When working with plumbing, construction, or mechanical systems, pipes are everywhere. But not all pipes are created equal—some are thicker, some thinner, and that difference matters when handling pressure, durability, and overall performance. That’s where the pipe schedule chart comes in.

The term pipe schedule simply refers to the thickness of the pipe wall. It doesn’t change the outer diameter (OD), but it changes the inner diameter (ID), which affects flow capacity and strength. Understanding pipe schedules can help you select the right type of pipe for your project, whether it’s for water supply, gas lines, oil pipelines, or industrial use.

In this guide, we will explore what pipe schedule means, why it is important, how to read a pipe schedule chart, and provide examples with metric and imperial measurements.

What is Pipe Schedule?

The word schedule in piping does not mean time—it’s a technical term developed by the American Society of Mechanical Engineers (ASME). A pipe schedule (often abbreviated as SCH) is a standard that shows the wall thickness of pipes.

For example:

Schedule 40 pipe has a medium wall thickness and is the most common type.

Schedule 80 pipe has a thicker wall, making it stronger and better for high-pressure applications.

Schedule 160 pipe is extremely thick and is used in specialized heavy-duty industries.

Even though the outer diameter (OD) of a pipe stays the same for a given nominal pipe size (NPS), the inner diameter (ID) shrinks as the schedule number increases.

Why is Pipe Schedule Important?

Pressure Handling – A thicker wall (higher schedule) means the pipe can handle more internal pressure.

Durability – Heavy-duty schedules resist cracking, corrosion, and wear better.

Flow Capacity – A thinner wall (lower schedule) means a larger internal diameter and better fluid flow.

Safety – Choosing the wrong schedule can lead to leaks, bursts, or failures.

Pipe Schedule Number Formula

The schedule number is calculated using this formula:

Schedule Number=1000×PSSchedule Number = \frac{1000 \times P}{S}

Where:

P = Internal pressure (psi)

S = Allowable stress (psi) of the material

This formula shows why different schedules exist—higher pressures require stronger (thicker) pipes.

Common Pipe Schedules

The most commonly used pipe schedules are:

Schedule 10 (SCH 10): Thin-walled, often used in low-pressure applications.

Schedule 40 (SCH 40): Standard thickness, widely used for plumbing and general applications.

Schedule 80 (SCH 80): Thicker and stronger, used in industrial and high-pressure systems.

Schedule 160 (SCH 160): Very thick, heavy-duty use.

XXS (Double Extra Strong): Special applications requiring maximum strength.

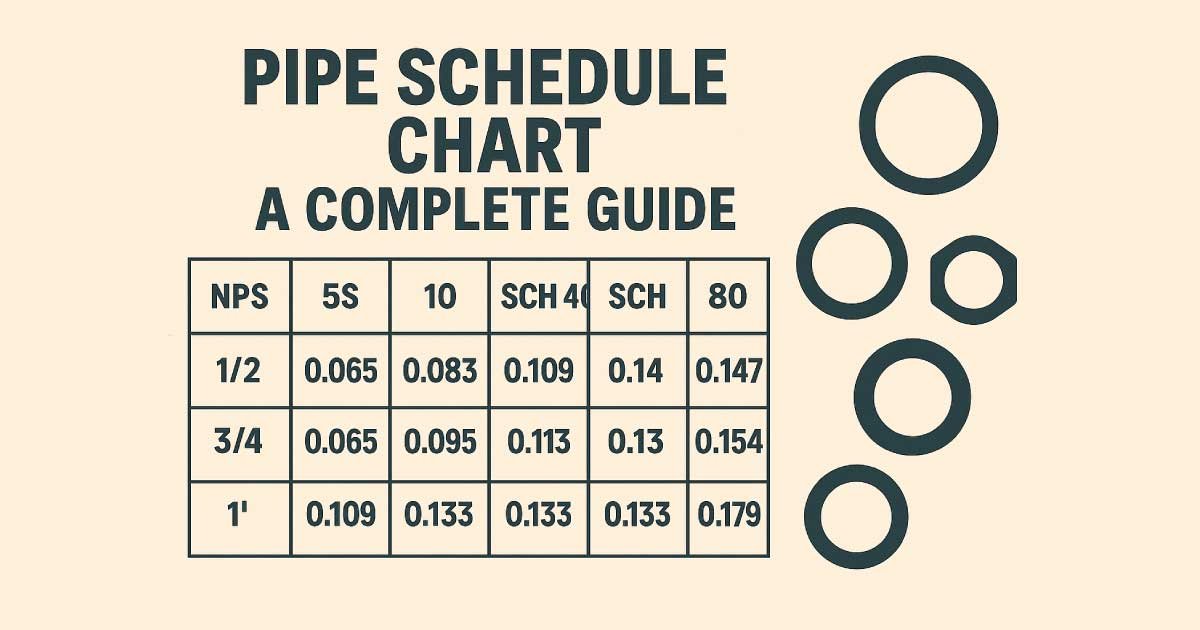

Pipe Schedule Chart (Imperial)

Here’s a simplified chart of some common nominal pipe sizes (NPS) with OD and wall thickness values for Schedule 40 and 80:

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | SCH 40 Wall Thickness | SCH 80 Wall Thickness |

|---|---|---|---|

| 1/2 inch | 0.84 in (21.3 mm) | 0.109 in (2.77 mm) | 0.147 in (3.73 mm) |

| 1 inch | 1.315 in (33.4 mm) | 0.133 in (3.38 mm) | 0.179 in (4.55 mm) |

| 2 inch | 2.375 in (60.3 mm) | 0.154 in (3.91 mm) | 0.218 in (5.54 mm) |

| 4 inch | 4.5 in (114.3 mm) | 0.237 in (6.02 mm) | 0.337 in (8.56 mm) |

| 6 inch | 6.625 in (168.3 mm) | 0.28 in (7.11 mm) | 0.432 in (10.97 mm) |

| 8 inch | 8.625 in (219.1 mm) | 0.322 in (8.18 mm) | 0.5 in (12.7 mm) |

Pipe Schedule Chart (Metric Conversion)

For engineers and users outside the U.S., the following shows the same data in millimeters:

| Nominal Pipe Size (DN) | Outside Diameter (mm) | SCH 40 Wall Thickness | SCH 80 Wall Thickness |

|---|---|---|---|

| DN 15 (1/2 inch) | 21.3 mm | 2.77 mm | 3.73 mm |

| DN 25 (1 inch) | 33.4 mm | 3.38 mm | 4.55 mm |

| DN 50 (2 inch) | 60.3 mm | 3.91 mm | 5.54 mm |

| DN 100 (4 inch) | 114.3 mm | 6.02 mm | 8.56 mm |

| DN 150 (6 inch) | 168.3 mm | 7.11 mm | 10.97 mm |

| DN 200 (8 inch) | 219.1 mm | 8.18 mm | 12.7 mm |

Schedule 40 vs Schedule 80 Pipes

Schedule 40: Lighter, cheaper, easier to install, suitable for most residential and commercial applications.

Schedule 80: Thicker walls, stronger, can handle higher pressures, used in chemical plants, oil refineries, and industrial systems.

If you’re just working on a home water line, SCH 40 is usually enough. But if you’re running a high-pressure steam or chemical line, SCH 80 or higher is recommended.

Applications of Different Pipe Schedules

Residential Plumbing: Mostly Schedule 40 for water supply and drainage.

Irrigation Systems: Schedule 40 PVC pipes are common.

Industrial Piping: Schedule 80 and above for pressure lines, chemicals, and gases.

Oil & Gas Pipelines: Schedule 160 or XXS for extreme pressure conditions.

HVAC Systems: Mix of SCH 40 and SCH 80 depending on design requirements.

Tips for Choosing the Right Pipe Schedule

Check the pressure rating of your system.

Consider the type of fluid (water, oil, chemicals, gas).

Ensure material compatibility (steel, stainless steel, PVC).

Factor in cost vs safety—thicker schedules cost more but last longer.

Always consult a pipe schedule chart before purchase.

How to Read a Pipe Schedule Chart

Understanding a pipe schedule chart is easier than it seems once you know what to look for. A standard pipe schedule chart lists nominal pipe sizes (NPS or DN), outside diameters (OD), wall thicknesses for different schedules, and sometimes the corresponding pressure ratings. Here’s how to make the most of it:

Identify Nominal Pipe Size (NPS/DN): Start by finding the pipe size you need. Remember, nominal size refers to the approximate inner diameter for Schedule 40 pipes.

Check the Outer Diameter (OD): The OD remains the same regardless of schedule, which ensures fittings and flanges match correctly.

Compare Wall Thicknesses: The chart shows wall thickness for SCH 10, 40, 80, 160, and sometimes XXS. Thicker walls (higher schedules) can withstand higher pressures.

Match Application Requirements: Use the chart to choose a schedule that meets pressure, durability, and flow requirements for your system.

Benefits of Using a Pipe Schedule Chart

Using a pipe schedule chart can save time, reduce errors, and improve system performance. Here are key benefits:

Ensures Safety: Choosing the wrong schedule can lead to leaks, bursts, or equipment failure.

Optimizes Flow: A thinner wall increases the inner diameter, improving fluid flow while reducing energy consumption.

Saves Costs: Selecting an unnecessarily thick pipe increases material costs. The chart helps balance strength and budget.

Supports Compliance: Many industries require adherence to ASME or ANSI standards. Using the chart ensures compliance with engineering regulations.

Simplifies Planning: Engineers and DIY enthusiasts can quickly compare pipe schedules, reducing guesswork and avoiding installation errors.

By understanding how to read and use a pipe schedule chart, you can confidently choose the right pipe for any project—whether it’s plumbing, HVAC, industrial piping, or high-pressure systems.

Final Thoughts

The pipe schedule chart is a vital tool in plumbing, mechanical, and industrial engineering. It helps professionals and DIY enthusiasts choose the correct pipe thickness for safety, durability, and efficiency. Whether you’re working on a household water line or an industrial pipeline, understanding pipe schedules ensures your system performs without leaks or failures.

By using the charts above, you can confidently select the right pipe for your project—balancing strength, flow capacity, and the cost.

Also, read our latest post: