In the world of manufacturing and product development, speed and accuracy can make or break your project. This is especially true when it comes to creating prototypes — the first physical versions of a product used to test design, fit, function, and manufacturability. That’s where rapid prototype machining shines. It’s a process designed to quickly produce prototypes using precise machining methods, allowing engineers and designers to move swiftly from concept to tangible reality.

If you are new to this, or just curious about how it works, this post will guide you through everything: the rapid prototype machining process, common techniques, the types of materials used, how it compares with other methods like 3D printing, and why it might be the perfect fit for your next project. Along the way, I’ll include important info about costs, lead times, and real-world applications.

What is Rapid Prototype Machining?

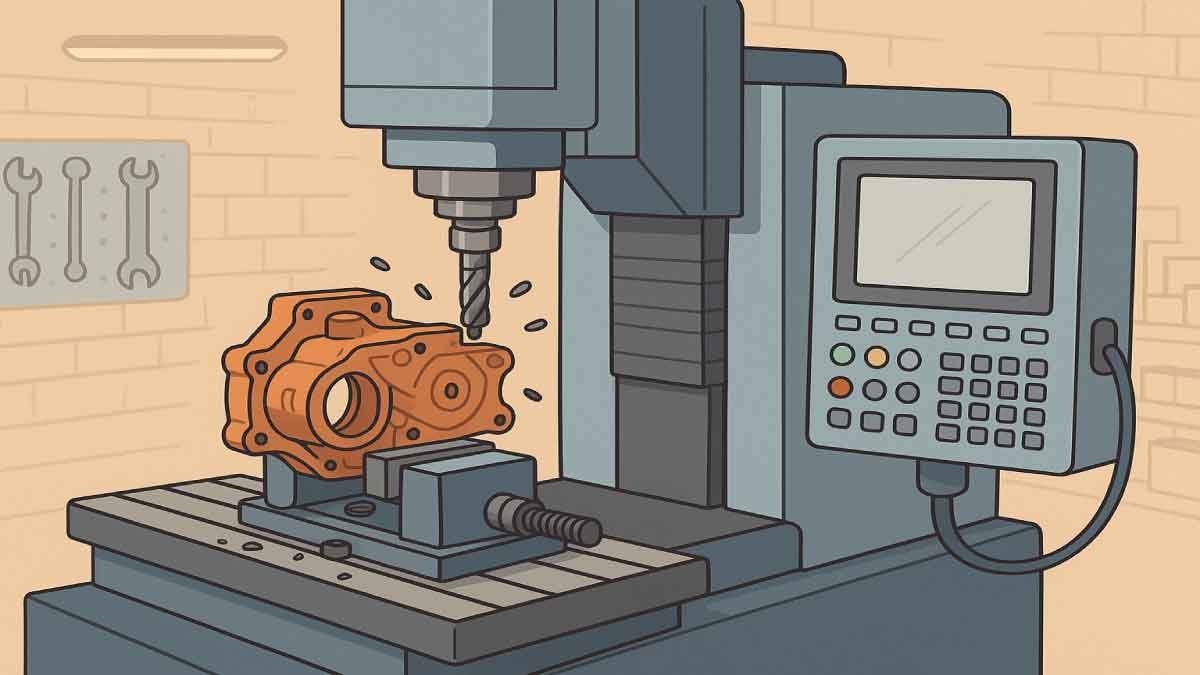

Let’s start with the basics. Rapid prototype machining refers to the use of machining tools and technologies to quickly create prototypes. Machining means physically cutting away material — metals, plastics, or composites — using machines controlled by computers (known as CNC machines). These machines follow detailed instructions derived from digital models to produce a part that matches the design specifications.

The key word here is “rapid.” Traditional machining for prototypes could take weeks and be costly due to tooling setups and manual labor. In contrast, rapid prototype machining leverages advanced CNC programming, faster machines, and streamlined workflows to get parts made in days or even hours.

Rapid prototype machining is part of a broader category called rapid prototype manufacturing, which also includes methods like 3D printing and injection molding. But what sets machining apart is its ability to create strong, functional parts that closely mimic the final product’s material properties and mechanical performance. This is why it’s often the go-to method when you need a prototype not just for visualization but for real-world testing.

👉 Want to become a CNC expert? Read our complete guide: CNC Machining 101: Beginner-to-Expert Guide to explore everything from basic principles to advanced CNC techniques and boost your real-world skills.

Rapid Prototype Machining Process: Step-by-Step

Understanding the rapid prototype machining process helps you appreciate how efficiently this technology can turn your ideas into reality. Here’s a breakdown:

Design Preparation: Everything starts with a 3D CAD (Computer-Aided Design) model of the part. This digital file contains all the dimensions and geometry needed for manufacturing. Designers usually finalize the design and ensure it’s optimized for machining, sometimes adjusting wall thicknesses or adding fillets to improve manufacturability.

Material Selection: This is a crucial step. Based on what the prototype needs to do, you’ll pick from various rapid prototype machining materials like aluminum for lightweight strength or ABS plastic for simple, low-stress parts. The choice affects cost, machining speed, and the prototype’s performance.

Programming CNC Machines: Skilled machinists or CAM (Computer-Aided Manufacturing) programmers convert the CAD model into machine code. This code tells the CNC machine how to move, cut, and shape the raw material. Efficient programming is essential for minimizing production time while ensuring quality.

Machining the Prototype: The CNC machines go to work milling, turning, or cutting the material layer by layer until the prototype is complete. Modern machines can work with impressive speed and precision, sometimes running unattended overnight.

Finishing & Inspection: After machining, the prototype undergoes finishing touches such as deburring, polishing, or coating. Then, quality control ensures the part meets tight machining tolerance standards, confirming it matches the original design accurately.

Thanks to this streamlined process, rapid prototype machining often delivers finished parts much faster than traditional methods, making it invaluable for quick iteration cycles.

Techniques in Rapid Prototyping Machining

Not all machining is the same. There are several rapid prototyping machining techniques that manufacturers use depending on the complexity and nature of the prototype:

CNC Milling: This is the most common technique where rotary cutting tools remove material from a solid block. It’s excellent for creating complex shapes, cavities, and flat surfaces, and works with a wide variety of materials.

CNC Turning: Perfect for parts with cylindrical shapes, turning involves spinning the workpiece against a cutting tool to shape it. This technique is often used for shafts, pins, and threaded parts.

Electrical Discharge Machining (EDM): When prototypes require intricate details or are made from extremely hard materials, EDM can be used. It removes material by electrical sparks, allowing for very precise cuts without mechanical force.

Laser Machining: This uses high-powered lasers to cut or engrave materials with great accuracy. It’s especially useful for delicate finishing or adding fine features that conventional tools can’t achieve.

Among these, CNC rapid prototyping is the backbone of most rapid prototype machining projects because of its versatility, repeatability, and ability to work with a broad range of materials.

Materials Used in Rapid Prototype Machining

One of the biggest advantages of rapid prototype machining materials is the flexibility to choose from many options that closely resemble the final production parts. Here are some popular materials used:

Metals: Aluminum is favored for its light weight and machinability; stainless steel offers strength and corrosion resistance; titanium is used where strength-to-weight ratio is critical; brass and bronze are used for decorative or mechanical properties.

Plastics: ABS and polycarbonate are common for durable prototypes that require impact resistance; nylon is good for parts requiring flexibility; acrylic is chosen for transparent prototypes.

Composites and specialty materials can also be machined, though often with specialized equipment.

Choosing the right material depends on whether your prototype is just a visual model or if it needs to perform under real conditions, such as stress testing or heat exposure.

Advantages of Rapid Prototype Machining

Why is rapid prototype machining gaining so much popularity? Here are some of its standout benefits:

Speed: Prototypes can be machined in a matter of days, drastically cutting down development time.

Precision: With CNC control, you get high accuracy and fine machining tolerance, ensuring prototypes are reliable for functional testing.

Material Variety: Unlike some rapid prototyping methods limited to plastics, machining lets you use actual metals and engineering-grade plastics.

Functional Prototypes: Since machined parts are often made from the same materials as final products, they’re perfect for performance testing, including mechanical, thermal, and chemical testing.

Cost-Effective Small Runs: For short runs or one-offs, machining doesn’t require expensive tooling, making it more affordable than injection molding or other mass production techniques.

These benefits make rapid prototype machining an ideal choice when your prototype needs to closely simulate the final product in both form and function.

Rapid Prototype Machining vs 3D Printing: What’s the Difference?

You may be wondering how rapid prototype machining compares to the now very popular 3D printing. Both are part of rapid prototype manufacturing, but they serve different purposes. Here’s a quick comparison:

| Aspect | Rapid Prototype Machining | 3D Printing |

|---|---|---|

| Material Options | Wide range including metals and plastics | Mostly plastics and some metals |

| Precision & Tolerance | High precision, tight tolerances | Lower precision, sometimes rougher finish |

| Surface Finish | Smooth, ready for functional use | Often requires post-processing |

| Speed | Fast for small to medium batches | Very fast for complex shapes and one-offs |

| Cost | Moderate for prototypes with higher durability | Low for concept models |

| Applications | Functional testing, mechanical parts | Concept models, visual prototypes |

If your goal is to produce a prototype that looks good but doesn’t need to work under stress, 3D printing is quick and cost-effective. But if you want a prototype that can actually be used for mechanical testing or assembly, rapid prototype machining is the way to go.

Rapid Prototype Machining Applications

This technology isn’t limited to a single field. Its versatility means it’s used in many industries for various purposes:

Automotive Industry: Prototyping engine parts, brackets, housings, or even aerodynamic components.

Aerospace: Creating lightweight yet strong prototype parts for testing before committing to expensive production tooling.

Medical Devices: Machining prototypes of surgical tools or implants that require biocompatible materials and exact specifications.

Consumer Electronics: Developing cases, internal components, or connectors where precision and finish are critical.

Industrial Equipment: Producing functional parts to test machinery performance or fit before mass production.

Thanks to these broad rapid prototype machining applications, manufacturers across the board can innovate faster and with greater confidence.

Cost and Lead Time in Rapid Prototype Machining

When considering rapid prototype machining cost, many factors come into play:

Material choice: Metals cost more than plastics.

Complexity: Intricate parts with tight tolerances require more machine time.

Volume: Small batches are usually cheaper than large runs because machining is flexible.

Finishing requirements: Additional polishing or coatings add cost.

On average, the cost per prototype is reasonable considering you get a high-quality, functional part.

As for rapid prototype machining lead time, this can be anywhere from 24 hours to a week, depending on the complexity and availability of materials. This speed is a major advantage over traditional prototyping methods, which can take weeks or months.

Finding the Right Rapid Prototype Machining Services and Companies

To get the best results, you need to partner with the right rapid prototype machining companies. Look for those with:

Extensive experience in your industry.

Access to a variety of machining techniques and materials.

Strong customer reviews and case studies.

Transparent quotes and reliable lead times.

Capabilities for finishing and inspection.

Many companies also provide design consultation to optimize your CAD files for machining, reducing errors and speeding up production.

Summary Table: Rapid Prototype Machining vs Other Methods

| Feature | Rapid Prototype Machining | 3D Printing | Injection Molding |

|---|---|---|---|

| Speed | Fast (days) | Very fast (hours to days) | Slow (weeks to months) |

| Material Variety | Metals, plastics, composites | Mostly plastics | Limited to moldable plastics |

| Prototype Strength | High, functional | Low to medium | High |

| Cost per Prototype | Moderate | Low | High (tooling costs) |

| Suitable for Complex Shapes | Moderate | Excellent | Moderate |

| Best Use | Functional prototypes, testing | Concept models | Mass production |

Final Thoughts

Rapid prototype machining offers an excellent blend of speed, precision, and material options that few other prototyping methods can match. For engineers and designers needing functional, high-quality prototypes fast, it’s often the best choice.

By understanding the rapid prototype machining process, comparing it to alternatives like 3D printing, and knowing the advantages and typical applications, you can make smarter decisions for your next project. Whether you’re in automotive, aerospace, medical, or consumer products, rapid prototype machining can help you innovate faster and with confidence.

If you have any questions or want recommendations for rapid prototype machining services, feel free to reach out in the comments. I’m here to help!

Check out this latest and comprehensive guide we have prepared for you

FAQs:

What is rapid prototype machining?

Rapid prototype machining is a fast manufacturing process where CNC machines carve out prototypes from solid materials based on digital designs. It allows engineers to quickly create accurate, functional models to test fit, form, and function before mass production. Unlike 3D printing, it uses actual metals and plastics, producing stronger prototypes suitable for real-world testing and validation.

How long does rapid prototype machining take?

The time for rapid prototype machining depends on the part’s complexity and material, but typically it takes from a few hours to a few days. Simple parts can be finished within 24-48 hours, while more detailed or larger pieces may take up to a week. The process is much faster than traditional machining, helping companies shorten product development cycles.

What materials are used in rapid prototype machining?

Common materials include aluminum, stainless steel, ABS plastic, polycarbonate, and nylon. Metals are chosen for prototypes requiring strength and durability, while plastics are used for lightweight or less-stressed parts. The ability to machine actual production-grade materials allows for functional testing that closely replicates final product conditions.

Is rapid prototype machining expensive?

Compared to traditional prototyping methods, rapid prototype machining offers a cost-effective solution for small to medium runs without expensive tooling. Costs depend on factors like material choice, complexity, and finishing requirements. While it may be pricier than 3D printing for purely visual models, the functional benefits often justify the investment.

What industries use rapid prototype machining?

Rapid prototype machining is widely used in automotive, aerospace, medical device manufacturing, consumer electronics, and industrial equipment sectors. These industries rely on it to quickly develop precise, functional prototypes for testing product designs, mechanical performance, and assembly fit before committing to full-scale production.

How accurate is rapid prototype machining?

Rapid prototype machining offers high accuracy with tight machining tolerances, often within microns. CNC machines ensure precise cuts and consistent dimensions, making machined prototypes suitable for functional testing and quality validation. This precision surpasses many other prototyping methods, especially for metal and engineering plastic parts.