Linear bearings are a critical component in many mechanical and automation systems, allowing smooth, precise linear motion with minimal friction.

From CNC machines and 3D printers to industrial automation and medical equipment, selecting the correct linear bearing size is essential for performance, durability, and safety.

This comprehensive linear bearing size guide will walk you through everything you need to know—from understanding linear bearing dimensions and load ratings to selecting the right size for your application.

Whether you are an engineer, designer, or hobbyist, this guide will help you make confident, informed decisions.

What Is a Linear Bearing ?

A linear bearing (also known as a linear motion bearing) is a mechanical element that enables movement along a straight path while reducing friction between moving parts.

Linear bearings typically operate on a hardened shaft or rail and use rolling elements (balls or rollers) or sliding surfaces to support motion.

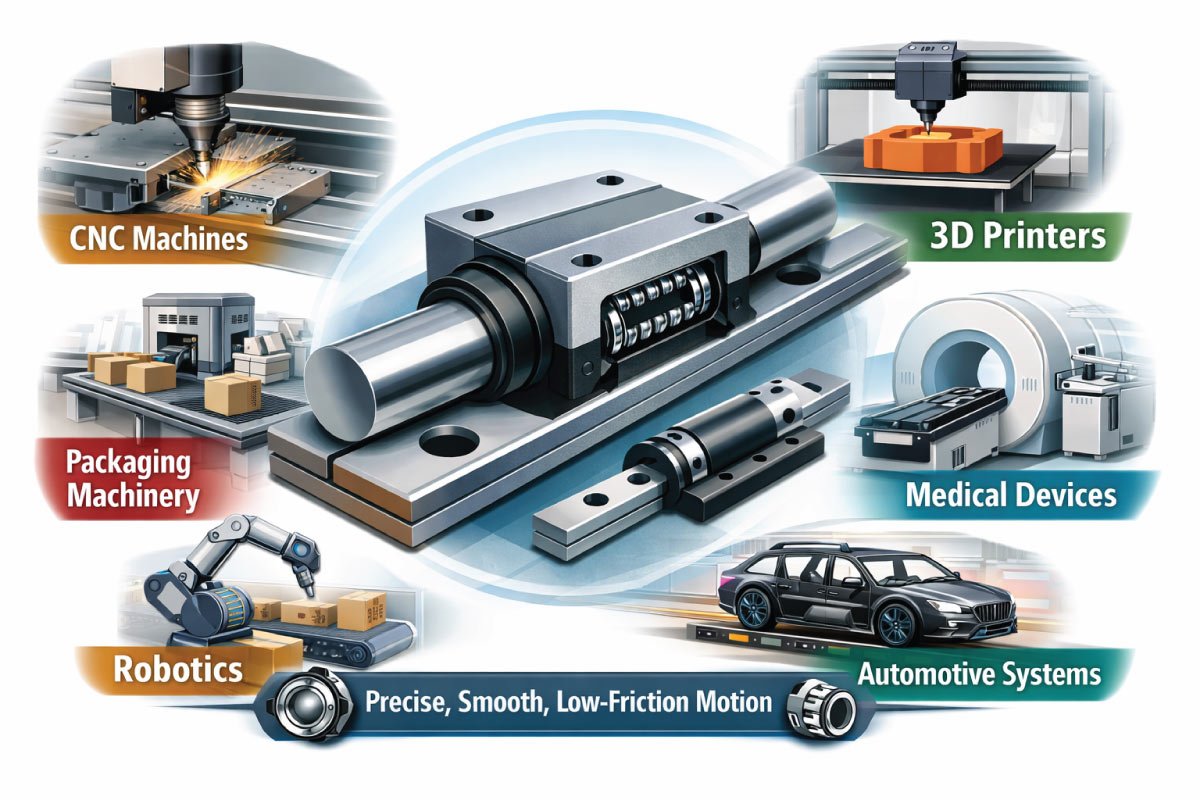

Common Applications

Linear bearings are crucial components in industries and devices where precise, smooth, and repeatable motion is required.

They reduce friction, support loads, and maintain accuracy across moving parts.

From CNC machines and 3D printers to robotics, packaging equipment, automotive systems, and medical devices,

properly selected and sized linear bearings ensure performance, longevity, and reliability in both industrial and high-precision applications.

1- CNC Machines

Linear bearings are essential in CNC machines, where precise, repeatable movement of tools and workpieces is critical.

They reduce friction along guide shafts, ensuring smooth motion and maintaining machining accuracy.

Properly sized bearings support heavy loads, prevent deflection, and extend the life of both the machine and its components, contributing to consistent, high-quality production.

2- 3D Printers

In 3D printers, linear bearings guide the print head or build platform along precise axes.

Smooth, low-friction movement is vital for layer accuracy and surface quality.

Correct bearing selection ensures stable motion, reduces wear on shafts and rails, and maintains dimensional consistency, even during extended printing sessions or high-speed operations.

3- Packaging Machinery

Linear bearings in packaging machinery facilitate fast, repetitive motions with minimal resistance.

They ensure components move precisely and reliably during filling, sealing, or labeling processes.

Properly sized and installed bearings reduce downtime, maintain throughput, and withstand continuous operation in industrial environments, where accuracy and durability are essential.

4- Robotics

Robotic systems rely on linear bearings for precise, controlled linear motion in arms, slides, and actuators.

Bearings minimize friction and wear while supporting dynamic loads, ensuring smooth, repeatable movement.

Selecting the right size and type is crucial for performance, motion accuracy, and the long-term reliability of robotic mechanisms.

5- Automotive Systems

Linear bearings in automotive applications support moving components in assembly lines, steering mechanisms, and suspension systems.

They provide smooth, low-friction motion while handling high loads and vibrations.

Proper bearing sizing ensures safety, durability, and consistent performance, contributing to vehicle reliability and efficient manufacturing processes.

6- Medical Devices

Medical equipment often requires precise, smooth, and reliable motion, which linear bearings provide.

Applications include imaging devices, surgical robots, and diagnostic machines.

Correctly sized bearings reduce friction, ensure accurate movement, and extend the service life of critical equipment, supporting both patient safety and procedural precision.

Because linear bearings directly affect motion accuracy and system lifespan, choosing the correct size is not optional—it’s critical.

Why Linear Bearing Size Matters

Selecting the correct linear bearing size is critical for system performance, reliability, and longevity.

The right bearing ensures smooth motion, precise positioning, and proper load distribution, while the wrong size can lead to failures, reduced accuracy, and increased maintenance.

Understanding the consequences of incorrect sizing helps prevent costly downtime and damage.

1- Excessive Wear and Premature Failure

A bearing that is too small or improperly matched to the load can wear unevenly and fail early.

This accelerates wear on both the bearing and the shaft, shortening the overall lifespan of the system and requiring more frequent replacements or repairs.

2- Reduced Motion Accuracy

Incorrectly sized bearings can create play or binding in the system, reducing positioning precision.

This is especially critical in applications like CNC machines, 3D printers, and robotics, where accurate, repeatable motion is essential for proper operation.

3- Increased Vibration and Noise

Improper fits or load distribution can cause the system to vibrate or produce noise during operation.

These vibrations not only affect performance but can also accelerate wear on surrounding components, leading to further maintenance issues.

4- Shaft Deflection or Damage

When a bearing does not properly support the shaft, uneven forces can cause bending or permanent damage.

Shaft deflection compromises motion smoothness and can lead to additional failures in connected components.

5- Higher Maintenance Costs

Frequent failures, wear, and misalignment caused by wrong bearing sizing increase maintenance requirements.

This raises operational costs, reduces uptime, and may require more frequent inspections or part replacements to keep the system running efficiently.

The correct bearing size ensures:

Key Linear Bearing Size Parameters

Selecting the right linear bearing requires a clear understanding of the key size parameters that determine fit, performance, and durability.

Each dimension affects how the bearing interacts with the shaft, housing, and applied loads, making precise measurement and specification essential for smooth, reliable operation.

1- Inner Diameter (ID)

The inner diameter must match the shaft diameter exactly, as it determines the bearing’s rotational or sliding fit.

An incorrect ID can cause excessive play, misalignment, or premature wear, affecting the overall performance of the system.

2- Outer Diameter (OD)

The outer diameter defines how the bearing fits into its housing or mounting block.

A proper OD ensures secure installation and prevents movement or loosening during operation, maintaining stability under load.

3- Length

Bearing length influences load capacity and stability. Longer bearings distribute forces over a greater area, reducing tilting and increasing the lifespan of both the bearing and the shaft.

Shorter bearings may be suitable for compact applications but handle lower loads.

4- Load Rating

Load ratings indicate the maximum force a bearing can support without permanent deformation or a significant reduction in service life.

Selecting a bearing with an appropriate load rating prevents failures and ensures consistent performance under operational stresses.

5- Tolerance Class

Tolerance class defines the precision of the bearing’s dimensions.

Tighter tolerances are critical in high-precision or high-speed applications, influencing fit, motion accuracy, and smoothness.

Choosing the right tolerance ensures reliability and minimizes vibration or backlash.

Common Linear Bearing Size Standards

Linear bearings are generally standardized to ensure interchangeability and reliable performance across different systems.

Metric sizing is the most common, though some imperial options exist.

The LM series is widely used in industrial and DIY applications, providing consistent shaft fit and housing compatibility.

Tip: In LM series bearings, the “UU” designation usually indicates double rubber seals, which protect the bearing from dust, debris, and other contaminants, extending its lifespan.

Common Metric Linear Bearing Sizes (LM Series)

| Bearing Model | Shaft Diameter (mm) | Outer Diameter (mm) | Length (mm) |

|---|---|---|---|

| LM6UU | 6 | 12 | 19 |

| LM8UU | 8 | 15 | 24 |

| LM10UU | 10 | 19 | 29 |

| LM12UU | 12 | 21 | 30 |

| LM16UU | 16 | 28 | 37 |

| LM20UU | 20 | 32 | 42 |

Tip: The “UU” designation typically indicates double rubber seals for contamination protection.

Understanding Load Capacity and Bearing Size

Typical Load Ratings for Common Linear Bearings

Understanding load ratings is essential for selecting a linear bearing that meets both operational and safety requirements.

Bearings are rated for dynamic loads, which occur during motion, and static loads, which act when the system is stationary.

Choosing a bearing with appropriate load ratings ensures smooth operation, prevents premature wear, and avoids structural damage.

| Bearing Model | Dynamic Load Rating (N) | Static Load Rating (N) |

|---|---|---|

| LM8UU | 330 | 550 |

| LM10UU | 480 | 760 |

| LM12UU | 700 | 1,100 |

| LM16UU | 1,200 | 2,000 |

| LM20UU | 1,800 | 3,000 |

Dynamic load applies to moving systems, while static load refers to stationary conditions.

Choosing the Right Linear Bearing Size: Step-by-Step

Selecting the correct linear bearing size ensures smooth motion, reliable performance, and long service life.

The process involves matching the bearing to the shaft, understanding load demands, optimizing length, and accounting for environmental factors.

Careful consideration at each step prevents premature wear, misalignment, or failure, making your linear motion system efficient and durable.

Step 1: Determine Shaft Diameter

The shaft diameter is the most critical factor in selecting a linear bearing, as it directly determines the bearing’s inner diameter (ID).

A precise match ensures smooth motion and prevents play, wobbling, or uneven wear. For example:

8 mm shaft → LM8UU

12 mm shaft → LM12UU

Always match bearing ID exactly to the shaft size.

Step 2: Calculate Load Requirements

Accurately calculating load requirements is essential to prevent premature bearing failure and ensure smooth operation.

Consider all forces acting on the bearing, including:

Include:

Weight of moving components

External forces

Safety factor (typically 1.5–2×)

Step 3: Consider Bearing Length

Bearing length plays a key role in load distribution and system stability. Longer bearings offer higher load capacity, better resistance to tilting, and smoother, more stable motion.

Shorter bearings save space and are suitable for compact designs but may need multiple units to handle the same load effectively.

Choosing the right length balances strength, stability, and design constraints.

Higher load capacity

Better resistance to tilting

Improved motion stability

Short bearings save space but may require multiple units to handle loads.

Step 4: Evaluate Environmental Conditions

Environmental factors play a critical role in selecting the right linear bearing.

Dust, moisture, high or low temperatures, and chemical exposure can all affect performance, lifespan, and maintenance requirements.

Choosing the proper bearing type, seals, and materials ensures reliable operation under these conditions.

- Contamination:

- Moisture and Corrosion:

- Temperature:

- Chemical Exposure:

Factors such as dust, moisture, temperature, and chemicals influence bearing size and type.

Linear Bearing Size vs. Application Type

Linear bearing selection depends heavily on the specific application, as different systems have varying requirements for load capacity, precision, and space constraints.

Matching the bearing size to the application ensures smooth motion, reliability, and longevity while preventing over- or under-sizing.

The table below provides recommended bearing sizes for common applications based on typical shaft diameters.

Recommended Linear Bearing Sizes by Application

Different applications have unique requirements for precision, load capacity, and space constraints, making proper bearing selection critical.

The table below provides guidance on typical shaft diameters and the corresponding recommended linear bearing sizes.

Following these recommendations helps ensure smooth motion, reliability, and long service life across a variety of systems and industries.

| Application Type | Typical Shaft Size (mm) | Recommended Bearing |

|---|---|---|

| 3D Printers | 8–10 | LM8UU / LM10UU |

| Desktop CNC Machines | 12–16 | LM12UU / LM16UU |

| Industrial Automation | 16–25 | LM16UU / LM20UU |

| Robotics | 10–20 | LM10UU – LM20UU |

| Medical Equipment | 6–12 | LM6UU – LM12UU |

Discover More:

Oversized vs. Undersized Linear Bearings

Choosing the correct bearing size is critical for system performance, and selecting one that is too large or too small can impact reliability, cost, and space requirements.

Understanding the trade-offs helps ensure smooth motion, sufficient load handling, and long-term durability.

Oversized Bearings

Pros

Higher load capacity

Increased rigidity

Longer lifespan

Cons

Higher cost

More space required

Increased system weight

Undersized Bearings

Pros

Compact design

Lower cost

Lightweight

Cons

Reduced lifespan

Higher risk of failure

Limited load capacity

Rule of thumb: If in doubt, choose the slightly larger bearing size—especially for industrial or continuous-duty applications.

Discover More:

Linear Bearing Size Tolerances and Fit

Precise tolerances are essential for linear bearings to operate smoothly and maintain accuracy.

The fit between the shaft, bearing, and housing directly affects motion quality, load distribution, and service life.

Shaft tolerance: Usually h6 or h7

Housing tolerance: Typically H7

Incorrect tolerances can cause:

Excessive play

Binding or seizure

Reduced bearing life

Always refer to manufacturer specifications when selecting sizes.

Discover More:

Common Mistakes When Selecting Linear Bearing Size

Selecting the wrong linear bearing size can compromise system performance, reliability, and lifespan.

Many issues arise not from poor quality bearings but from improper selection.

Understanding common pitfalls helps avoid premature wear, inaccurate motion, and unexpected failures, ensuring smooth operation and longer-lasting components.

Choosing based on shaft size alone

Ignoring moment and shock loads

Underestimating duty cycle

Overlooking environmental factors

Using a single bearing when multiple are required

Avoiding these mistakes ensures smoother motion and fewer failures.

Discover More:

Final Thoughts

Selecting the right linear bearing size requires balancing several factors, including shaft compatibility, load capacity, available space, and the specific demands of the application.

Understanding key dimensions, tolerance classes, and load ratings ensures the bearing can handle operational forces while maintaining smooth, accurate motion.

A properly sized linear bearing reduces friction and wear, enhances positional accuracy, minimizes maintenance costs, and improves overall system reliability.

Whether designing a compact 3D printer or a heavy-duty industrial automation system, using a comprehensive linear bearing size guide helps engineers,

And designers make informed decisions, that extend component life, optimize performance, and prevent costly failures.

Discover More: