When it comes to plumbing, irrigation, construction, or even DIY projects, PVC pipes (Polyvinyl Chloride pipes) are one of the most widely used materials. They are lightweight, durable, cost-effective, and resistant to corrosion, making them the top choice for both residential and industrial applications.

But here’s the catch: PVC pipes come in different types, sizes, wall thicknesses, and pressure ratings. Choosing the wrong size can lead to leaks, reduced water pressure, or even system failure. That’s why understanding a PVC pipe size chart is critical before starting any project.

In this guide, we’ll break down everything you need to know about PVC pipe sizing, from nominal size to outer diameter (OD), inner diameter (ID), and schedules. Plus, we’ll include easy-to-read PVC pipe size charts that you can use as a reference.

Understanding PVC Pipe Sizes

Before we dive into the charts, let’s clarify the main terms used in PVC sizing:

Nominal Size (NPS): The labeled size of the pipe (like 1″, 2″, 4″). It does not always match the actual diameter.

Outer Diameter (OD): The total outside width of the pipe. This measurement never changes for a nominal size.

Inner Diameter (ID): The hollow space inside the pipe, which varies depending on wall thickness.

Wall Thickness: Controlled by the pipe schedule. Thicker walls mean higher pressure resistance.

Schedule (SCH): Refers to the wall thickness of the pipe (e.g., SCH 40, SCH 80). Schedule 80 pipes are thicker and stronger than Schedule 40.

Types of PVC Pipes

PVC pipes come in several types depending on application:

Schedule 40 PVC – Standard thickness, commonly used for residential plumbing and drainage.

Schedule 80 PVC – Thicker walls, used for higher pressure systems.

CPVC (Chlorinated PVC) – Designed to handle hot water applications.

PVC Conduit – For electrical wiring protection.

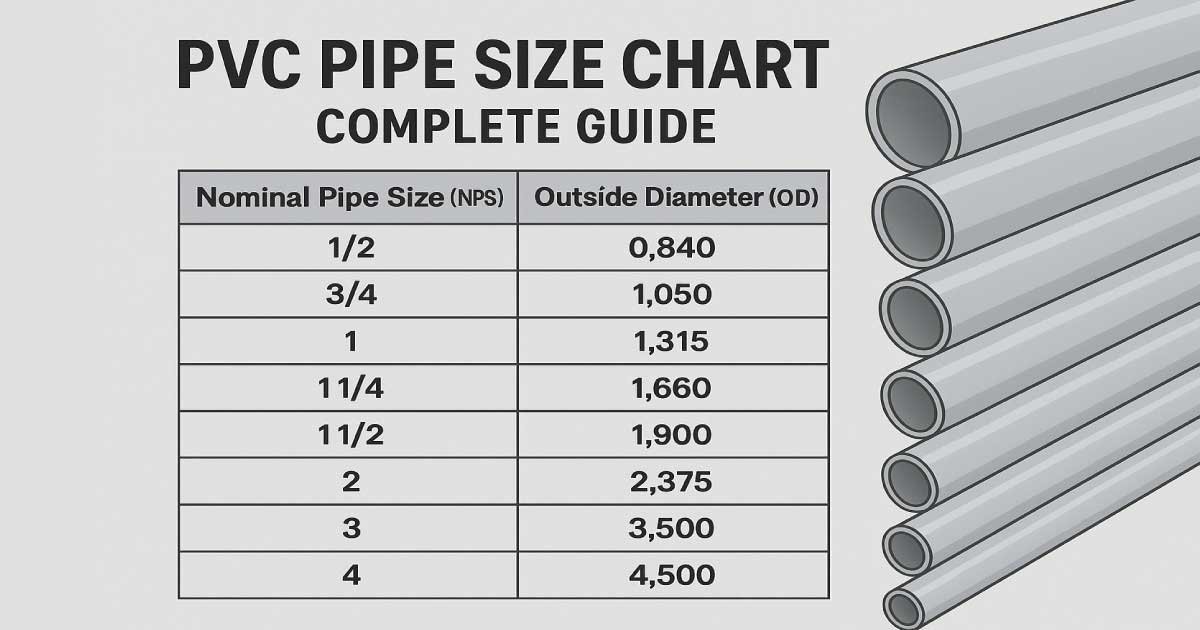

PVC Pipe Size Chart (Schedule 40)

The most common type of PVC used in plumbing is Schedule 40. Here’s a detailed chart:

Chart 1: PVC Pipe Size Chart (Schedule 40)

| Nominal Pipe Size (inches) | Outer Diameter (OD) (inches) | Inner Diameter (ID) (inches) | Wall Thickness (inches) |

|---|---|---|---|

| 1/2″ | 0.840 | 0.622 | 0.109 |

| 3/4″ | 1.050 | 0.824 | 0.113 |

| 1″ | 1.315 | 1.049 | 0.133 |

| 1-1/4″ | 1.660 | 1.380 | 0.140 |

| 1-1/2″ | 1.900 | 1.610 | 0.145 |

| 2″ | 2.375 | 2.067 | 0.154 |

| 3″ | 3.500 | 3.042 | 0.216 |

| 4″ | 4.500 | 3.998 | 0.237 |

| 6″ | 6.625 | 6.031 | 0.280 |

| 8″ | 8.625 | 7.942 | 0.322 |

| 10″ | 10.750 | 9.976 | 0.365 |

| 12″ | 12.750 | 11.889 | 0.406 |

PVC Pipe Size Chart (Schedule 80)

If you’re dealing with high-pressure applications, Schedule 80 PVC pipes are the right choice.

Chart 2: PVC Pipe Size Chart (Schedule 80)

| Nominal Pipe Size (inches) | Outer Diameter (OD) (inches) | Inner Diameter (ID) (inches) | Wall Thickness (inches) |

|---|---|---|---|

| 1/2″ | 0.840 | 0.546 | 0.147 |

| 3/4″ | 1.050 | 0.742 | 0.154 |

| 1″ | 1.315 | 0.957 | 0.179 |

| 1-1/4″ | 1.660 | 1.278 | 0.191 |

| 1-1/2″ | 1.900 | 1.500 | 0.200 |

| 2″ | 2.375 | 1.939 | 0.218 |

| 3″ | 3.500 | 2.864 | 0.318 |

| 4″ | 4.500 | 3.786 | 0.337 |

| 6″ | 6.625 | 5.709 | 0.432 |

| 8″ | 8.625 | 7.565 | 0.500 |

| 10″ | 10.750 | 9.493 | 0.593 |

| 12″ | 12.750 | 11.294 | 0.687 |

Comparing Schedule 40 vs. Schedule 80

| Feature | Schedule 40 | Schedule 80 |

|---|---|---|

| Wall Thickness | Standard | Thicker |

| Pressure Resistance | Moderate | Higher |

| Weight | Lightweight | Heavier |

| Common Uses | Home plumbing, irrigation | Industrial, high-pressure |

| Cost | Cheaper | More expensive |

PVC Pipe Size Chart Pdf:

Choosing the right PVC pipe size is essential for plumbing, irrigation, and industrial applications. Since pipe dimensions can be confusing, a detailed chart is the best way to avoid mistakes. This PVC Pipe Size Chart PDF provides complete dimensions for Schedule 40 and Schedule 80 pipes, including outer diameter, inner diameter, and wall thickness. Download it now to keep a handy reference for your projects

Also Read:

Tube Size Chart | Complete Guide 2025

Applications of PVC Pipes

Residential Plumbing: Used for cold water supply lines and drain systems.

Irrigation Systems: Ideal for farms, gardens, and landscaping.

Industrial Applications: Used for transporting chemicals and high-pressure fluids.

Electrical Conduit: Protects wires from physical damage and moisture.

DIY Projects: PVC is popular for furniture, greenhouse frames, and custom storage.

How to Choose the Right PVC Pipe Size

Know Your Application: Determine if it’s for water supply, drainage, electrical conduit, or industrial use.

Check Pressure Requirements: For high-pressure, always prefer Schedule 80.

Measure OD, Not Just NPS: Always confirm by measuring outer diameter.

Consider Flow Rate: Larger IDs allow higher water flow.

Match Fittings: Ensure fittings and pipe sizes are compatible.

Advantages of PVC Pipes

Corrosion-resistant and durable.

Lightweight and easy to install.

Cost-effective compared to copper or steel.

Versatile in size and application.

Long service life (50+ years in many cases).

PVC Pipe Pressure Ratings

One of the most important factors in selecting PVC pipes is their ability to handle pressure. Each pipe schedule and size has a maximum working pressure measured in PSI (pounds per square inch).

Schedule 40 PVC is ideal for residential water systems, irrigation, and drainage. It can handle pressures up to 450 PSI in smaller diameters but decreases as the pipe size increases.

Schedule 80 PVC has thicker walls and can manage higher pressures—often 200–300 PSI more than Schedule 40 of the same size.

Example: Pressure Comparison

A 1″ Schedule 40 pipe: ~450 PSI

A 1″ Schedule 80 pipe: ~630 PSI

This shows why industrial systems almost always prefer Schedule 80, especially where pressure fluctuations are common.

Flow Capacity of PVC Pipes

Flow rate depends on the inner diameter (ID) of the pipe. A larger ID allows more water to pass with less friction loss. This is especially important in irrigation, pool systems, or municipal water lines.

Smaller pipes (½”–1”): Best for home plumbing or garden irrigation.

Medium pipes (2”–4”): Suitable for industrial water distribution and swimming pools.

Large pipes (6”–12”): Common in municipal supply lines, drainage systems, and agricultural irrigation.

Engineers often use PVC pipe charts with flow rates to design efficient systems, ensuring that pumps and outlets are properly matched with the right pipe size.

International Standards for PVC Pipes

PVC pipe sizing may vary slightly depending on region and standards used:

ANSI/ASTM (USA): Most common in North America, covers Schedule 40 and 80.

DIN (Germany): Uses a metric sizing system based on millimeters.

ISO (International): Standardized worldwide metric dimensions.

BS (British Standard): Common in the UK and some Commonwealth countries.

This means if you’re working on an international project or buying imported pipes, always double-check which sizing system applies.

PVC Pipe Pressure Ratings

One of the most important factors in selecting PVC pipes is their ability to handle pressure. Each pipe schedule and size has a maximum working pressure measured in PSI (pounds per square inch).

Schedule 40 PVC is ideal for residential water systems, irrigation, and drainage. It can handle pressures up to 450 PSI in smaller diameters but decreases as the pipe size increases.

Schedule 80 PVC has thicker walls and can manage higher pressures—often 200–300 PSI more than Schedule 40 of the same size.

Example: Pressure Comparison

A 1″ Schedule 40 pipe: ~450 PSI

A 1″ Schedule 80 pipe: ~630 PSI

This shows why industrial systems almost always prefer Schedule 80, especially where pressure fluctuations are common.

Flow Capacity of PVC Pipes

Flow rate depends on the inner diameter (ID) of the pipe. A larger ID allows more water to pass with less friction loss. This is especially important in irrigation, pool systems, or municipal water lines.

Smaller pipes (½”–1”): Best for home plumbing or garden irrigation.

Medium pipes (2”–4”): Suitable for industrial water distribution and swimming pools.

Large pipes (6”–12”): Common in municipal supply lines, drainage systems, and agricultural irrigation.

Engineers often use PVC pipe charts with flow rates to design efficient systems, ensuring that pumps and outlets are properly matched with the right pipe size.

International Standards for PVC Pipes

PVC pipe sizing may vary slightly depending on region and standards used:

ANSI/ASTM (USA): Most common in North America, covers Schedule 40 and 80.

DIN (Germany): Uses a metric sizing system based on millimeters.

ISO (International): Standardized worldwide metric dimensions.

BS (British Standard): Common in the UK and some Commonwealth countries.

This means if you’re working on an international project or buying imported pipes, always double-check which sizing system applies.

Also Read:

Final Thoughts

Choosing the right PVC pipe size is crucial for ensuring the efficiency and safety of any plumbing or construction project. With the help of the PVC pipe size charts above, you can easily identify the correct pipe dimensions, wall thickness, and applications.

Whether you’re a plumber, engineer, contractor, or DIY enthusiast, understanding PVC pipe sizing will save you from costly mistakes and ensure a long-lasting system.

FAQs About PVC Pipe Sizes

What is the difference between nominal size and actual diameter in PVC pipes?

Nominal size (NPS) is the labeled size of a PVC pipe, like 1″ or 2″, but it doesn’t always match the actual inner diameter. Instead, the outer diameter remains constant for each nominal size, while the wall thickness and inner diameter vary depending on the pipe’s schedule.

Why is Schedule 40 PVC the most commonly used pipe type?

Schedule 40 PVC is lightweight, cost-effective, and easy to install, making it perfect for residential plumbing, irrigation, and drainage projects. It provides moderate pressure resistance while being affordable and widely available. This balance of strength and value is why Schedule 40 is considered the standard choice in most household and light commercial applications.

When should I use Schedule 80 PVC instead of Schedule 40?

Schedule 80 PVC has thicker walls, which allow it to handle higher pressure systems. It’s often used in industrial applications, chemical transport, and heavy-duty systems where durability is critical. Although heavier and more expensive than Schedule 40, it ensures extra strength and reliability in high-pressure environments.

How do I select the right PVC pipe size for my project?

Start by identifying your application—plumbing, irrigation, or industrial. Then, check the pressure requirements: for higher pressure, use Schedule 80. Measure the outer diameter, not just the nominal size, to ensure fittings match. Lastly, consider flow rate needs, as larger inner diameters provide greater water capacity.

Can PVC pipes be used for hot water applications?

Standard PVC is not suitable for hot water because high temperatures can weaken it. For hot water applications, CPVC (Chlorinated PVC) is the better choice. CPVC can handle higher temperatures safely, making it ideal for hot water supply lines in both residential and commercial plumbing systems.

Do PVC pipe sizes vary in different countries?

Yes, PVC sizing standards differ worldwide. In the USA, ANSI/ASTM standards define Schedule 40 and 80 pipes. Europe often uses DIN or ISO metric sizing, while the UK follows British Standards (BS). Always confirm the sizing system before purchasing, especially when working on international projects or using imported materials.