In today’s fast-paced world of advanced manufacturing, CNC machine tools have revolutionized how things are made. Whether it’s automotive parts, aerospace components, or intricate metal designs, chances are they were shaped using a CNC machine. But what exactly is a CNC machine tool, and why is it such a game-changer in the industrial world?

Let’s explore this fascinating technology in plain, easy-to-understand language.

Understanding CNC: What Does It Mean?

CNC stands for Computer Numerical Control. It refers to the method used to automate the control of machining tools using a computer. In simple terms, a CNC machine tool is a piece of equipment—like a lathe, mill, router, or grinder—that is operated by a computer rather than by hand.

This technology has replaced many traditional manual machines and has brought precision machining tools to the next level.

👉 Want to become a CNC expert? Read our complete guide: CNC Machining 101: Beginner-to-Expert Guide to explore everything from basic principles to advanced CNC techniques and boost your real-world skills.

How CNC Machines Work

The process begins with a digital design, usually created in CAD (Computer-Aided Design) software. That design is then converted into a machine-readable language (G-code) using CAM (Computer-Aided Manufacturing) software. The G-code contains instructions that tell the machine where to move, how fast to move, and what operations to perform.

This entire flow is part of what we call the CNC machining process.

Here’s how it works step-by-step:

Design the part in CAD software.

Convert it into G-code with CAM software.

Upload the G-code into the CNC machine.

Run the program and let the tool do the cutting, shaping, or drilling.

Components of a CNC Machine

To understand the full picture, it helps to know the CNC machine components that make it work:

Controller: The brain of the machine that interprets the G-code.

Drive system: Moves the tool or part based on instructions.

Feedback system: Checks accuracy and adjusts movements.

Tool turret or spindle: Holds the actual cutting tool.

Worktable or bed: Where the material is fixed during machining.

Each of these parts works together to ensure incredible accuracy and tolerance—often down to thousandths of an inch!

Types of CNC Machine Tools

CNC machine tools come in various types, each tailored for specific manufacturing tasks. The right machine depends on the material being used, the type of design, and the level of precision required. Here’s a deeper look at the most common types:

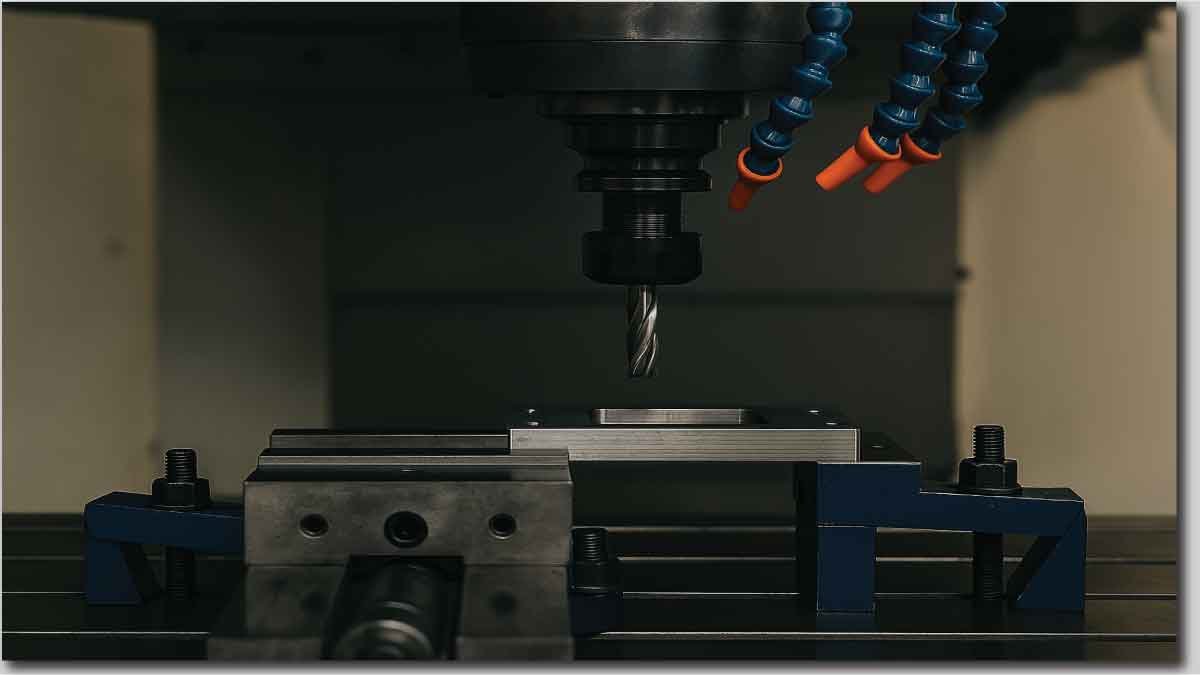

1. CNC Milling Machines

CNC milling machines are some of the most versatile tools in modern manufacturing. They use rotating multi-point cutting tools to remove material from a stationary workpiece. These machines are excellent for producing complex shapes, slots, and flat surfaces. Milling is widely used in the production of metal parts, molds, and components requiring detailed contours.

2. CNC Lathes

CNC lathes perform turning operations by spinning the workpiece while a stationary cutting tool removes material. This method is ideal for creating cylindrical or symmetrical shapes such as shafts, bushings, or bolts. Lathes offer high precision and are commonly used in automotive, aerospace, and industrial machinery sectors.

3. CNC Routers

Primarily used for softer materials like wood, plastic, and foam, CNC routers are great for carving, engraving, cutting, and shaping. They’re often used in woodworking, furniture making, and sign production due to their speed and flexibility.

4. CNC Plasma Cutters

These machines use a high-temperature plasma torch to cut through conductive materials such as steel, stainless steel, and aluminum. They’re perfect for cutting intricate designs in metal quickly and cleanly.

5. CNC Grinders

CNC grinders provide smooth finishes and exact dimensions, making them ideal for polishing or refining metal surfaces. They’re essential in applications where tight tolerances and surface quality are critical.

Each of these tools plays a unique role in the CNC ecosystem, helping manufacturers achieve efficiency, consistency, and high-quality results.

CNC Milling vs CNC Turning: What’s the Difference?

A lot of people confuse CNC milling vs CNC turning, but they are quite different.

CNC Milling: The cutting tool rotates while the workpiece stays still.

CNC Turning: The workpiece rotates while the cutting tool stays in position.

Both are used widely in manufacturing, but turning is best for round parts, while milling can handle more complex 3D shapes.

CNC Machine Programming: Behind the Scenes

No CNC machine can function without proper programming. This is where CNC machine programming comes in. Skilled operators or engineers write code (often G-code) that tells the machine exactly what to do.

Think of it like telling a robot exactly where to move, how fast, and what to do once it gets there.

With advancements in technology, modern systems now use intuitive CAM software to generate CNC toolpaths automatically—removing much of the manual coding.

Manual vs CNC Machines

Before CNC, all machining was done manually by skilled workers. Comparing manual vs CNC machines, the differences are clear:

| Feature | Manual Machine | CNC Machine |

|---|---|---|

| Accuracy | Depends on operator skill | Extremely high precision |

| Speed | Slower | Much faster |

| Consistency | May vary per piece | Perfectly repeatable results |

| Labor Required | High | Minimal once programmed |

| Complexity | Limited | Can handle very complex parts |

Simply put, CNC machines offer efficiency, repeatability, and precision machining tools like never before.

Applications of CNC Machines

CNC machines are incredibly versatile and play a crucial role in a wide range of industries. Their ability to deliver high-precision, repeatable results makes them a go-to choice for both mass production and custom manufacturing. Here’s how different industries rely on CNC technology:

Aerospace

In the aerospace industry, even the smallest error can have serious consequences. CNC machines are used to craft precision components like turbine blades, aircraft frames, and structural parts. The high tolerances and consistency offered by CNC ensure flight safety and performance.

Automotive

From engine blocks and gearboxes to brake components and custom frames, CNC machines are essential in automotive manufacturing. Their speed and accuracy help streamline production while maintaining strict quality standards.

Medical

In the medical field, CNC machining is used to produce surgical instruments, orthopedic implants, dental devices, and prosthetic limbs. The precision and cleanliness of the process make it ideal for sensitive applications where human health is at stake.

Electronics

Tiny components like circuit boards, connectors, and metal housings are often created using CNC machines. With the miniaturization of electronics, CNC’s accuracy becomes even more valuable.

Construction

CNC routers and mills are used to cut custom wood, metal, or plastic components for architectural features, furniture, or building supports. This allows builders to achieve unique, complex designs with minimal manual labor.

Jewelry

CNC machines enable jewelers to engrave intricate patterns, shape delicate pieces, and create detailed molds—speeding up production while maintaining handcrafted quality.

In short, CNC machines empower nearly every industry where precision, efficiency, and innovation are key.

Benefits of CNC Machining

CNC machining offers a wide array of benefits that set it apart from traditional manual machining. These advantages have made it a cornerstone of modern manufacturing, allowing companies to produce parts faster, more accurately, and with far greater consistency.

High Accuracy and Tight Tolerances

One of the most significant advantages of CNC machining is its precision. CNC machines can achieve tolerances as tight as a few microns, which is essential in high-stakes industries like aerospace, defense, and medical device manufacturing. Whether it’s a turbine blade or a surgical implant, exact specifications can be met with ease.

Faster Production and 24/7 Operation

CNC machines are capable of running continuously, around the clock, with minimal human intervention. Once a program is set and the machine is calibrated, it can keep producing parts nonstop. This results in much faster turnaround times compared to manual processes.

Consistency Across Every Part

Since the operations are controlled by pre-programmed computer instructions, every part produced is virtually identical. This consistency is critical in mass production, where quality control and uniformity matter most.

Reduced Waste and Lower Error Rates

CNC machining significantly reduces human error, leading to less material waste. Because the machines follow exact paths and instructions, mistakes due to fatigue or misjudgment are nearly eliminated, saving both time and money.

Capability for Complex Designs

CNC machines can handle intricate shapes, fine details, and multi-axis movements that would be extremely difficult—or even impossible—to achieve by hand. This opens up creative and engineering possibilities that weren’t feasible before.

In essence, CNC machining combines precision, efficiency, and innovation in one powerful package.

CNC Toolpath Generation: The Key to Smooth Operation

A CNC toolpath is the route the tool takes during the cutting process. Good CNC toolpath generation ensures smooth operations, minimal tool wear, and efficient machining time.

Advanced software like Mastercam, Fusion 360, and SolidCAM helps in generating optimal paths that reduce unnecessary movements and speed up production.

CAD/CAM in CNC Machining

You’ve probably heard of CAD/CAM in CNC machining—but what does it really mean?

CAD (Computer-Aided Design): Used to create 2D or 3D models.

CAM (Computer-Aided Manufacturing): Converts those models into machine-readable code.

This combo allows manufacturers to go from idea to prototype to production with remarkable speed and precision.

CNC Machine Accuracy and Tolerance

One of the reasons why CNC tools are trusted in critical industries is their exceptional accuracy and tolerance. Many machines can achieve tolerances of ±0.001 inches or better, which is crucial when making parts that must fit together perfectly.

Even minor variations can cause massive problems in engines, aircraft, or medical devices—so this level of accuracy matters.

The Future of CNC Technology

CNC machines are evolving rapidly. The future of CNC technology includes AI-powered toolpaths, smarter automation, and even 3D printing integrations. Some systems now include sensors to predict maintenance needs before a machine fails.

There’s also a growing push toward eco-friendly CNC machining by reducing waste, recycling materials, and optimizing energy usage.

With Industry 4.0 and IoT (Internet of Things), CNC tools are becoming smarter, more connected, and more efficient than ever before.

Final Thoughts

So, what is a CNC machine tool?

It’s a powerful, computer-controlled machine that has changed the face of manufacturing. From precision machining tools to CNC toolpath generation, this technology is at the heart of nearly every modern product you can think of.

Whether you’re a student, a hobbyist, or someone exploring a new career in the mechanical field, understanding CNC machines is essential in today’s world.

And as we look ahead, the future of CNC technology only gets more exciting, more powerful, and more important.

👉 Want to Learn More?

If you are interested in diving deeper, stay tuned to [Mech Forged] for more guides, tutorials, and insights into the world of CNC, manufacturing, and machining tools.

FAQs:

What does CNC stand for in machining?

CNC stands for Computer Numerical Control. It refers to automated machine tools controlled by a computer that follows pre-programmed code. CNC technology allows for precise and repeatable manufacturing of parts, reducing human error and increasing efficiency across various industries like aerospace, automotive, and medical equipment.

How does a CNC machine work?

A CNC machine works by reading coded instructions (G-code) from a computer program to control the movement of tools and machinery. The system automates cutting, shaping, drilling, and milling processes with extreme accuracy. Operators design parts using CAD software, which is then converted into machine-readable code for production.

What are the main types of CNC machines?

Common types of CNC machines include CNC milling machines, CNC lathes, CNC routers, CNC plasma cutters, and CNC grinders. Each machine serves a specific purpose depending on the material and complexity of the part, ranging from detailed wood carvings to precision metal components.

What industries use CNC machining?

CNC machining is widely used in aerospace, automotive, electronics, medical, construction, and even jewelry industries. It provides the high precision and consistency required for manufacturing parts such as aircraft components, engine blocks, circuit boards, implants, and more.

Is CNC machining better than manual machining?

Yes, CNC machining is generally better for precision, speed, and repeatability. While manual machining allows for more hands-on customization, CNC machines can run 24/7, produce identical parts consistently, and handle more complex geometries with minimal human intervention.