead advancement test – Ensuring the lead extends and retracts smoothly.

✅ Drop test – Checking the pencil’s durability by dropping it from a certain height.

✅ Grip comfort test – Evaluating the ergonomic design for comfortable use.

✅ Eraser efficiency test – Ensuring the eraser works effectively without smudging.

Only the best-quality pencils pass the quality control process and move to the final packaging stage.

Packaging and Distribution

Once the mechanical pencils pass all quality tests, they are packaged for retail distribution. The packaging process includes:

📦 Individual Packaging – Each pencil is packed in a plastic sleeve or cardboard box.

📦 Bulk Packaging – Large quantities are packed for wholesale distribution.

📦 Branding and Labeling – The manufacturer adds logos, labels, and product information.

After packaging, the mechanical pencils are shipped to retailers worldwide.

Sustainable Manufacturing of Mechanical Pencils

With growing environmental concerns, manufacturers are adopting eco-friendly methods in mechanical pencil production.

♻ Use of Recycled Plastics – Some brands use recycled ABS plastic for the pencil casing.

♻ Biodegradable Leads – New formulations use natural binders for eco-friendly graphite leads.

♻ Minimal Packaging Waste – Companies use recyclable paper packaging instead of plastic.

Sustainable manufacturing helps reduce waste and environmental impact while providing high-quality mechanical pencils.

Why Are Mechanical Pencils Popular?

The manufacturing process of a mechanical pencil ensures that these writing tools are durable, precise, and long-lasting. Here’s why mechanical pencils are widely used:

✔ No need for sharpening – Lead refills eliminate the hassle of sharpening.

✔ Consistent line thickness – Perfect for technical drawings and neat handwriting.

✔ Refillable and reusable – A cost-effective and environmentally friendly choice.

✔ Variety of lead grades – Suitable for different writing and drawing styles.

These advantages make mechanical pencils a preferred choice for professionals, students, and artists alike.

Also Read:

Manufacturer: Definition, Types and Key Roles, Detailed Explanation

Final Thoughts

The manufacturing process of a mechanical pencil is a combination of precision engineering, quality materials, and efficient assembly. From designing the casing to producing the graphite lead and assembling the final product, each step ensures a high-quality writing instrument.

With the demand for durable and eco-friendly stationery increasing, manufacturers are now adopting sustainable practices to create mechanical pencils that are both functional and environmentally responsible.

Whether you’re an artist sketching a masterpiece or a student taking notes, mechanical pencils offer a reliable and precise writing experience. Understanding their manufacturing process gives us a deeper appreciation for this essential tool!

Frequently Asked Questions (FAQs)

🔹 How is the lead in a mechanical pencil made?

The lead is made from a mixture of graphite and clay, extruded into thin rods, and baked at high temperatures to harden.

🔹 What materials are used to make mechanical pencils?

Mechanical pencils are made from plastic or metal casings, graphite leads, rubber erasers, and spring mechanisms.

🔹 Why do some mechanical pencils have a twist mechanism?

A twist mechanism allows smooth and controlled lead advancement without using a button.

🔹 Are mechanical pencils environmentally friendly?

Some brands use recycled materials and biodegradable leads to make mechanical pencils more sustainable.

By understanding the manufacturing process of a mechanical pencil, we can appreciate the engineering behind this everyday writing tool. Now, the next time you use a mechanical pencil, you’ll know exactly how it was made! 🚀