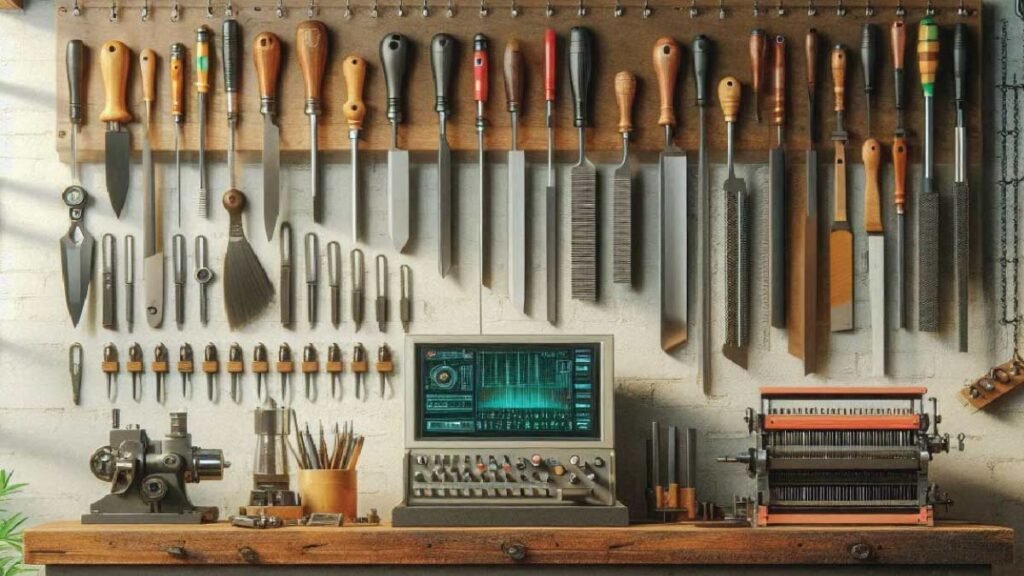

Types of mechanical tools are essential for a wide range of tasks in industries, workshops, and even homes. Whether you are a professional mechanic, an engineer, or a DIY enthusiast, knowing the right tools for the job can make all the difference. In this article, we’ll explore the top 13 types of mechanical tools, detailing their names and uses. We’ll cover different types of mechanical tools, all types of mechanical tools, and provide mechanical tools examples. This guide will help you understand each tool’s purpose, ensuring you can choose the right one for your needs.

What is the Meaning of Mechanical Tools and Mechanical Tools Types

Mechanical tools are devices designed to perform a specific mechanical task, such as cutting, shaping, tightening, or loosening. These tools are essential in various fields, including automotive repair, construction, manufacturing, and home improvement. Understanding mechanical tools involves knowing their purpose and how they function. There are many types of mechanical tools, each tailored for a particular use. From wrenches and screwdrivers to pliers and drills, each tool plays a crucial role in making mechanical tasks easier and more efficient. In this article, we’ll explore the different types of mechanical tools, highlighting their uses and why they are indispensable for any mechanical work.

13 Different Types of Mechanical Tools

If you want to know about the different types of mechanical tools or are curious about what mechanical tools are essential for various tasks, you have come to the right place. Mechanical tools are crucial for a wide range of applications, from simple home repairs to complex industrial tasks. Understanding the right tools for the job can make your work more efficient and effective. In this article, we’ll explore the top 13 types of mechanical tools that are indispensable for every mechanic and DIY enthusiast. Whether you’re tightening bolts, cutting materials, or ensuring your work is level, these tools are essential for any mechanical work. Read on to discover more about each tool’s unique functions and applications.

1. Types of Mechanical Tools with Uses: Wrenches

Types of Wrenches

Adjustable Wrench: Also known as a crescent wrench, the adjustable wrench features a movable jaw, allowing it to fit various sizes of nuts and bolts. This versatility makes it a must-have tool in any toolkit. Whether you’re working on plumbing fixtures or automotive parts, an adjustable wrench can adapt to the job.

Socket Wrench: A socket wrench employs removable sockets that fit different bolt sizes and are usually operated with a ratchet handle. This type of wrench is ideal for tasks that require frequent changes of socket sizes, such as automotive repair. The ratchet mechanism allows for efficient tightening and loosening without needing to remove and reposition the tool.

Allen Wrench: Also known as a hex key, this L-shaped tool is specifically designed for hexagonal screws. Commonly used in furniture assembly and bicycle maintenance, Allen wrenches come in various sizes and are often sold in sets. Their compact design allows for easy storage and accessibility.

Uses of Wrenches

Wrenches are fundamental tools for tightening and loosening nuts and bolts. Their design varies to accommodate different tasks and sizes of fasteners.

Adjustable Wrenches: Versatile and adaptable, adjustable wrenches are useful for various household and mechanical repairs.

Socket Wrenches: They allow for quick and efficient work, particularly in automotive and machinery maintenance, where different bolt heads are encountered.

Allen Wrenches: These are essential for tasks involving hex screws, such as assembling flat-pack furniture or maintaining bicycles.

2. Types of Mechanical Tools with Uses: Screwdrivers

Types of Screwdrivers

Flathead Screwdriver: Designed for screws with a straight, flat groove, the flathead screwdriver is one of the oldest and most widely used types. It’s essential for many general-purpose tasks, from assembling furniture to opening paint cans.

Phillips Screwdriver: Featuring a cross-shaped tip, the Phillips screwdriver is designed for screws with a corresponding groove. This design helps prevent the screwdriver from slipping out of the screw head, providing better torque and efficiency. It’s commonly used in electronics, appliances, and construction.

Torx Screwdriver: Recognizable by its star-shaped tip, the Torx screwdriver is used for Torx screws, which are found in automotive, electronics, and security applications. The design allows for higher torque and reduces the risk of damaging the screw head.

Uses of Screwdrivers

Screwdrivers are essential tools for driving screws into various materials and removing them when necessary.

Flathead Screwdrivers: They are versatile and can be used in a wide range of applications, including prying open objects and adjusting small screws.

Phillips Screwdrivers: Ideal for tasks requiring more torque, these screwdrivers are perfect for assembling and disassembling appliances and electronics.

Torx Screwdrivers: Used in specialized applications, they are ideal for automotive repairs and electronic devices where precision and higher torque are required.

3. Types of Mechanical Tools with Uses: Pliers

Types of Pliers

Needle-Nose Pliers: With their long, slender jaws, needle-nose pliers are perfect for precision work in tight spaces. They are often used in electrical work, jewelry making, and intricate mechanical tasks.

Slip-Joint Pliers: These pliers have adjustable jaw sizes, allowing them to handle a variety of tasks. They are commonly used for bending wires, gripping objects, and holding materials securely in place.

Locking Pliers: Also known as Vise-Grips, locking pliers can lock onto objects, providing a firm and secure grip. They are useful for holding parts together, removing stripped screws, and gripping rounded bolts.

Uses of Pliers

Pliers are versatile tools used for gripping, bending, and cutting wires and other materials.

Needle-Nose Pliers: Ideal for detailed work, such as bending wire in electrical projects or accessing hard-to-reach areas.

Slip-Joint Pliers: Suitable for a wide range of tasks, from household repairs to automotive work, due to their adjustable jaw sizes.

Locking Pliers: Essential for tasks requiring a strong grip, they are perfect for holding objects in place, especially when both hands are needed for other tasks.

4.Types of Mechanical Tools with Uses: Hammers

Types of Hammers

Claw Hammer: Featuring a dual-purpose design with a striking face on one side and a claw for nail removal on the other, the claw hammer is a staple in carpentry and general construction.

Ball-Peen Hammer: Used primarily in metalworking, the ball-peen hammer has a rounded end for shaping metal and a flat end for driving chisels and punches.

Sledgehammer: A heavy-duty tool with a long handle, the sledgehammer is designed for demolition work. Its weight and size make it ideal for breaking apart concrete, driving stakes, and other heavy-duty tasks.

Uses of Hammers

Hammers are essential tools for driving nails, shaping metal, and demolition work.

Claw Hammers: Widely used in carpentry for driving nails and removing them with the claw end.

Ball-Peen Hammers: Common in metal fabrication and automotive repair, they are used for shaping metal and driving chisels.

Sledgehammers: Ideal for demolition tasks, they can break apart concrete, stone, and other tough materials.

Discover how to use a wrench and a torque wrench effectively for precision and durability in your projects. Our comprehensive guide covers everything you need to know about these essential tools. For expert tips and detailed instructions, don’t miss the full post—click through to enhance your tool skills today!

5. Types of Mechanical Tools with Uses: Measuring Tools

Types of Measuring Tools

Tape Measure: A flexible ruler used to measure size or distance. It is a common measuring tool in carpentry and construction. Tape measures come in various lengths, typically ranging from 12 feet to 30 feet, and can be made of fabric, plastic, or metal.

Caliper: A precision instrument used to measure the distance between two opposite sides of an object. Calipers can be digital, dial, or vernier, each offering varying degrees of accuracy. They are extensively used in mechanical engineering, metalworking, and automotive applications.

Level: An instrument designed to indicate whether a surface is horizontal (level) or vertical (plumb). Levels come in various forms, including bubble levels, laser levels, and digital levels. They are essential in construction and carpentry for ensuring accuracy in alignment and balance.

Uses of Measuring Tools

The use of these types of mechanical tools are essential for precision and accuracy in various fields, including construction, engineering, and DIY projects.

Tape Measures: Used to measure lengths, widths, and heights. They are indispensable in ensuring materials are cut to the correct size and pieces fit together properly. For instance, in home improvement projects, a tape measure is used to measure spaces for furniture or appliances.

Calipers: Provide highly accurate measurements of internal and external dimensions, depths, and steps. They are crucial in manufacturing and machining processes where precision is vital. For example, calipers are used to measure the thickness of brake discs in automotive maintenance.

Levels: Ensure that surfaces are perfectly horizontal or vertical, which is crucial in maintaining structural integrity and achieving a professional finish. In construction, a level is used to check the evenness of floors, walls, and ceilings.

6. Types of Mechanical Tools with Uses: Cutting Tools

Types of Cutting Tools

Utility Knife: A versatile cutting tool with a retractable blade, used for cutting various materials such as cardboard, plastic, and leather. Utility knives are essential for tasks like opening boxes, trimming excess materials, and crafting.

Hacksaw: A fine-toothed saw with a blade under tension, used for cutting metal, plastic, and wood. Hacksaws are particularly useful in plumbing, metalworking, and DIY projects that involve cutting through pipes, rods, and other materials.

Chisel: A tool with a sharp cutting edge at the end of a metal blade, used for carving or cutting hard materials such as wood, stone, or metal. Chisels come in different shapes and sizes, each suited for specific tasks such as woodworking, masonry, or sculpting.

Uses of Cutting Tools

The use of these types of mechanical tools are fundamental for shaping and cutting materials in construction, woodworking, metalworking, and crafting.

Utility Knives: Ideal for tasks requiring precision cutting, such as trimming materials to size, crafting, or removing old caulking. Their sharp blades make them perfect for detailed work and intricate cuts.

Hacksaws: Used for cutting through metal pipes, plastic tubing, and wood, making them indispensable in plumbing and metalworking. For example, a hacksaw can cut through a metal rod or trim a piece of PVC pipe to the required length.

Chisels: Used in woodworking and masonry for carving and shaping materials. Wood chisels, for instance, are used to carve joints and intricate designs, while masonry chisels are employed to shape and size stone and bricks.

7. Types of Mechanical Tools with Uses: Clamps

Types of Clamps

C-Clamp: Named for its C-shaped frame, the C-clamp is used to hold a wood or metal workpiece in place. It is adjustable, with a screw mechanism that tightens the clamp securely onto the material. These clamps are commonly used in woodworking, welding, and metalworking.

Bar Clamp: Also known as an F-clamp due to its shape, a bar clamp consists of a long bar with adjustable clamping jaws. It provides a wide clamping surface, making it ideal for larger projects such as cabinetry and furniture assembly.

Spring Clamp: This clamp operates with a spring mechanism, allowing it to be quickly applied and removed. Spring clamps are small and portable, making them useful for light-duty tasks, such as holding fabric or paper in place during crafting.

Uses of Clamps

The use of these types of mechanical tools are vital for holding materials together securely during various tasks, ensuring precision and safety.

C-Clamps: Used to hold workpieces steady during sawing, drilling, or welding. They provide a strong grip, preventing movement and ensuring accuracy. For instance, when welding metal parts, a C-clamp can hold them together firmly until the weld is complete.

Bar Clamps: Ideal for larger projects where a wide clamping surface is needed. They are frequently used in woodworking to hold boards together while glue dries or to assemble large furniture pieces. For example, a bar clamp can keep multiple boards aligned while assembling a tabletop.

Spring Clamps: Perfect for quick, temporary holds on lightweight materials. They are useful in crafting, model building, and other hobbies where a secure but easily adjustable hold is needed. For instance, a spring clamp can hold fabric in place while sewing or gluing.

Explore the various Uses and types of pliers, and their uses in our detailed article, including a special focus on snap ring pliers. Discover which pliers are best suited for your tasks and how snap ring pliers can make your job easier. Dive into the full post for expert insights and practical advice!

8. Types of Mechanical Tools with Uses: Saws

Types of Mechanical Tools: Saws

Hand Saw: The hand saw is a traditional tool that has been used for centuries in woodworking. It consists of a long, flat blade with a series of sharp teeth along one edge, attached to a handle. The hand saw is versatile and can be used to cut wood into various shapes and sizes. It is ideal for carpentry, DIY projects, and situations where precision cutting is required.

Hacksaw: A hacksaw is a fine-toothed saw, typically used for cutting metal and plastic. The blade is usually thin and replaceable, allowing it to cut through harder materials with relative ease. The hacksaw’s frame is adjustable, enabling it to hold different sizes of blades. It is commonly used by plumbers, electricians, and metalworkers.

Circular Saw: A circular saw is a powerful tool equipped with a rotating disc blade. It is designed for making straight cuts in various materials, including wood, metal, plastic, and even masonry. Circular saws are widely used in construction, woodworking, and home improvement projects. They come in different sizes and types, such as sidewinder and worm drive, each suited for specific tasks.

Uses:

The use of these types of mechanical tools is indispensable for cutting materials, making them essential in various trades and DIY projects.

Hand Saws: Hand saws are ideal for basic woodworking tasks such as cutting timber, molding, and creating joints. They are especially useful in situations where a power source is unavailable or when a more delicate touch is needed.

Hacksaws: Hacksaws are perfect for cutting through metal pipes, rods, and plastic materials. They are often used in plumbing to cut pipes to the desired length or in metalworking to trim metal components.

Circular Saws: Circular saws are favored for their speed and precision. They can quickly rip through large sheets of plywood, cut framing lumber to size, and even slice through metal sheets with the appropriate blade. Their versatility makes them a staple in any professional or amateur toolkit.

9. Types of Mechanical Tools with Uses: Drills

Types:

Hand Drill: The hand drill is a manual tool, often used for small tasks that require precision and control. It consists of a handle, a chuck that holds the drill bit, and a gear mechanism that drives the bit when the handle is turned. Hand drills are simple, durable, and do not require a power source, making them useful in remote areas or for delicate jobs.

Electric Drill: Electric drills are the most common type of drill used today. They are powered by electricity, either through a cord or battery, and can be used for drilling holes and driving screws. Electric drills come with various speed settings and can accommodate different drill bits and accessories, making them highly versatile.

Hammer Drill: A hammer drill combines the rotary drilling motion with a hammering action. This dual function makes it especially effective for drilling into tough materials such as concrete, brick, and stone. Hammer drills are commonly used in construction and renovation projects where drilling into hard surfaces is required.

Uses:

The use of these types of mechanical tools are versatile tools that are used across multiple trades and applications.

Hand Drills: Hand drills are suitable for light work, such as drilling small holes in wood or soft materials. They are often used in woodworking, model making, and other crafts where precision is more important than speed.

Electric Drills: Electric drills are the go-to tool for most drilling and screwing tasks. They can be used to drill holes in wood, metal, plastic, and other materials, as well as for driving screws into various surfaces. Their versatility and power make them essential in construction, home improvement, and manufacturing.

Hammer Drills: Hammer drills are indispensable when working with concrete, stone, or brick. The hammering action allows the drill bit to break up the hard material while the rotary motion clears it away, making it possible to create holes in surfaces that would be difficult or impossible with a standard drill.

Discover the 25 types of screwdrivers and their specific uses in our comprehensive guide, and explore the 20 types of hammers to find the perfect tool for every job. Learn the differences and applications of these essential tools. Read the full post to enhance your toolkit with expert recommendations!

10. Types of Mechanical Tools with Uses: Measuring Tools

Types:

Tape Measure: A tape measure is a flexible ruler made from metal, fiberglass, or cloth. It is used for measuring lengths and distances, typically in feet, inches, or centimeters. Tape measures are retractable, making them easy to carry and store. They are widely used in construction, tailoring, and any field where accurate measurements are needed.

Caliper: A caliper is a precision measuring instrument that measures the distance between two opposite sides of an object. It can be used to measure internal and external dimensions, as well as depths. Calipers come in different types, including vernier, dial, and digital, each offering varying degrees of accuracy and ease of use.

Micrometer: A micrometer is a highly precise instrument used for measuring small distances, typically to the nearest thousandth of a millimeter or inch. It consists of a spindle that moves along a calibrated scale and a thimble that turns to adjust the measurement. Micrometers are essential in engineering, machining, and any application where fine tolerances are required.

Uses:

The use of these types of mechanical tools tools are essential in ensuring the accuracy and quality of any project.

Tape Measures: Tape measures are versatile and can be used in a wide range of applications, from measuring the dimensions of a room to sizing fabric for sewing. They are a staple in construction, carpentry, and DIY projects, where precise measurements are crucial.

Calipers: Calipers provide precise measurements of internal and external dimensions, making them invaluable in machining, engineering, and quality control. They are used to measure components, ensuring they meet the required specifications.

Micrometers: Micrometers offer the highest precision among measuring tools, making them essential in industries that require tight tolerances, such as aerospace, automotive, and medical device manufacturing. They are used to measure components, ensuring they are within the required dimensional limits.

11. Types of Mechanical Tools with Uses: Levels

Types:

Spirit Level: A spirit level is a traditional tool used to indicate whether a surface is level. It consists of a sealed tube containing a liquid and a bubble. When the bubble is centered between two lines on the tube, the surface is level. Spirit levels are simple, effective, and come in various sizes, from small pocket levels to large framing levels.

Laser Level: A laser level is a more advanced tool that projects a laser beam to create a level line over a distance. It can be used to align objects, mark out straight lines, and ensure surfaces are level over large areas. Laser levels are commonly used in construction, interior design, and any application where accuracy over distance is required.

Uses:

The use of these types of mechanical tools is essential for ensuring that surfaces are perfectly horizontal or vertical.

Spirit Levels: Spirit levels are widely used in carpentry, masonry, and construction to ensure that walls, floors, and structures are level. They are also used in home improvement projects, such as hanging pictures, installing shelves, and aligning appliances.

Laser Levels: Laser levels offer greater accuracy and convenience, especially over longer distances. They are used in large-scale construction projects to align walls, set foundations, and ensure that everything is perfectly level. They are also used in interior design for tasks such as aligning tiles, wallpaper, and lighting.

12. Types of Mechanical Tools with Uses: Files

Types:

Flat File: A flat file is a straight, flat tool with a rough surface, used for smoothing flat surfaces. It is commonly used in metalworking, woodworking, and other trades where precise shaping and smoothing are required. Flat files come in various sizes and grades of coarseness, making them suitable for different materials and levels of finish.

Round File: A round file, also known as a rat-tail file, is a cylindrical tool used for filing rounded surfaces and creating concave shapes. It is often used in metalworking, jewelry making, and other trades where detailed shaping of curved surfaces is needed.

Half-Round File: A half-round file has a flat side and a curved side, making it a versatile tool for filing both flat and curved surfaces. It is commonly used in metalworking, woodworking, and automotive repair. The half-round file is particularly useful when working on surfaces that require both types of filing, such as when smoothing out welds or shaping intricate curves.

13. Types of Mechanical Tools with Uses: Vises

Types:

Bench Vise: A bench vise is a heavy-duty vise mounted on a workbench, used to hold workpieces securely in place. It consists of two jaws that can be opened and closed by turning a handle. Bench vises are a staple in workshops and are used for a wide range of tasks, including cutting, drilling, filing, and assembling. They provide a stable and secure hold, allowing for precise and safe work.

Pipe Vise: A pipe vise is specifically designed to hold pipes and other cylindrical objects securely. It has a set of V-shaped jaws that grip the pipe firmly, preventing it from slipping or rotating during work. Pipe vises are commonly used by plumbers and pipefitters for cutting, threading, and bending pipes.

Vacuum Vise: A vacuum vise is a portable vise with a suction base that allows it to be temporarily attached to any smooth, flat surface. It is ideal for light-duty tasks where a permanent vise installation is not possible or practical. Vacuum vises are often used in small workshops, garages, and by hobbyists who need a flexible and mobile solution for holding workpieces.

Uses:

The use of these types of mechanical tools are crucial for holding workpieces steady, allowing for precise and safe work.

Bench Vises: Bench vises are used in a variety of tasks, from woodworking to metalworking. They provide a stable platform for cutting, filing, drilling, and assembling components, ensuring that the workpiece stays in place and allowing for accurate work. The strong grip of a bench vise also enhances safety by preventing the workpiece from moving unexpectedly.

Pipe Vises: Pipe vises are essential in plumbing and pipefitting, where pipes need to be held securely for cutting, threading, and assembling. The V-shaped jaws of a pipe vise grip the pipe tightly, allowing for precise work without damaging the material. They are also used in metalworking and fabrication when working with cylindrical objects.

Vacuum Vises: Vacuum vises offer flexibility and convenience, making them ideal for light-duty tasks in various locations. They are commonly used by hobbyists, model makers, and in small workshops where space is limited. The suction base allows the vise to be quickly attached and removed from any smooth surface, providing a temporary yet secure hold for small workpieces.

Conclusion Types Of Mechanical Tools

Understanding the names and uses of these top 13 types of mechanical tools can greatly enhance your efficiency and accuracy in any mechanical or DIY project. Each tool serves a specific purpose and choosing the right one can make your work easier and more effective. Whether you are tightening a bolt, cutting through material, or ensuring your work is level, these tools are indispensable in any toolkit. Invest in quality tools, maintain them well, and they will serve you for years to come.

Explore our detailed guide on 40 different types of pliers and discover how each can simplify your tasks. Plus, dive into 30 types of wrenches to find the right tool for any job. Don’t miss out on this comprehensive article—read the full post to upgrade your toolkit today!

FAQs:

What are the most common types of mechanical tools used in workshops?

The most common mechanical tools used in workshops include wrenches, pliers, screwdrivers, hammers, and torque wrenches. These tools are essential for various tasks such as tightening, gripping, and assembling components.

How do I choose the right type of mechanical tool for a specific job?

To choose the right mechanical tool, consider the task at hand and the specific requirements of the job. For example, use a wrench for tightening or loosening bolts, pliers for gripping and bending, and screwdrivers for fastening screws. Refer to tool specifications and recommendations for optimal results.

What are the different types of wrenches and their uses?

Different types of wrenches include adjustable wrenches, socket wrenches, and combination wrenches. Adjustable wrenches can handle various sizes of nuts and bolts, socket wrenches provide a secure fit for specific fasteners, and combination wrenches offer both open and closed-end options for versatility.

Can you explain the purpose of a torque wrench?

A torque wrench is a precision tool used to apply a specific amount of torque to fasteners such as bolts and nuts. It ensures that the correct tightness is achieved, which is crucial for maintaining the integrity and safety of mechanical assemblies.