When you are working on DIY projects, woodworking, construction, or even simple household repairs, screws are among the most common fasteners you will use. But if you have ever stood in the hardware aisle staring at boxes of screws labeled with numbers, fractions, or millimeters, you know how confusing it can be. That’s where a screw size chart becomes invaluable.

This complete guide will help you understand screw sizes, the different systems used (metric vs. imperial), how to read a screw size chart, and how to select the right screw for your project.

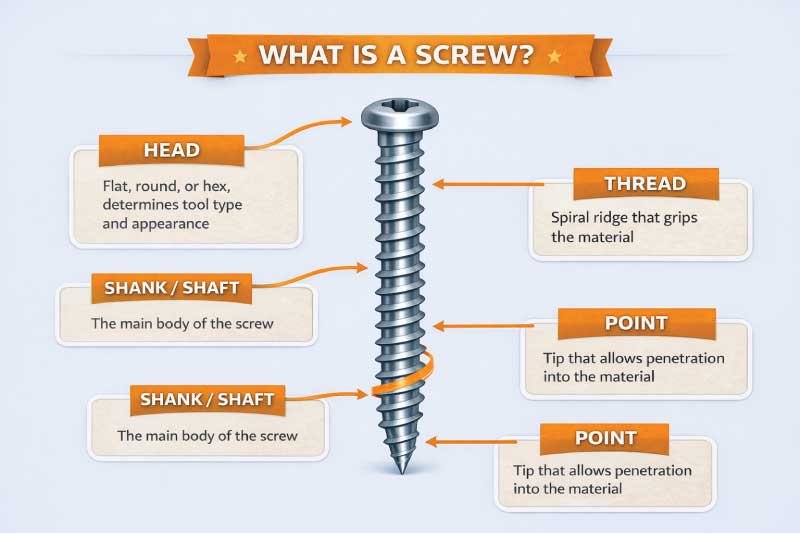

What is a Screw?

A screw is a type of fastener designed to hold objects together by creating a tight grip in materials like wood, metal, or plastic. It has a helical thread around a cylindrical shaft and a head that allows it to be driven with a screwdriver, wrench, or drill.

Screws work by converting rotational force into linear holding power, making them stronger than nails for many applications. They come in various types, sizes, lengths, threads, and head styles, each suited for specific materials and purposes.

Key parts of a screw:

Head: Flat, round, or hex, determines tool type and appearance

Shank/Shaft: The main body of the screw

Thread: Spiral ridge that grips the material

Point: Tip that allows penetration into the material

What Are Screw Sizes?

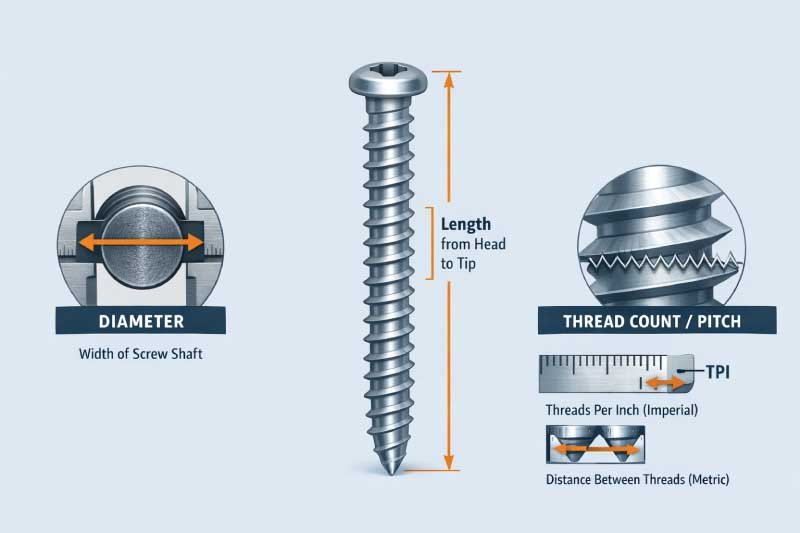

Screw sizes describe the diameter, length, and thread count of a screw. These measurements are essential because they determine how well a screw holds materials together and whether it fits into a pre-drilled hole.

The three main aspects of a screw’s size are:

Diameter (gauge or millimeters): The thickness of the screw shaft.

Length: The distance from the head to the tip of the screw.

Thread count/pitch: How many threads are on the screw per inch (imperial) or the distance between threads in millimeters (metric).

Why Do You Need a Screw Size Chart?

A screw size chart helps you choose the correct screw by clearly showing sizes, threads, and applications. It saves time, prevents costly mistakes, and ensures strong, safe connections in woodworking, metalwork, construction, and mechanical projects—especially when precision and load-bearing strength really matter.

Stripped threads

Weak joints

Splitting wood

Poor load-bearing strength

By using a chart, you can quickly confirm which screw works best for drywall, decking, cabinetry, metal, or machinery.

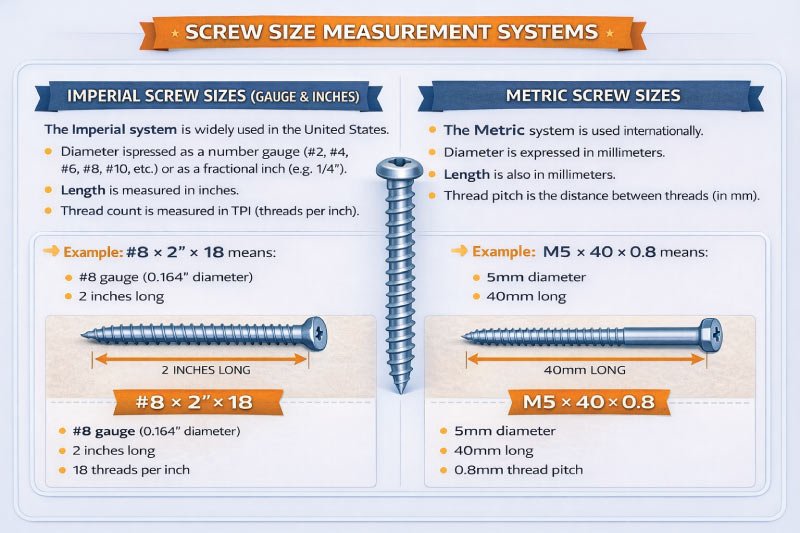

Screw Size Measurement Systems

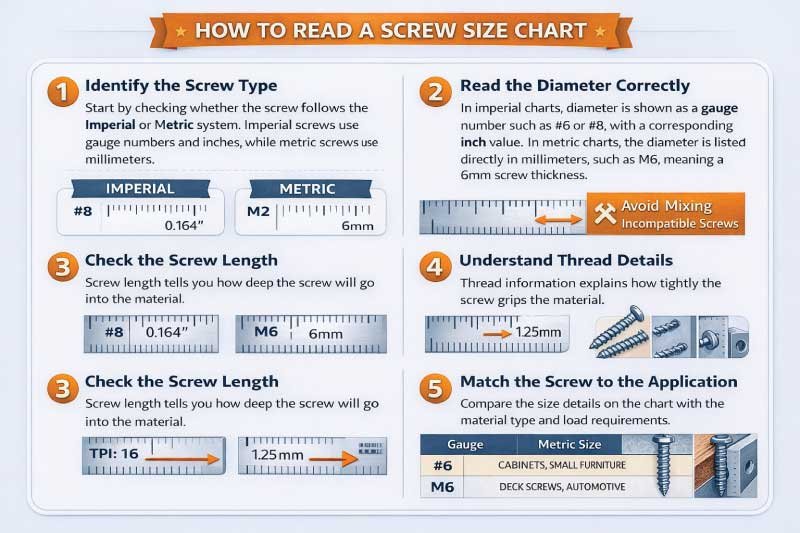

Screw size measurement systems explain how screw dimensions are defined and labeled. Understanding these systems helps you select the correct screw for strength, compatibility, and proper fit. The two most common standards used worldwide are the Imperial (U.S.) system and the Metric system.

1. Imperial Screw Sizes (Gauge and Inches)

The Imperial system is widely used in the United States. It identifies screws by gauge number, length in inches, and thread count per inch. Knowing this system is essential for woodworking, construction, and machinery that follows U.S. standards.

Diameter is expressed as a number gauge (#2, #4, #6, #8, #10, etc.) or as a fractional inch (e.g., 1/4″).

Length is measured in inches.

Thread count is measured in TPI (threads per inch).

👉 Example: A screw labeled #8 × 2″ × 18 means:

#8 gauge (0.164″ diameter)

2 inches long

18 threads per inch

2. Metric Screw Sizes

The Metric system is used internationally and measures screws in millimeters. It defines diameter, length, and thread pitch clearly, making it easier to achieve precise fits. Metric screws are common in automotive, industrial, and modern mechanical applications.

Diameter is expressed in millimeters.

Length is also in millimeters.

Thread pitch is the distance between threads (in mm).

👉 Example: A screw labeled M5 × 40 × 0.8 means:

5mm diameter

40mm long

0.8mm thread pitch

Also Read:

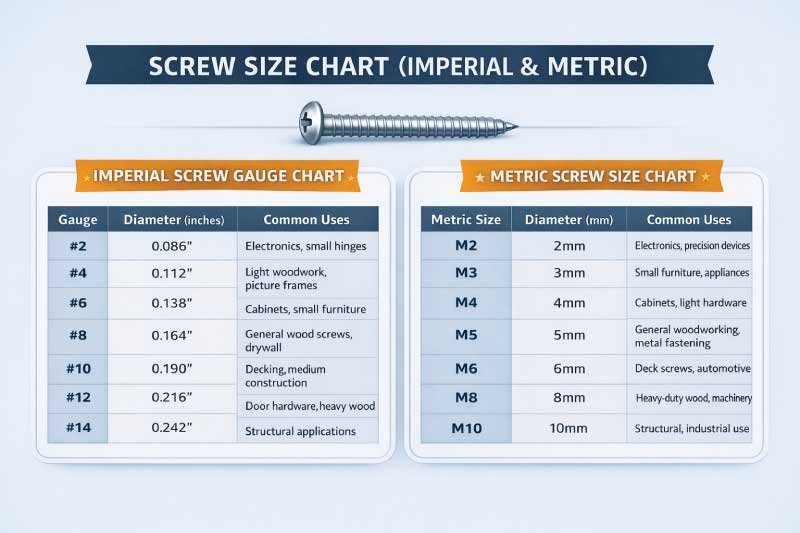

Screw Size Chart (Imperial & Metric)

A screw size chart makes it easy to compare imperial screw gauges with their actual diameters and common applications. Using a reference chart helps you quickly choose the right screw for strength, fit, and material type, whether you are working on light household tasks or heavy construction projects.

1- Imperial Screw Gauge Chart

This chart shows common imperial screw gauges with their exact diameters and typical uses. It helps you quickly match the correct screw size to your project, ensuring proper grip, strength, and compatibility in woodworking, construction, and general repair tasks.

| Gauge | Diameter (inches) | Common Uses |

|---|---|---|

| #2 | 0.086″ | Electronics, small hinges |

| #4 | 0.112″ | Light woodwork, picture frames |

| #6 | 0.138″ | Cabinets, small furniture |

| #8 | 0.164″ | General wood screws, drywall |

| #10 | 0.190″ | Decking, medium construction |

| #12 | 0.216″ | Door hardware, heavy wood |

| #14 | 0.242″ | Structural applications |

2- Metric Screw Size Chart

This metric screw size chart lists standard metric diameters with their common applications. It is useful for projects that require precise measurements, especially in automotive, machinery, and modern furniture, where metric fasteners are widely used.

| Metric Size | Diameter (mm) | Common Uses |

|---|---|---|

| M2 | 2mm | Electronics, precision devices |

| M3 | 3mm | Small furniture, appliances |

| M4 | 4mm | Cabinets, light hardware |

| M5 | 5mm | General woodworking, metal fastening |

| M6 | 6mm | Deck screws, automotive |

| M8 | 8mm | Heavy-duty wood, machinery |

| M10 | 10mm | Structural, industrial use |

Some Explanations:

#6 Screw Diameter:

A #6 screw has a nominal diameter of approximately 0.138 inches (3.51 mm). It is commonly used for small woodworking projects, cabinets, and furniture assembly. Its size provides a good balance of strength and ease of installation without splitting the material.

#8 Screw Diameter:

A #8 screw measures about 0.164 inches (4.17 mm) in diameter. This versatile size is widely used in general woodworking, drywall installation, and light construction. It offers strong holding power while remaining easy to drive into wood, plastic, or light metal materials.

#10 Screw Diameter:

A #10 screw has a diameter of approximately 0.190 inches (4.83 mm). It is suitable for medium-duty projects like decking, door hardware, and furniture. Its larger size provides enhanced load-bearing strength, making it ideal for joining thicker wood pieces or heavier materials.

Also Read:

Screw Size Chart (Imperial & Metric) PDF

The Screw Size Chart (Imperial & Metric) PDF is a quick reference guide that helps you easily compare screw gauges in both measurement systems. It includes imperial sizes commonly used in woodworking, construction, and household projects, alongside metric sizes widely applied in electronics, automotive, and industrial work. Having this chart in PDF format makes it convenient for DIY enthusiasts, mechanics, and professionals to access accurate screw dimensions anytime, ensuring precise selection for every project.

Screw_Size_Chart Pdf

Screw Length Guide

Choosing the correct screw length is essential for strong and secure fastening. The right length ensures enough thread engagement without damaging the material. Screw length depends on material thickness, load requirements, and application type, from light hardware installation to heavy-duty construction work.

1/2″ to 1″ (12–25mm): For thin materials, hinges, brackets.

1 1/4″ to 2″ (30–50mm): For woodworking and drywall.

2 1/2″ to 3″ (65–75mm): Decking, framing.

3 1/2″ and above (90mm+): Heavy-duty construction.

Also Read:

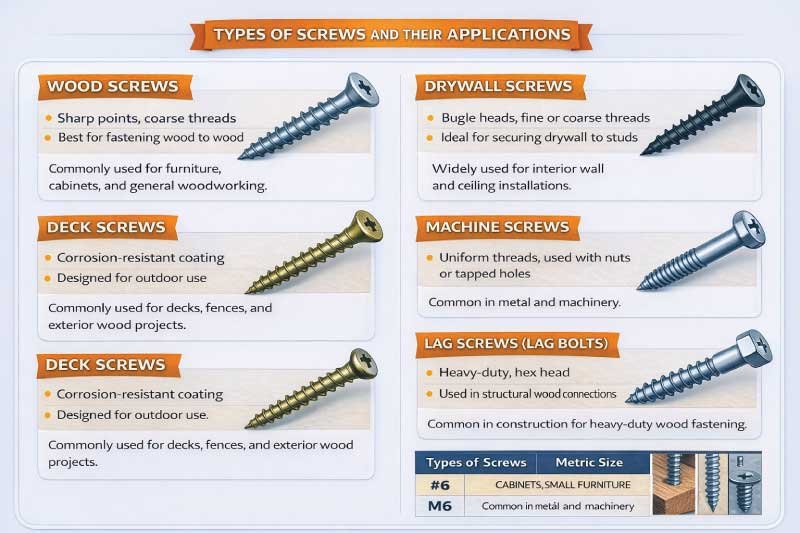

Types of Screws and Their Applications:

Different screws are designed for specific materials and job requirements. Understanding screw types helps you achieve better holding strength, cleaner installation, and long-term durability. Below is a clear explanation of common screw types, while keeping their key features and uses exactly as listed.

1- Wood Screws:

Wood screws are designed to grip wood fibers tightly and create strong joints. Their design allows easy penetration and firm holding without splitting the material. They are commonly used in furniture making, cabinets, shelves, and general woodworking where wood-to-wood fastening is required.

Sharp points, coarse threads

Best for fastening wood to wood

2- Drywall Screws:

Drywall screws are optimized for attaching drywall sheets securely without tearing the paper surface. Their head shape allows them to sit flush, creating a smooth finish. They are widely used in interior wall and ceiling installations with both wood and metal studs.

Bugle heads, fine or coarse threads

Ideal for securing drywall to studs

3- Deck Screws:

Deck screws are built to withstand outdoor conditions such as moisture and temperature changes. Their protective coating prevents rust and corrosion, ensuring long-lasting strength. These screws are commonly used in decks, fences, outdoor furniture, and exterior wood projects.

Corrosion-resistant coating

Designed for outdoor use

4- Machine Screws:

Machine screws are precision fasteners used where accuracy and strength are important. Their uniform threads allow easy removal and reinstallation. They are commonly found in machines, appliances, and metal assemblies where nuts or threaded holes are used.

Uniform threads, used with nuts or tapped holes

Common in metal and machinery

5- Sheet Metal Screws:

Sheet metal screws are designed to fasten thin metal sheets securely. Their pointed or self-tapping ends allow them to cut threads during installation. They are frequently used in HVAC systems, metal panels, ducts, and light industrial work.

Pointed or self-tapping ends

Used for fastening metal sheets

6- Lag Screws (Lag Bolts):

Lag screws are heavy-duty fasteners made for high-strength applications. Their large size and hex head allow strong tightening using tools. They are commonly used in construction projects where structural wood connections must support heavy loads.

Heavy-duty, hex head

Used in structural wood connections

Tips for Choosing the Right Screw

Selecting the right screw is just as important as choosing the right material. The correct screw improves strength, prevents damage, and ensures long-term durability. These practical tips will help you make the best choice for any woodworking, construction, or mechanical project.

Match screw to material: Wood screws for wood, machine screws for metal, drywall screws for gypsum boards.

Use correct length: At least half of the screw length should penetrate into the base material.

Check thread type: Coarse threads grip soft materials better; fine threads suit metal and hard materials.

Choose proper head type: Flat, round, or hex heads depending on appearance and torque needs.

Consider corrosion resistance: Use stainless steel or coated screws for outdoor projects.

Common Mistakes to Avoid

Even experienced users can make simple screw-selection mistakes that weaken joints or damage materials. Avoiding these common errors will help you achieve stronger fastening, cleaner installation, and longer-lasting results in woodworking, construction, and mechanical projects.

Using the wrong diameter – Too small and it won’t hold; too big and it splits the material.

Over-tightening – Can strip threads or break the screw.

Mixing metric and imperial – Always stick to the right measurement system.

Ignoring pilot holes – For hardwood and large screws, pre-drilling prevents splitting.

Final Thoughts

A screw size chart is one of the most useful tools you can keep in your workshop or toolbox. By understanding gauge sizes, metric equivalents, lengths, and thread types, you’ll save time and avoid costly mistakes.

Whether you are hanging shelves, building furniture, repairing electronics, or tackling heavy construction projects, the right screw size ensures a safe, strong, and lasting connection.

Keep a screw size chart handy, and you’ll never second-guess which screw to use again.

Read our newest article here:

FAQs Related to Screw Size

What does the “gauge” in screw sizes mean?

The gauge number in screw sizes tells you the thickness of the screw’s shaft. For example, a #6 screw is thinner than a #10 screw. It’s mainly used in the U.S. system, and the higher the gauge, the thicker the screw. To fully understand the size, you also need the screw’s length and thread type, not just the gauge.

How do I read metric screw size labels like “M6 × 40 × 1.0”?

Metric screw sizes may look confusing at first, but they’re very straightforward. “M6” means the screw’s diameter is 6 millimeters. The “40” indicates the screw’s length is 40 millimeters. The last number, “1.0,” shows the thread pitch—the distance between threads in millimeters. If the pitch isn’t shown, it usually means a standard coarse thread. This system makes choosing the right screw precise and simple.

When should I use coarse vs. fine thread screws?

Coarse threads are best when you need quick fastening in soft materials like wood, drywall, or plastic. They grip easily and resist stripping. Fine threads are more suitable for hard materials such as metal, or when you need a stronger hold against vibration. Fine threads also allow more threads to fit in a shorter space, which increases strength. Choosing the right type depends on the material and job requirements.

How long should a screw be for safe embedment in wood?

A good rule is that at least half the screw’s length should be buried into the main piece of wood. If you’re joining two boards, aim for two-thirds of the screw length to anchor in the base material. Too short and the joint will be weak; too long doesn’t add much strength. Always size screws according to the thickness of the materials you’re working with.

How do I prevent wood from splitting when using large diameter screws?

To avoid splitting wood, always drill a pilot hole before driving in larger screws. The pilot hole should be slightly smaller than the screw’s shaft. Keep screws away from the very edges of the wood and drive them in straight. Applying steady pressure instead of forcing the screw also helps. If working with hardwood, you can rub a little wax or soap on the screw for smoother driving.

How do I choose the correct screw size for metal parts?

When fastening metal, you need to match the screw diameter to the pre-drilled or tapped hole. The thread pitch must also match to avoid stripping. The length should be long enough to pass through the material and give strong engagement, but not too long to cause interference. Stainless steel or coated screws are ideal for metal to prevent rust. Always check the fit before final tightening.

What screw sizes are most common in household use?

For everyday household projects, the most commonly used screw sizes are #6, #8, and #10, usually in lengths between 1 and 2 inches. These sizes cover tasks like mounting shelves, hanging fixtures, or assembling furniture. In homes with metric hardware, M4, M5, and M6 screws are equally common. Having a small assortment of these popular sizes on hand makes most DIY jobs much quicker and easier.