If you work in metal fabrication or have ever explored the world of precision cutting, chances are you’ve heard the term “CNC plasma table.” But what exactly is a CNC plasma table, and why is it a game-changer in the manufacturing industry?

In this comprehensive guide, we’ll break down everything you need to know about CNC plasma tables—from how they work to their advantages, common applications, software requirements, and more. Whether you’re a beginner or a seasoned fabricator, this article will help you understand the value and functionality of this powerful tool.

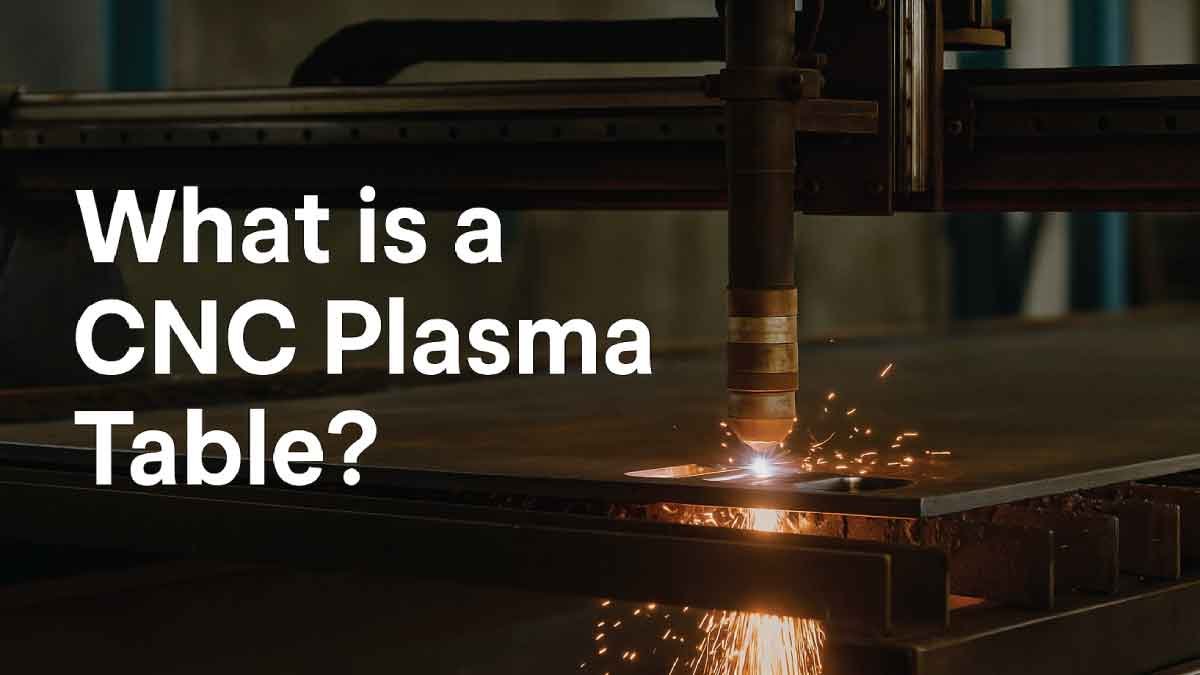

What is a CNC Plasma Table?

A CNC plasma table is a type of automated cutting machine that uses a plasma torch to cut through electrically conductive materials such as steel, aluminum, brass, and copper. The acronym “CNC” stands for Computer Numerical Control, meaning the machine is controlled by a computer that interprets a digital design to guide the plasma cutter along the desired cutting path.

Unlike traditional cutting tools, a CNC plasma cutter offers the ability to make intricate cuts with precision and consistency. The process is largely hands-off once the design has been programmed, which means it minimizes human error and increases productivity. These tables come in a range of sizes and configurations, from compact desktop models for small workshops to large industrial systems for heavy-duty production.

How Does a CNC Plasma Table Work?

The CNC plasma cutting process involves directing a jet of hot plasma (ionized gas) at high speed onto the metal surface. The plasma torch creates an electric arc between an electrode and the workpiece, heating the gas to extreme temperatures and melting the metal. The high-velocity gas blows the molten metal away, creating a clean, precise cut.

The movement of the plasma cutter is controlled by the CNC system, which follows a set of programmed instructions. These instructions are usually generated using computer-aided design (CAD) and computer-aided manufacturing (CAM) software. The system interprets these instructions (known as G-code) and converts them into precise motor movements.

Some advanced models also include features like height control systems, which maintain the correct distance between the torch and the material surface, ensuring optimal cutting quality throughout the operation.

👉 “Please check out our detailed guide on:

Key Components of a CNC Plasma Table

Understanding the parts of a CNC plasma table helps you grasp how the machine operates and where you might need to focus your maintenance or upgrade efforts.

Plasma Torch: This is the business end of the cutter, producing the plasma arc used to cut the metal. It typically uses compressed air or inert gases like nitrogen.

CNC Controller: The controller is the brain of the system. It processes the G-code instructions and directs the motors and torch accordingly.

Cutting Table: This is where the workpiece is placed. Tables may include water beds or downdraft systems to manage sparks and fumes.

Gantry System: Supports and moves the plasma torch across the X, Y, and Z axes, enabling it to reach different areas of the workpiece.

Drive Motors: These electric motors, usually stepper or servo types, move the gantry and torch with high precision.

Power Supply: Supplies the electricity needed to generate the plasma arc.

CNC Plasma Cutting Software

Software is an integral part of operating a CNC plasma table. You’ll need two main types of software:

CAD Software: Used to design parts and drawings. These digital blueprints are the starting point for every project.

CAM Software: Converts CAD drawings into G-code, the language understood by CNC machines. CAM software can also optimize cutting paths and provide nesting capabilities.

Popular CAD/CAM software options include:

- AutoCAD

- Fusion 360

- SolidWorks

- SheetCAM

- Inkscape (for simpler designs)

Many of these platforms offer cloud integration and libraries of templates, which are particularly useful for beginners. With intuitive interfaces and robust features, modern CNC plasma cutting software has become more accessible to hobbyists and professionals alike.

👉 “Please check out our detailed guide on:

Advantages of CNC Plasma Cutting

There are numerous reasons why CNC plasma cutting is preferred in many industries:

High Precision: Offers accurate, repeatable cuts with tolerances within a fraction of a millimeter.

Speed: Plasma cutters operate much faster than oxy-fuel and manual cutting methods.

Versatility: Can cut various electrically conductive metals, including mild steel, stainless steel, and aluminum.

Automation: Reduces the need for manual labor and decreases the risk of human error.

Cost-Effective: Reduces material waste and allows for optimal use of raw sheets through nesting algorithms.

Ease of Use: Modern systems are increasingly user-friendly and require minimal training.

Low Maintenance: With proper care, these machines have fewer moving parts and last longer than traditional equipment.

These advantages make a CNC plasma cutter ideal for both small shops and large-scale industrial operations.

CNC Plasma Table vs Laser Cutter

A common question is how CNC plasma tables compare to laser cutters. While both offer automated, precise cutting, each has its strengths:

Material Thickness: Plasma cutters handle thicker materials better, often cutting steel up to 2 inches thick or more.

Speed: Plasma is typically faster for thicker metals due to its high energy output.

Cost: Plasma tables are generally more affordable than laser systems, both in terms of initial investment and maintenance.

Precision: Lasers offer higher precision and cleaner edges, especially for thin metals and intricate designs.

Operating Costs: Plasma tables usually have lower consumable and operational costs.

Choosing between the two often depends on your specific needs and budget. If your focus is on cutting thick, conductive metals quickly and economically, a CNC plasma table is the better option.

👉 “Please check out our detailed guide on:

CNC Plasma Table for Metal Fabrication

Metal fabrication shops benefit immensely from CNC plasma cutting machines. These tables are used to create parts for a wide range of industries including automotive, aerospace, agriculture, and construction.

Applications include:

- Cutting structural beams and plates

- Fabricating custom machine parts

- Producing decorative elements and signs

- Creating HVAC ductwork and fittings

The ability to automate the cutting process improves efficiency, reduces error rates, and allows for higher production volumes. For fabricators, investing in a CNC plasma table can be a critical step in scaling operations and improving profitability.

Best CNC Plasma Table for Beginners

If you’re just starting out, choosing the best CNC plasma table for beginners is crucial. Consider the following features:

User-friendly software: Look for software with an intuitive interface.

Compact design: Suitable for garage or small-shop use.

Safety features: Emergency stop buttons, grounding systems, and shielding.

Good customer support: Essential for troubleshooting and learning.

Brands like Langmuir Systems, STV CNC, and CrossFire offer excellent entry-level models that are affordable, reliable, and easy to set up. These systems are ideal for learning the basics of CNC plasma cutting without a huge upfront investment.

👉 “Please check out our detailed guide on:

DIY CNC Plasma Table: Is It Worth It?

For hobbyists and tinkerers, building a DIY CNC plasma table can be a rewarding and cost-saving project. You can buy kits that include essential components or source parts individually.

Pros:

- Full customization

- Lower initial cost

- Opportunity to learn CNC technology

Cons:

- Time-consuming to assemble

- Requires technical knowledge

- Less support and reliability

A DIY CNC plasma table is ideal for makers who enjoy engineering and want to tailor their machine to specific needs. Just be sure to plan thoroughly and understand the electrical and mechanical requirements before you start.

Industrial CNC Plasma Table: For Heavy-Duty Jobs

Industrial-grade CNC plasma tables are designed for high-volume production and heavy-duty materials. These machines often include features like:

- High amperage plasma torches (up to 400 amps or more)

- Water or downdraft cutting tables to manage smoke and debris

- Automated material loading and unloading systems

- Multi-torch capabilities for parallel processing

- Advanced motion control systems for ultra-precise movement

Such systems are commonly used in industries like shipbuilding, infrastructure, heavy machinery, and automotive manufacturing. The investment in an industrial CNC plasma table can pay off quickly by increasing throughput and reducing labor costs.

👉 “Please check out our detailed guide on:

CNC Plasma Table Applications

The applications of CNC plasma tables are diverse and continue to grow:

- Custom metal art and signage

- HVAC ductwork and fittings

- Agricultural equipment and repair parts

- Structural steel components

- Automotive brackets and body parts

- Machine frames and guards

- Ornamental gates and fencing

The versatility of CNC plasma cutting opens doors to new business opportunities and creative projects. Whether you’re crafting a decorative wall piece or building components for a tractor, the machine delivers precision and repeatability.

CNC Plasma Table Setup and Maintenance

Proper setup and maintenance ensure your machine performs optimally and lasts for years. Here are key steps:

Setup:

- Place the machine on a level, vibration-free surface.

- Ensure adequate ventilation and dust control.

- Connect to a reliable power source and air compressor.

- Install and configure the software.

- Calibrate motors and run test patterns.

Maintenance:

- Clean the cutting bed and gantry after each use.

- Replace torch consumables regularly.

- Inspect cables and connections for wear.

- Lubricate bearings and linear rails.

- Update software and firmware as needed.

Scheduled maintenance minimizes downtime, reduces wear and tear, and ensures optimal performance.

👉 “Please check out our detailed guide on:

Plasma Table Cutting Speed: What to Expect

Cutting speed depends on several factors including material type, thickness, torch amperage, and feed rate. For instance:

- Thin sheet metal (16-gauge steel) may be cut at over 200 IPM (inches per minute).

- 1/4-inch mild steel typically cuts around 50-80 IPM.

- Thicker steel (1/2 inch or more) may slow to 20-30 IPM.

Cutting speed also affects edge quality and consumable life. By adjusting speed, amperage, and air pressure, you can optimize for speed or quality depending on the project.

Final Thoughts

A CNC plasma table is a powerful tool that brings precision, speed, and automation to metal cutting tasks. Whether you’re a hobbyist considering a DIY CNC plasma table or a business owner investing in an industrial CNC plasma table, understanding the core components, advantages, and applications is crucial.

From improving cutting accuracy to increasing production efficiency, the benefits of using a CNC plasma cutter are hard to ignore. Add in modern CNC plasma cutting software and proper maintenance, and you have a machine that can transform your workflow.

As the demand for custom fabrication and rapid prototyping grows, CNC plasma tables continue to evolve with smarter software, better components, and more accessible pricing. Now that you know what a CNC plasma table is and what it can do, you’re better equipped to make an informed decision and take your fabrication projects to the next level.

FAQs:

What materials can a CNC plasma table cut?

A CNC plasma table can cut electrically conductive metals like mild steel, stainless steel, aluminum, brass, and copper. It’s ideal for varying thicknesses and shapes, making it popular in fabrication shops and industrial settings. Non-metallic materials like wood or plastic cannot be cut using plasma technology due to its reliance on electrical conductivity.

Is a CNC plasma table hard to use for beginners?

Not at all. Many modern CNC plasma tables are beginner-friendly, offering intuitive software and guided setups. With basic computer skills and a little practice, most people can start cutting in a day or two. Online tutorials, customer support, and templates also make it easier for newcomers to learn and create accurate metal cuts.

How much does a CNC plasma table cost?

Prices range widely depending on size and features. Entry-level hobby models start around $2,000–$5,000, while industrial-grade CNC plasma tables can exceed $50,000. Costs also depend on software, power supply, and support options. For most small businesses or workshops, a solid mid-range machine costs between $8,000 and $15,000.

What’s the difference between a plasma table and a laser cutter?

Plasma tables cut thicker metals faster and cost less upfront than laser cutters. However, lasers offer cleaner, more precise cuts on thinner materials and are better for detailed engraving. Plasma is great for heavy-duty work; lasers are ideal for fine, intricate tasks. Choosing one depends on your specific material and accuracy needs.

Do CNC plasma tables need a special power supply?

Yes, most CNC plasma tables require a dedicated power supply to run the plasma torch—commonly 220V or 3-phase power for industrial use. Hobbyist models may run on standard 110V. Always check the manufacturer’s specs and ensure your workspace has the appropriate electrical setup to handle the machine safely and efficiently.