If you have ever stood in a hardware store staring at rows of pipes, wondering why the sizes don’t seem to match their labels, you’re not alone. Pipe sizing can feel confusing—even for people who work with tools regularly. A pipe labeled “1 inch” rarely measures exactly one inch, and different materials follow different standards.

Understanding pipe sizes is not just for plumbers or engineers. Homeowners, DIY enthusiasts, and anyone involved in construction or repairs can save time, money, and frustration by learning how pipe sizes really work. In this guide, we’ll break everything down in a simple, human way—no unnecessary technical jargon—so you can confidently choose the right pipe for any job.

What Does Pipe Size Really Mean?

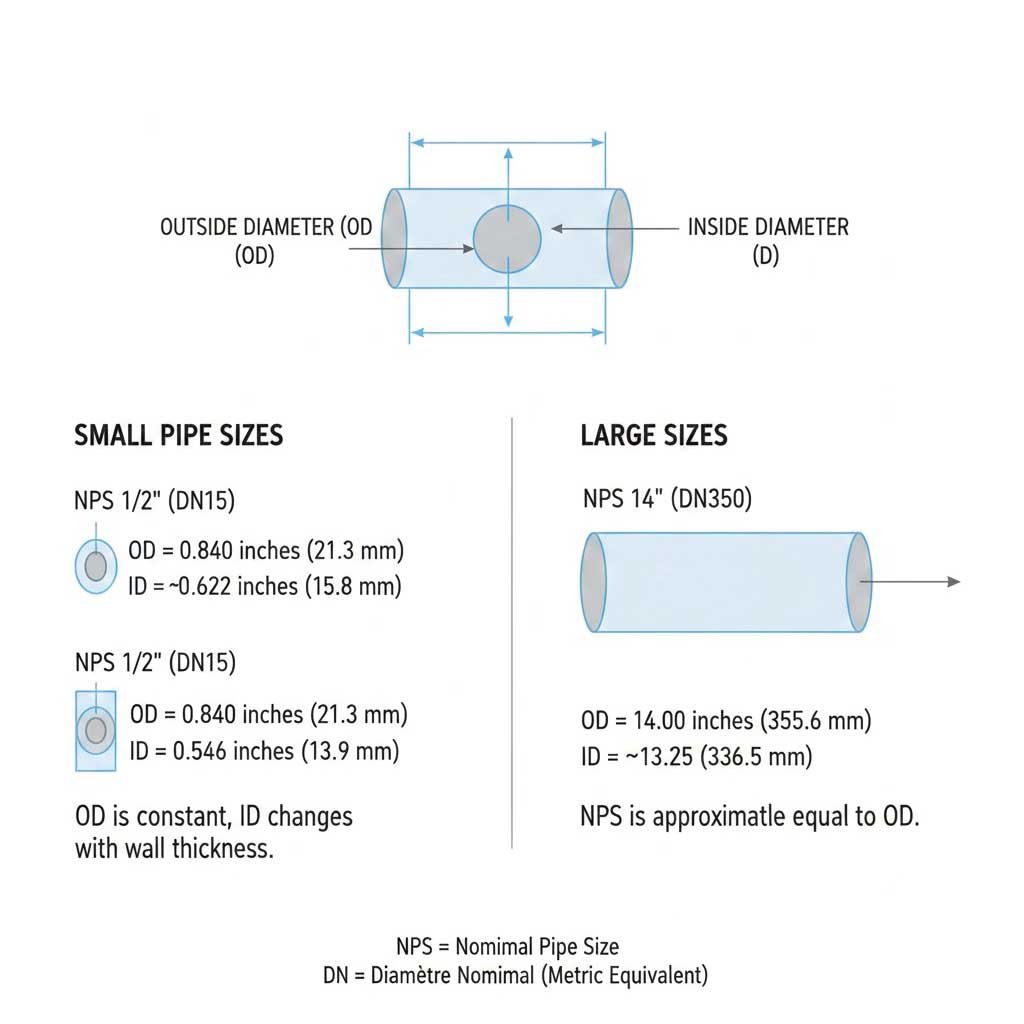

At first glance, pipe size sounds straightforward. You’d think a 1-inch pipe has a 1-inch diameter. But in reality, pipe sizes are usually nominal, meaning they are names rather than exact measurements.

Most pipes are identified by Nominal Pipe Size (NPS). This system was created long ago when pipes had thick walls and smaller internal diameters. As materials improved and walls became thinner, the naming stayed the same for standardization.

So when you hear “1-inch pipe,” it refers to a standard category, not an exact physical measurement.

Key Pipe Measurements You Must Know

Before choosing or measuring pipes, it’s important to understand three basic terms. These measurements form the foundation of all pipe sizing systems and help determine how much fluid can flow, how strong the pipe is, and whether it will safely handle pressure in real-world applications.

Outside Diameter (OD): The distance across the outside of the pipe

Inside Diameter (ID): The open space inside the pipe where fluid flows

Wall Thickness: The thickness of the pipe material itself

These three measurements are related, and changing one affects the others.

Nominal Pipe Size (NPS) Explained Simply

Nominal Pipe Size (NPS) is the most widely used pipe sizing system in plumbing, gas distribution, and industrial piping, especially across the United States. It was created to standardize pipe dimensions so that different pipes and fittings can work together reliably, even when materials or wall thickness vary.

For smaller pipes (up to 12 inches):

The outside diameter (OD) stays constant

The inside diameter (ID) changes based on wall thickness

For larger pipes:

The NPS number is usually very close to the actual outside diameter

This system allows fittings, valves, and accessories to remain compatible across different pipe materials and wall thicknesses, making installation easier and reducing costly sizing mistakes.

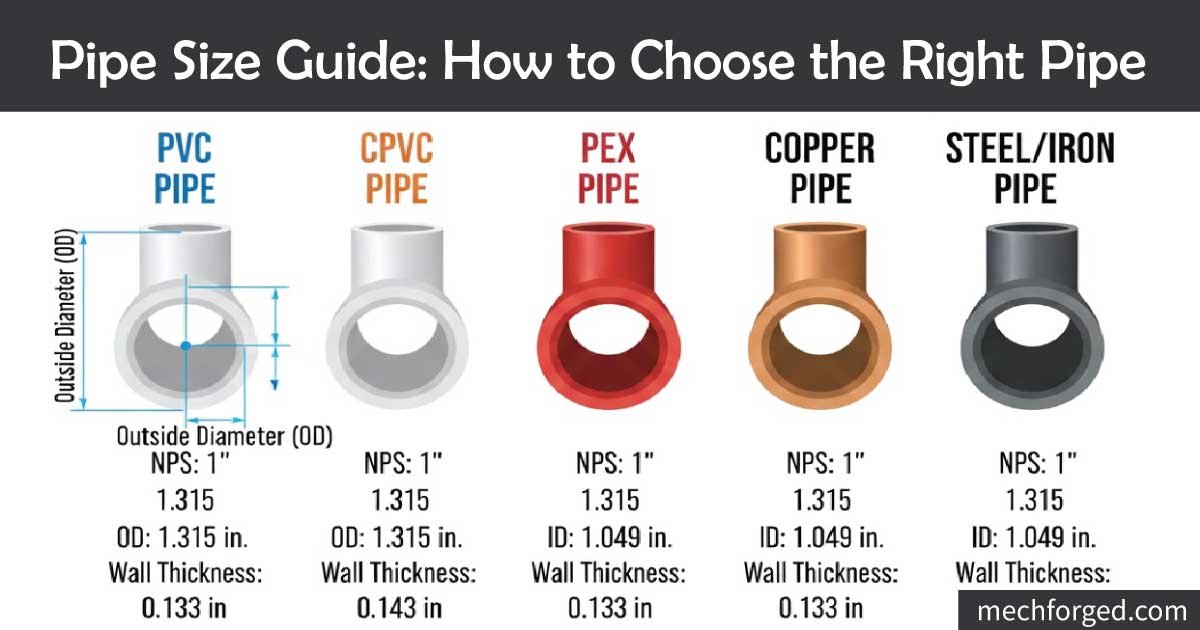

Common Pipe Materials and Their Sizing Behavior

Different pipe materials follow different sizing standards, which is where confusion often begins for many people. Pipes may look similar in size, but their actual measurements and compatibility can vary based on material, making correct identification essential before buying fittings or replacements.

Metal Pipes

Steel, stainless steel, and iron pipes usually follow the Nominal Pipe Size (NPS) system. Their outside diameter remains consistent for each nominal size, while the inside diameter changes based on wall thickness, allowing standard fittings to work across different schedules and pressure ratings.

Plastic Pipes

PVC, CPVC, and PEX pipes may follow:

- Nominal sizing (similar to NPS)

- CTS (Copper Tube Size)

- SDR (Standard Dimension Ratio)

Understanding which system your pipe uses is critical before buying fittings.

Pipe Size Chart: Nominal Size vs Actual Diameter

The table below illustrates why pipe sizing can often seem confusing at first. Even though pipes are labeled with nominal sizes, their actual inside and outside diameters can differ significantly, which may surprise beginners and cause mistakes if not checked carefully.

| Nominal Pipe Size (NPS) | Outside Diameter (inches) | Approx. Inside Diameter (inches) |

|---|---|---|

| ½ inch | 0.84 | 0.62 |

| ¾ inch | 1.05 | 0.82 |

| 1 inch | 1.32 | 1.05 |

| 1½ inch | 1.90 | 1.61 |

| 2 inch | 2.38 | 2.07 |

As you can see, the outside diameter is always larger than the nominal size.

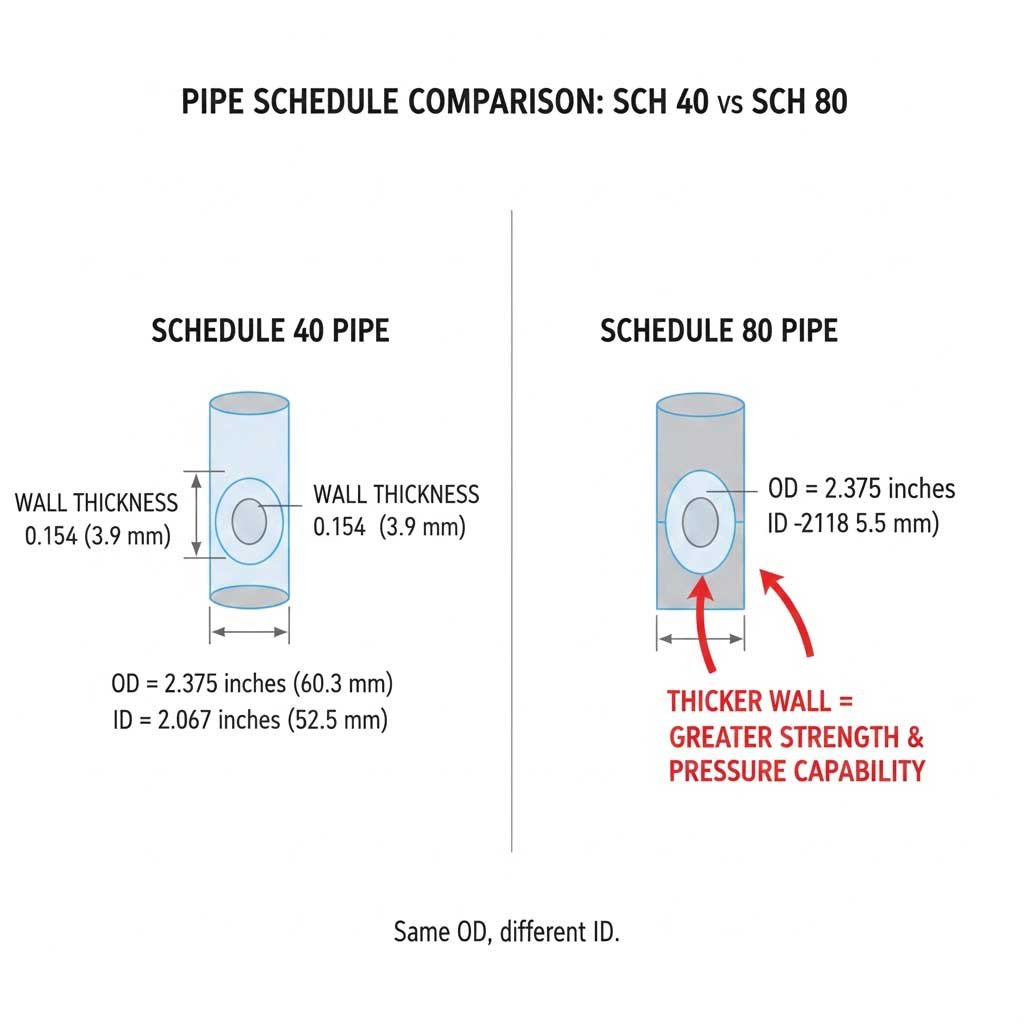

Pipe Schedule and Wall Thickness

Pipe schedule refers to the thickness of a pipe’s wall, which directly affects its strength, pressure rating, and durability. A higher schedule number means a thicker wall, making the pipe stronger and more suitable for demanding or high-pressure applications.

Common schedules include:

Schedule 40: Standard choice for most residential and commercial plumbing systems

Schedule 80: Thicker walls designed for higher pressure and more industrial environments

The pipe schedule affects the inside diameter, not the outside diameter, which is why fittings remain compatible across different schedules.

Schedule 40 vs Schedule 80 Comparison

Here’s a simple comparison that makes it easier to understand the difference between schedules and wall thickness. By looking at actual dimensions side by side, you can quickly see how inside diameters change while outside diameters remain consistent.

| Pipe Size | Schedule | Outside Diameter | Inside Diameter | Typical Use |

|---|---|---|---|---|

| 1 inch | Sch 40 | 1.32 in | 1.05 in | Plumbing, irrigation |

| 1 inch | Sch 80 | 1.32 in | 0.94 in | High-pressure systems |

| 2 inch | Sch 40 | 2.38 in | 2.07 in | Drainage, water supply |

| 2 inch | Sch 80 | 2.38 in | 1.94 in | Industrial use |

Notice how the outside diameter stays the same, ensuring fittings still work.

Types of Pipes and Their Common Uses

Choosing the right pipe size can feel confusing, especially with so many materials, standards, and schedules to consider. Understanding pipe measurements, types, and uses is essential for any plumbing, irrigation, or industrial project. This guide explains everything clearly, helping you select the right pipe for every application.

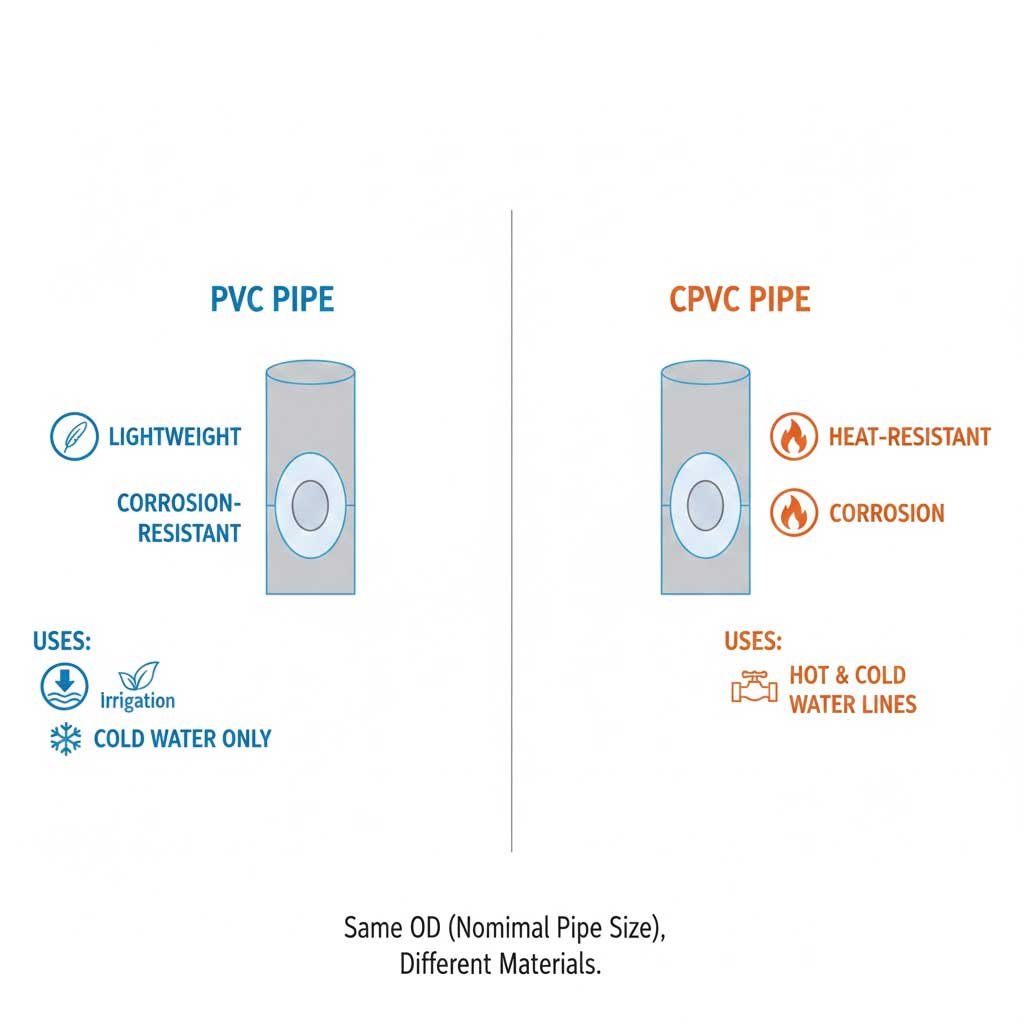

1. PVC Pipes

PVC pipes are lightweight, affordable, and corrosion-resistant, making them a popular choice for both residential and commercial projects. They are easy to cut and join, reducing labor time and installation costs, and they perform well in systems carrying cold water or non-corrosive fluids.

They are commonly used for:

Drainage systems

Irrigation

Cold water supply

PVC typically uses Schedule 40 or Schedule 80 sizing, which ensures compatibility with fittings and durability for different pressure levels.

2. CPVC Pipes

CPVC looks similar to PVC but is specially formulated to handle higher temperatures without warping or cracking. Its heat-resistant properties make it ideal for carrying hot water safely in homes and light commercial buildings, where durability and reliability are critical.

Common uses include:

Hot and cold water lines

Residential plumbing

Sizing is similar to PVC but not always interchangeable, so it’s important to check fittings and schedules before installation to avoid leaks or pressure issues.

3. PEX Pipes

PEX pipes are flexible, durable, and easy to install, which significantly reduces labor and material costs. Their bendable nature allows for fewer fittings in complex layouts, and they resist scale buildup, corrosion, and freezing better than rigid piping.

They are widely used in:

Modern home plumbing

Radiant heating systems

PEX sizing often follows CTS standards, which differ slightly from NPS, so confirming compatibility with connectors and valves is important for safe installation.

4. Copper Pipes

Copper pipes are highly durable, long-lasting, and resistant to bacteria, making them a premium choice for water supply lines. They handle high temperatures and pressures effectively and are often preferred in homes where water quality and pipe longevity are priorities.

They follow Copper Tube Size (CTS), meaning:

The nominal size refers to the inside diameter

The outside diameter stays consistent

Copper pipes require soldered, compression, or push-fit connections, ensuring leak-free systems when installed properly.

5. Steel and Iron Pipes

Steel and iron pipes are extremely strong and suitable for high-pressure and heavy-duty applications. They are often used in gas distribution, industrial piping, and situations where durability, safety, and long-term structural integrity are essential.

They strictly follow NPS and schedule-based sizing, which ensures compatibility with industrial fittings, valves, and pressure-rated systems.

They are commonly used for:

Gas lines

Industrial systems

High-pressure applications

Pipe Size Selection by Application

Choosing the right pipe size depends on what you’re using it for.

| Application | Recommended Pipe Size Range | Common Materials |

|---|---|---|

| Household water supply | ½” – 1″ | PEX, Copper, CPVC |

| Drainage systems | 1½” – 4″ | PVC, ABS |

| Irrigation | ¾” – 2″ | PVC |

| Gas lines | ½” – 2″ | Steel, Iron |

| Industrial fluids | 1″ – 12″+ | Steel, Stainless Steel |

Using the wrong size can lead to pressure loss, leaks, or system failure.

Also Read:

How to Measure Pipe Size Correctly

If you already have a pipe and need to determine its size, accurate measurement is crucial. Even minor errors can result in leaks, improper connections, or reduced system efficiency. Taking the time to measure carefully ensures the correct pipe is selected, avoids compatibility issues with fittings, and helps maintain proper pressure and flow. Careful measurement saves time, money, and prevents long-term problems in any plumbing or industrial system.

Measure the outside diameter using a caliper or measuring tape

Check the pipe material, as different materials follow different sizing standards

Compare your measurement with a pipe size chart to find the correct nominal size

Confirm the schedule or wall thickness, especially for pressure-rated systems

Never guess—small differences can cause big problems.

Why Pipe Size Matters So Much

Pipe size is far more important than many people realize because it directly affects the efficiency, safety, and longevity of any plumbing or industrial system. Using the wrong size can cause low water pressure, increased wear on pipes and fittings, leaks, and even code violations that may require costly rework. Small mistakes in sizing can create long-term problems that are expensive and difficult to fix. Correct pipe sizing ensures smooth flow, maintains proper pressure, prevents unnecessary damage, and guarantees reliable performance over time, saving both time and money for homeowners and professionals alike.

Also Read:

Common Pipe Size Mistakes to Avoid

When working with pipes for the first time, it’s easy to make sizing mistakes that seem minor but can cause serious problems later. Most of these errors happen due to misunderstanding how pipe sizing systems work or rushing the selection process.

Many beginners make the same mistakes:

Assuming nominal size equals actual diameter

Mixing CTS and NPS fittings, which are not always compatible

Ignoring wall thickness and pressure ratings, especially in pressurized systems

Using undersized pipes for high-flow systems, leading to pressure loss

A little planning can prevent costly fixes later.

Final Thoughts

Understanding pipe sizes doesn’t require an engineering degree. Once you learn the difference between nominal size, actual diameter, and schedule, everything starts to make sense. Pipes are standardized for a reason—to ensure compatibility, safety, and performance.

Whether you’re fixing a small leak, planning a plumbing upgrade, or just trying to understand what you’re buying, knowing how pipe sizes work puts you in control. Take a moment to measure, check charts, and choose wisely—you’ll thank yourself later.

Also Read: