When you are working with nuts, bolts, and fasteners, one tool you’ll always need is a spanner (often called a wrench in the U.S.). Choosing the right spanner size ensures you can grip the fastener firmly, apply torque safely, and avoid damaging the hardware. That’s why a spanner size chart is essential—it helps you match the correct tool to the job.

In this guide, we will explore the different spanner size standards, provide conversion charts, and share practical tips so you’ will never struggle with mismatched tools again.

What is a Spanner?

A spanner (or wrench) is a hand tool used to tighten or loosen nuts and bolts. The jaws of the spanner grip the sides of a fastener, allowing you to turn it with torque. Spanners come in different types, such as:

Open-end spanner – grips two sides of a nut or bolt.

Ring spanner – closed loop design for stronger grip.

Combination spanner – open-end on one side, ring on the other.

Adjustable spanner (Crescent wrench) – can adapt to multiple sizes.

Socket wrench – uses detachable sockets with ratchet handles.

Each type relies on correct sizing to fit securely over the fastener.

Why Spanner Size Matters

Using the wrong size spanner can cause problems such as:

Rounding off the bolt head (slipping and damaging the edges).

Injury risk from slips when too much force is applied.

Reduced efficiency since you’ll struggle to turn the fastener.

Damage to the tool when over-stressing smaller spanners.

That is why professionals and DIYers alike depend on spanner size charts to make sure the right size is always chosen.

Spanner Size Standards

Different regions of the world use different sizing systems for spanners. The most common are:

1. Metric Sizes

Measured in millimeters (mm).

Common in Europe, Asia, and modern machinery worldwide.

Examples: 8 mm, 10 mm, 13 mm, 17 mm, 19 mm, 24 mm.

2. Imperial (AF – Across Flats) Sizes

Measured in inches.

Common in older British and American machinery.

Examples: 1/4”, 5/16”, 1/2”, 3/4”.

3. Whitworth (BSW) Sizes

Based on bolt diameter, not head size.

Mostly found in older British equipment.

4. SAE Sizes

Standard used in the U.S. (Society of Automotive Engineers).

Overlaps with AF (across flats) measurements.

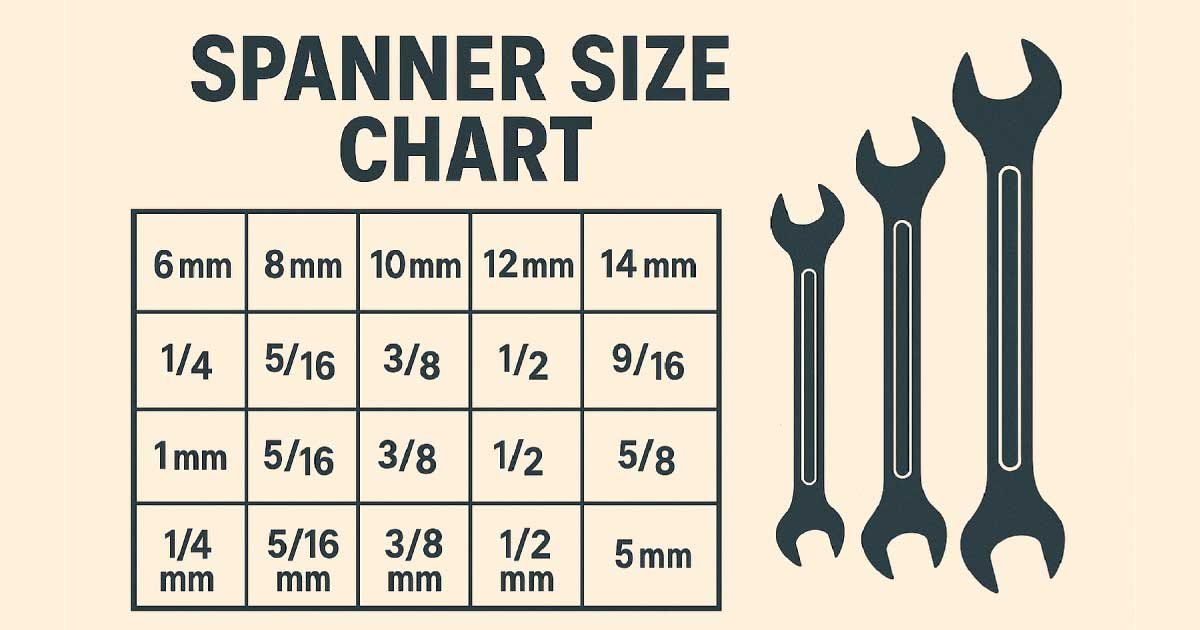

Spanner Size Conversion Chart

Here’s a metric to imperial conversion chart for spanners:

| Metric (mm) | Imperial (inches) | Common Use |

|---|---|---|

| 6 mm | 1/4” | Small bolts, electronics |

| 8 mm | 5/16” | Auto, bikes |

| 10 mm | 3/8” | One of the most common sizes |

| 11 mm | 7/16” | General machinery |

| 12 mm | 15/32” | Automotive parts |

| 13 mm | 1/2” | Widely used in vehicles |

| 14 mm | 9/16” | Industrial fasteners |

| 16 mm | 5/8” | Larger machinery |

| 17 mm | 11/16” | Car wheel nuts, plumbing |

| 19 mm | 3/4” | Very common in automotive |

| 22 mm | 7/8” | Heavy-duty applications |

| 24 mm | 15/16” | Trucks, large bolts |

| 27 mm | 1-1/16” | Industrial machines |

| 30 mm | 1-3/16” | Construction equipment |

| 32 mm | 1-1/4” | Heavy machinery |

Common Spanner Sizes in Everyday Use

Certain spanner sizes appear more frequently depending on the application:

Automotive: 8 mm, 10 mm, 13 mm, 17 mm, 19 mm.

Bicycles: 8 mm, 9 mm, 10 mm, 15 mm.

Plumbing: 22 mm, 24 mm, 30 mm.

Home Repairs: 10 mm, 13 mm, 17 mm.

Fun fact: Many mechanics joke that the 10 mm spanner is the most commonly used—and the most commonly lost—tool in the workshop!

How to Read a Spanner Size

If it says 13 mm, it means the jaws of the spanner are 13 millimeters wide, designed to fit a bolt head with that width.

For imperial sizes like 1/2”, it means the jaws fit a bolt head measuring half an inch across flats.

Choosing the Right Spanner

Here are some quick tips for selecting the right spanner size:

Measure Across Flats (AF) – Use a caliper or ruler to measure the bolt head across the flats.

Check a Conversion Chart – If you only have metric spanners but the bolt is imperial, use the chart to find the nearest equivalent.

Avoid Using “Almost Fits” – Using the wrong size will round off bolts.

Invest in a Full Set – A complete set of metric and imperial spanners ensures you always have the right size.

Spanner Materials and Quality

Not all spanners are created equal. Quality matters when it comes to strength and durability.

Chrome Vanadium Steel: Most common, durable for everyday use.

Drop-Forged: Stronger and more resistant to wear.

Polished Finish: Prevents rust and makes cleaning easier.

Insulated Spanners: For electrical work, prevent shock.

Spanner Size for Nut & Bolt Combinations

Different bolts and nuts are manufactured with standard head sizes. Here are a few common examples:

| Bolt Diameter (Metric) | Spanner Size (mm) |

|---|---|

| M6 | 10 mm |

| M8 | 13 mm |

| M10 | 17 mm |

| M12 | 19 mm |

| M14 | 22 mm |

| M16 | 24 mm |

| M20 | 30 mm |

This table is handy when matching nuts and bolts with the right spanner size.

Spanner Size Mistakes to Avoid

Using adjustable spanners for everything – They’re versatile but may slip and damage nuts.

Confusing metric and imperial – Always double-check with a conversion chart.

Over-tightening – This can strip threads or break bolts.

Not replacing worn tools – A worn-out spanner can cause accidents.

Organizing Spanner Sets

A messy toolbox wastes time. Here is how to keep your spanners in order:

Use rack holders or foam inserts with labeled sizes.

Arrange from smallest to largest for easy access.

Keep metric and imperial sets separate to avoid confusion.

Always wipe spanners after use to prevent rust.

Common Spanner Sizes for Everyday Projects

Understanding which spanner size to use can save time and prevent damage to bolts and tools. Here are some practical guidelines:

Automotive Work – Frequently used sizes include 8 mm, 10 mm, 13 mm, 17 mm, and 19 mm. These cover most car components such as engine parts, suspension, and brake assemblies.

Bicycles and Small Machinery – 8 mm, 9 mm, 10 mm, and 15 mm spanners fit most bolts on bicycles, scooters, and small machines.

Plumbing and Heavy Duty Applications – 22 mm, 24 mm, and 30 mm sizes handle larger nuts on pipes, valves, and industrial equipment.

Home Repairs – 10 mm, 13 mm, and 17 mm are versatile for furniture assembly, fixtures, and general DIY tasks.

Knowing the common spanner sizes for specific applications allows you to choose the right tool quickly and avoid frustration.

Tips for Selecting the Correct Spanner Size

Choosing the proper spanner size is more than just reading a number off the handle. Follow these key points:

Measure Across Flats (AF) – Use a caliper to check the width of the bolt or nut to ensure a perfect fit.

Use Conversion Charts – If working with mixed metric and imperial fasteners, always consult a spanner size chart for equivalent measurements.

Avoid “Almost Fits” Tools – Using a slightly smaller or larger spanner risks rounding bolt heads and damaging hardware.

Invest in a Complete Set – A full metric and imperial spanner set guarantees you always have the right size.

Check Material and Quality – Chrome vanadium steel, drop-forged, or insulated spanners provide durability and safety depending on your project.

By following these tips and keeping a spanner size chart handy, you’ll improve efficiency, protect fasteners, and make every project safer and smoother.

Final Thoughts

A spanner size chart is an indispensable tool for mechanics, DIYers, and professionals alike. Whether you are tightening a bicycle nut, repairing your car, or assembling industrial machinery, the right spanner size ensures safety, precision, and efficiency.

By keeping a chart handy and investing in a well-organized spanner set, you will avoid the frustration of mismatched tools and stripped bolts. Remember: in the world of nuts and bolts, size really does matter.

Here’s our newest post: