When it comes to plumbing, piping, or any kind of mechanical fitting work, choosing the right elbow fitting size makes all the difference. It’s not just about connecting two pipes — it’s about making sure everything fits perfectly, no leaks occur, and the flow remains smooth.

In this post, I will walk you through everything you need to know about elbow fittings — their types, materials, and most importantly, the elbow fitting size chart that helps you pick the correct one for your project.

What Is an Elbow Fitting?

An elbow fitting is a type of pipe fitting used to change the direction of flow in a piping system. Usually, it’s used when you need to bend a pipe by 45°, 90°, or sometimes 180°.

Imagine water or gas running through a straight pipe — if you need that flow to turn around a corner or move upward, you can’t just bend the pipe itself (that would cause cracks or pressure damage). Instead, you install an elbow fitting at that spot.

So, simply put:

➡️ Elbow = A safe turn for your pipeline.

Common Angles of Elbow Fittings

45° Elbow – Used where a slight direction change is needed.

90° Elbow – The most common type; makes a perfect right-angle turn.

180° Elbow (U-Bend) – Used where the flow direction needs to reverse completely.

Each of these elbows comes in different sizes, materials, and connection types (like threaded or welded), depending on your application.

Materials Used in Elbow Fittings

Elbow fittings are made from a variety of materials, depending on the type of system — water, gas, air, or oil. Some of the most popular ones include:

Stainless Steel: Strong, corrosion-resistant, perfect for industrial use.

Brass: Commonly used in plumbing, corrosion-resistant, and durable.

PVC (Plastic): Lightweight and great for water supply systems.

Copper: Used for water lines and HVAC applications.

Carbon Steel: Heavy-duty use for high-pressure and temperature systems.

Each material has its own benefits, so it’s always wise to match the material with the type of fluid or gas passing through the pipe.

Why Elbow Fitting Size Matters

Many beginners underestimate the importance of the correct fitting size. If your elbow size does not match your pipe diameter, you will face one of two problems:

Leakage due to loose connection, or

Pressure loss due to restricted flow.

In mechanical and plumbing projects, accuracy is everything. That’s where the elbow fitting size chart comes in handy. It helps you match the fitting size to your pipe’s inner and outer diameter.

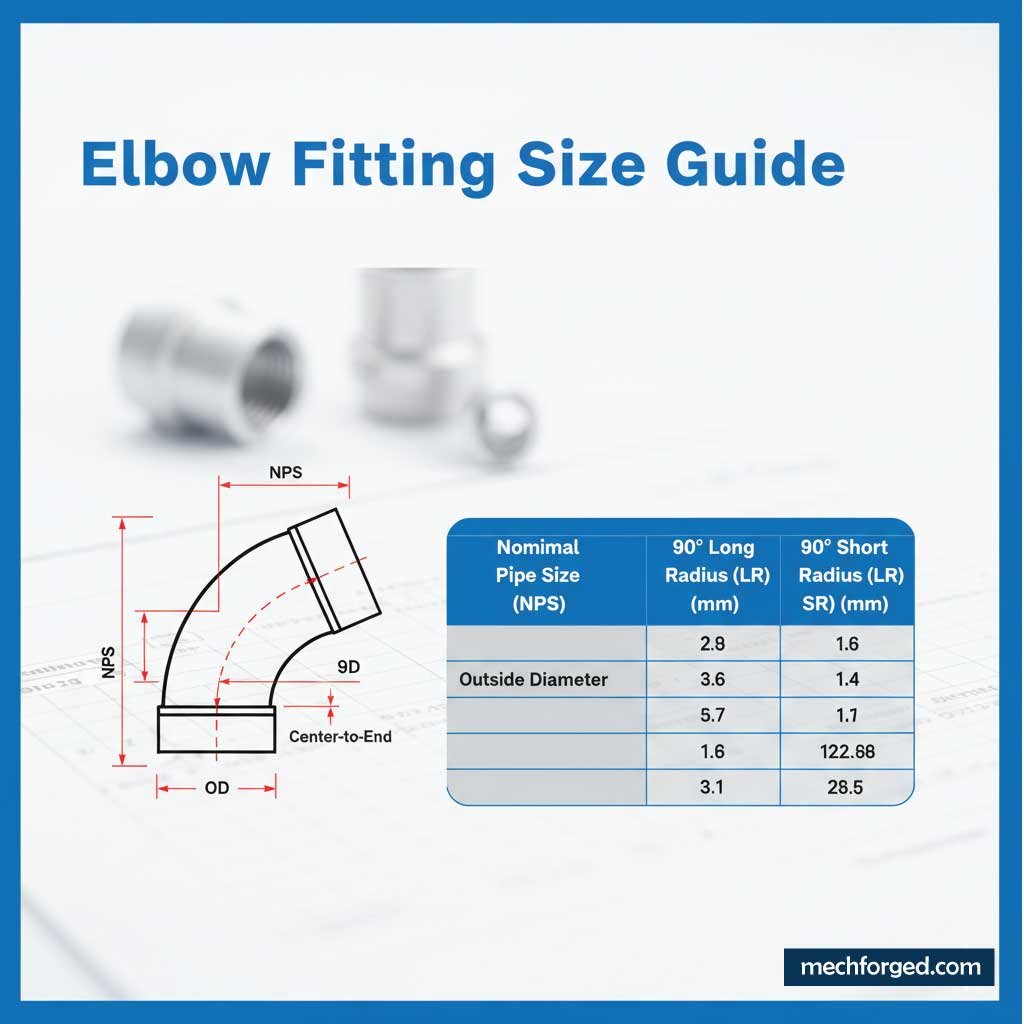

Elbow Fitting Size Chart

Below is a general elbow fitting size chart that includes both nominal pipe size (NPS) and outside diameter (OD) — the two key factors when selecting elbow fittings.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Elbow Radius (90° Elbow) | Elbow Radius (45° Elbow) |

|---|---|---|---|

| 1/2 inch | 21.3 mm | 38 mm | 16 mm |

| 3/4 inch | 26.7 mm | 57 mm | 24 mm |

| 1 inch | 33.4 mm | 76 mm | 31 mm |

| 1-1/4 inch | 42.2 mm | 95 mm | 39 mm |

| 1-1/2 inch | 48.3 mm | 114 mm | 47 mm |

| 2 inch | 60.3 mm | 152 mm | 63 mm |

| 2-1/2 inch | 73.0 mm | 190 mm | 79 mm |

| 3 inch | 88.9 mm | 229 mm | 94 mm |

| 4 inch | 114.3 mm | 305 mm | 126 mm |

| 5 inch | 141.3 mm | 381 mm | 157 mm |

| 6 inch | 168.3 mm | 457 mm | 189 mm |

| 8 inch | 219.1 mm | 610 mm | 252 mm |

| 10 inch | 273.0 mm | 762 mm | 315 mm |

| 12 inch | 323.8 mm | 914 mm | 378 mm |

This chart is a standard reference for most industrial and plumbing fittings. However, always check the manufacturer’s specifications — because dimensions can vary slightly based on design or standard (ASME, ASTM, or DIN).

Elbow Fitting Size Chart PDF

The Elbow Fitting Size Chart PDF provides complete dimensions for 45° and 90° elbow fittings, including nominal pipe sizes, outside diameters, and bend radii. It’s ideal for plumbers, engineers, and DIY users to ensure accurate pipe connections. Download the chart to quickly reference fitting sizes for steel,

Are You Read Our This latest Post

Collet Sizes Chart: Latest 2025 Guide

Short Radius vs Long Radius Elbow

You might often come across the terms short radius (SR) and long radius (LR) elbows. Here’s what they mean:

Long Radius (LR): The radius of curvature is 1.5 times the pipe diameter.

✅ Used where flow resistance needs to be minimal.Short Radius (SR): The radius of curvature is equal to the pipe diameter.

✅ Used where space is tight or compact fitting is required.

Example:

If you are using a 2-inch pipe,

LR Elbow radius = 2 × 1.5 = 3 inches

SR Elbow radius = 2 inches

This little difference affects flow efficiency and pressure drop — so it’s crucial to know which type you need.

How to Measure an Elbow Fitting Size

If you already have an elbow and you’re unsure what size it is, you can measure it easily. Here’s how:

Measure the Pipe’s Outside Diameter (OD): Use a caliper or measuring tape to find the distance across the outer edge.

Check the Inner Diameter (ID): This is the distance across the inside of the fitting.

Identify the Elbow Angle: Determine if it’s 45°, 90°, or 180°.

Match It With the Chart: Use the elbow fitting size chart above to find the corresponding nominal size.

It’s always better to measure twice before purchasing, especially if you’re replacing old fittings.

Types of Elbow Fitting Connections

There are several ways elbows connect to pipes. The connection type often depends on the material and pressure requirements.

Threaded Elbows: Common in small-size pipes and plumbing systems. Easy to install and remove.

Butt-Welded Elbows: Used in industrial pipelines for permanent and leak-proof joints.

Socket Weld Elbows: Suitable for small diameter pipes that need strong connections.

Compression Elbows: Common in copper or PVC piping — easy to connect without welding.

Push-Fit Elbows: Modern and user-friendly fittings for quick installations — no tools required!

Applications of Elbow Fittings

Elbow fittings are used almost everywhere — from your home plumbing to massive industrial systems. Some common applications include:

Water Supply Lines

Irrigation Systems

HVAC (Heating, Ventilation, and Air Conditioning)

Oil and Gas Pipelines

Chemical and Process Plants

Automotive and Hydraulic Systems

No matter the field, the purpose remains the same — to redirect flow efficiently and safely.

Readers Choice:

American Screw Size Chart 2025: Complete Guide + Free PDF

Tips for Choosing the Right Elbow Fitting

Here are a few simple but practical tips:

Always match material to fluid type (e.g., PVC for water, steel for oil).

Check the pressure rating before installing.

Don’t mix different metal types — it can cause corrosion.

Choose long radius elbows for smoother flow in large systems.

Always check the fitting standard (ASME/ANSI/DIN) before purchase.

Maintenance and Longevity

Elbow fittings usually last for years if installed properly, but routine maintenance helps avoid leaks or damage. A quick check every 6–12 months is a good habit, especially in high-pressure systems.

If you notice:

Leakage at the joint,

Rust or corrosion,

Reduced pressure,

then it’s time to inspect or replace the elbow. Prevention is always cheaper than repair!

Final Thoughts

Choosing the right elbow fitting size is not just about numbers — it’s about ensuring your system runs smoothly, efficiently, and safely. With the elbow fitting size chart above, you can easily find the correct match for any pipe diameter, whether for home, workshop, or industrial use.

Always remember:

➡️ A perfect connection begins with the right fitting.

Whether you are a plumber, mechanic, or DIY enthusiast, understanding elbow fittings gives you the confidence to build leak-free, durable piping systems.

Do not Skip This Post:

Machine Screw Size Chart: Complete Guide 2025 + Free PDF

FAQs:

What is the purpose of an elbow fitting in plumbing?

An elbow fitting helps change the direction of a pipe, typically by 45° or 90°. It’s essential when routing pipes around corners or obstacles. Without elbows, pipes would need to bend, which could cause cracks, pressure drops, or leaks. Elbows ensure smooth, safe, and efficient fluid or gas flow.

What is the difference between a short radius and long radius elbow?

A long radius (LR) elbow has a bend radius 1.5 times the pipe diameter, allowing smoother flow with less pressure loss. A short radius (SR) elbow has a radius equal to the pipe diameter and is used in tight spaces where compact design is needed. LR elbows are ideal for high-flow systems.

How do I measure the correct size of an elbow fitting?

To measure an elbow, determine your pipe’s outside diameter (OD) and inside diameter (ID) using a caliper or tape. Then, match these measurements with the nominal pipe size (NPS) in an elbow fitting size chart. Always measure twice before buying to ensure a leak-free and precise fit for your piping system.

Which materials are best for elbow fittings?

The best material depends on the type of system you’re working with. PVC works well for water lines, stainless steel for industrial use, brass for plumbing, and copper for HVAC systems. Always match material with the fluid type and check temperature and pressure ratings before installation to ensure long-lasting performance.

Can I mix different metal fittings in one system?

It’s not recommended. Mixing metals like copper and steel can cause galvanic corrosion, leading to leaks or joint failure over time. Always use fittings and pipes made of the same material or compatible metals. This ensures better durability, smoother connections, and fewer maintenance issues in the long run.

How often should elbow fittings be checked or replaced?

For long-lasting performance, inspect your elbow fittings every 6–12 months, especially in high-pressure or industrial systems. Look for leaks, rust, or reduced flow. If any signs appear, replace the fitting immediately. Regular checks prevent costly damage and ensure your plumbing or mechanical system runs smoothly and safely.