When working with electrical projects, one of the most critical things to understand is wire size. Using the wrong wire gauge can lead to overheating, electrical failure, or even fire hazards. That’s why electricians, engineers, mechanics, and DIY enthusiasts rely on a wire gauge size chart. This chart helps identify the correct wire thickness (gauge) needed for safe current handling, proper efficiency, and reliable performance.

In this guide, we’ll break down everything you need to know about wire gauge sizes, including what they mean, how to read the chart, and where different gauges are commonly used. By the end, you will not only understand the numbers but also feel confident choosing the right wire for your project.

What is Wire Gauge?

The term wire gauge refers to the thickness or diameter of a wire. It’s usually measured in American Wire Gauge (AWG) in the United States, while other systems like SWG (Standard Wire Gauge) or metric millimeters are used in different regions.

The most widely used system is AWG, which uses a numbering method where the larger the gauge number, the thinner the wire. For example:

10 AWG wire is thicker than 20 AWG wire.

4 AWG wire is thicker than 12 AWG wire.

This might feel counterintuitive at first, but once you get used to it, reading wire sizes becomes second nature.

Why Wire Gauge Matters

Choosing the right wire size is more than just a technical detail — it directly impacts safety and performance. Here’s why it matters:

Electrical Safety

Wires that are too thin for the current load can overheat, melt insulation, and cause electrical fires.Efficiency

Thicker wires reduce resistance, which means less energy loss and better efficiency, especially for long-distance runs.Device Protection

Using the wrong gauge can damage appliances, motors, or sensitive electronics due to incorrect voltage supply.Regulatory Standards

Electrical codes require specific wire sizes for different applications (house wiring, automotive, industrial use, etc.), so following the chart ensures compliance.

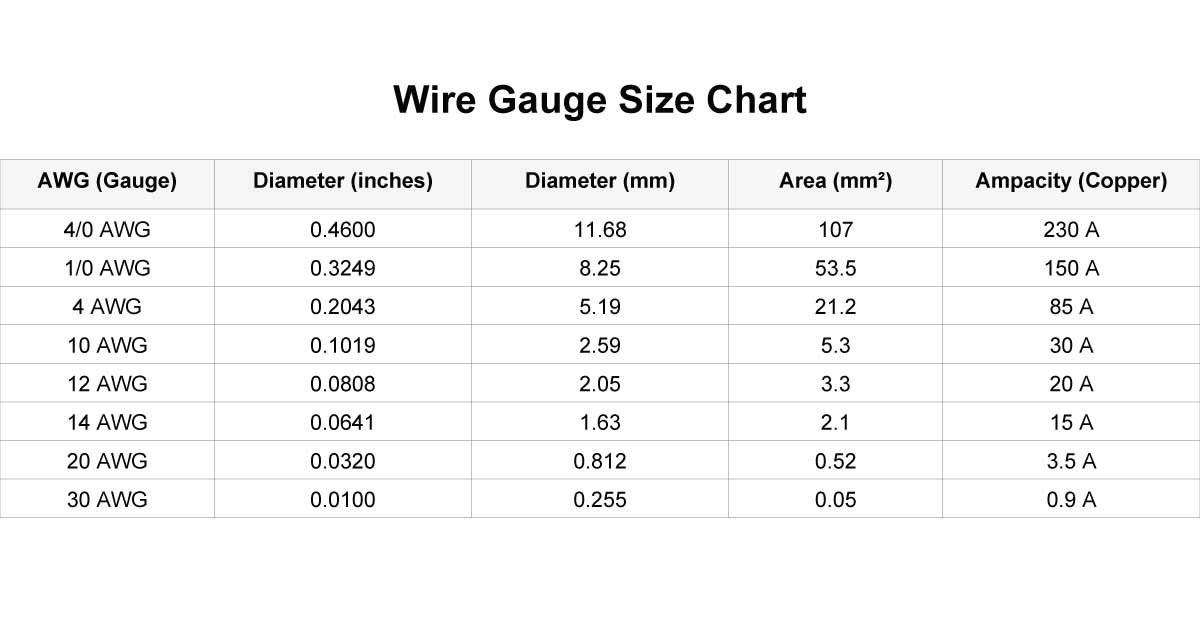

Understanding the Wire Gauge Size Chart

The Wire Gauge Size Chart is a handy reference that shows the relationship between the gauge number, wire diameter, cross-sectional area, and current capacity (ampacity). Let’s look at the basics:

| AWG (Gauge) | Diameter (inches) | Diameter (mm) | Area (mm²) | Ampacity (Copper) |

|---|---|---|---|---|

| 4/0 AWG | 0.4600 in | 11.68 mm | 107 mm² | 230 A |

| 1/0 AWG | 0.3249 in | 8.25 mm | 53.5 mm² | 150 A |

| 4 AWG | 0.2043 in | 5.19 mm | 21.2 mm² | 85 A |

| 10 AWG | 0.1019 in | 2.59 mm | 5.3 mm² | 30 A |

| 12 AWG | 0.0808 in | 2.05 mm | 3.3 mm² | 20 A |

| 14 AWG | 0.0641 in | 1.63 mm | 2.1 mm² | 15 A |

| 20 AWG | 0.0320 in | 0.812 mm | 0.52 mm² | 3.5 A |

| 30 AWG | 0.0100 in | 0.255 mm | 0.05 mm² | 0.9 A |

Note: Ampacity depends on material (copper vs aluminum), insulation, and installation conditions.

How to Use the Chart

Let’s walk through a practical example:

Suppose you need to wire a 20-amp kitchen circuit.

Looking at the chart, you’ll see 12 AWG copper wire safely handles 20 amps.

If you mistakenly use 14 AWG wire (rated for 15 amps), the wire could overheat under full load.

For high-power applications like electric ovens, water heaters, or subpanels, you’ll need thicker wires (8 AWG, 6 AWG, or even larger). For low-power uses like LED lighting or electronics, thinner wires (18 AWG or 20 AWG) are sufficient.

Common Applications of Wire Gauge Sizes

Different gauges are used in specific applications depending on current requirements. Here are some common examples:

14 AWG – Standard lighting circuits, outlets in residential wiring (15A).

12 AWG – Kitchen, bathroom, and outdoor outlets (20A).

10 AWG – Water heaters, clothes dryers, or A/C units (30A).

8 AWG – Electric stoves and large appliances (40–50A).

6 AWG and thicker – Subpanels, large equipment, and heavy-duty circuits.

18–20 AWG – Low-voltage applications like doorbells, thermostats, or speaker wires.

24–30 AWG – Electronics, signal wires, and delicate devices.

Copper vs. Aluminum Wire in the Chart

The chart is typically based on copper wire, which has excellent conductivity. However, aluminum wire is also used in some cases, especially for large service cables due to lower cost.

Copper wires: Smaller in size for the same ampacity, more durable, better for household wiring.

Aluminum wires: Larger diameter for the same current, lighter, and less expensive, but more prone to oxidation.

When reading the chart, always check if it specifies copper or aluminum wire.

Wire Gauge and Voltage Drop

For long wire runs, voltage drop becomes an issue. Even if a wire can handle the current, too much resistance over distance can reduce voltage at the device end.

For example:

Running a 12 AWG wire for 100 feet on a 20-amp circuit may result in noticeable voltage drop.

In that case, upgrading to 10 AWG wire ensures efficiency and protects equipment.

Most electricians aim for less than 3% voltage drop in circuits.

How to Measure Wire Gauge

Sometimes you come across an unknown wire without labeling. Here’s how to identify its gauge:

Use a Wire Gauge Tool – These tools have slots that match wire diameters.

Measure Diameter – Use calipers or a micrometer, then compare to the chart.

Check Insulation Markings – Many wires are labeled with gauge and type (e.g., 12 AWG THHN).

Tips for Choosing the Right Wire

Always check your local electrical code.

Choose a wire that can handle 20–30% more current than your expected load for safety.

For high-heat environments, use special insulation-rated wires.

Don’t undersize wires just to save cost—safety always comes first.

International Wire Gauge Standards

While the American Wire Gauge (AWG) system is widely used in the United States, other parts of the world rely on different standards. For example:

SWG (Standard Wire Gauge): Commonly used in the UK and older systems.

Metric Wire Sizes: Many countries simply specify wire diameter in millimeters (e.g., 2.5 mm² wire).

IEC Standards: Internationally, the IEC defines cross-sectional areas for cables rather than gauge numbers.

If you’re reading international charts or product descriptions, keep in mind that AWG 12 wire (2.05 mm diameter) is roughly equal to 2.5 mm² wire in the metric system. Being able to convert between standards is especially useful if you’re buying wires online or working on global projects.

Common Mistakes When Choosing Wire Gauge

Even with a chart, people sometimes make costly mistakes when selecting wires. Here are a few to avoid:

Ignoring Distance: Many DIYers size the wire only for current but forget that long runs increase resistance. Always factor in voltage drop.

Using Aluminum Wire Without Adjustment: If you swap copper for aluminum, you need to move up at least two sizes. For example, replace 4 AWG copper with 2 AWG aluminum.

Overfusing: Installing a fuse or breaker that’s too large for the wire gauge can cause overheating without tripping the breaker.

Not Checking Insulation Type: A 12 AWG wire rated for 20 amps in standard insulation might handle more in special high-heat insulation, but you can’t assume. Always read the label.

Real-World Example

Imagine you are installing a 40-amp electric range. Looking at the chart, you’ll see that 8 AWG copper wire is typically rated for 40 amps. But if the range is located 70 feet away from the breaker panel, the voltage drop could be an issue. To be safe, you might choose 6 AWG copper instead.

This small adjustment prevents performance issues and avoids long-term damage to the appliance. That’s how the chart, combined with real-world conditions, helps you make better decisions.

Final Thoughts

The wire gauge size chart is more than just numbers—it’s a crucial guide that ensures electrical safety, efficiency, and reliability. Whether you’re wiring a home, repairing a car, or setting up electronics, knowing which gauge to use can prevent dangerous mistakes and save money in the long run.

Always remember: smaller gauge numbers mean thicker wires, and the correct size depends on the current load, distance, and application. With the chart in hand and the right knowledge, you’ll be well-prepared to choose wires confidently for any project.

Read our newest article here: