When it comes to creating threaded holes for screws and bolts, accuracy is everything. If the hole is too small, the tap might break during threading. If it’s too large, the screw will not hold properly. That is where a tap drill size chart comes in.

A tap drill size chart is a reference table that helps you select the correct drill bit before tapping threads into a hole. It connects the diameter and pitch of a screw or bolt to the drill size required, ensuring that the threads you cut are strong, accurate, and secure.

In this post, we will cover everything you need to know about tap drill size charts: what they are, why they matter, different types, and how to use them. We’ll also provide examples of common tap drill size charts for both metric and imperial systems.

What is a Tap Drill Size Chart?

A tap drill size chart is a guide that matches the size of a screw or bolt with the correct drill size required for tapping threads. Before cutting threads with a tap, you must first drill a hole slightly smaller than the screw’s major diameter.

For example:

If you are cutting threads for a ¼”-20 UNC screw, the chart shows you should use a #7 drill bit (0.201 inches).

For an M6 × 1.0 metric bolt, the chart recommends a 5.0 mm drill bit.

By using the correct size, you ensure that the tap can cut threads properly without breaking and that the screw fits snugly.

Why Do You Need a Tap Drill Size Chart?

Many beginners assume drilling a hole equal to the screw diameter is correct. Unfortunately, this often causes serious problems. A proper tap drill size chart solves this by guiding you to the right drill size for threading.

Here’s why using a tap drill size chart is essential:

Prevents Tap Breakage – Too-small holes put too much pressure on taps.

Ensures Thread Strength – Threads are clean, deep, and hold screws securely.

Improves Accuracy – Helps match the screw’s pitch and diameter perfectly.

Saves Time – Reduces trial and error when drilling holes.

Works Across Materials – Useful in metalworking, woodworking, and plastics.

Key Terms to Understand

Before using a tap drill size chart, it’s important to understand a few terms:

Tap – A tool used to cut threads inside a drilled hole.

Major Diameter – The outside diameter of the screw/bolt.

Minor Diameter – The diameter of the hole after threads are cut.

Thread Pitch – The distance between threads (mm in metric, or threads per inch in imperial).

Percent of Thread – How much of the thread depth is engaged. Usually, 75% engagement is recommended.

A tap drill size chart is based on these relationships.

Types of Tap Drill Size Charts

Tap drill size charts come in several formats depending on the type of fastener and measurement system.

1. Metric Tap Drill Size Chart

Used worldwide.

Screw sizes are given in millimeters (M3, M6, M10, etc.).

Thread pitch can be coarse (standard) or fine.

2. Imperial (UNC/UNF) Tap Drill Size Chart

Common in the United States and Canada.

Screw sizes are in inches with threads per inch (TPI).

UNC = Unified Coarse Thread, UNF = Unified Fine Thread.

3. Pipe Thread Tap Drill Size Chart (NPT)

Used for plumbing and fluid systems.

Requires tapered taps to create leak-proof seals.

4. Specialty Tap Charts

Designed for plastics, soft metals, or thin sheet materials.

Sometimes include recommended drill speeds and feed rates.

How to Use a Tap Drill Size Chart

Using a tap drill size chart is straightforward:

Identify the Screw or Bolt Size

– Example: M8 × 1.25 (metric) or ⅜”-16 UNC (imperial).Check the Chart

– Find the recommended drill size for that screw.Select the Drill Bit

– Use the closest drill size available in your set.Drill the Hole

– Ensure the hole is straight and clean.Tap the Threads

– Use a tap wrench with proper cutting fluid. Turn ½ forward, ¼ back to clear chips.Test the Fit

– Insert the screw/bolt to make sure it threads smoothly.

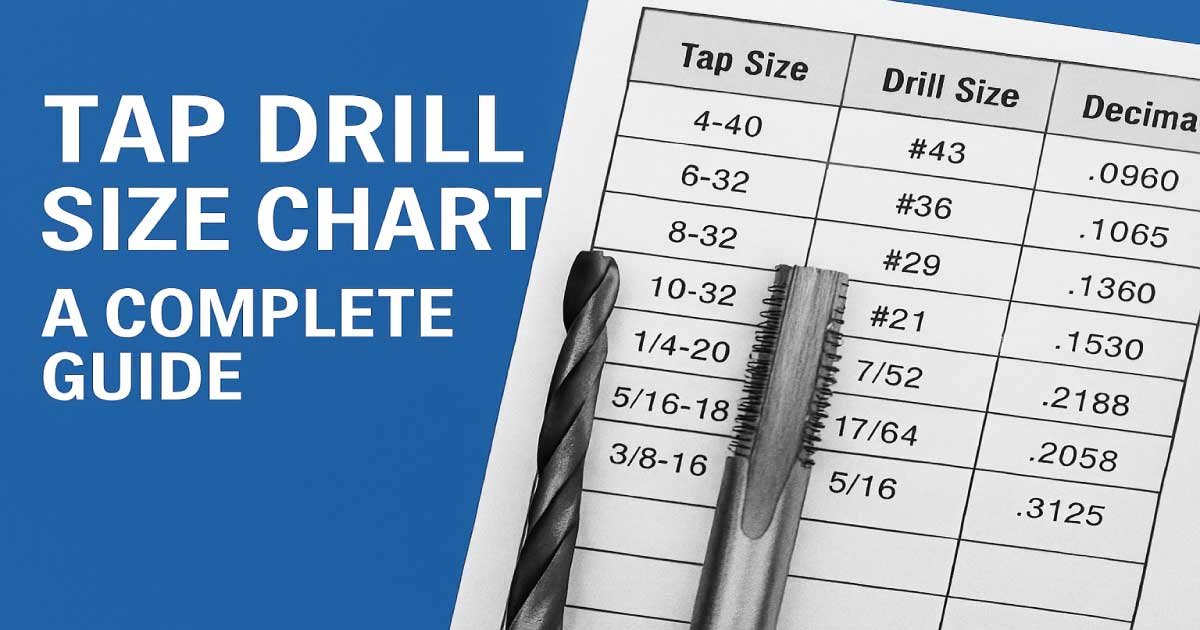

Example Tap Drill Size Chart (Imperial UNC/UNF)

| Screw Size | Threads Per Inch (TPI) | Tap Drill Size | Decimal Equivalent (in) |

|---|---|---|---|

| #4-40 UNC | 40 | #43 | 0.0890 |

| #6-32 UNC | 32 | #36 | 0.1065 |

| #8-32 UNC | 32 | #29 | 0.1360 |

| #10-24 UNC | 24 | #25 | 0.1495 |

| ¼”-20 UNC | 20 | #7 | 0.2010 |

| ¼”-28 UNF | 28 | #3 | 0.2130 |

| 5/16″-18 UNC | 18 | F | 0.2570 |

| 3/8″-16 UNC | 16 | 5/16″ | 0.3125 |

Example Tap Drill Size Chart (Metric)

| Metric Screw Size | Thread Pitch (mm) | Tap Drill Size (mm) |

|---|---|---|

| M3 × 0.5 | 0.50 | 2.5 mm |

| M4 × 0.7 | 0.70 | 3.3 mm |

| M5 × 0.8 | 0.80 | 4.2 mm |

| M6 × 1.0 | 1.00 | 5.0 mm |

| M8 × 1.25 | 1.25 | 6.8 mm |

| M10 × 1.5 | 1.50 | 8.5 mm |

| M12 × 1.75 | 1.75 | 10.2 mm |

| M16 × 2.0 | 2.00 | 14.0 mm |

Advanced Tips for Using a Tap Drill Size Chart

While a tap drill size chart gives the correct drill bit for threading, combining it with practical techniques ensures stronger threads, cleaner holes, and longer tool life.

1. Select the Right Drill Bit Material:

Different materials require specific drill bits:

High-Speed Steel (HSS): Ideal for wood, plastic, and soft metals.

Cobalt Steel: Suitable for hard metals like stainless steel.

Carbide-Tipped Bits: Perfect for masonry or extremely hard materials.

Choosing the right bit preserves both the tool and the workpiece.

2. Use Pilot Holes for Larger Screws:

Even with the correct tap drill size, a smaller pilot hole can guide larger screws, reducing stress on taps and preventing splitting, especially in wood.

3. Mark and Secure Your Workpiece:

Use a pencil or center punch to mark drilling spots. Clamp the material firmly to prevent shifting, which ensures accuracy and safety.

4. Lubricate and Cool When Necessary:

For metals, applying cutting oil or lubricant reduces friction, prevents overheating, and prolongs the life of your tap and drill bit.

5. Maintain Drill Bit Sharpness:

Dull drill bits create rough holes, oversized threads, and increase the risk of tap breakage. Regularly inspect and sharpen or replace bits.

6. Check Thread Engagement:

After tapping, test-fit the screw or bolt. A snug fit confirms correct hole size, pitch, and thread depth, ensuring reliable fastening.

7. Leverage Digital Tools:

Digital apps or calculators can convert between metric, fractional, and numbered sizes, reducing errors when working with mixed fasteners.

By combining a tap drill size chart with these advanced tips, you guarantee precision, reduce material waste, and extend tool life. Whether you’re working on woodworking, metal fabrication, or DIY home projects, following these practices ensures professional-quality threads every time.

Common Mistakes to Avoid

When using a tap drill size chart, avoid these errors:

Skipping the Chart – Guessing drill sizes often causes poor threads.

Using the Wrong Measurement System – Don’t mix metric and imperial.

Tapping Without Lubrication – Increases the risk of broken taps.

Drilling Oversized Holes – Threads won’t hold the screw securely.

Not Backing Out the Tap – Always reverse slightly to clear chips.

Practical Tips for Success

Keep a printed tap drill chart in your workshop for quick reference.

Use digital apps or calculators for mobile convenience.

Start with a center punch to prevent drill wandering.

Use sharp, high-quality drill bits for accurate holes.

For hard materials like stainless steel, use special taps and cutting oils.

Benefits of Using a Tap Drill Size Chart

Precision – Ensures strong, accurate threads.

Durability – Reduces tool wear and prevents broken taps.

Efficiency – Speeds up the drilling and tapping process.

Universal Reference – Works for woodworking, metalworking, plastics, and more.

Professional Results – Clean, secure threads that hold fasteners properly.

Final Thoughts

A tap drill size chart is a simple but powerful tool for anyone who works with screws, bolts, or the threaded holes. It removes the guesswork from drilling, ensures strong threads, and saves both time and materials.

Whether you are working on a DIY home project, machining a metal part, or installing components in an industrial setting, a tap drill size chart is your best guide. Keep one nearby—printed, digital, or laminated—and you’ll never struggle with incorrect thread sizes again.

Next time you need to cut threads, do not guess. Use a tap drill size chart and drill with confidence.

Catch up on our latest article: