Nuts and bolts are the backbone of almost every machine, structure, or tool we use in daily life. From holding car engines together to fastening furniture parts, nuts ensure secure connections. But here’s the challenge—nuts come in a wide variety of sizes, standards, and thread types. Choosing the wrong nut can mean loose connections, broken parts, or wasted time. That is where a nut size chart becomes essential.

This guide will walk you through everything you need to know about nut sizes, including measurement standards, conversion charts, and practical tips for selecting the right nut every time.

Why Nut Sizes Matter

Picking the correct nut is not just about convenience—it is about safety, durability, and performance.

Correct fit: Prevents loosening under vibration.

Structural strength: Ensures the joint can handle weight or stress.

Prevents damage: Wrong sizes can strip threads or crack the material.

Saves time & effort: No more trial and error during projects.

Whether you’re a mechanic, engineer, or DIY enthusiast, knowing nut sizes is crucial.

Nut Size Standards

Nut sizes are determined by bolt diameter, thread pitch, and across-flats measurement (AF). Different regions follow different standards:

1. Metric Sizes

Used worldwide in automotive, machinery, and construction.

Measured in millimeters (mm).

Example: M6, M8, M10 (M = metric thread, number = bolt diameter).

2. Imperial / SAE Sizes

Common in the United States.

Measured in inches.

Example: 1/4″-20 (bolt diameter = 1/4 inch, thread pitch = 20 threads per inch).

3. BSW & BSF (British Standards)

Used on older British machinery.

BSW (British Standard Whitworth) and BSF (British Standard Fine) are less common today.

Understanding Nut Measurements

When you look at a nut size chart, you’ll see these key terms:

Thread Diameter – The diameter of the bolt/nut thread.

Thread Pitch (metric) – Distance between threads, measured in millimeters.

Threads Per Inch (TPI) – For imperial nuts, number of threads in one inch.

Across Flats (AF) – The distance between two parallel sides of the nut (spanner size needed).

Nut Height – Thickness of the nut.

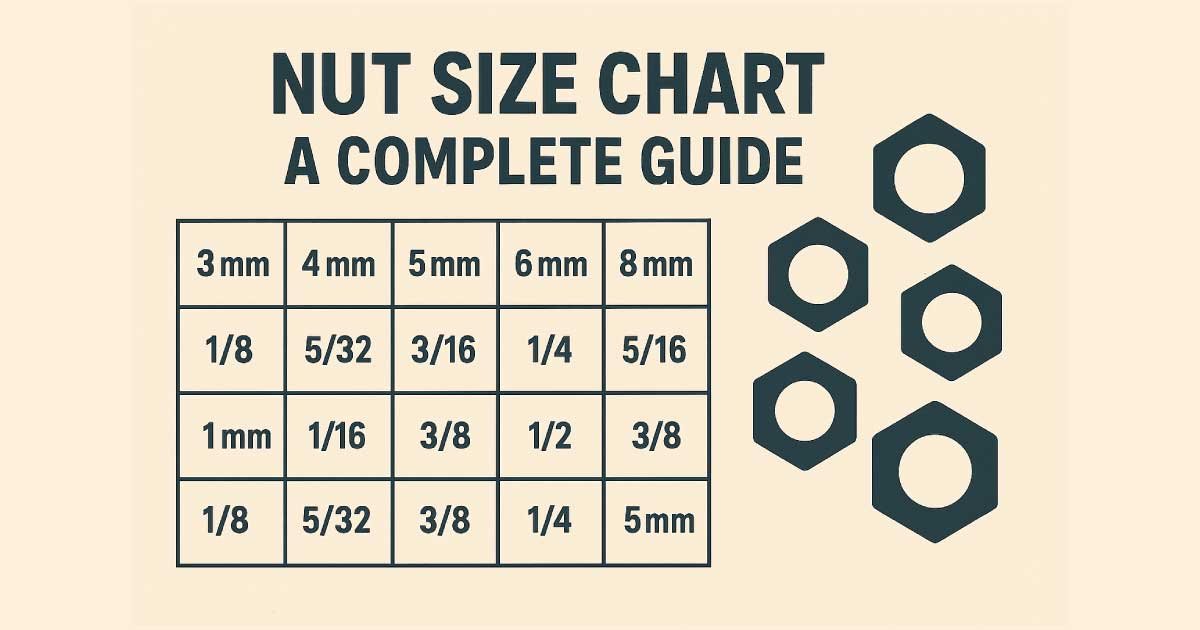

Nut Size Chart (Metric & Imperial)

Here’s a simplified nut size chart for quick reference:

| Bolt Diameter (Metric) | Nut Size AF (mm) | Bolt Diameter (Imperial) | Nut Size AF (inches) |

|---|---|---|---|

| M4 | 7 mm | 1/4″ | 7/16” (0.438”) |

| M5 | 8 mm | 5/16″ | 1/2” (0.500”) |

| M6 | 10 mm | 3/8″ | 9/16” (0.562”) |

| M8 | 13 mm | 7/16″ | 11/16” (0.688”) |

| M10 | 17 mm | 1/2″ | 3/4” (0.750”) |

| M12 | 19 mm | 9/16″ | 7/8” (0.875”) |

| M14 | 22 mm | 5/8″ | 15/16” (0.938”) |

| M16 | 24 mm | 3/4″ | 1-1/8” (1.125”) |

| M20 | 30 mm | 7/8″ | 1-5/16” (1.312”) |

| M24 | 36 mm | 1″ | 1-1/2” (1.500”) |

This table shows both metric and imperial nut sizes with the corresponding across-flats measurement.

Nut Sizes for Common Applications

1. Automotive Industry

Common sizes: M6, M8, M10, M12, M14.

Example: Car wheel lug nuts are usually M12 or M14.

2. Bicycles

Nuts are usually smaller, such as M5, M6, M8.

Used for handlebar clamps, wheel axles, and seat posts.

3. Plumbing & Construction

Larger nuts like M16, M20, M24 are used in pipelines and structural connections.

4. Electronics & Appliances

Small nuts such as M2, M3, M4 hold circuit boards and panels.

Nut Size Conversion (Quick Reference)

Sometimes you only have metric nuts but your bolt is imperial (or vice versa). Here’s a quick conversion guide:

M6 ≈ 1/4 inch

M8 ≈ 5/16 inch

M10 ≈ 3/8 inch

M12 ≈ 1/2 inch

M16 ≈ 5/8 inch

M20 ≈ 3/4 inch

Types of Nuts and Their Sizes

Not all nuts are created equal—different types have different size standards.

1. Hex Nuts

Most common type.

Sizes range from M2 to M36 in metric.

2. Nyloc Nuts (Lock Nuts)

Feature a nylon insert to prevent loosening.

Common in automotive and vibration-heavy applications.

3. Flange Nuts

Built-in washer for load distribution.

Popular in automotive assemblies.

4. Cap Nuts

Domed top to protect exposed threads.

Used where appearance and safety matter.

5. Wing Nuts

Can be tightened by hand.

Ideal for furniture, temporary fixtures.

6. Square Nuts

Four-sided shape, larger surface area.

Used in woodworking and vintage machinery.

How to Measure a Nut Correctly

Measure across flats (AF): Use a caliper or spanner to measure width.

Check thread size: For metric, measure pitch with a thread gauge. For imperial, count threads per inch (TPI).

Match to bolt diameter: Ensure the nut size corresponds to the bolt diameter.

Confirm standard: Metric vs. imperial—don’t mix them up.

Common Mistakes with Nut Sizes

Mixing metric and imperial – Leads to stripped threads.

Using wrong spanner size – Damages nut corners.

Over-tightening – Causes thread stripping or bolt failure.

Ignoring thread pitch – Not all M10 bolts fit the same M10 nut (coarse vs. fine thread).

Nut Size and Strength (Grades)

Nut size isn’t the only factor—strength grade matters too:

Metric nuts: Grade 8, 10, 12 (higher = stronger).

Imperial nuts: Grade 2, Grade 5, Grade 8.

For example:

Grade 8 nuts (imperial) are hardened for heavy-duty applications.

Grade 10 or 12 nuts (metric) are used in structural steel and automotive.

Organizing Nuts by Size

Since nuts are small and easy to lose, organization is key:

Use assorted nut & bolt kits for home workshops.

Label containers by size (M6, M8, etc.).

Keep metric and imperial in separate boxes.

Store in a dry place to avoid rust.

Practical Tips for Choosing Nuts

Always buy nuts and bolts together when possible.

For replacement, carry the old nut to the hardware store for an exact match.

In high-vibration areas, use lock nuts or washers.

For critical applications (cars, machinery), follow manufacturer torque specs.

Common Nut Sizes for Everyday Applications

Knowing the right nut size for your project is essential to ensure secure fastening and smooth assembly. Here’s a quick overview of common nut sizes and where they are typically used:

Automotive Applications – M6, M8, M10, M12, and M14 nuts are widely used in cars, trucks, and motorcycles. Wheel lug nuts are often M12 or M14, while smaller components use M6 or M8.

Bicycles and Small Machines – M5, M6, and M8 nuts are perfect for handlebar clamps, wheel axles, and other bicycle parts. Small nuts like M2–M4 are common in electronics and appliances.

Plumbing & Construction – Larger nuts such as M16, M20, and M24 handle pipes, valves, and structural joints in buildings or industrial setups.

Furniture & DIY Projects – M6 and M8 nuts are most common, making assembly fast and reliable without the need for high-strength hardware.

Understanding which nut size fits each application prevents stripped threads, loose connections, and wasted time.

Tips for Selecting and Measuring Nut Sizes

Accurate measurement and proper selection of nut sizes make your projects safer and more efficient. Key points include:

Measure Across Flats (AF) – Use a caliper or spanner to check the width of the nut to match the bolt perfectly.

Check Thread Pitch or TPI – Metric nuts use millimeter pitch; imperial nuts use threads per inch. Always match the nut’s thread to the bolt.

Use a Nut Size Chart – Keep a nut size chart handy to quickly identify metric and imperial equivalents and avoid mistakes.

Consider Nut Type – Hex, lock (nyloc), flange, cap, or wing nuts may have different size standards; pick the correct type for your application.

Avoid Mixing Standards – Never use a metric nut on an imperial bolt and vice versa; it risks stripped threads or joint failure.

Following these tips ensures your fasteners are secure, reduces maintenance issues, and improves overall reliability in mechanical and DIY projects.

Final Thoughts

A nut size chart is an invaluable reference for anyone working with hardware. Whether you are fixing your bike, assembling furniture, repairing a car, or constructing machinery, the correct nut size ensures safety, efficiency, and durability.

By keeping a chart handy and learning how to measure nut dimensions properly, you will avoid the frustration of mismatched fasteners and stripped threads.

Remember: in fastening systems, the right nut size makes all the difference.

Catch up on our latest article: