Open‑Die vs Closed‑Die Forging is a choice every metalworker and engineer faces at some point. When I first stepped into the world of industrial forging, I did not know there were so many ways to shape hot metal. I was fresh out of school, excited to get my hands dirty, and utterly confused when a senior engineer asked me, “Do you think open-die or closed-die is better for this job?” I had no clue. I just knew we had a glowing chunk of steel and a hydraulic press hissing behind us.

Years later, after countless hours on the shop floor, working on aerospace parts, heavy machinery, and one-off prototypes, I have developed a deep respect for both open-die and closed-die forging. They are each powerful in their own right but not interchangeable. Choosing the right method isn’t just a technical decision—it’s a financial one, a timeline one, and sometimes even a safety one.

This post is not just a theory rundown. It’s based on hands-on experience and real-world decisions that matter, especially if you are in manufacturing, metalworking, or engineering roles where precision and efficiency are everything.

What Is Forging in Simple Terms?

Before diving into the comparison, it helps to understand what forging is at its core. Forging is a metal shaping process that applies compressive force often with heat to deform and shape metal into a desired form. It’s one of the oldest manufacturing processes, yet it remains irreplaceable in modern industry due to its strength, grain alignment, and cost-effectiveness for the right volumes.

Now, let’s look at the two main categories we’re comparing:

What Is Open‑Die Forging?

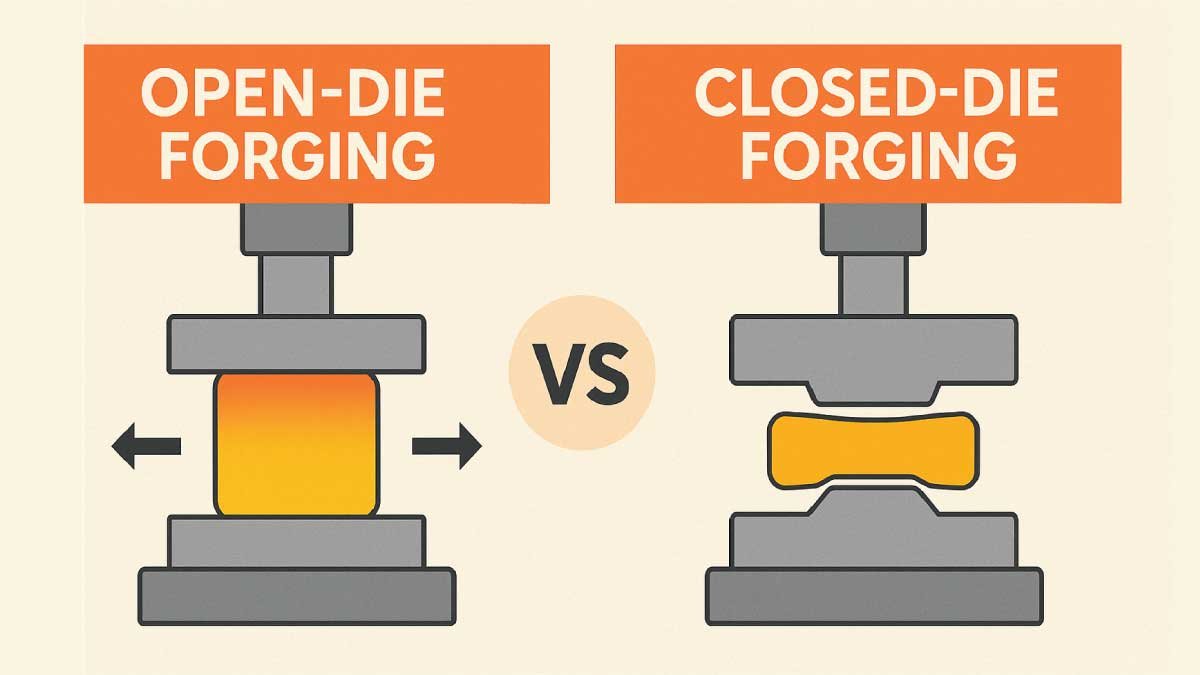

Open-die forging, sometimes called smith forging, involves deforming a metal workpiece between flat or slightly contoured dies that don’t enclose the material completely. The metal is compressed and manipulated manually or through CNC-controlled equipment, allowing for custom shapes and sizes.

Real Use Case from My Workshop

We once had a job making large shafts for a power plant in Ohio. These were over six feet long and weighed several hundred pounds. Closed-die tooling would’ve cost a fortune and taken weeks. Open-die forging let us shape the material with precision and flexibility. The grain flow stayed uninterrupted, and we reduced material waste dramatically.

What Is Closed‑Die Forging?

Closed-die forging, or impression-die forging, uses dies that completely enclose the metal within a specific cavity. The metal flows to fill the mold as pressure is applied. It’s precise, repeatable, and ideal for high-volume production.

Where It Shines

We regularly use closed-die forging for automotive components—like connecting rods or crankshafts—where tolerances are tight, and cycle time matters. Once the tooling is ready, we can produce thousands of identical parts with minimal post-processing.

Head-to-Head Comparison: Open-Die vs Closed-Die Forging

Let’s break it down in a practical way. This is the kind of decision-making matrix I’ve used with project managers, buyers, and engineers across industries.

1. Part Size and Shape Flexibility

Open-Die: Excellent for large, simple shapes like bars, rings, and shafts. You have more room to manipulate.

Closed-Die: Better for complex, intricate geometries like brackets, gears, or levers.

💡 If you are forging a 12-foot long shaft, open-die is your friend. If you’re forging a complex aerospace bracket, go closed-die.

2. Tooling Cost and Lead Time

Open-Die: Low tooling cost. You can use standard dies or minimal customizations. Lead time is shorter.

Closed-Die: High initial tooling investment. Precision dies take time and money to manufacture.

🛠 In one startup project, we saved over $50,000 in initial investment by going with open-die while validating our part design.

3. Production Volume

Open-Die: Ideal for low- to medium-volume production or custom one-offs.

Closed-Die: Economical at high volumes due to repeatability and lower per-part cost once tooling is in place.

📦 For one-off or prototype work, closed-die doesn’t make sense. But once we ramped to 10,000 units, closed-die crushed our cost-per-part metrics.

4. Precision and Tolerances

Open-Die: Moderate tolerances. Requires secondary machining for tight specs.

Closed-Die: High precision. Parts often come out near-net shape, reducing or eliminating machining.

✂️ When I was forging flanges for offshore equipment, open-die gave us good blanks, but we still had to lathe and drill. Closed-die would’ve been overkill.

5. Material Utilization and Waste

Open-Die: Higher material waste due to trimming and rough shaping.

Closed-Die: Better material efficiency due to controlled cavity shaping.

🔧 Over time, closed-die saves more material, especially when using expensive alloys like Inconel or titanium.

6. Mechanical Properties and Grain Flow

Open-Die: Excellent grain flow control. Great for fatigue resistance and strength-critical applications.

Closed-Die: Still strong, but some grain disruption may occur depending on geometry and flow direction.

🧪 For a military spec component requiring extreme fatigue resistance, we used open-die specifically to preserve grain orientation.

Choosing the Right Forging Process: A Practical Guide

Here’s how I approach forging decisions in my line of work:

✅ Use Open‑Die Forging If:

You are working with large or simple shapes.

The part is custom or low volume.

You need flexibility in shape or design.

Tooling budget is limited.

You want optimal grain flow for strength.

✅ Use Closed‑Die Forging If:

You need complex shapes with tight tolerances.

Production volumes are high.

Precision and repeatability matter.

Material utilization is important.

You have time and budget for die development.

Real-World Industry Examples

Aerospace

Aircraft landing gear components often start as open-die forgings due to their size and stress-critical nature. Smaller parts like brackets or fasteners are usually closed-die forged.

Automotive

Connecting rods, gears, and crankshafts are almost always closed-die forged due to the precision and high-volume needs.

Oil & Gas

High-strength valves and flanges often come from open-die forging, especially for deep-sea or high-pressure environments.

My Experience: What I have Learned Over the Years

No process is better universally. One of the biggest mistakes I have seen is engineers jumping to closed-die forging because it “looks cleaner” on paper only to face massive delays in tooling and unnecessary cost. On the flip side, I’ve also seen open-die forgings fail because the part needed tighter tolerances and more efficient material use.

Once, we were forging a set of stainless steel pump shafts for a chemical plant in Louisiana. Our team debated for hours whether open-die would be accurate enough. We finally settled on open-die, knowing we do need a final machining pass. The decision saved us $20,000 in tooling costs and we delivered the parts a week early.

Final Thoughts on Open‑Die vs Closed‑Die Forging

In the end, it all comes down to knowing your part, your volume, your budget, and your lead time. Forging is not just hammering hot metal, it’s a critical decision that impacts performance, cost, and time.

If you are working on a one-off prototype, building oversized equipment, or need exceptional fatigue resistance go with open-die. If your project demands high volume, tight specs, and material efficiency closed-die is likely the better choice.

Every forging project tells a story. Your job is to make sure it’s a successful one from the first heat to the final product.

Call to Action:

If you are still unsure which method is right for your specific application, don’t guess, reach out to a forging expert or supplier early. A 15-minute conversation can save weeks of delay and thousands in costs.

And if you are new to forging, consider spending a day in the shop. There is no substitute for watching red-hot steel take shape under a press, and feeling the force that turns raw material into precision components.

Also Read Our Comprehensive Guide On:

FAQs:

What is the main difference between open-die and closed-die forging?

The biggest difference lies in how the metal is shaped. Open-die forging uses flat dies and manual manipulation, giving you more flexibility for large or custom parts. Closed-die forging involves shaped dies that press the metal into an exact mold, ideal for high-volume and precise parts. Think of open-die like hand-sculpting clay, while closed-die is more like using a cookie cutter.

When should I choose open-die forging over closed-die?

If you are dealing with large parts, low production volume, or need flexibility in shape, open-die forging is a smart choice. It’s often faster to set up and more cost-effective when you are not producing thousands of parts. It also gives excellent grain flow and mechanical strength. We’ve used it many times when lead time and part size made closed-die forging impractical.

Is closed-die forging more expensive than open-die?

Upfront, yes—closed-die forging usually costs more because of the tooling required. Custom dies can run thousands of dollars. But for large production runs, the cost per part drops significantly due to speed and repeatability. So, while open-die is cheaper for small batches, closed-die pays off if you’re producing thousands of consistent parts quickly and efficiently.

Which forging method gives better strength—open or closed die?

Both methods can produce strong parts, but open-die forging typically wins for maximum strength. That’s because the grain flow can be aligned along stress directions, reducing fatigue and failure. It’s ideal for structural or rotating components. Closed-die parts are also strong, but complex die shapes might interrupt grain flow slightly, which can affect performance in very demanding applications.

Can closed-die forging produce near-net shapes?

Yes, that’s one of the biggest advantages of closed-die forging. It produces parts that are very close to the final dimensions, which reduces the need for machining and material waste. For example, we often deliver parts from a closed-die press that only need minimal finishing saving both time and raw material costs. This is especially useful in the automotive and aerospace industries.

How long does it take to make closed-die tooling?

On average, creating a closed-die set takes anywhere from 2 to 6 weeks, depending on the complexity of the part. That includes design, CNC machining of the dies, heat treating, and testing. It’s a time investment upfront, but once the dies are ready, you can produce parts rapidly and consistently. We always factor in tooling time when planning a production schedule.