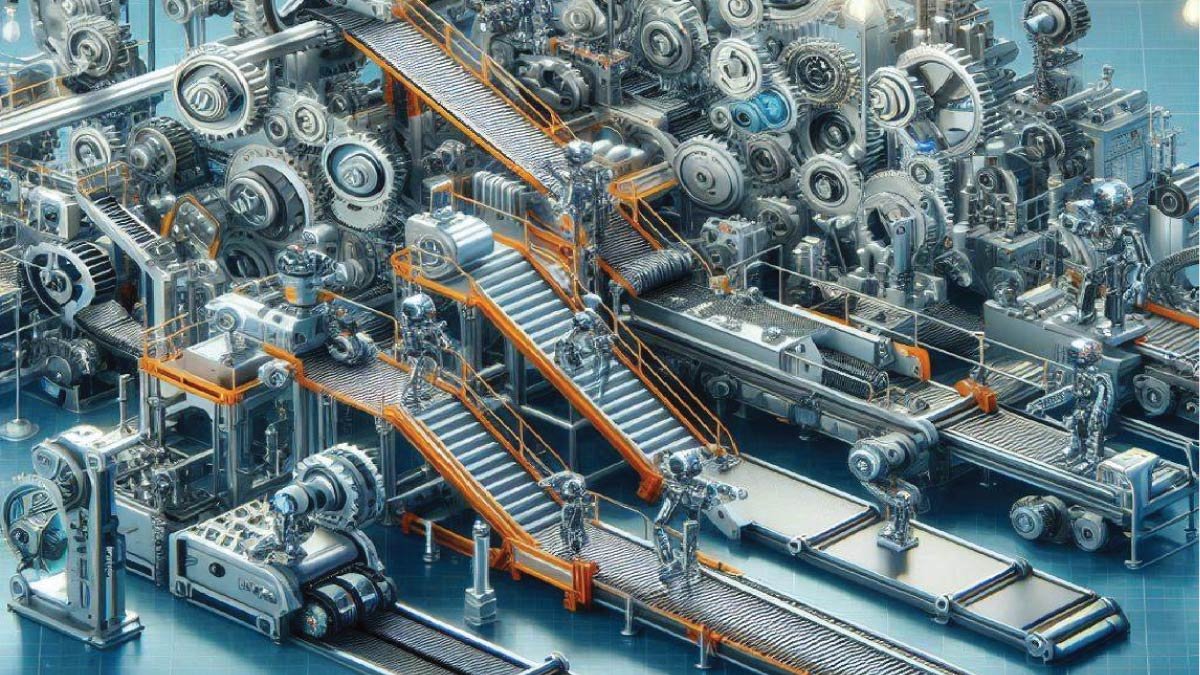

In the realm of engineering, understanding and managing mechanical processes is pivotal for achieving optimal performance and efficiency. From Mechanical Process Design and Mechanical Process Optimization to Mechanical Process Control and Mechanical Process Management, each aspect plays a critical role in refining systems and processes. This guide delves into various facets of mechanical processes, offering insights into how design, simulation, and automation contribute to improved performance and reliability. Whether you are an engineer, a process manager, or simply interested in mechanical systems, this comprehensive overview will equip you with the knowledge to enhance your mechanical processes effectively.

Mechanical Process Design

Mechanical Process Design involves creating and optimizing mechanical systems and processes to achieve desired performance and efficiency. This process encompasses various stages, including conceptual design, detailed design, and validation. In Mechanical system process design, engineers analyze the requirements of a system, develop models, and simulate performance to ensure that the design meets all specifications.

This involves selecting appropriate materials, components, and technologies that will operate efficiently under specified conditions. Advanced tools and software are often used to predict the behavior of mechanical systems and optimize their performance.

Effective mechanical system process design is crucial for developing reliable and cost-effective machinery, equipment, and systems in industries such as manufacturing, aerospace, and automotive.

Mechanical Process Optimization

Mechanical Process Optimization refers to the process of improving mechanical systems to enhance their performance, efficiency, and reliability. This involves analyzing existing processes, identifying bottlenecks or inefficiencies, and implementing changes to address these issues. Optimization techniques can include adjustments to process parameters, redesigning components, or incorporating advanced technologies.

For example, in manufacturing, optimizing a Mechanical system process might involve improving the efficiency of a production line or reducing waste. Mechanical system process optimization aims to achieve better outcomes such as increased productivity, reduced operational costs, and extended equipment lifespan.

Engineers use various analytical tools and methodologies, including simulations and data analysis, to ensure that the optimized process meets performance criteria and industry standards.

Mechanical Process Engineering

Mechanical Process Engineering is a branch of engineering focused on designing, analyzing, and improving mechanical systems and processes. It combines principles of mechanical engineering with process engineering to develop efficient and effective solutions for various industrial applications.

Mechanical system process engineers are involved in the entire lifecycle of a project, from conceptual design to implementation and maintenance. They work on systems such as manufacturing processes, energy systems, and mechanical equipment. Their role includes conducting feasibility studies, creating detailed engineering drawings, and ensuring that systems operate safely and efficiently.

Mechanical process engineering is vital for enhancing productivity, optimizing resource use, and ensuring compliance with regulatory standards in sectors like automotive, aerospace, and chemical processing.

Mechanical Process Simulation

Mechanical Process Simulation involves using computational models to predict the behavior of mechanical systems under different conditions. This simulation helps engineers and designers understand how a system will perform before physical prototypes are built.

By employing specialized software, engineers can simulate various scenarios, analyze the results, and make data-driven decisions to improve the design. Mechanical process simulation is used to evaluate factors such as stress, thermal effects, and fluid dynamics.

It allows for the optimization of designs and processes, reduces the need for costly physical testing, and accelerates development timelines. This approach is essential in industries like aerospace, automotive, and manufacturing, where precision and efficiency are critical.

Mechanical Process Control

Mechanical Process Control involves managing and regulating mechanical systems to ensure they operate within desired parameters. This includes the use of sensors, controllers, and feedback mechanisms to monitor and adjust processes in real-time.

Effective mechanical process control helps maintain optimal performance, prevent system failures, and improve safety. Engineers design control systems that can handle variables such as temperature, pressure, and flow rates, ensuring that mechanical systems operate efficiently and reliably.

Advanced control strategies, such as automation and real-time monitoring, play a crucial role in industries such as manufacturing, chemical processing, and energy management. Mechanical process control is essential for achieving consistent product quality and reducing operational costs.

Mechanical Process Flow

Mechanical Process Flow refers to the sequence and management of mechanical processes within a system or facility. It involves mapping out the steps and interactions between various mechanical components and systems to ensure smooth and efficient operation.

Understanding the mechanical process flow helps in identifying potential bottlenecks, optimizing resource use, and improving overall system performance. This analysis is crucial in designing manufacturing processes, optimizing production lines, and integrating new technologies.

Effective Mechanical system process flow management ensures that each component functions harmoniously with others, leading to enhanced productivity, reduced downtime, and improved product quality. It is a fundamental aspect of process engineering and operations management.

Mechanical Process Improvement

Mechanical Process Improvement focuses on enhancing the efficiency, effectiveness, and reliability of mechanical Operation and processes. This involves identifying areas for improvement, implementing changes, and evaluating their impact.

Improvement strategies can include redesigning components, updating technologies, or streamlining workflows. Engineers use various tools and methodologies, such as Six Sigma and Lean Manufacturing, to drive process improvement.

The goal is to achieve better performance, reduce costs, and increase overall productivity. Mechanical operation improvement is vital for maintaining competitive advantage, ensuring high-quality output, and meeting regulatory standards in industries like automotive, aerospace, and manufacturing.

Mechanical Process Automation

Mechanical Process Automation involves using technology to control and manage mechanical systems with minimal human intervention. This can include the use of robotics, programmable logic controllers (PLCs), and automated machinery to perform repetitive or complex tasks.

Automation enhances efficiency, precision, and consistency in mechanical procedure by reducing human error and increasing throughput. It is widely applied in manufacturing, where automated systems can handle tasks such as assembly, welding, and material handling.

Mechanical procedure automation also contributes to improved safety, as it can reduce the need for human operators to work in hazardous environments. It is a key driver of modern industrial efficiency and productivity.

Mechanical Process Analysis

Mechanical Process Analysis involves examining and evaluating mechanical systems to understand their performance and identify areas for improvement. This analysis includes assessing factors such as efficiency, reliability, and resource usage.

Engineers use various techniques, such as data analysis, simulations, and performance testing, to gain insights into how mechanical procedure operate and interact. Mechanical Procedure analysis helps in identifying inefficiencies, predicting potential issues, and implementing corrective actions.

It is essential for optimizing system performance, reducing operational costs, and ensuring compliance with industry standards. This analysis is crucial in fields like manufacturing, energy production, and aerospace, where precision and reliability are paramount.

Mechanical Process Management

Mechanical Process Management involves overseeing and coordinating the various aspects of mechanical systems and processes to ensure they operate effectively and efficiently. This includes planning, implementing, and monitoring mechanical procedure to achieve organizational goals.

Effective management involves setting performance targets, managing resources, and ensuring compliance with regulations. It also requires regular evaluation and adjustment of processes to adapt to changing conditions and improve outcomes.

Mechanical procedure management is crucial for maintaining high levels of productivity, quality, and safety in industries such as manufacturing, construction, and energy. It helps organizations streamline operations, reduce costs, and enhance overall performance.

Conclusion

Mastering Mechanical Procedure is essential for enhancing system efficiency, reducing costs, and ensuring high-quality outcomes. By understanding and applying principles of mechanical method design, Optimization, Control, and Management, professionals can drive significant improvements in performance and reliability. This guide provides a foundational understanding of these critical elements, highlighting their importance in the broader context of engineering and manufacturing. Embracing these concepts not only leads to better operational outcomes but also supports innovation and competitive advantage in today’s dynamic industrial landscape.

Discover how to optimize your Mechanical System and ensure peak performance with our detailed guide. Learn essential strategies for Mechanical Equipment Maintenance to extend the lifespan of your machinery. Dive into our full post for expert tips and practical insights to enhance your mechanical systems effectively.

FAQs:

How can Mechanical Process Optimization improve system performance?

Mechanical Process Optimization enhances system performance by identifying and addressing inefficiencies. Through analysis and adjustments, such as improving process parameters or redesigning components, engineers can increase productivity, reduce operational costs, and extend equipment lifespan. Optimization techniques often involve data analysis and simulation to achieve the best outcomes.

What role does Mechanical Process Control play in industrial systems?

Mechanical Process Control involves managing and regulating mechanical systems to maintain desired performance levels. It uses sensors, controllers, and feedback mechanisms to monitor and adjust variables like temperature, pressure, and flow rates. Effective control ensures systems operate efficiently, reduces downtime, and improves safety in industrial applications.

How does Mechanical Process Simulation benefit engineers?

Mechanical Process Simulation benefits engineers by allowing them to model and analyze mechanical systems under various conditions without physical prototypes. It helps predict system behavior, identify potential issues, and optimize designs. This approach reduces the need for costly physical testing and accelerates the development process.

What are the key components of Mechanical Process Management?

Mechanical Process Management involves planning, implementing, and overseeing mechanical systems to ensure they function effectively. Key components include setting performance targets, managing resources, and ensuring compliance with regulations. Effective management also involves regular evaluation and adjustment of processes to improve efficiency and achieve organizational goals.