When working with sheet metal, leather, or even paper crafting, precision is everything. One of the most important tools in fabrication and crafting is the punch. Punches are widely used in industries like mechanical engineering, metal fabrication, construction, leather crafting, and even jewelry making. But here’s the catch: every project requires a different punch size, and without a proper punch size chart, it becomes tricky to choose the right tool.

In this complete guide, we’ll explore what punch sizes mean, why they matter, and provide a comprehensive punch size chart for reference. By the end, you’ll have a clear understanding of how to select the right punch size for your specific application.

What Is a Punch?

A punch is a tool designed to make holes or indentations in a material using force. The punch itself is typically a hardened steel rod with a tip shaped to cut or indent material when pressed or hammered into it.

There are many types of punches, including:

Center Punch – used to mark drill points.

Hole Punch – used to cut round holes in sheet metal, leather, or gaskets.

Drive Punch – used for driving pins out of mechanical assemblies.

Letter and Number Punches – used for stamping characters into metal.

But when it comes to hole-making, the punch size determines the exact diameter of the hole created.

Why Is Punch Size Important?

Punch size matters because:

Accuracy – Using the correct punch size ensures holes are properly aligned with design specifications.

Material Integrity – Choosing too large or too small a punch can damage or warp the material.

Tool Life – The right size reduces wear and breakage of punches and dies.

Application Fit – Whether for rivets, fasteners, or decorative holes, the punch size ensures a perfect fit.

Standard Punch Sizes

Punch sizes are usually measured in fractions of an inch or millimeters (mm) depending on region and industry standards. For example:

Inch system is common in the U.S.

Metric system is widely used in Europe and Asia.

To make things easier, manufacturers often provide charts to show the available punch sizes and their equivalents.

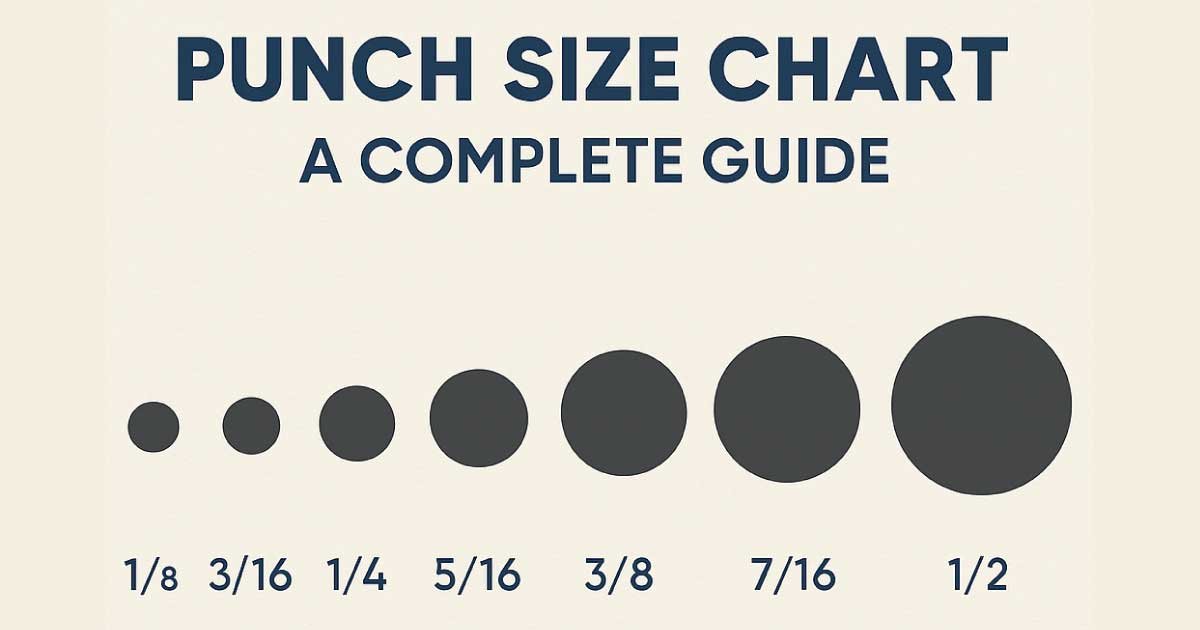

Punch Size Chart

Here’s a detailed punch size chart showing common punch diameters in both inches and millimeters:

| Punch Size (inches) | Punch Size (mm) | Common Use Case |

|---|---|---|

| 1/16″ | 1.6 mm | Small pilot holes, leather, jewelry |

| 3/32″ | 2.4 mm | Light sheet metal, gasket making |

| 1/8″ | 3.2 mm | Rivet holes, craft projects |

| 5/32″ | 4.0 mm | Metal fabrication, woodworking |

| 3/16″ | 4.8 mm | General-purpose holes |

| 1/4″ | 6.4 mm | Bolt holes, industrial use |

| 5/16″ | 7.9 mm | Heavy-duty fabrication |

| 3/8″ | 9.5 mm | Pipe fittings, mechanical work |

| 7/16″ | 11.1 mm | Construction, machinery |

| 1/2″ | 12.7 mm | Large fasteners, heavy sheet metal |

| 5/8″ | 15.9 mm | Industrial punch presses |

| 3/4″ | 19.0 mm | Structural steel, heavy gaskets |

| 1″ | 25.4 mm | Large cut-outs, industrial projects |

Also Read:

Punch Size Chart in PDF:

When working with sheet metal, leather, or other materials, choosing the correct punch size is critical for accuracy and efficiency. To make things easier, we’ve prepared a detailed Punch Size Chart in PDF, so you can quickly download and reference it whenever needed. This guide covers standard punch sizes in inches and millimeters, their common applications, and practical tips for selecting the right punch for your projects.

How to Choose the Right Punch Size

When selecting a punch size, consider:

Material Thickness – Thicker materials may require larger punches and more force.

Application Requirement – For example, rivets require a slightly larger hole than the rivet shank.

Type of Material – Softer materials like leather or rubber allow for smaller punches, while steel requires robust punches.

Fit and Clearance – Always allow slight clearance between the punch and die to avoid tool damage.

Tips for Using Punches Safely

Always use the correct punch and die combination.

Keep punches sharp and well-maintained.

Apply steady force instead of hammering excessively.

For large sizes, consider hydraulic or mechanical punch presses instead of manual force.

Wear safety goggles when punching metal to protect against flying debris.

Applications of Punches in Different Fields

Punches are versatile tools used across industries. Some examples include:

Metal Fabrication – Punching holes for fasteners, rivets, and ventilation.

Automotive Industry – Creating precise holes in panels and parts.

Leather Crafting – Making clean holes for belts, bags, and shoes.

Construction – Punching through sheet metal and structural steel.

DIY & Crafts – Paper punching, decorative patterns, and hobby projects.

Maintaining Punch Tools

To ensure long life and consistent performance:

Regularly clean punches after use.

Store in a dry place to prevent rust.

Use lubricants when punching through thick metal.

Sharpen or regrind the punch tip if it becomes dull.

Summary

A punch size chart is an essential reference for anyone working with metal, leather, or other materials. From small precision holes to large industrial cut-outs, the punch size directly impacts accuracy, durability, and overall project success.

By using the chart provided in this guide, you can quickly match the right punch to your application, save time, and improve efficiency in your work.

Also Read: