Mechanical assembly plays a vital role across diverse industries, from manufacturing to automotive repair. Whether you’re a seasoned professional or a novice entering the field, the right tools can significantly enhance your efficiency, accuracy, and safety. This comprehensive guide covers a mechanical assembly tools list to help you understand the essential equipment needed for successful mechanical work.

Table of Contents

ToggleWhy Are Mechanical Assembly Tools Important?

Mechanical assembly tools are essential for building, repairing, and maintaining machinery with precision and efficiency. They serve as the foundation for ensuring tasks are performed safely and accurately, regardless of the complexity of the project.

1. Precision and Accuracy

Mechanical tools like calipers, micrometers, and torque wrenches are designed to provide precise measurements and apply controlled force. These tools ensure components fit perfectly, reducing errors that can lead to mechanical failures. Accurate assembly is especially critical in industries like aerospace and automotive, where even small deviations can have significant consequences.

2. Enhanced Safety

Using the correct tools minimizes the risk of workplace injuries and damage to equipment. For example, using a torque wrench ensures bolts are tightened to the appropriate specifications, preventing over-tightening that could weaken components or lead to accidents.

3. Improved Efficiency

High-quality tools streamline tasks, making them quicker and less labor-intensive. Power tools like cordless drills and impact wrenches save time, allowing professionals to complete repetitive or heavy-duty tasks with ease.

4. Prolonged Component Lifespan

Proper assembly tools prevent mishandling, misalignment, and over-tightening, which can damage machinery parts. This not only reduces repair costs but also extends the life of your equipment.

From intricate industrial projects to routine maintenance, mechanical assembly tools are indispensable for ensuring quality, safety, and efficiency.

Mechanical Assembly Tools List

1. Basic Hand Tools

Basic hand tools are the first step in any toolkit, offering versatility and reliability for a range of mechanical tasks.

Wrenches

Wrenches are indispensable for tightening or loosening nuts and bolts, and their variety caters to different scenarios:

Open-End Wrench: A straightforward tool for gripping two opposite sides of a nut or bolt. Ideal for quick adjustments in tight spaces.

Box-End Wrench: Surrounds the bolt entirely, minimizing slipping and enhancing torque application.

Adjustable Wrench: Known for its adaptability, this wrench can handle various nut and bolt sizes, making it a go-to for general purposes.

Screwdrivers

Screwdrivers are simple yet vital for assembling or disassembling components held together by screws:

Flathead Screwdriver: Effective for slotted screws, commonly found in furniture and electrical installations.

Phillips Screwdriver: Designed for crosshead screws, its design prevents over-tightening by camming out under excessive force.

Torque Screwdriver: Ensures screws are tightened to a specific torque, reducing the risk of damage to delicate components.

Pliers

Pliers provide grip and precision, often essential for handling small, intricate tasks:

Needle-Nose Pliers: Ideal for reaching into tight spaces or handling small objects in electronics or jewelry-making.

Slip-Joint Pliers: Their adjustable design accommodates various sizes, making them versatile for gripping and bending tasks.

Cutting Pliers: Used to cut wires, cables, or small metal pieces, they are a staple in electrical and construction work.

Hammers

Hammers are versatile tools used for driving, shaping, or even dismantling:

Claw Hammer: A classic choice for driving nails and prying them out with its claw end.

Ball-Peen Hammer: Designed for metalworking, it’s excellent for peening (hardening) or shaping metal surfaces.

Dead Blow Hammer: Filled with sand or shot, it minimizes rebound, making it perfect for tasks requiring controlled force.

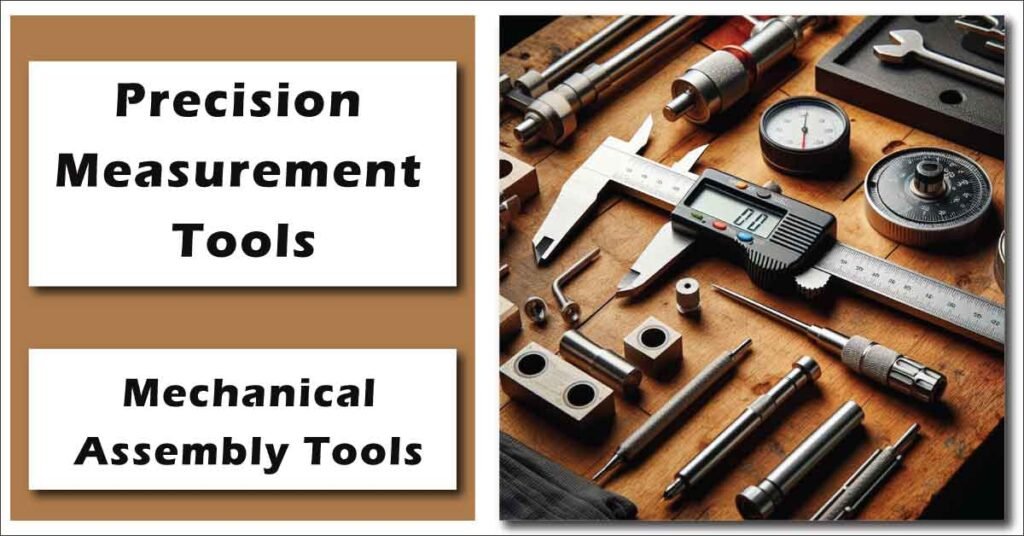

2. Precision Measurement Tools

Precision measurement tools are critical in mechanical assembly to ensure components align perfectly, reducing errors.

Calipers

Digital Calipers: Provide digital readouts for quick and accurate measurements of external, internal, and depth dimensions.

Vernier Calipers: Though manual, these offer highly precise readings, favored by professionals for their reliability.

Micrometers

Micrometers excel in achieving minute measurement accuracy:

Outside Micrometer: Used for measuring the external dimensions of small objects.

Inside Micrometer: Specifically designed for internal diameters, such as pipes or cylinders.

Tape Measure

A must-have for quick measurements. Dual-unit options (imperial and metric) are especially handy for versatility across regions.

Dial Indicators

Dial indicators measure small linear displacements or surface alignments, crucial in tasks like engine assembly or machine alignment.

3. Cutting Tools

Cutting tools allow professionals to shape or trim materials with efficiency and precision.

Hacksaws

Hacksaws are excellent for cutting metal pipes, rods, or even plastic materials with the right blade.

Utility Knives

These multi-purpose tools handle tasks ranging from cutting wires to trimming packaging materials. Their replaceable blades add to their longevity.

Snips and Shears

Tin Snips: Perfect for cutting thin sheet metals like aluminum.

Aviation Snips: Designed for thicker materials, providing clean and precise cuts.

Angle Grinders

Powerful tools for cutting, grinding, and polishing metal surfaces, angle grinders are a mainstay in metalworking.

4. Power Tools for Assembly

Power tools significantly enhance efficiency, particularly for repetitive or heavy-duty tasks.

Cordless Drill

Cordless drills are versatile, offering features like adjustable speed and torque for drilling and screwing tasks.

Impact Wrench

For applications demanding high torque, such as automotive repairs, impact wrenches are invaluable.

Rotary Tools

Compact and multi-functional, rotary tools can sand, polish, grind, or even carve, making them a favorite for detailed work.

Power Screwdrivers

Power screwdrivers save time and reduce strain in repetitive screwing tasks, especially in assembly lines.

5. Fastening Tools

Fastening tools ensure secure connections and prevent mechanical failures.

Torque Wrench

A precision tool for applying exact torque to fasteners, critical for avoiding under- or over-tightening.

Rivet Gun

Used to join materials like metal sheets, rivet guns are common in construction and automotive industries.

Clamps

C-Clamps: Provide strong holding power for parts during assembly.

Spring Clamps: Offer quick, temporary holding for lighter tasks.

Nut Drivers

Compact tools for tightening nuts in confined spaces, particularly in electrical and automotive work.

6. Specialized Tools

For niche applications, specialized tools address specific mechanical needs.

Allen Keys (Hex Keys)

Commonly used for hexagonal screws in bicycles, furniture, and machinery.

Punch Tools

Create indentations or marks before drilling, ensuring accuracy.

Pipe Wrenches

Essential for gripping and turning pipes or cylindrical fittings in plumbing or industrial applications.

Thread Taps and Dies

Vital for creating or repairing screw threads, ensuring compatibility and longevity.

7. Safety and Maintenance Tools

Safety is paramount when working with mechanical tools, as is maintaining their condition.

Safety Goggles

Protect eyes from flying debris, sparks, or harmful liquids during cutting or grinding tasks.

Gloves

Task-specific gloves enhance safety:

Cut-Resistant Gloves: For handling sharp objects or tools.

Heat-Resistant Gloves: Essential for tasks involving high temperatures.

Ear Protection

Noise-canceling earmuffs or plugs safeguard against hearing damage from loud tools like drills or grinders.

Cleaning Tools

Brushes, cloths, and lubricants keep tools clean and functional, extending their lifespan.

8. Storage Solutions

Organized storage ensures tools are protected and easily accessible.

Toolboxes

Rugged toolboxes safeguard tools from damage and simplify transportation.

Tool Bags

Lightweight and portable, tool bags are perfect for professionals on the move.

Pegboards and Racks

Ideal for workshops, pegboards keep tools visible and within reach, promoting efficiency.

Also Read:

How to Choose the Right Mechanical Assembly Tools

Selecting the right tools for mechanical assembly is a crucial step that can make the difference between a smooth project and one riddled with frustrations. With countless options available, it’s essential to approach this decision with careful consideration of your specific needs and circumstances. Here’s a detailed guide to help you make informed choices.

1. Consider the Type of Project

The tools you need depend heavily on the nature of your work:

Industrial Projects: Heavy duty tools such as impact wrenches, torque wrenches, or hydraulic presses may be necessary for tasks involving industrial machinery. These tools are designed to handle high torque and precision requirements.

DIY or Home Repairs: For smaller projects like assembling furniture or fixing appliances, basic hand tools like screwdrivers, pliers, and adjustable wrenches are usually sufficient. Versatility is key here.

By assessing the scope and complexity of your project, you can avoid purchasing tools that are too advanced or not advanced enough for the job.

2. Evaluate Frequency of Use

How often you use your tools determines the quality and durability you should look for:

Frequent Use: If you’re a professional or regularly work on projects, invest in high-quality tools made from durable materials like chrome vanadium steel. These tools are built to withstand wear and tear over time.

Occasional Use: For infrequent tasks, budget-friendly options might suffice. However, ensure they meet basic quality standards to avoid issues like breakage or premature wear.

3. Set a Realistic Budget

While it’s tempting to go for the cheapest option, investing in reliable tools often pays off in the long run. High-quality tools may have a higher upfront cost, but they save money by lasting longer and reducing the risk of tool failure during critical tasks. Strike a balance between your budget and the quality required for your needs.

4. Research Brand Reputation

Established brands with good reputations often provide better warranties, customer support, and product longevity. Look for reviews, testimonials, and recommendations from professionals to identify trusted names in the market. Brands like Stanley, Bosch, and Craftsman are well-known for delivering reliable tools.

Also Read:

Tips for Maintaining Your Tools

Once you’ve selected the right tools, proper maintenance is essential to ensure they remain functional and safe for years to come. Here are some practical tips:

1. Clean Tools After Every Use

After using your tools, wipe them down with a clean cloth to remove dust, dirt, and moisture. For tools exposed to grease or oils, use a degreaser or mild cleaning solution. This simple habit prevents rust and keeps your tools looking and performing like new.

2. Store Tools Correctly

Proper storage protects tools from environmental factors like humidity, which can cause corrosion. Use a toolbox, tool bag, or wall-mounted pegboard to keep your tools organized and accessible. Ensure your storage space is dry and well-ventilated.

3. Inspect Tools Regularly

Before starting any project, take a moment to inspect your tools. Look for cracks, loose parts, or signs of wear. Using damaged tools can lead to accidents or compromise the quality of your work. Promptly repair or replace any tools that show significant wear.

4. Lubricate Moving Parts

Tools with moving components, such as wrenches or pliers, benefit from regular lubrication. Apply a few drops of machine oil or a suitable lubricant to hinges and joints to reduce friction, prevent rust, and maintain smooth operation.

Also Read:

Conclusion

Having a comprehensive set of mechanical assembly tools is essential for tackling any project with confidence. From basic hand tools to advanced power tools, each piece plays a crucial role in ensuring precision, safety, and efficiency. Whether you’re a professional or a hobbyist, investing in high-quality tools and maintaining them properly will save you time, effort, and costs in the long run.

Equip yourself with this complete mechanical assembly tools list, and you’ll be prepared to handle any mechanical assembly challenge that comes your way.

Also Read: