Choosing the correct plywood thickness is one of the most important steps in any woodworking, construction, or DIY project.

Whether you are building furniture, installing flooring, making cabinets, or working on structural applications, plywood thickness directly affects strength, durability, weight, and cost.

Using the wrong thickness can lead to bending, cracking, or unnecessary expenses.

This comprehensive plywood thickness guide explains standard plywood thicknesses, common uses, how thickness is measured, and how to choose the right option for your project.

By the end, you will confidently know which plywood thickness works best for your needs.

What Is Plywood?

Plywood is an engineered wood product made by bonding multiple thin layers of wood veneer together.

Each layer is placed with its grain running perpendicular to the previous layer, which increases strength, stability, and resistance to warping.

Because of this layered structure, plywood is stronger and more dimensionally stable than solid wood of the same thickness.

Plywood is widely used in construction, furniture making, cabinetry, roofing, flooring, and decorative projects due to its versatility and affordability.

Why Plywood Thickness Matters

Plywood thickness determines how much weight the panel can support, how stiff it is, and where it can be safely used.

Thin plywood is flexible and lightweight, making it ideal for decorative or backing applications. Thicker plywood provides structural strength and is necessary for load-bearing uses.

Choosing the right thickness helps:

Prevent sagging or bending

Improve durability and lifespan

Reduce material waste

Control overall project cost

How Plywood Thickness Is Measured

Plywood thickness plays a crucial role in construction accuracy, strength, and fit. While plywood is labeled using nominal thickness in inches or millimeters.

The actual thickness is often slightly less due to sanding during manufacturing.

Understanding how plywood thickness is measured helps avoid fitting issues, ensures structural reliability, and is especially important for cabinetry, furniture making, and precision joinery projects.

1. What Nominal Plywood Thickness Means

Nominal plywood thickness refers to the size stated on the product label, such as ½ inch or ¾ inch.

This measurement represents the thickness before final sanding and finishing. Manufacturers use nominal sizes for standardization,

but builders should not rely on this number alone when precise fits, joints, or structural tolerances are required.

2. Understanding Actual Plywood Thickness

Actual plywood thickness is the true measured thickness of the sheet after manufacturing and sanding.

This value is usually slightly smaller than the nominal size. For example, ¾-inch plywood often measures around 23/32 inch.

Knowing the actual thickness is essential for accurate cuts, tight joints, and proper alignment in woodworking projects.

3. Why Plywood Is Thinner Than Labeled

Plywood becomes thinner than its nominal size because it is sanded to achieve a smooth, uniform surface.

Sanding improves appearance and usability but removes small amounts of material from each side.

This process ensures consistency across sheets but results in a reduced final thickness compared to the labeled nominal measurement.

4. How Plywood Thickness Is Measured Accurately

To measure plywood thickness accurately, use a caliper or a precise measuring tool rather than a standard tape measure.

Measurements should be taken at multiple points along the sheet to account for minor variations.

Accurate measurement helps prevent fitting issues, especially in cabinetry, shelving, and structural framing applications.

5. Common Nominal vs Actual Thickness Examples

Many plywood sizes follow predictable nominal-to-actual thickness differences.

For instance, nominal ½-inch plywood typically measures about 15/32 inch, while nominal ¾-inch plywood measures around 23/32 inch.

Being familiar with these common conversions helps builders plan cuts, joints, and material spacing more accurately.

6. Importance of Thickness in Cabinetry and Joinery

Precise plywood thickness is especially critical in cabinetry and fine joinery. Even small thickness differences can affect dado cuts, grooves, and joinery alignment.

Using actual thickness measurements ensures tight-fitting joints, professional finishes, and reduces the need for adjustments during installation or assembly.

7. Metric vs Imperial Thickness Measurements

Plywood thickness may be labeled in inches or millimeters depending on regional standards.

Metric plywood often follows standardized thicknesses like 12 mm or 18 mm, which may not convert exactly to imperial sizes.

Understanding both measurement systems prevents ordering mistakes and ensures compatibility with tools and construction plans.

8. Why Understanding Thickness Prevents Costly Errors

Misunderstanding plywood thickness can lead to poor fits, wasted materials, and structural weaknesses.

Builders who rely solely on nominal measurements may face alignment issues or rework.

Knowing the difference between nominal and actual thickness ensures accurate planning, reduces material waste, saves time, and improves overall project quality.

Standard Plywood Thickness Chart (Inches & Millimeters)

Choosing the correct plywood thickness is easier when you understand the difference between nominal, actual, and metric measurements.

This standard plywood thickness chart provides a quick reference for commonly available sizes in inches and millimeters.

It helps builders, carpenters, and DIYers select the right sheet thickness for accurate fitting, strength requirements, and professional-quality results.

| Nominal Thickness | Actual Thickness (Approx.) | Metric Equivalent |

|---|---|---|

| 1/8 inch | 3 mm | 3 mm |

| 1/4 inch | 6 mm | 6 mm |

| 3/8 inch | 9 mm | 9 mm |

| 1/2 inch | 12 mm | 12 mm |

| 5/8 inch | 15 mm | 15 mm |

| 3/4 inch | 18–19 mm | 18 mm |

| 1 inch | 25 mm | 25 mm |

This chart gives a quick reference for commonly available plywood thicknesses.

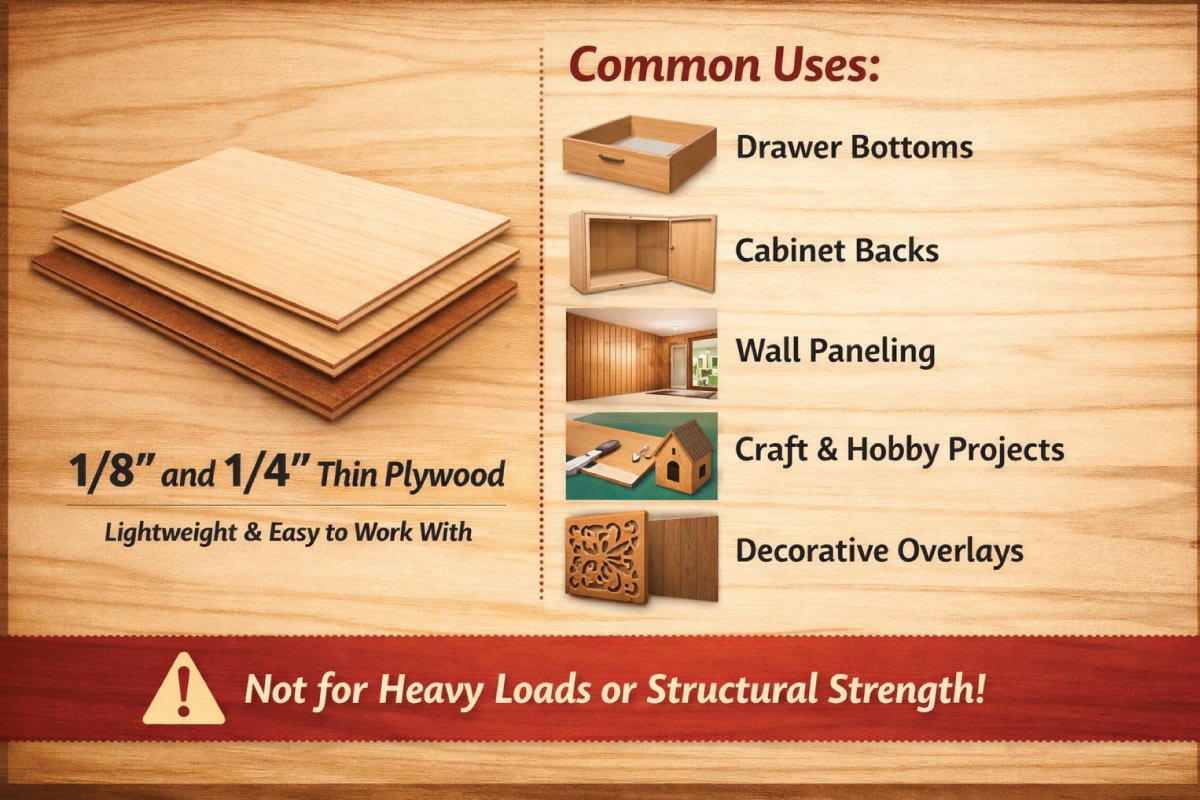

Thin Plywood Thicknesses and Their Uses

Thin plywood sheets, typically ranging from 1/8 inch to 1/4 inch in thickness, are lightweight, flexible, and easy to work with.

These properties make them well suited for non-structural applications where appearance and ease of installation matter more than strength.

Understanding their limitations helps ensure they are used safely and effectively in woodworking and interior projects.

Common Uses:

Drawer bottoms

Cabinet backs

Wall paneling

Craft and hobby projects

Decorative overlays

Thin plywood should not be used where heavy loads or structural strength are required.

Medium Plywood Thicknesses Explained

Medium plywood thicknesses, typically ranging from 3/8 inch to 1/2 inch, offer an ideal balance between strength and flexibility.

These sheets are sturdy enough for moderate loads while remaining easy to cut and handle.

Because of this versatility, medium-thickness plywood is widely used in furniture making, cabinetry, and interior construction projects.

Common Uses:

Furniture panels

Shelving (light to medium loads)

Cabinet sides

Interior wall sheathing

Subfloor underlayment

This thickness range is popular for DIY furniture projects and interior applications.

Thick Plywood Thicknesses for Structural Work

Thick plywood panels, commonly available in 5/8 inch, 3/4 inch, and 1 inch thicknesses, are designed for strength and rigidity.

These heavy-duty sheets are ideal for structural and load-bearing applications where durability matters most.

Although thicker plywood costs more and weighs more, it provides superior stability, long-term performance, and resistance to bending under heavy loads.

Common Uses:

Subflooring

Roofing decks

Heavy-duty shelving

Workbenches

Structural furniture frames

Thicker plywood costs more and weighs more but provides excellent strength and durability.

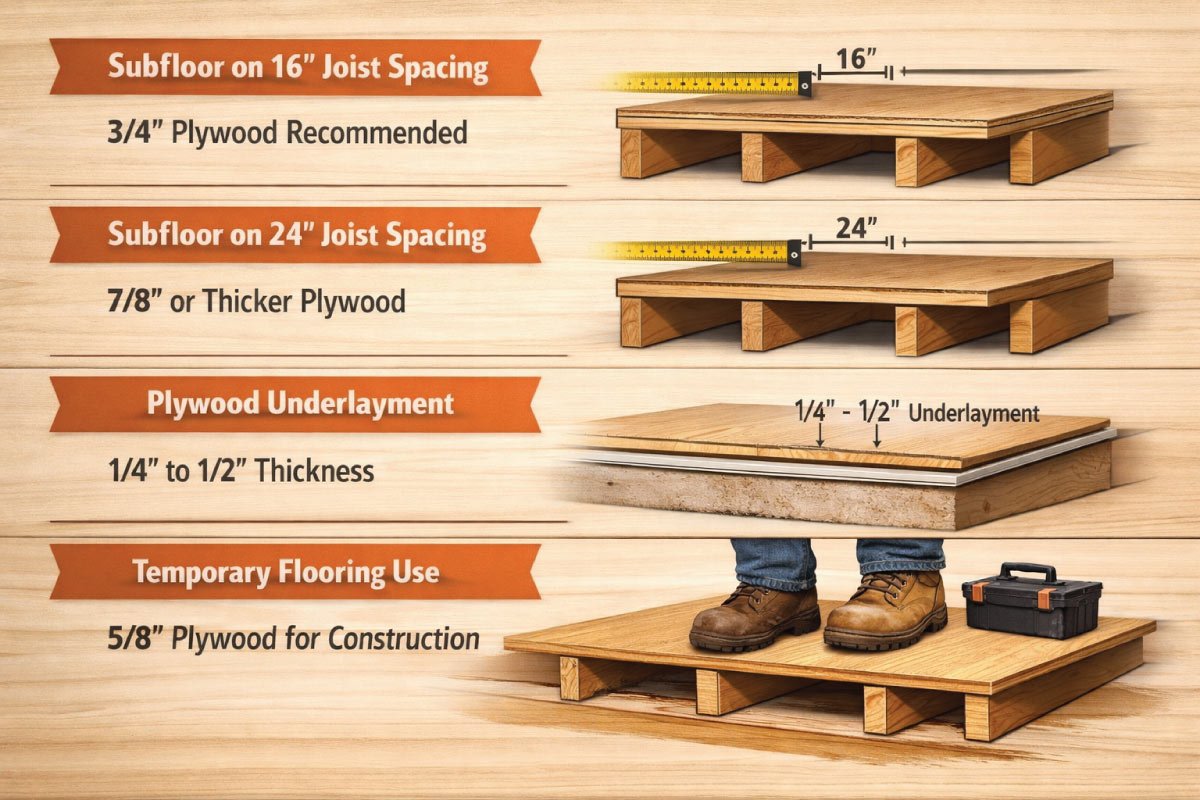

Plywood Thickness for Flooring Applications

Selecting the correct plywood thickness for flooring is essential to ensure strength, stability, and long-term durability.

The right thickness depends on joist spacing, load requirements, and whether the plywood is used as a subfloor or underlayment.

Proper thickness selection helps prevent squeaks, sagging, and movement that can damage finished flooring over time.

1. Subfloor on Joists Spaced 16 Inches On Center

For joists spaced 16 inches on center, 3/4-inch plywood is the recommended standard.

This thickness provides sufficient stiffness to support foot traffic, furniture, and appliances without flexing.

It minimizes floor movement, reduces squeaking, and creates a solid base for hardwood, tile, laminate, or vinyl flooring installations.

2. Subfloor on Joists Spaced 24 Inches On Center

When joists are spaced 24 inches apart, thicker plywood is required to prevent deflection.

A minimum of 7/8-inch plywood, or thicker engineered panels, is recommended.

This added thickness increases rigidity, distributes loads more evenly, and prevents long-term sagging or structural issues in residential and commercial flooring systems.

3. Plywood Underlayment Thickness

Underlayment plywood typically ranges from 1/4 inch to 1/2 inch and is installed over the subfloor to create a smooth, even surface.

It helps conceal seams, minor imperfections, and fasteners.

Proper underlayment thickness improves the appearance and lifespan of finished flooring without adding unnecessary height or weight.

4. Temporary Flooring Applications

For temporary flooring used during construction or renovations, 5/8-inch plywood is commonly sufficient.

This thickness offers adequate strength for foot traffic and light equipment while remaining easier to remove later.

Using plywood that is too thin may lead to cracking or flexing, while thicker panels increase cost without added benefit.

Plywood Thickness for Furniture and Cabinets

Choosing the right plywood thickness is essential for furniture and cabinet construction, where strength, stability, and ease of fabrication must be balanced.

Using plywood that is too thin can lead to sagging or failure, while overly thick panels add unnecessary weight and cost.

Proper thickness selection ensures durability, clean joinery, and professional-quality results.

1. Plywood Thickness for Cabinet Boxes

Cabinet boxes typically use plywood between 1/2 inch and 3/4 inch thick.

Thicker panels provide better rigidity and screw-holding strength, especially for wall-mounted cabinets.

Choosing the correct thickness helps cabinets remain square, supports heavy contents, and prevents warping or joint failure over time.

2. Plywood Thickness for Cabinet Backs

Cabinet backs commonly use 1/4-inch plywood because it is lightweight yet sufficient for enclosure and stability.

While not load-bearing, the back panel helps keep the cabinet square.

Proper fastening ensures structural integrity without adding unnecessary thickness or weight to the cabinet design.

3. Plywood Thickness for Bookshelves

Bookshelves typically require 3/4-inch plywood to support the weight of books without sagging. This thickness offers excellent stiffness and durability.

For shelves longer than 30 inches, thicker plywood or added support such as edging, cleats, or center dividers is recommended to maintain long-term strength.

4. Plywood Thickness for Tables and Desks

Tables and desks usually use 3/4-inch plywood for tops and structural components.

This thickness provides the necessary rigidity to resist bending under weight and daily use. It also allows for strong joinery and fastening, ensuring the furniture remains stable, level, and durable over time.

5. Plywood Thickness for Drawer Bottoms

Drawer bottoms are commonly made from 1/4-inch plywood due to its lightweight nature and flexibility.

When properly supported with grooves or dadoes, this thickness is sufficient for most household drawers.

For heavier loads, thicker plywood or reinforced designs may be necessary to prevent bowing.

Plywood Thickness for Roofing and Walls

Selecting the correct plywood thickness for roofing and wall construction is critical for structural safety, weather resistance, and code compliance.

The right thickness ensures proper load distribution, prevents deflection, and provides a stable surface for roofing materials or wall finishes.

Always match plywood thickness to the application and local building requirements.

1-Roof Decking Plywood Thickness

Roof decking typically uses plywood between 1/2 inch and 5/8 inch thick.

Thicker panels provide better support for roofing loads, especially in areas with heavy snowfall or wider rafter spacing.

Proper thickness helps prevent sagging, improves nail-holding strength, and extends the roof’s overall lifespan.

2-Exterior Wall Plywood Thickness

Exterior walls commonly require 1/2-inch plywood to provide adequate shear strength and resistance against wind loads.

This thickness also supports exterior finishes like siding or cladding. Using properly rated exterior-grade plywood ensures moisture resistance and long-term durability in varying weather conditions.

3-Interior Wall Plywood Thickness

Interior wall applications generally use plywood ranging from 3/8 inch to 1/2 inch. Thinner panels are suitable for non-load-bearing partitions, while thicker sheets offer added rigidity.

Choosing the right thickness ensures flat walls, secure fastening, and a solid base for paint, paneling, or wall coverings.

4-Sheathing Plywood Thickness

Sheathing commonly uses 7/16-inch plywood or OSB, which meets standard building code requirements for strength and performance.

This thickness provides structural stability while remaining cost-effective. Proper installation and fastening patterns are essential to achieve the intended load resistance and overall building integrity.

Discover More:

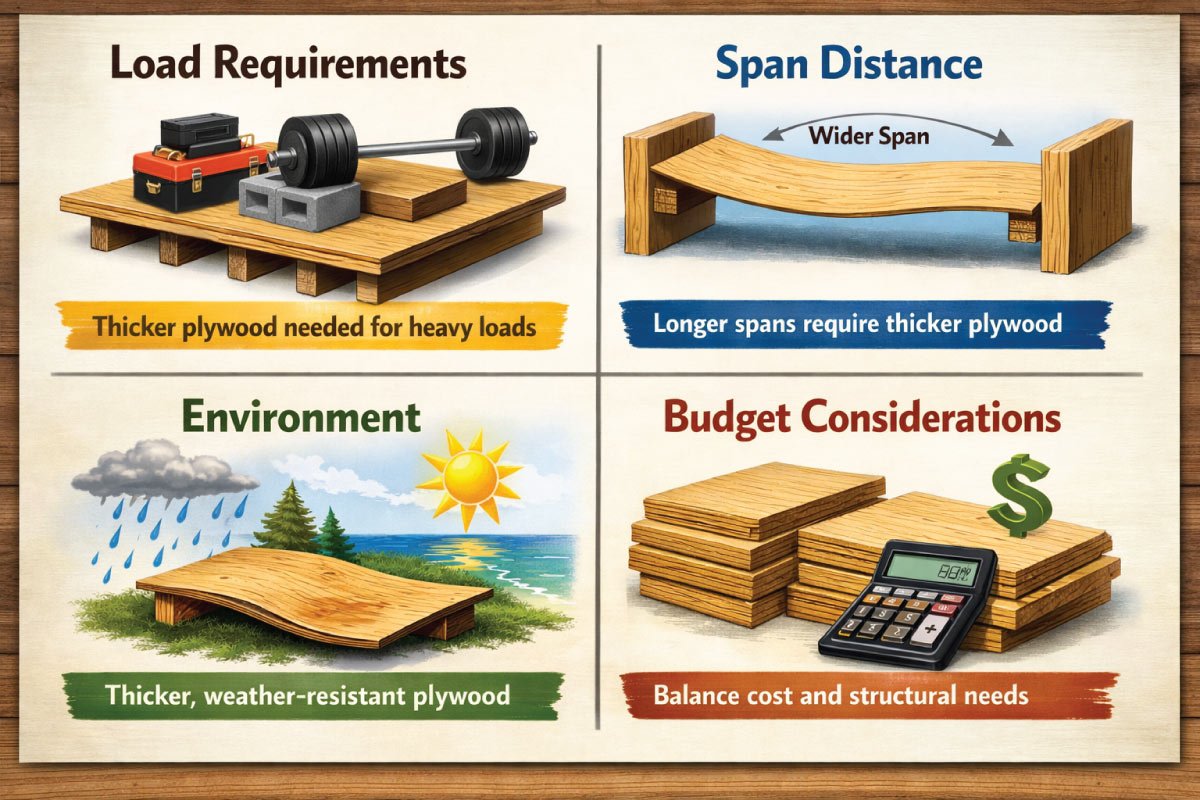

Factors to Consider When Choosing Plywood Thickness

Choosing the correct plywood thickness is not just about availability—it directly affects strength, durability, and cost.

Understanding key factors helps ensure your project performs well over time without unnecessary expense or material waste.

1-Load Requirements

The amount of weight the plywood must support is one of the most important factors.

Heavier loads demand thicker plywood to prevent sagging, cracking, or failure.

Flooring, shelving, and work surfaces typically require thicker panels than decorative or non-structural applications.

2-Span Distance

Span distance refers to the space between supports such as joists or studs. As the span increases, plywood must be thicker to maintain rigidity.

Thinner sheets may bend or flex over long spans, while thicker plywood provides better stiffness and long-term structural stability.

3-Environment

Environmental conditions greatly affect plywood performance. Moisture, humidity, and outdoor exposure can weaken thinner panels over time.

In such conditions, using exterior-grade or marine-grade plywood—often in thicker sizes—helps prevent warping, delamination, and premature deterioration.

4-Budget Considerations

Thicker plywood costs more and adds weight to a project. To control costs, select the minimum thickness that safely meets structural and usage requirements.

Balancing strength, durability, and budget ensures efficient material use without compromising safety or performance.

Discover More:

Plywood Thickness vs Plywood Grade

Plywood thickness determines strength, while plywood grade controls appearance and finish quality.

Choosing the right combination is essential for both performance and aesthetics.

In many cases, a thinner high-grade plywood is more suitable for visible furniture or cabinetry than a thicker low-grade sheet used for structural purposes.

Understanding Plywood Grades and Their Uses

| Plywood Grade | Surface Quality | Typical Uses | Best Thickness Range |

|---|---|---|---|

| A-Grade | Smooth, sanded, paint-ready | Cabinets, furniture, decorative panels | 1/4″ – 3/4″ |

| B-Grade | Minor defects, solid appearance | Furniture frames, shelving, interiors | 3/8″ – 3/4″ |

| C-Grade | Visible knots and repairs | Subfloors, wall sheathing, structural work | 1/2″ – 1″ |

| D-Grade | Rough surface, open knots | Temporary structures, roof and wall sheathing | 5/8″ – 1″ |

Common Plywood Thickness Mistakes to Avoid

Selecting the wrong plywood thickness is a common source of frustration and project failure.

Many beginners overlook critical factors such as actual versus nominal thickness, load requirements, or environmental conditions.

Understanding common mistakes helps prevent sagging shelves, wasted materials, and structural issues, ensuring your woodworking or construction project is both cost-effective and durable.

Choosing plywood that is too thin for shelves

Ignoring actual thickness measurements

Overpaying for thicker plywood than necessary

Not accounting for moisture exposure

Forgetting support spacing

Avoiding these mistakes saves money and improves project quality.

Discover More:

Quick Plywood Thickness Selection Guide

Choosing the right plywood thickness doesn’t have to be complicated.

This quick reference guide provides recommended thicknesses for common projects, from decorative panels to flooring and outdoor structures.

By following these guidelines, builders, DIYers, and woodworkers can save time, avoid errors, and ensure their projects are strong, stable, and professional-quality without unnecessary guesswork.

| Project Type | Best Thickness |

|---|---|

| Decorative panels | 1/8 – 1/4 inch |

| Cabinets | 1/2 – 3/4 inch |

| Shelving | 3/4 inch |

| Flooring subfloor | 3/4 inch |

| Roofing | 1/2 – 5/8 inch |

| Outdoor projects | 3/4 inch |

This table helps you choose quickly without confusion.

Final Thoughts

Selecting the correct plywood thickness is essential for strength, durability, and cost-efficiency.

From thin decorative panels to thick structural sheets, each plywood thickness has a specific purpose.

Understanding standard sizes, applications, and load requirements helps you avoid costly mistakes and ensures long-lasting results.

Whether you’re a DIY enthusiast or a professional builder, using this plywood thickness guide will help you choose the right material with confidence and precision.

Discover More: