Pillow block bearings, also known as plummer block bearings, are mounted bearing units that provide support for a rotating shaft with the help of compatible housings and bearings.

They are widely used in industrial machinery, conveyors, agricultural equipment, HVAC systems, and manufacturing plants.

Choosing the correct pillow block bearing size is critical for ensuring smooth operation, reducing vibration, extending bearing life, and preventing premature failure.

This comprehensive pillow block bearing size guide explains everything you need to know about sizes, dimensions, load ratings, shaft compatibility, and housing types so you can confidently select the right unit for your application.

What Is a Pillow Block Bearing?

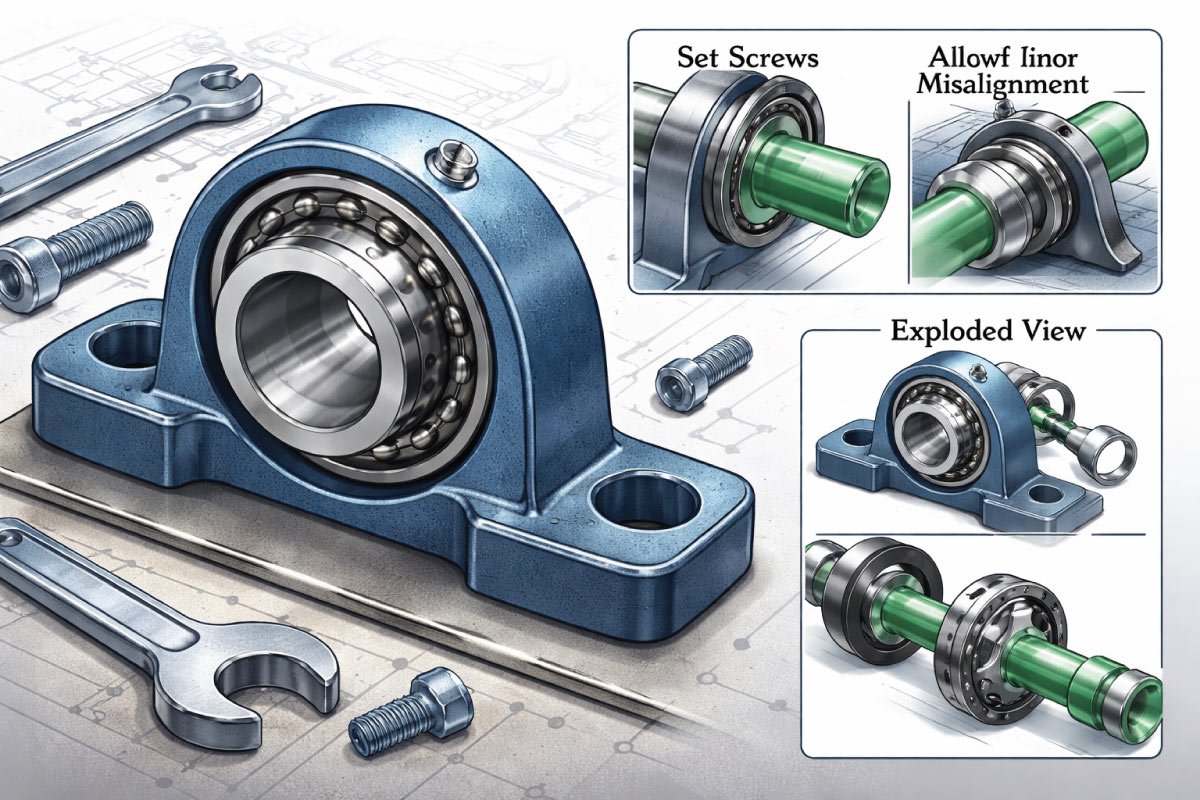

A pillow block bearing is a combination of a bearing (usually a ball bearing) and a housing designed to mount securely to a foundation.

The housing is typically made of cast iron, ductile iron, stainless steel, or thermoplastic, while the bearing insert is often a deep-groove ball bearing.

The key advantage of pillow block bearings is their ease of installation and maintenance.

Most units allow minor shaft misalignment and include set screws or locking collars to secure the bearing to the shaft.

Why Pillow Block Bearing Size Matters

Selecting the correct pillow block bearing size goes beyond matching the shaft diameter.

Improper sizing can lead to excessive heat, increased vibration and noise, shaft misalignment, reduced bearing life, and unexpected machine downtime.

Properly sized bearings ensure optimal load distribution, stable shaft support, and reliable machine performance, particularly in high-load or continuous-duty industrial applications.

1- Impact on Heat Generation

The wrong bearing size can cause excessive friction between the bearing and the shaft, generating unwanted heat.

Overheating can degrade lubricant performance, accelerate wear, and eventually lead to bearing failure.

Correct sizing ensures proper contact, reduces internal friction, and maintains a safe operating temperature, improving reliability and extending the service life of both the bearing and the supported shaft.

2. Effect on Vibration and Noise

Improper pillow block bearing size can create uneven load distribution, causing vibrations and abnormal noise during operation.

Increased vibration not only affects machine performance but can also lead to premature wear on connected components.

Properly sized bearings provide stable support, absorb operational loads efficiently, and ensure smooth, quiet performance, especially in precision or high-speed machinery applications.

3. Shaft Alignment Considerations

Incorrect bearing sizing can lead to shaft misalignment, resulting in uneven load distribution, excessive stress on the bearing, and potential shaft deformation.

Properly sized pillow block bearings help maintain accurate alignment, ensuring that the shaft rotates smoothly and transfers forces efficiently.

This prevents operational inefficiencies, reduces wear, and maintains consistent performance over time.

4. Influence on Bearing Life

Bearing life is directly linked to proper sizing. Undersized bearings may overload quickly, while oversized bearings can create unnecessary stress or improper fit.

Both scenarios reduce operational lifespan. Selecting the correct pillow block bearing ensures balanced load distribution, smooth rotation.

And minimal stress, allowing bearings to achieve their designed service life and reducing maintenance costs.

5. Prevention of Machine Downtime

Incorrectly sized bearings can lead to unexpected failures, resulting in costly machine downtime.

Overheated or misaligned bearings may seize, causing production halts or equipment damage.

Proper pillow block bearing sizing ensures reliable performance, reducing unscheduled maintenance,

And operational interruptions, especially in high-load or continuous-duty industrial environments.

6. Load Distribution Optimization

Properly sized bearings distribute radial and axial loads evenly across the bearing surfaces.

This prevents localized stress points that can accelerate wear or lead to deformation.

Optimized load distribution enhances machine efficiency, reduces maintenance requirements,

and ensures that shafts and connected components operate reliably under varying loads and operating conditions.

7. Lubrication Efficiency

Bearing size affects how lubrication spreads across rolling elements.

Oversized or undersized bearings may hinder proper lubricant coverage, leading to increased friction and wear.

Correct sizing allows for efficient lubrication, maintaining smooth operation, reducing heat generation, and extending bearing life while minimizing maintenance intervals.

Key Dimensions in Pillow Block Bearing Sizing

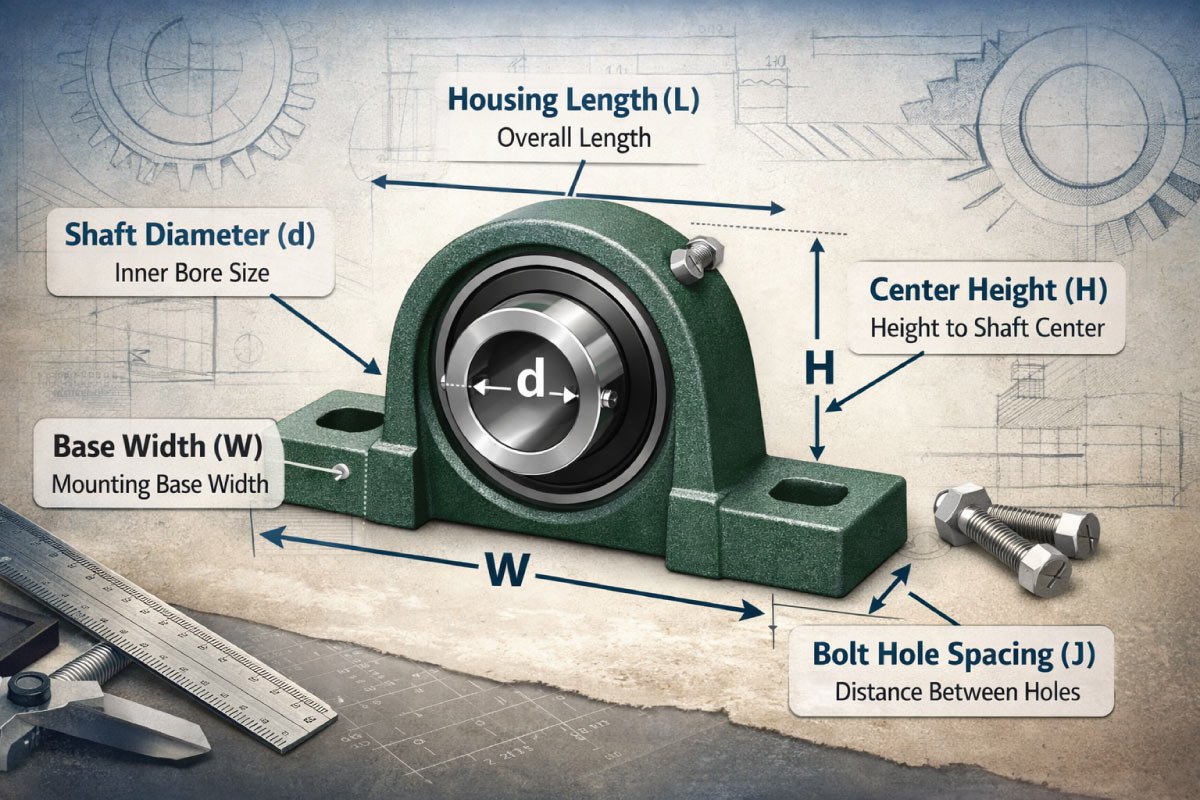

Understanding key dimensions is essential when selecting the right pillow block bearing.

These measurements ensure a proper fit on the shaft and secure mounting to the base.

Dimensions like shaft diameter, housing length, base width, bolt hole spacing, and center height determine load capacity,

alignment, and overall performance, helping engineers choose bearings that optimize reliability and machine efficiency.

Common Dimensions Explained

Shaft diameter (d): Inner bore size that fits the shaft

Housing length (L): Overall length of the pillow block

Base width (W): Width of the mounting base

Bolt hole spacing (J): Distance between mounting holes

Center height (H): Height from mounting surface to shaft center

Standard Pillow Block Bearing Size Chart (Metric)

A standard pillow block bearing size chart helps engineers select the correct bearing for a given shaft and mounting configuration.

By referencing shaft diameter, housing length, bolt spacing, and center height, you can ensure proper fit, alignment, and load handling.

Using standard sizes simplifies installation, reduces errors, and ensures reliable operation across industrial applications.

| Shaft Diameter (mm) | Bearing Unit | Housing Length (mm) | Bolt Spacing (mm) | Center Height (mm) |

|---|---|---|---|---|

| 20 | UCP204 | 127 | 95 | 33 |

| 25 | UCP205 | 140 | 105 | 36.5 |

| 30 | UCP206 | 165 | 121 | 42 |

| 35 | UCP207 | 184 | 135 | 47.5 |

| 40 | UCP208 | 200 | 145 | 49.2 |

Pillow Block Bearing Size Chart (Imperial)

The imperial pillow block bearing size chart provides essential dimensions for selecting the right bearing in inch-based systems.

By referencing shaft diameter, housing length, bolt spacing, and center height, engineers can ensure accurate fit, proper alignment, and efficient load transfer.

Using standard imperial sizes simplifies installation and maintenance while supporting reliable operation in industrial machinery.

| Shaft Diameter (inch) | Bearing Unit | Housing Length (inch) | Bolt Spacing (inch) | Center Height (inch) |

| 3/4 | UCP204-12 | 5.00 | 3.74 | 1.30 |

| 1 | UCP205-16 | 5.51 | 4.13 | 1.44 |

| 1-1/4 | UCP206-20 | 6.50 | 4.76 | 1.65 |

| 1-1/2 | UCP207-24 | 7.24 | 5.31 | 1.87 |

| 2 | UCP208-32 | 7.87 | 5.71 | 1.94 |

Common Pillow Block Bearing Series Explained

Pillow block bearings come in various series, each designed to meet specific shaft sizes, load capacities, and mounting requirements.

Popular series like UCP, UCPA, UCPH, and UCFL/UCFC offer options for standard, compact, high-center, or flanged applications.

Standardized size charts across these series make installation, replacement, and upgrades straightforward and ensure consistent performance across machinery.

Popular Series:

1- UCP Series: Standard Cast Iron Housing

The UCP series is the most commonly used pillow block bearing series.

Featuring a durable cast iron housing, these bearings are versatile and suitable for a wide range of industrial applications.

They provide stable shaft support, standard mounting dimensions, and reliable load handling.

Their widespread adoption makes them easy to source, replace, and maintain, making the UCP series ideal for general-purpose machinery.

2- UCPA Series: Narrow Housing for Compact Spaces

The UCPA series is designed with a narrower housing, making it perfect for applications with limited space.

Despite its compact design, it maintains robust load-bearing capability and stable shaft alignment.

UCPA bearings are ideal for machinery where floor space or mounting area is constrained, offering a reliable alternative without sacrificing performance, durability, or ease of installation.

3- UCPH Series: High Center Height for Larger Shafts

The UCPH series features a higher center height to accommodate larger shaft diameters.

This design provides increased load capacity and better alignment for heavy-duty machinery.

By elevating the shaft above the mounting surface, UCPH bearings can handle larger forces and reduce stress on connected components,

making them suitable for industrial environments that demand strength, precision, and long-term durability.

4- UCFL / UCFC Series: Flanged Alternatives for Vertical Mounting

The UCFL and UCFC series are flanged pillow block bearings designed for vertical or angled mounting applications.

Flanged housings allow secure attachment to walls, panels, or other non-horizontal surfaces while maintaining stable shaft support.

These series are ideal for conveyor systems, vertical shafts, and machinery layouts that require flexible installation without compromising load capacity or alignment accuracy.

Each series follows standardized size charts, making replacement and upgrades easier.

Load Ratings and Their Role in Size Selection

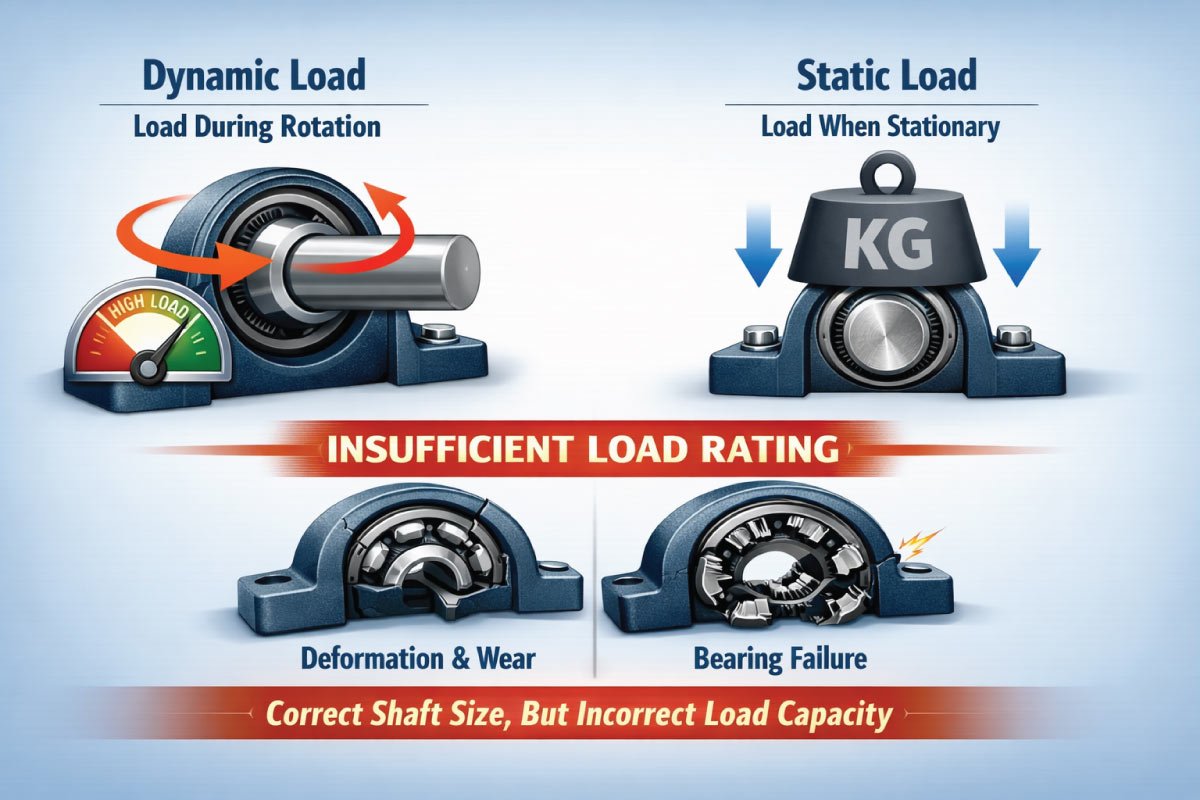

When selecting a pillow block bearing, load capacity is just as critical as physical dimensions.

Bearings are rated for dynamic loads experienced during rotation and static loads when stationary.

Choosing a bearing with insufficient load ratings can lead to deformation, premature wear, or failure—even if the shaft diameter,

And mounting fit are correct—making proper load assessment essential for reliable performance.

- Dynamic load: Load applied during rotation

- Static load: Load when stationary

Choosing a bearing with insufficient load rating can lead to deformation or failure, even if the shaft size is correct.

Typical Load Rating Table

Pillow block bearings are rated for both dynamic and static loads to ensure reliable operation under varying conditions.

A typical load rating table provides essential values for each bearing unit, showing the maximum load the bearing can safely handle while rotating or at rest.

Using this information helps engineers select bearings that match shaft size and operational demands.

| Bearing Unit | Shaft Size (mm) | Dynamic Load (kN) | Static Load (kN) |

| UCP204 | 20 | 12.8 | 6.65 |

| UCP205 | 25 | 14.0 | 7.85 |

| UCP206 | 30 | 19.5 | 11.2 |

| UCP207 | 35 | 25.5 | 15.3 |

| UCP208 | 40 | 30.7 | 19.0 |

Housing Materials and Size Considerations

The material used for a pillow block bearing housing directly influences durability, corrosion resistance, and dimensional stability.

Common materials like cast iron, ductile iron, stainless steel, and thermoplastics affect both strength and size tolerances.

While shaft dimensions remain constant, the choice of housing material can slightly alter external dimensions, impacting mounting, alignment, and suitability for specific industrial applications.

| Material | Strength Level | Corrosion Resistance | Typical Applications |

| Cast Iron | High | Medium | General industry |

| Ductile Iron | Very High | Medium | Heavy-duty loads |

| Stainless Steel | Medium | Very High | Food & chemical |

| Thermoplastic | Low–Medium | High | Washdown areas |

Different materials may slightly alter external dimensions while maintaining the same shaft size.

Shaft Tolerance and Fit Guidelines

Accurate shaft diameter and surface quality are critical for proper pillow block bearing fit.

Bearings allow slight tolerance variations, but excessive deviations can lead to slippage, uneven loading, or internal damage.

Following recommended shaft tolerances—h7 or h8 for metric, ±0.001 inch for imperial—and verifying roundness and surface finish ensures reliable performance and extended bearing life.

Recommended Shaft Tolerance

- Metric shafts: h7 or h8 tolerance

- Imperial shafts: ±0.001 inch

Always verify shaft roundness and surface finish before installation.

Mounting Bolt Size and Base Dimensions

Proper mounting bolt selection and base sizing are critical for pillow block bearing stability and performance.

Larger bearings require stronger bolts to handle increased loads, vibration, and shaft forces.

By matching the recommended bolt size to the bearing unit and ensuring adequate base width, engineers can maintain secure installation,

prevent misalignment, and extend both bearing and machine service life.

| Bearing Unit | Recommended Bolt Size | Base Width (mm) |

| UCP204 | M10 | 38 |

| UCP205 | M12 | 40 |

| UCP206 | M12 | 44 |

| UCP207 | M14 | 48 |

| UCP208 | M14 | 52 |

Common Applications by Bearing Size

Pillow block bearing size directly determines its suitable application.

Smaller bearings handle light-duty machinery like conveyors and fans, while larger bearings support heavy industrial equipment such as crushers and mining machinery.

Correctly matching bearing size to the load and operational requirements ensures efficient performance, reduces wear, prevents failures,

And maintains the safety and reliability of machines across various industries.

20–25 mm: Small conveyors, fans, packaging machines

30–35 mm: Agricultural equipment, belt drives

40–50 mm: Industrial conveyors, crushers

60 mm and above: Heavy-duty mining and steel plants

Matching size to application ensures efficiency and safety.

Installation Tips for Correct Sizing

Even correctly sized pillow block bearings can fail if installation is improper. Proper installation ensures alignment, secure mounting, and optimal performance.

Key practices include aligning the shaft before tightening bolts, evenly securing locking screws, avoiding overtightening, and following manufacturer lubrication guidelines.

Careful installation maximizes bearing lifespan, efficiency, and reliability in all industrial applications.

- Align shaft before tightening bolts

- Secure bearing locking screws evenly

- Avoid overtightening mounting bolts

- Lubricate according to manufacturer guidelines

Correct installation maximizes the benefits of choosing the right pillow block bearing size.

Discover More:

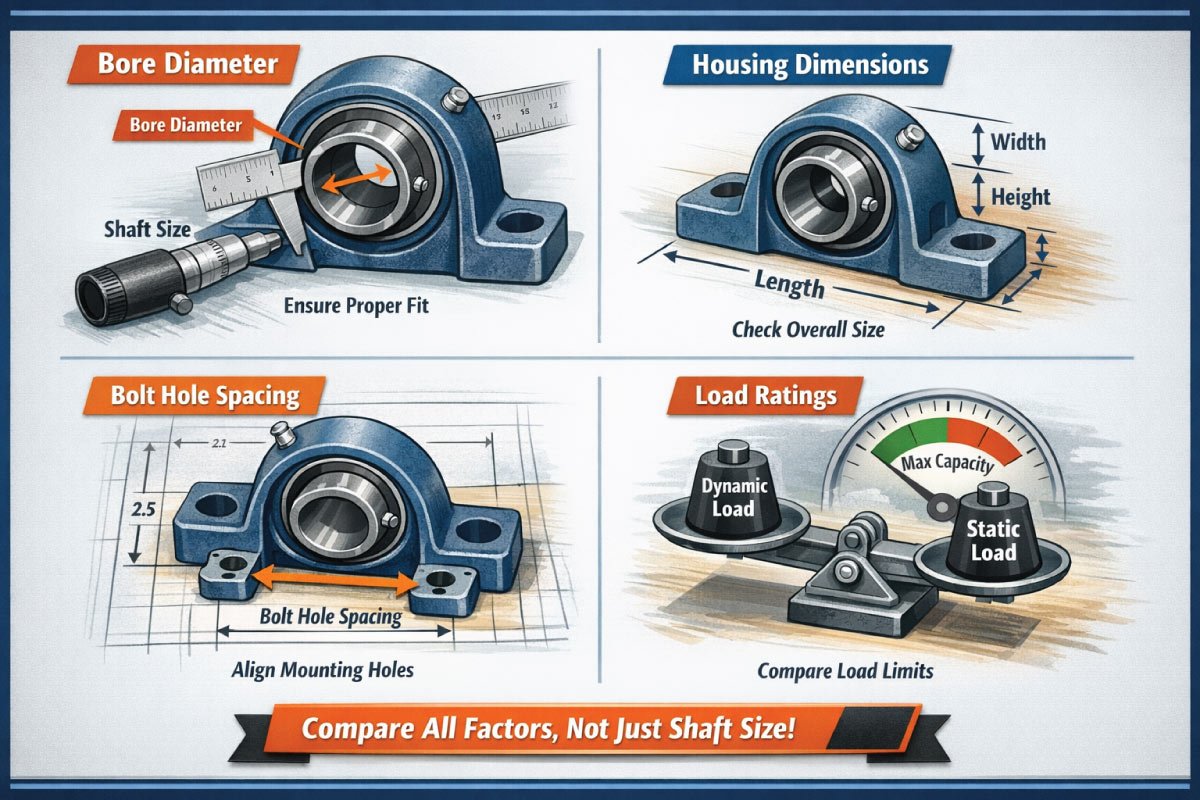

How to Read Manufacturer Size Charts

Manufacturer size charts provide essential information for selecting the correct pillow block bearing, but interpreting them correctly is key.

Charts typically include bore diameter, overall housing dimensions, bolt hole spacing, and load ratings.

To ensure proper fit and performance, always compare multiple parameters rather than relying solely on shaft size, preventing misalignment, excessive wear, or premature bearing failure.

1- Bore Diameter

The bore diameter is the inner diameter of the bearing that fits over the shaft. Accurate measurement is critical because a mismatch can lead to slippage, misalignment, or excessive wear.

Always verify the shaft size against the bore diameter listed in the chart, taking tolerances into account.

Properly matching the bore ensures secure fitting, smooth rotation, and optimal load transfer from the shaft to the bearing.

2- Overall Housing Dimensions

Overall housing dimensions include the length, width, and height of the bearing unit.

These measurements determine whether the bearing will fit the mounting area and allow for proper clearance.

Comparing housing dimensions across charts helps ensure compatibility with your equipment’s footprint,

prevents interference with other components, and maintains correct alignment for smooth shaft operation and long-term reliability.

3- Bolt Hole Spacing

Bolt hole spacing refers to the center-to-center distance between mounting holes on the bearing base.

Proper spacing ensures that bolts fit securely and the bearing remains stable under load.

Misaligned or incorrect bolt hole spacing can cause uneven load distribution, vibration, and premature wear.

Always check spacing against the mounting surface and consider bolt size when selecting the correct bearing unit.

4- Load Ratings

Load ratings indicate the maximum forces a bearing can safely handle. Dynamic load ratings relate to forces during rotation, while static load ratings apply when the bearing is stationary.

Using a bearing below its load capacity can cause deformation, failure, or reduced lifespan, even if the shaft fits perfectly.

Comparing load ratings alongside dimensions ensures the bearing meets operational demands safely and reliably.

Always compare multiple parameters instead of relying on shaft size alone.

Discover More:

Conclusion

A proper pillow block bearing size guide is essential for anyone working with rotating machinery.

By understanding shaft diameter, housing dimensions, load ratings, materials, and mounting requirements, you can select a bearing that delivers long service life and reliable performance.

Whether you are replacing an existing unit or designing a new system, using standardized pillow block bearing size charts,

And following sizing best practices will save time, reduce maintenance costs, and improve machine efficiency.